Patents

Literature

34results about How to "Breathable and moisture-permeable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame-retardant jean fabric

ActiveCN103233360ABreathable and moisture-permeableImprove wash resistanceBiochemical fibre treatmentDry-cleaning apparatus for textilesCelluloseTetrakis(hydroxymethyl)phosphonium chloride

The invention relates to a flame-retardant jean fabric. The flame-retardant jean fabric is prepared by comprising the following steps: (1) placing jean fabric in a jig dyeing machine, adding water and desizing enzyme for processing, then discharging liquid and washing with water; (2) enzyme washing: adding the desized jean fabric, water and neutral cellulose enzyme into the jig dyeing machine, performing temperature rise, discharging liquid and cleaning with water; (3) flame retardant padding-batching: mixing tetrakis hydroxymethyl phosphonium chloride, urea, etherified hexamethylol melamine resin and penetrating agent JFC to obtain flame-retardant finishing liquid, padding and batching the jean enzyme-washed fabric into the flame-retardant finishing liquid, performing twice padding and twice batching; (4) ammonia fumigation: performing ammonia fumigation to the flame retardant-padded-and-batched jean fabric in an ammonia fumigation flame-retardant machine; and (5) later-stage arrangement: performing once padding and once batching to the ammonia-fumigated jean fabric in hydrogen peroxide, and storing after padding and batching; and drying after being washed. According to the flame-retardant jean fabric, the excellent flame-retardant property of the jean fabric is endowed, and the added value of the product can be improved.

Owner:邦威防护科技股份有限公司

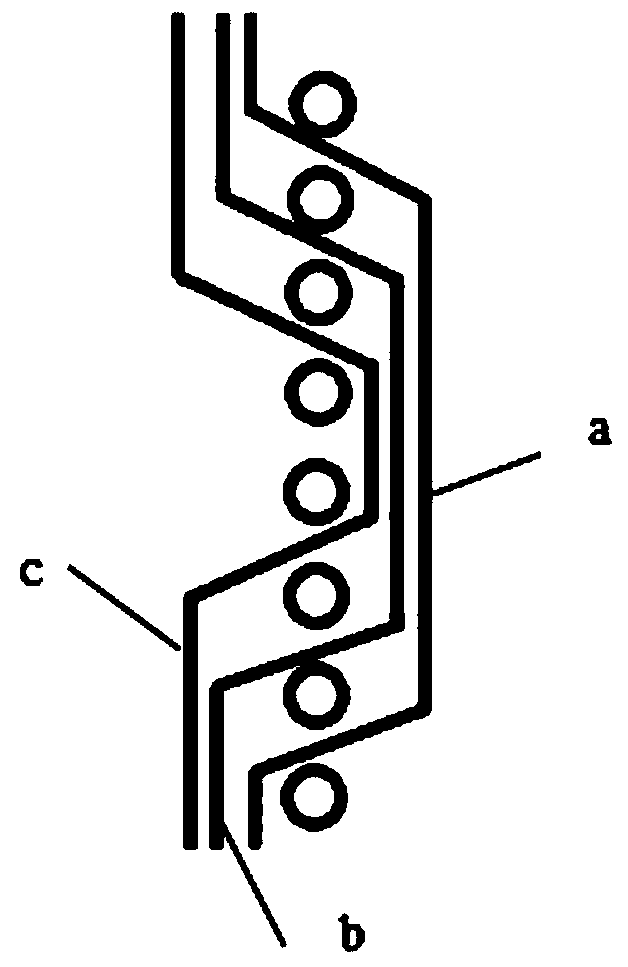

Down jacket and production method thereof

InactiveCN102524977AReduce stitchesTroubleshoot drilled issuesOvergarmentsClothes making applicancesComing outLaser cutting

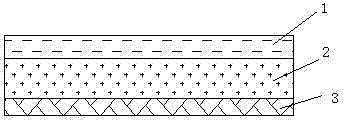

The invention discloses a down jacket and a production method thereof. The production method comprises a whole process from shell fabric forming to finished product forming. The production method comprises the following steps of: after sticking a breathable and moisture-permeable polyurethane film to the inner side of a warp-knitting or weft-knitting knitted fabric, carrying out laser cutting or ordinary cutting, at least carrying out a seamless plying-up process on a bodice part, then, filling eiderdown, and carrying out auxiliary sewing to form a knitted seamless down jacket. The knitted seamless down jacket can be next to the skin after being worn, is elastic and has a breathable and moisture-permeable function, so that the motion of a human body is greatly facilitated and the comfort is improved; furthermore, the advanced seamless hot-pressing technology is adopted, so that the sewing stitches are greatly reduced, and the problem that the eiderdown comes out from the sewing thread is solved; and the whole jacket is upgraded in both appearance and function.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Composite fiber fabric and method for manufacturing same

InactiveCN101736478AHigh strengthBreathable and moisture-permeableWeft knittingLayered productsYarnPolymer science

The invention relates to a composite fiber fabric and a method for manufacturing the same and belongs to the technical field of textile industry. The method manly comprises: mixing hide fibers difficult to spin with other fibers and then spinning yarns with the mixed fibers; and weaving an extremely breathable and moisture-penetrable fabric with the yarns. Due to the contractibility of the blended high-contractibility fibers under a heating condition in post processing, the yarns and fabrics made of the mixed fibers containing the hide fibers have a compact structure and aqueous strength and can be used for cleaning cloth, basic cloth, filter cloth and the like.

Owner:丁晨妍

Luminous blended fabric

The invention discloses a luminous blended fabric which comprises the following main ingredients, by weight, 35-55 parts of cotton fiber, 25-40 parts of corduroy, 20-30 parts of polyurethane filament, 15-22 parts of elastic fiber, 12-25 parts of soybean fiber, 8-15 parts of plush and 10-15 parts of camel wool. Then, spun fabric is coated with a luminous layer. The invention has advantages as follows: the fabric prepared by the formula has fine texture and soft hand feel, is comfortable, keeps warm, has air and water vapor permeability, has antimicrobial and bacteriostatic functions, doesn't shed fur or generate fur balls, has remarkable water absorption capability three times higher than all-cotton goods, is not irritating to skin, and more importantly can give out light when light is bad.

Owner:RUGAO SANFEI FASHION CO LTD

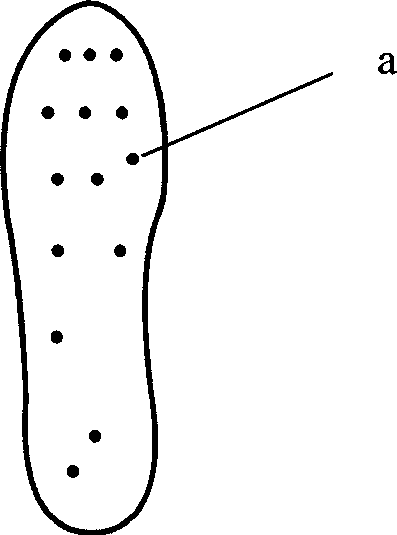

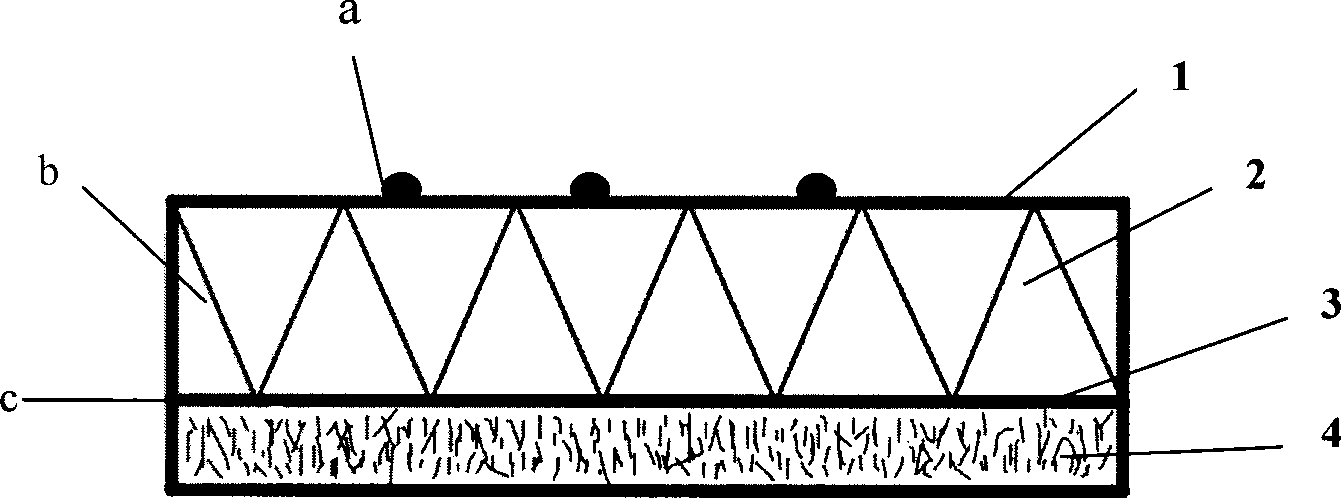

Multifunctional insole and a manufacture method thereof

InactiveCN101518378AEffective MassageIncrease elasticityInsolesDevices for pressing relfex pointsYarnSurface layer

