Polyvinylidene fluoride composite material, preparation method and applications thereof

A technology of polyvinylidene fluoride and composite materials, which is applied in the field of composite materials, can solve the problems of low polar phase content of polyvinylidene fluoride, achieve the goal of increasing the content of polar phases, making the preparation method simple and easy, and facilitating large-scale production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

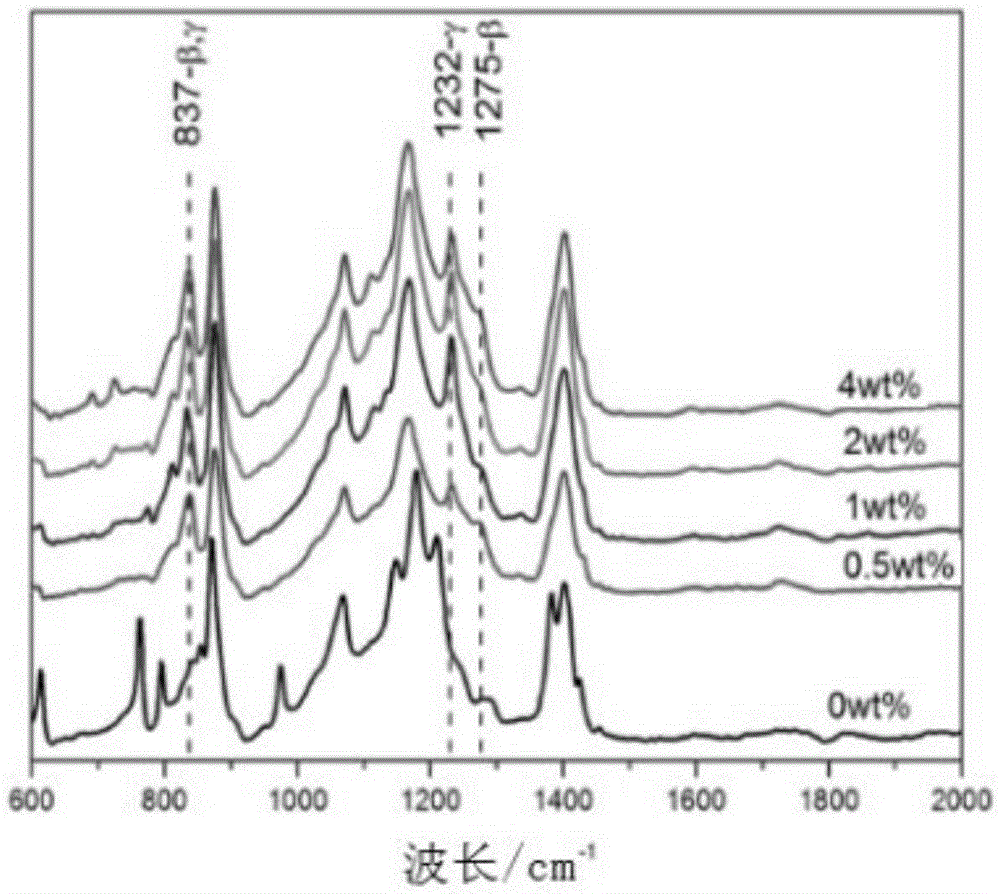

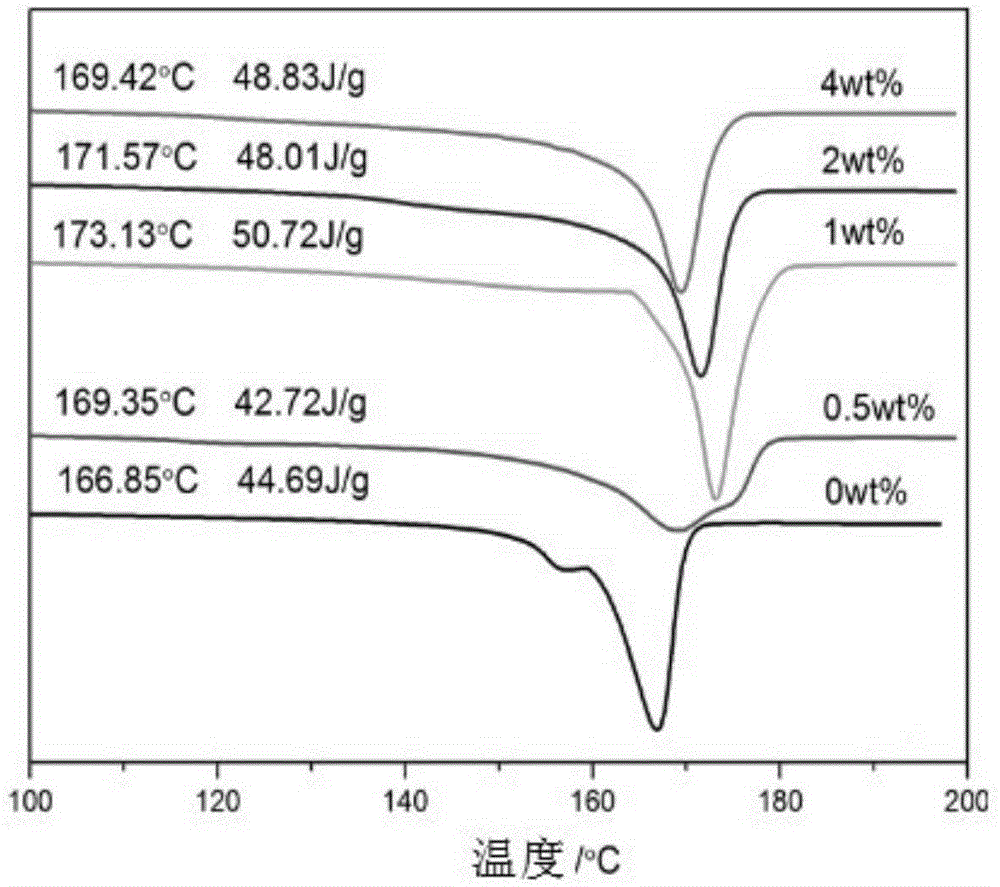

[0025] The polyvinylidene fluoride composite material is composed of polyvinylidene fluoride and TPPB, and the TPPB content is respectively 0.5wt%, 1wt%, 2wt%, 4wt%.

[0026] The preparation method of the above-mentioned polyvinylidene fluoride composite material: add polyvinylidene fluoride and TPPB into the internal mixer according to the composition, at a temperature of 190°C and a rotation speed of 100r / min, banbury for 10 minutes to obtain polyvinylidene fluoride base composite material.

Embodiment 2

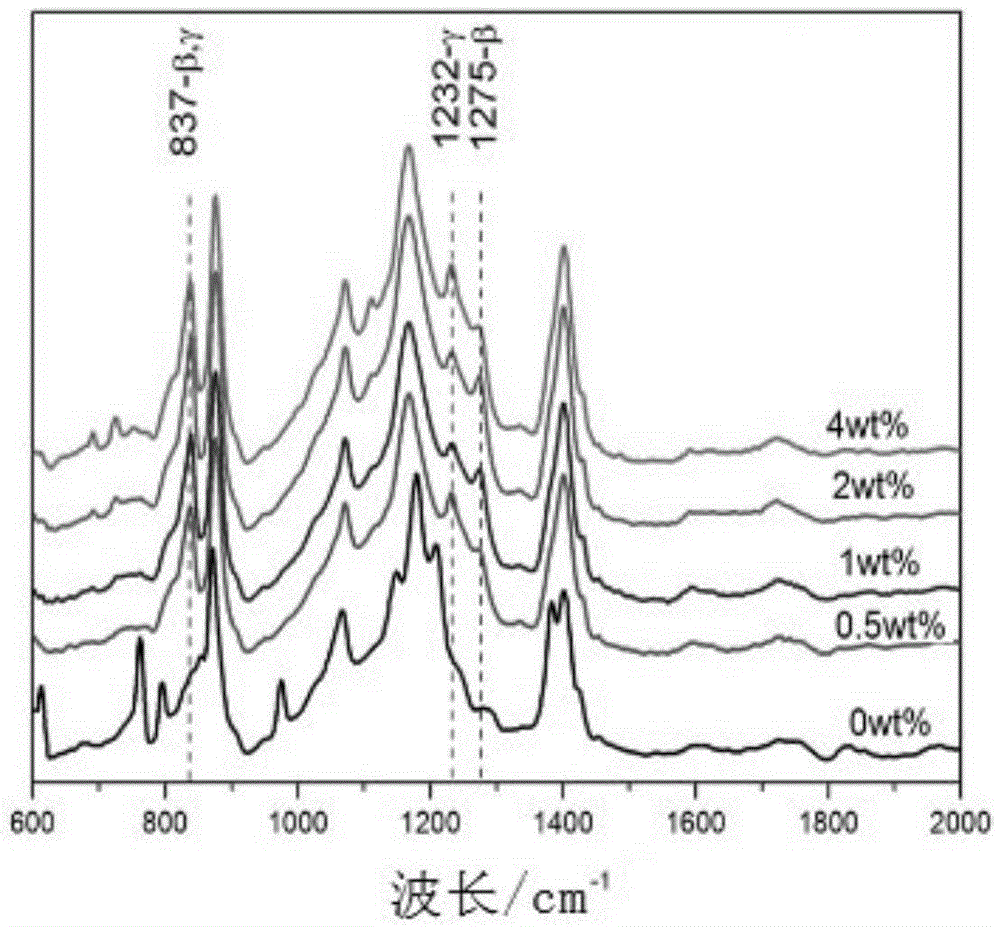

[0028] Polyvinylidene fluoride composite material, composed of polyvinylidene fluoride, organically modified montmorillonite (KSF, specific surface area 20-40m 2 / g) and TPPB composition, the content of organically modified montmorillonite is 0.5wt%, and the TPPB content is respectively 0.5wt%, 1wt%, 2wt%, 4wt%.

[0029] The preparation method of the above-mentioned polyvinylidene fluoride composite material: add polyvinylidene fluoride, KSF and TPPB into the internal mixer according to the composition, and banbury for 10 minutes at a temperature of 190 ° C and a rotation speed of 100 r / min to obtain polyvinylidene fluoride Fluorovinyl composite.

Embodiment 3

[0031] The polyvinylidene fluoride composite material is composed of polyvinylidene fluoride, carbon nanotubes and tetraphenylphosphine bromide, the content of carbon nanotubes is 5 wt%, and the content of tetraphenylphosphine bromide is 5 wt%.

[0032] The preparation method of the above polyvinylidene fluoride composite material: add polyvinylidene fluoride, carbon nanotubes and TPPB into the internal mixer according to the composition, and banbury for 15 minutes at a temperature of 185 ° C and a rotation speed of 80 r / min to obtain Polyvinylidene fluoride based composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com