The invention discloses a multifunctional insole and a manufacture method thereof, and belongs to the filed of spinning. The insole adopts a bamboo charcoal fiber warp knitted spaced fabric with embroidery according to acupuncture points on the sole as a main material; the upper surface layer of the fabric adopts a mesh structure formed by spinning bamboo charcoal yarns and is directly contacted with the foot; the lower surface layer of the fabric adopts a compact and stable weave construction; the middle of the fabric is a spaced monofilament layer with good compression elasticity; and the upper surface layer of the fabric is subjected to embroidery according to the acupuncture points of a human body, and then the fabric is cut according to the shape of the sole. The multifunctional insole utilizes characteristics of bamboo charcoal fibers such as adsorption, antibacterium, deodorization, conditioning treatment and the like and comfort characteristics of the warp knitted spaced fabric such as good elasticity, strong air permeability and moisture permeability, shock absorption and pressure reduction and the like, and combines the massage function of the embroidery effect on the acupuncture points on the foot of the human body, so the multifunctional insole integrates multiple functions, and is durable and easy to clean.

Owner:JIANGNAN UNIV

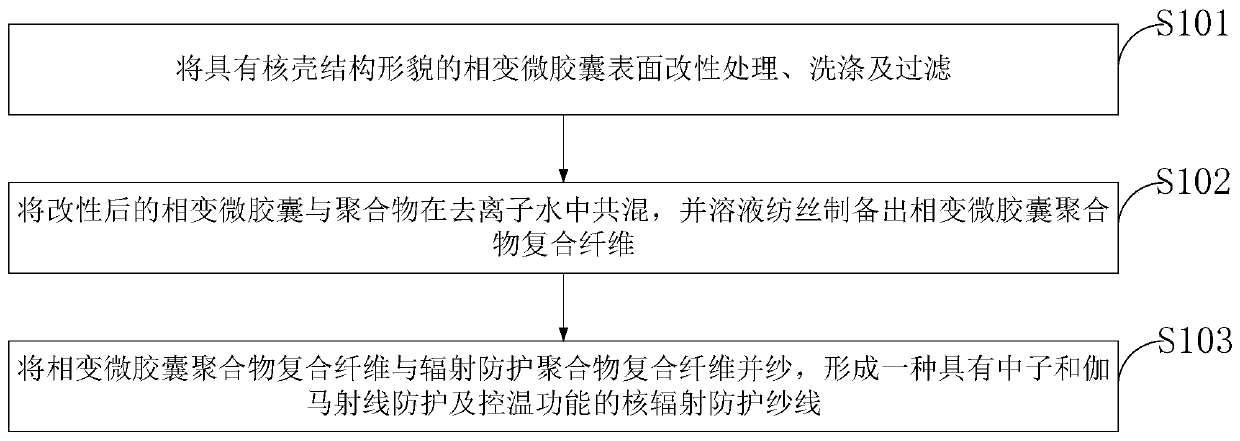

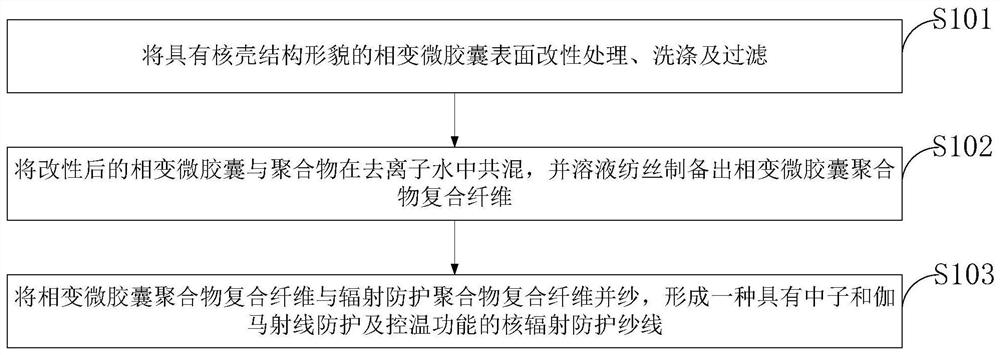

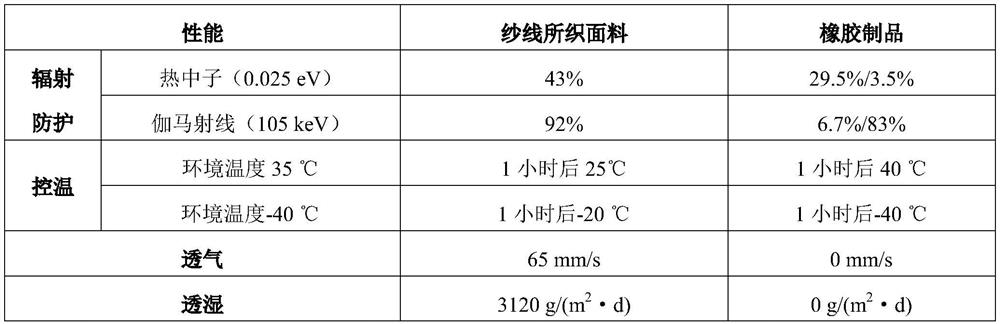

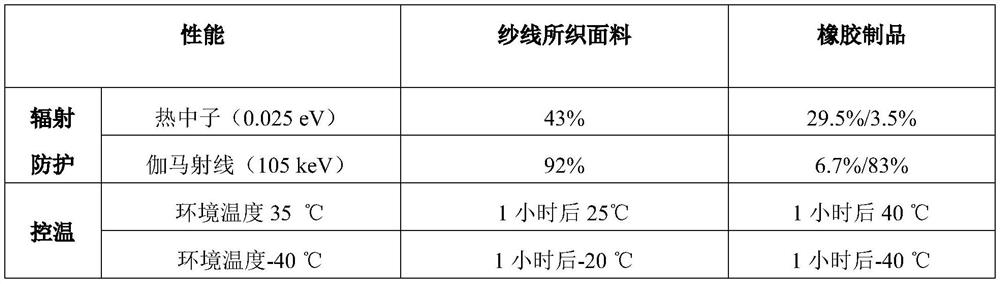

Nuclear-radiation-protection yarn with temperature control function and production method thereof

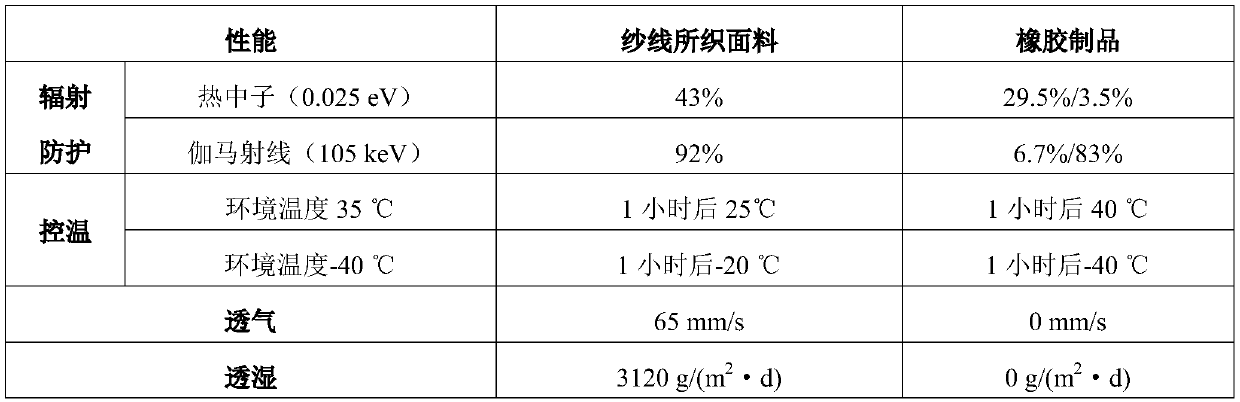

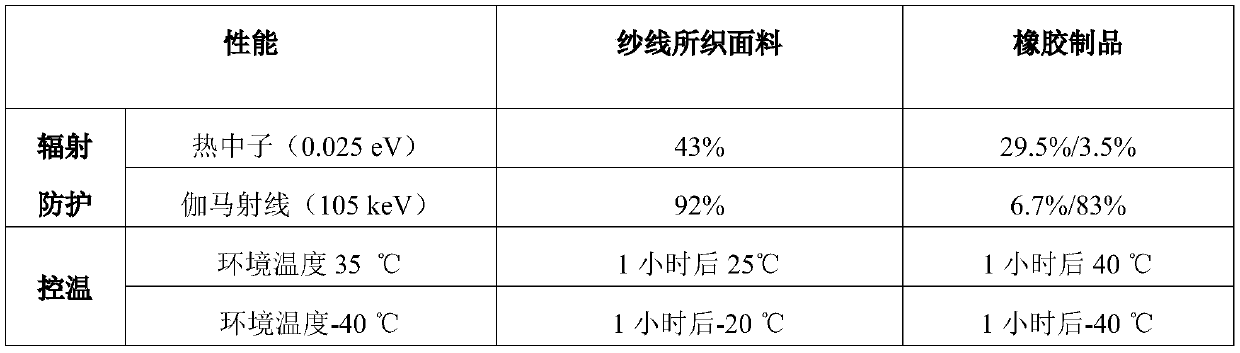

ActiveCN110359151AWith protective functionWith temperature control functionShieldingYarnFiberGamma ray

The invention belongs to the technical field of radiation protection and discloses nuclear-radiation-protection yarn with a temperature control function and a production method thereof. The productionmethod includes: subjecting core-shell-structured phase change microcapsules to surface modification, washing and filtering; blending the modified phase change microcapsules and polymer in deionizedwater, and performing solution spinning to produce phase change microcapsule-polymer composite fibers; doubling the change microcapsule-polymer composite fibers and radiation protection polymer composite fibers to form the nuclear-radiation-protection yarn with functions of neutron and gamma ray protection and temperature control. The nuclear-radiation-protection yarn can be further woven into nuclear-radiation-protection textile fabric and wearable nuclear-radiation-protection products and is promising in application prospect in fields such as nuclear operation and nuclear emergency. The novel preparation method is simple to operate, stable in process and low in cost.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Wet-process Yangbuck synthetic leather and preparation method thereof

ActiveCN111206432AThe preparation method is simple, safe and reliableGood fleeceTextiles and paperCelluloseFiber

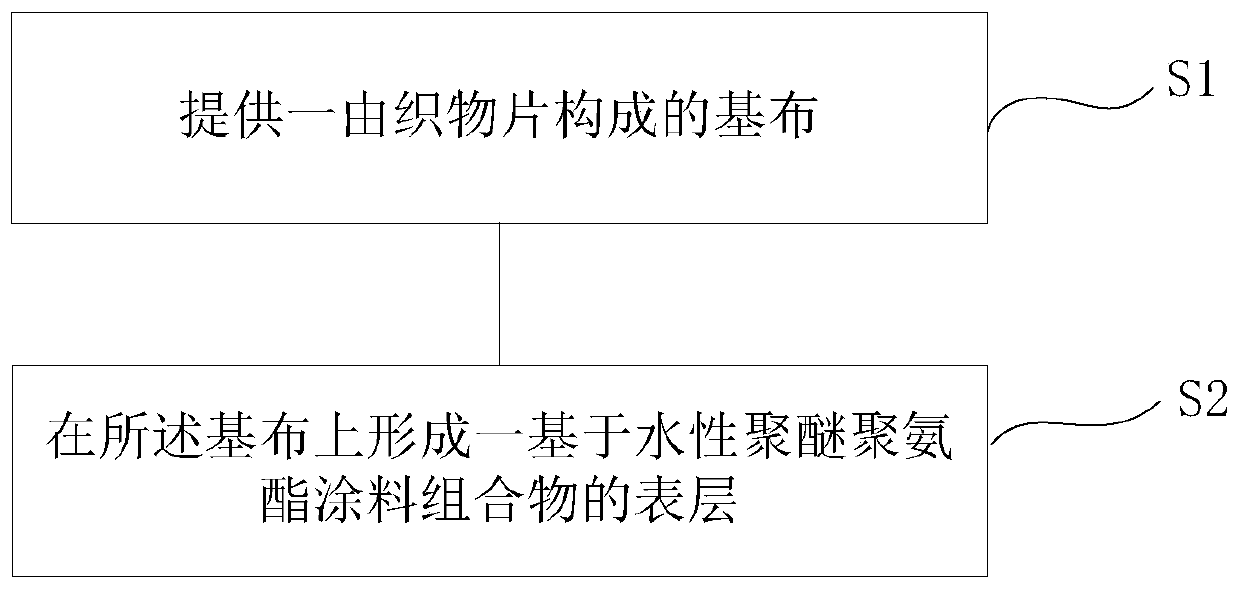

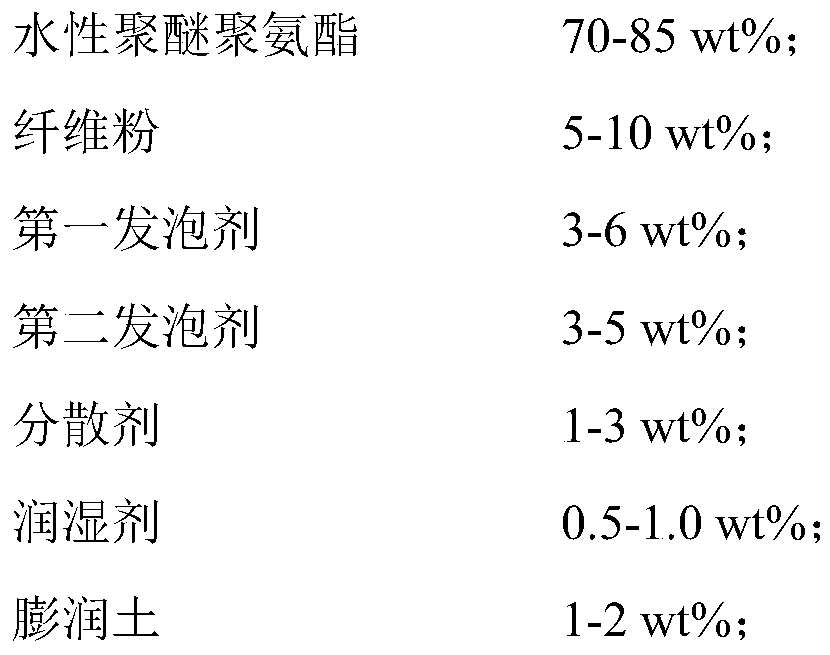

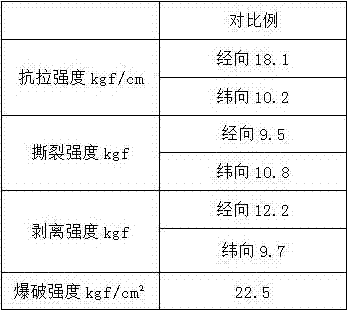

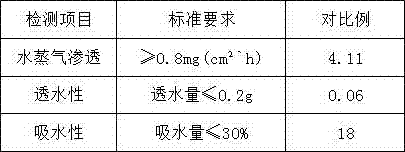

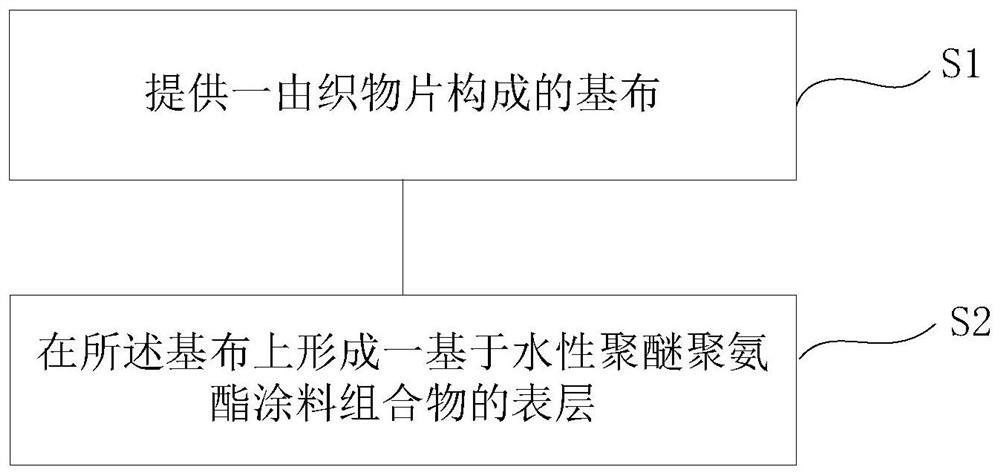

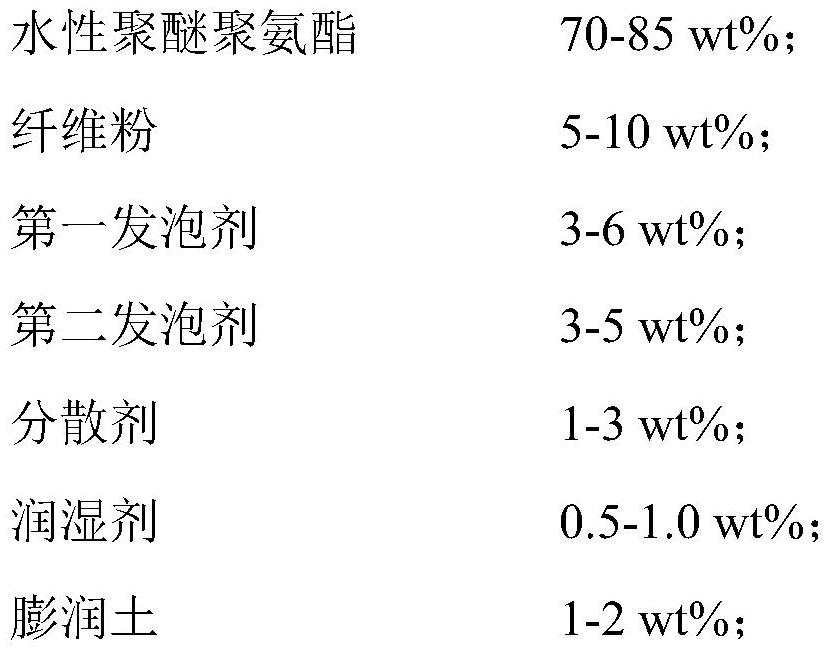

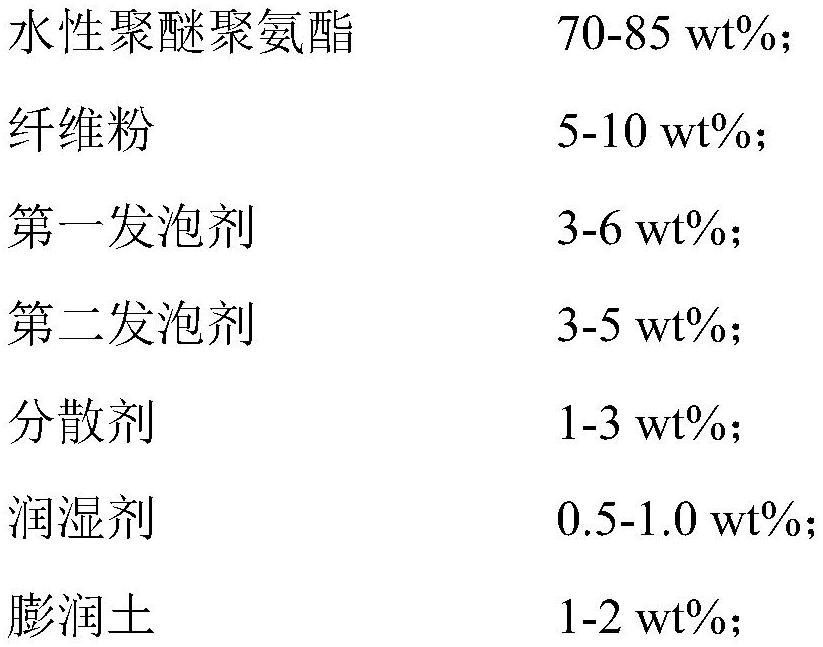

The present invention provides wet-process Yangbuck synthetic leather and a preparation method thereof. The wet-process Yangbuck synthetic leather comprises base cloth composed of fabric pieces and anaqueous polyether polyurethane coating composition based surface layer positioned on the base cloth. The surface layer has the porosity of 80-90%. The aqueous polyether polyurethane coating composition comprises 70-85wt% of aqueous polyether polyurethane, 5-10wt% of fiber powder, 3-6wt% of a first foaming agent, 3-5wt% of a second foaming agent, 1-3wt% of a dispersing agent, 0.5-1.0wt% of a wetting agent and 1-2wt% of bentonite, wherein the fiber powder consists of 95-97wt% of cellulose and 3-5wt% of fatty acid ester. The wet-process Yangbuck synthetic leather provided by the invention has excellent air permeability and moisture permeability, ideal yellowing resistance and delicate velvet surface.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +1

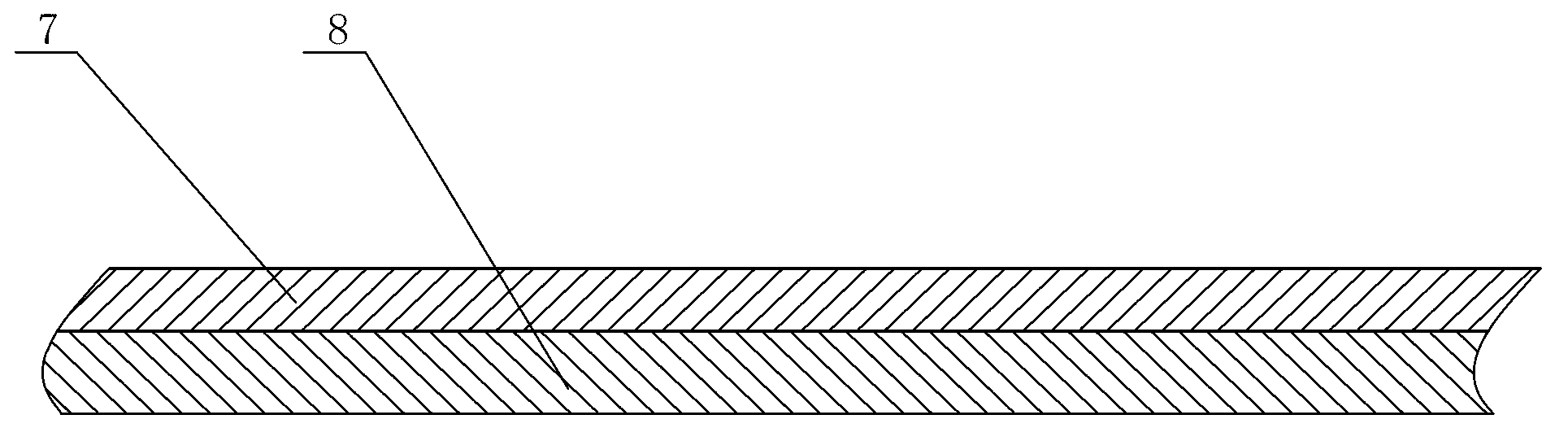

Firefighting uniform fabric

InactiveCN103935099AUniform pore size distributionBreathable and moisture-permeableSynthetic resin layered productsProtective garmentCeramic compositeCarbon fibers

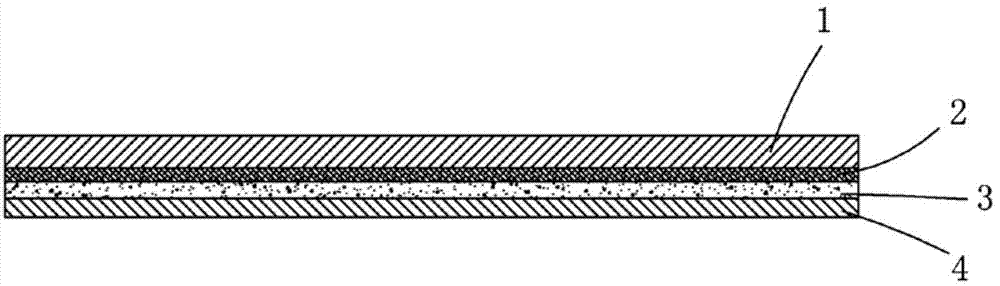

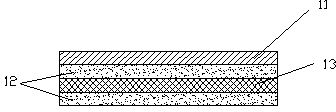

The invention relates to a firefighting uniform fabric. The fabric comprises a fire retardant layer, a polytetrafluoroethylene micro-porous membrane layer, which has been subjected to processes of material blending, blank manufacturing, extruding, rolling, stretching, and sinter curing, a hydrophilic PU layer, and an inner screen cloth layer. The fire retardant layer and the polytetrafluoroethylene micro-porous membrane layer are smelt together through a thermal pressing technology. The polytetrafluoroethylene micro-porous membrane layer and the hydrophilic PU layer are laminated together through a release paper transfer method. The hydrophilic PU layer and the inner screen cloth layer are adhered together through glue. The thickness of the polytetrafluoroethylene micro-porous membrane layer is 2 to 5 [mu]m, micro air holes are evenly arranged in the polytetrafluoroethylene micro-porous membrane layer, and the diameter of the air holes is in a range of 0.5 to 3 [mu]m. The thickness of the hydrophilic PU layer is 3 to 10 [mu]m. The fire retardant layer is composed of two or more components selected from: far infrared ceramic composite fiber, aramid fiber, and carbon fiber. The fabric is lightweight, can effectively prevent the penetration of liquid water, allows the free penetration of gas-stated water molecules, has the advantages of fire resistance, oil resistance, waterproofness, and good wear resistant property, and is a first choice material for firefighting uniforms.

Owner:HUZHOU SENNUO FLUORINE MATERIAL TECH

Multifunctional protective fabric

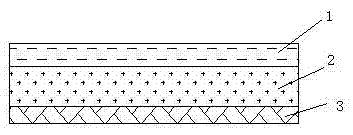

InactiveCN102326903ARadiation resistantHigh temperature resistantSynthetic resin layered productsProtective garmentMoisture permeabilityNatural fiber

The invention discloses a multifunctional protective fabric which comprises a blocking layer and a comfort layer, wherein the blocking layer is a ceramic aluminum oxide metal film layer, the comfort layer is a flame retarded natural fiber or man-made fiber woven layer, and a composite layer with a heat insulating function and ventilating and moisture permeable effects is compounded in the comfort layer. The multifunctional protective fabric has the characteristics of simple manufacture cost, low cost, radiation resistance, high temperature resistance, inflaming retarding, and multiple ideal functions and effects such as heat insulation, ventilation, moisture permeability, and the like.

Owner:DONGPENG TEXTILE SUZHOU

Coral fleece composite fabric

The invention discloses a coral fleece composite fabric comprising at least one layer of coral fleece fabric, at least one layer of bamboo fiber fabric and at least one layer of milk protein fiber fabric, wherein the bamboo fiber fabric is obtained by bamboo fibers and blended yarns in a longitude-latitude interweaving way; and the milk protein fiber fabric is obtained by milk protein fibers and blended yarns in the longitude-latitude interweaving way. According to the above method disclosed by the invention, the bamboo fiber fabric and the milk protein fiber fabric are composited with the coral fleece fabric, the advantages of the three fabrics are fully combined, and the obtained composite fabric has the advantages of fine texture, soft hand feel, being comfortable and warm-kept, air-permeable, moisture-permeable, and being capable of resisting and inhibiting bacteria.

Owner:陆国大

Tencel fiber semi-worsted blended yarn

The invention belongs to the technical field of spinning tools, and particularly relates to a tencel fiber semi-worsted blended yarn which comprises, by weight percentage, 30-50% of tencel fibers, 30-40% of bamboo fibers, and 10-30% of cashmere wool. Due to the fact that in the semi-worsted technology, a wool spinning machine and a cotton spinning machine are organically combined, the technology has the advantages that the yield is high, process is short, manpower is saved, and cost is low. Yarns manufactured through the semi-worsted technology have softness of cotton, gloss of silk, and smoothness of linen, and are superior to cashmere wool in abrasion resistance, pilling resistance and strength.

Owner:ZHEJIANG BAIDE TEXTILE

Tencel and cuprammonium blended knitted fabric

The invention relates to tencel and cuprammonium blended knitted fabric. The tencel and cuprammonium blended knitted fabric is characterized in that one side is plain; the transverse density is 52.5 longitudinal lines every 10cm; the longitudinal density is 45.5 transverse rows every 10cm; the size of a needle used for weaving on a computerized flat knitting machine is 12G; two pieces of 32S Siro spun yarns with 70% tencel and 30% cuprammonium fibers are plied into yarns, and the doubling twist is 300 twists per meter; the gram weight is 252 grams per square meter. The tencel and cuprammonium blended knitted fabric is woven by the yarns which are made by a Siro spinning technology, has the characteristics of softness, drapability, breathability, moisture permeability, excellent tactility, pilling resistance and great serviceability, and belongs to rare functional ecological textile.

Owner:JIANGYIN XIANGFEI APPAREL

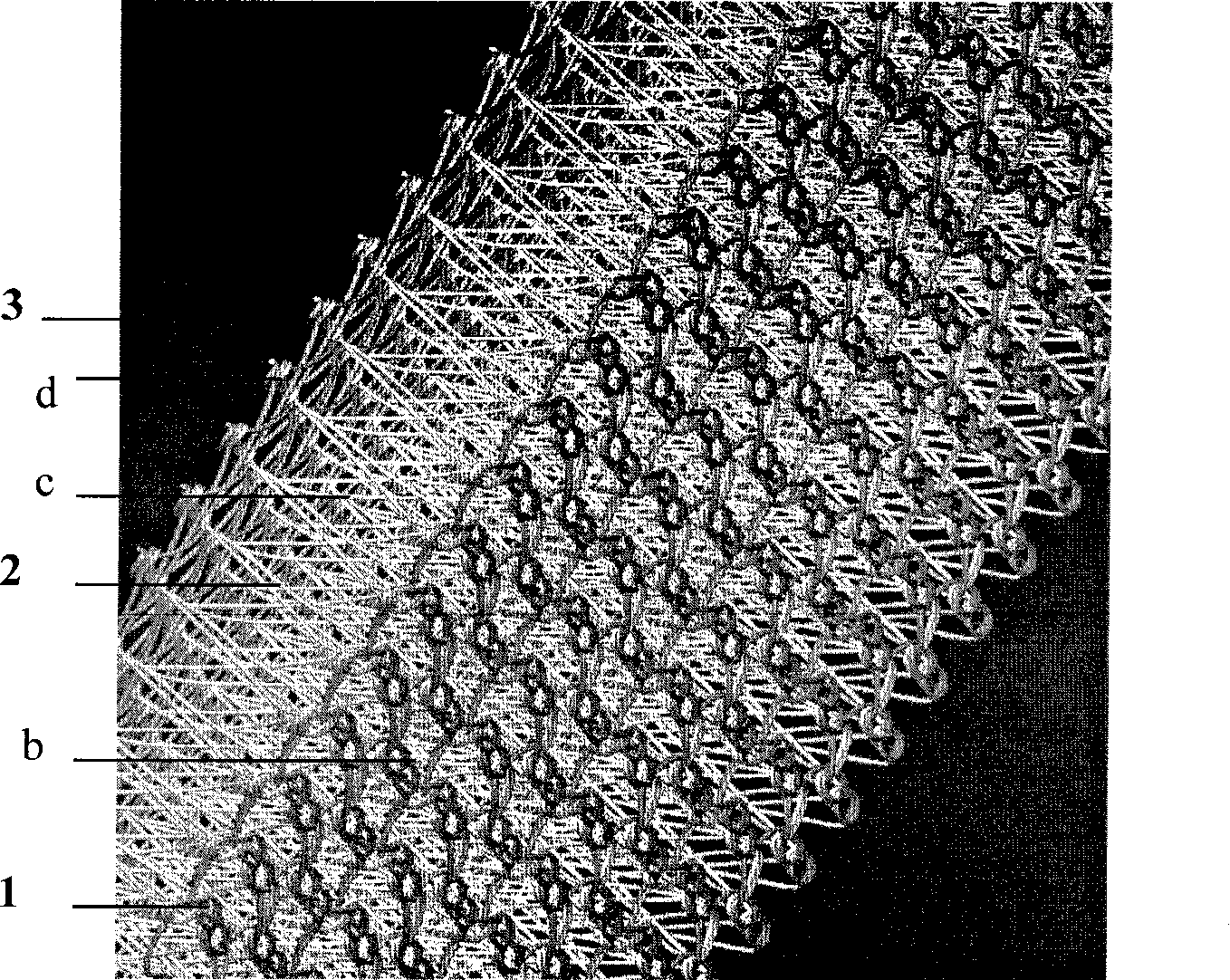

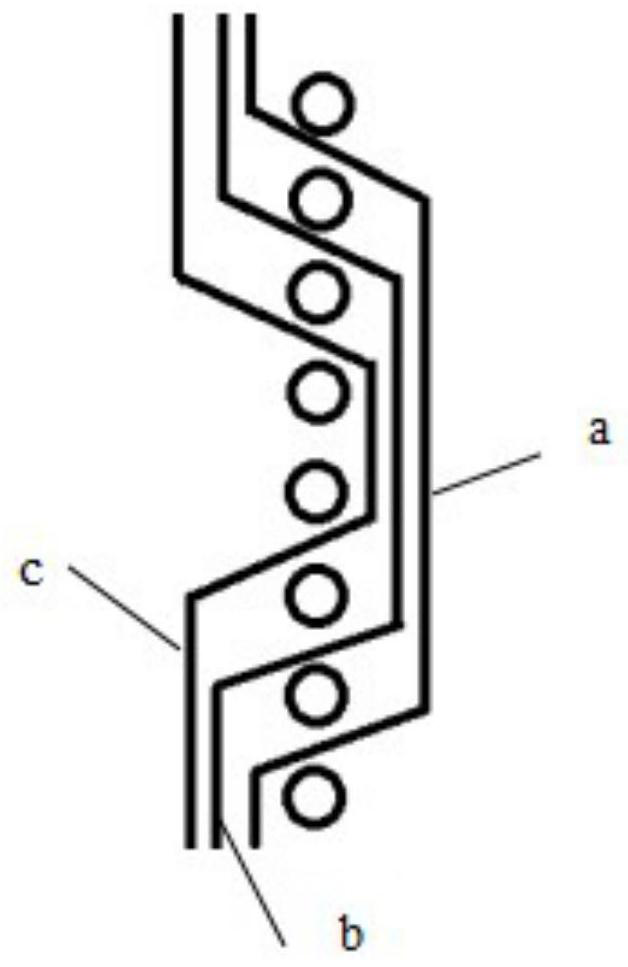

Uncontinuous 3D warp knitting gauze pad

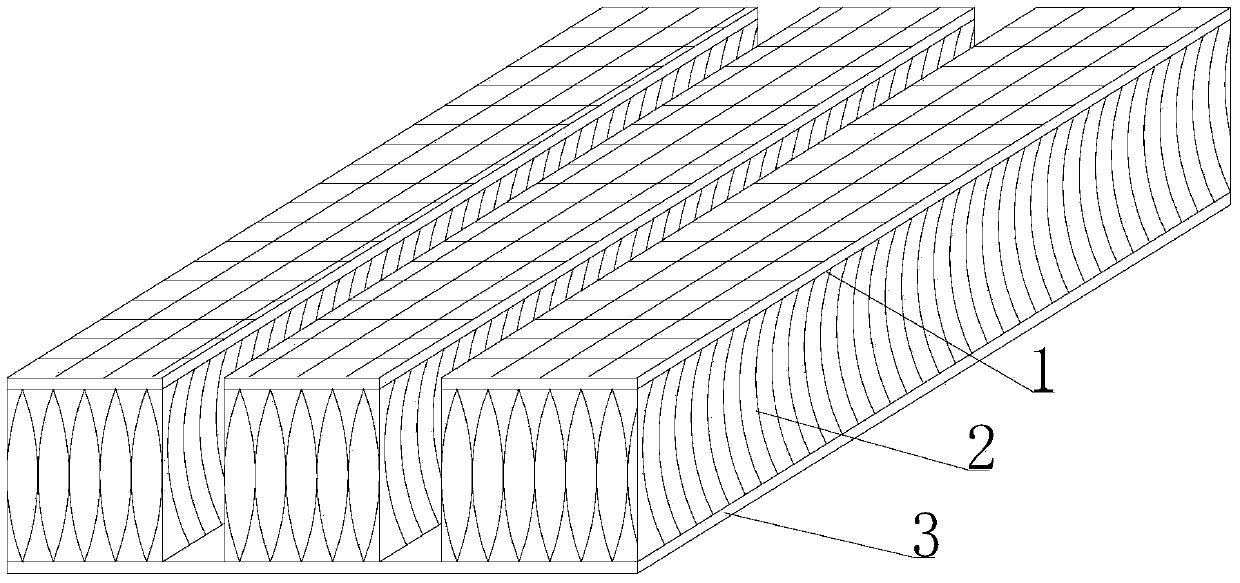

InactiveCN103806214ABreathable and moisture-permeableEasy to cleanStuffed mattressesWarp knittingPolymer scienceMoisture permeability

The invention relates to an uncontinuous 3D warp knitting gauze pad which comprises bottom yarn and multiple pieces of top yarn. The multiple pieces of top yarn are of a strip shape. All the pieces of the top yarn are mutually spaced and arranged on the bottom yarn in parallel in a warp knitting mode. Each piece of top yarn is composed of surface yarn and supporting yarn located between the surface yarn and the bottom yarn. The supporting yarn is woven into an X-shaped cross structure through monofilaments or multifilaments. The uncontinuous 3D warp knitting gauze pad is high in air permeability and moisture permeability, easy to wash and capable of effectively preventing bacteria and mites from propagating. Furthermore, the multiple pieces of top yarn formed by the surface yarn and the supporting yarn are distributed on the bottom yarn in a strip shape and in a spaced mode, the spaced arrangement allows the top yarn to swing within a certain range in the contact process of the top yarn, and therefore the gauze pad will not be too hard and is more delicate in hand feeling.

Owner:CHANGSHU DAFA WARP KNITTING WEAVING

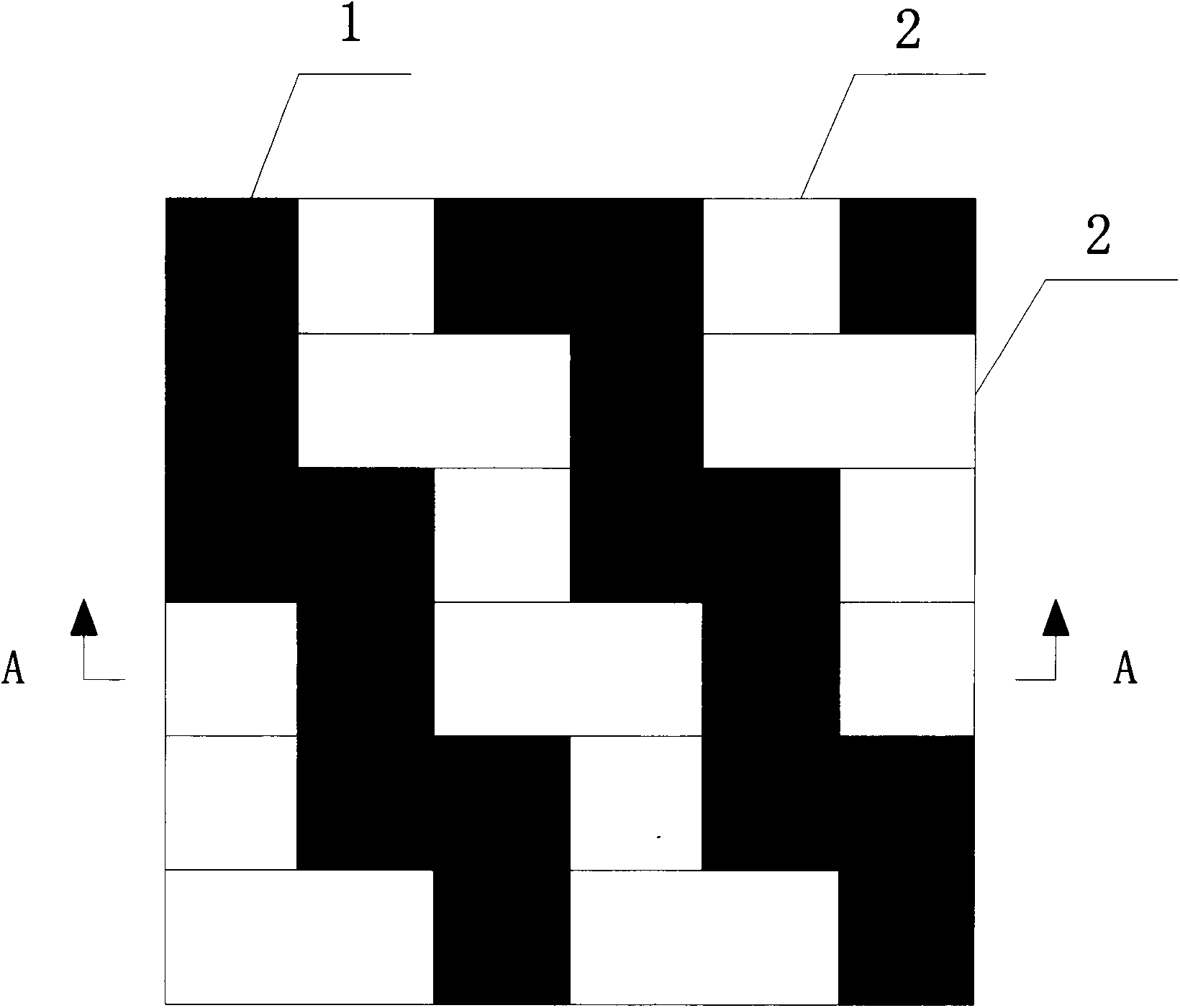

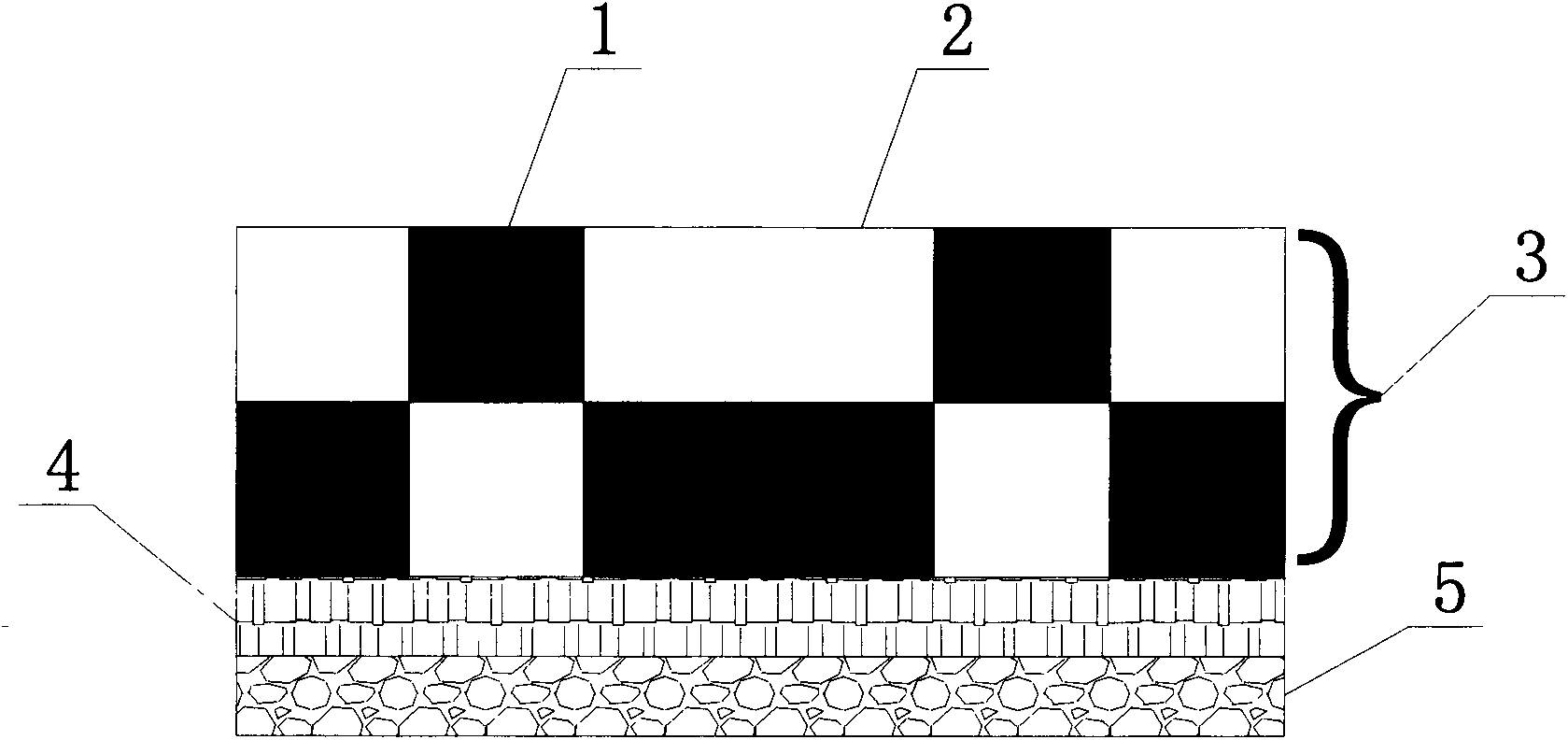

Pure cotton soft mat fabric and preparation method thereof

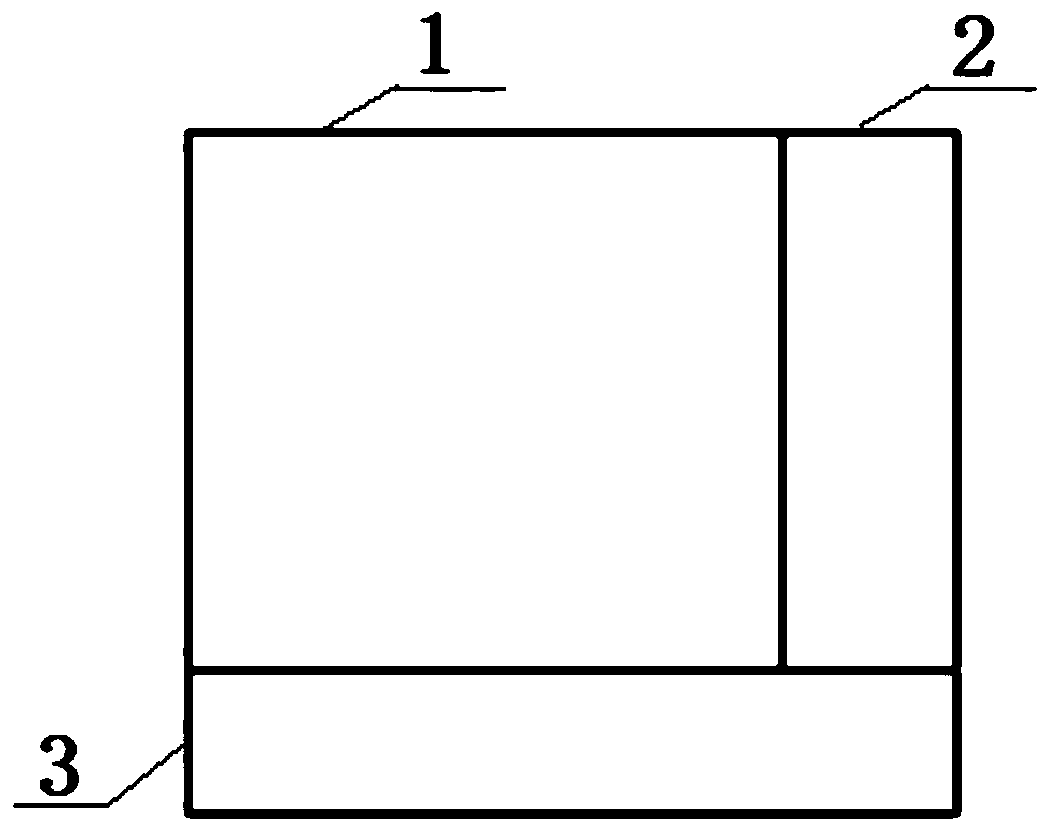

ActiveCN110983555ATight textureFine surfaceSucessive textile treatmentsFabric breaking/softeningPlain weavePolymer chemistry

The invention discloses pure cotton soft mat fabric and a preparation method thereof. The fabric is composed of basic units through circular arrangment, wherein each basic unit comprises a first region, a second region and a third region, wherein the first region and the second region are transversely arranged in parallel, and the third region is longitudinally arranged in parallel with the firstregion and the second region; each basic unit is formed by interweaving warp yarns A and warp yarns B with weft yarns; the first region, the second region and the third region are respectively a double warp weave, a through hole weave and a plain weave; and the warp yarns A are plied yarns, and the warp yarns B and the weft yarns are single yarns. The preparation method of the fabric comprises thefollowing steps of (1) before the yarns of the warp yarns A are plied, carrying out scouring and bleaching pretreatment on the single yarns; (2) warping the yarns, conducting sizing, drafting, denting and beating up to prepare gray fabric; and (3) conducting singeing, desizing, printing or dyeing and carrying out softening finishing on the gray fabric; and putting a printed or dyed product into asoftening finishing liquid for beating treatment. The pure cotton soft mat fabric disclosed by the invention is compact in texture, fine and smooth in touch, capable of absorbing moisture and heat, and breathable and moisture-permeable.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

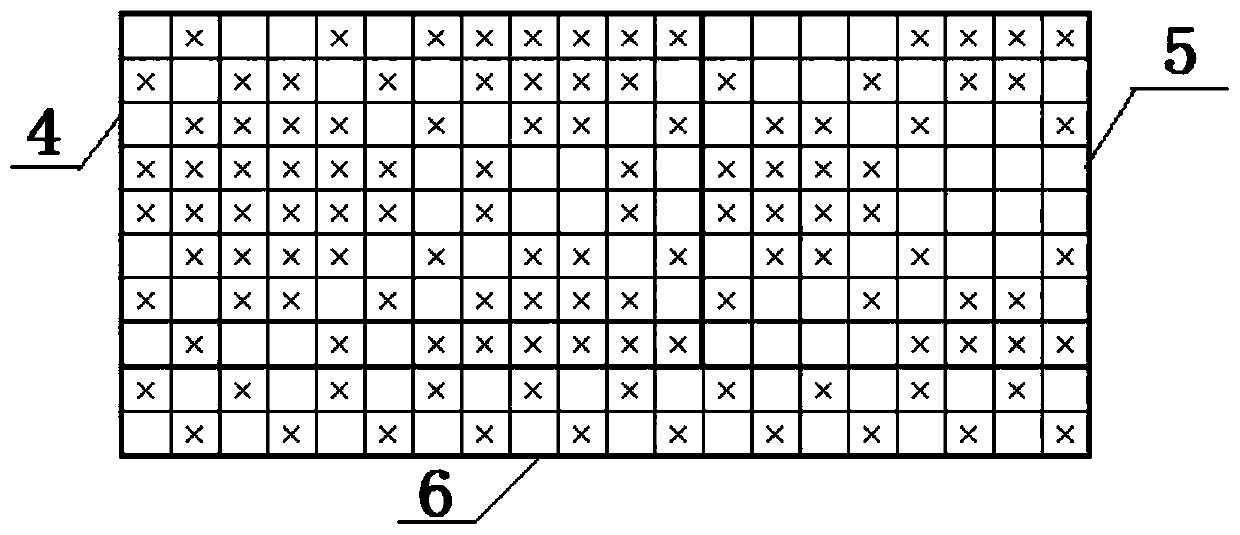

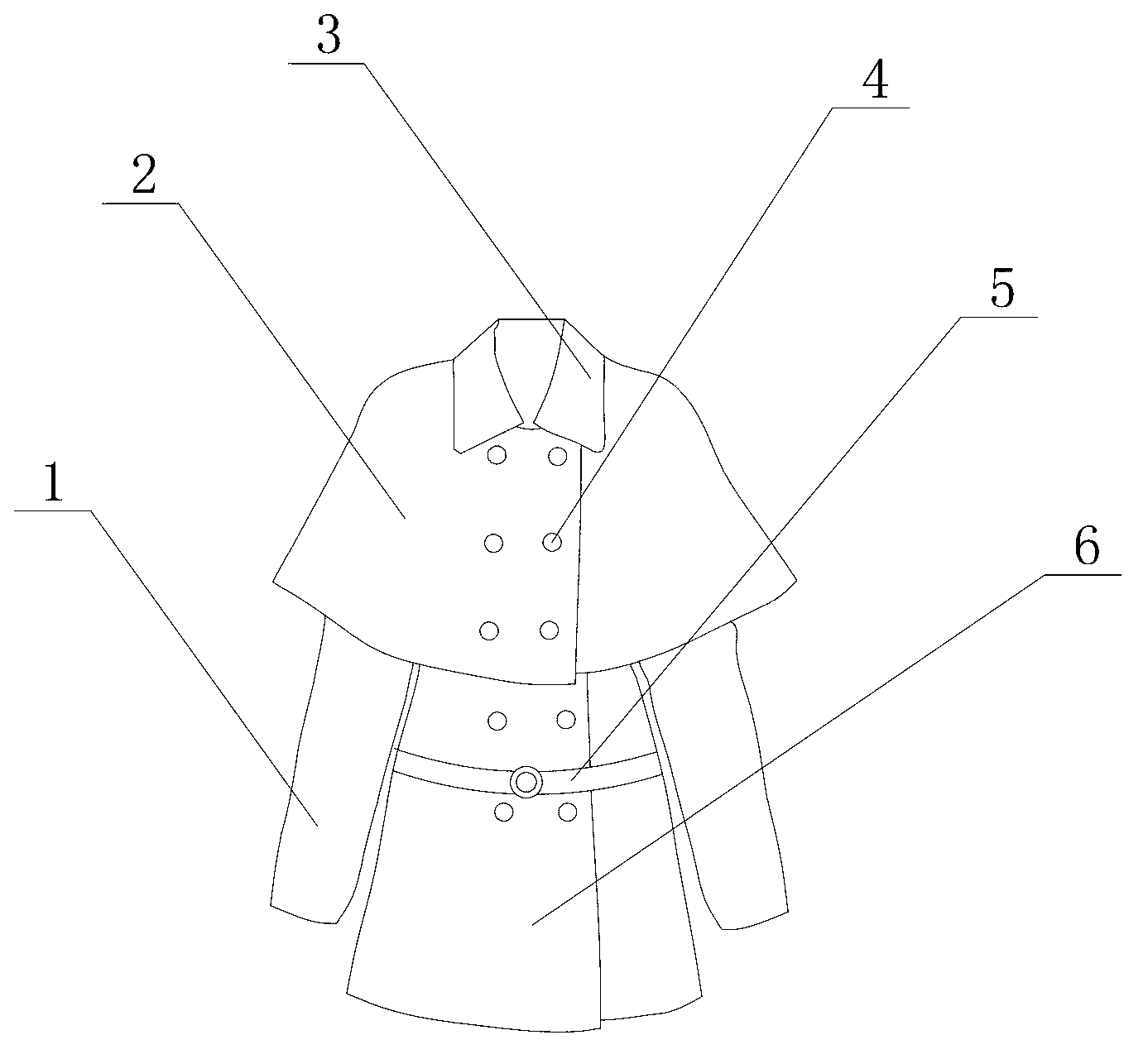

Warm-keeping composite fabric wind coat

InactiveCN103070501AGood windproof and warmBreathable and moisture permeableOvergarmentsProtective garmentCompound aWater vapor permeability

The invention discloses a warm-keeping composite fabric wind coat which comprises a coat body, a collar and sleeves, wherein a cape is arranged on the coat body. The warm-keeping composite fabric wind coat is characterized in that the coat body is made from warm-keeping composite fabric; the sleeves are made from warm-keeping composite fabric; a decorating belt is arranged at the middle of the coat body; and the cape penetrates through the collar and is connected onto the coat body. As an improvement, two ends of the cape are buckled on two sides at the upper part of the coat body. The warm-keeping composite fabric is formed by compounding a hair fine weaving layer with a lining layer. The warm-keeping composite fabric wind coat disclosed by the invention has favorable functions of resisting wind and keeping warmness and certain water vapor permeability; in addition, the composite fabric can be used for making clothes without lining and is an optimal choice for making wind coats and jacks. Meanwhile, a cutting-resisting aluminum alloy sheet is arranged on the coat body and is used for protecting the safety of properties and articles of people.

Owner:JIANGSU AOYANG TEXTILE IND

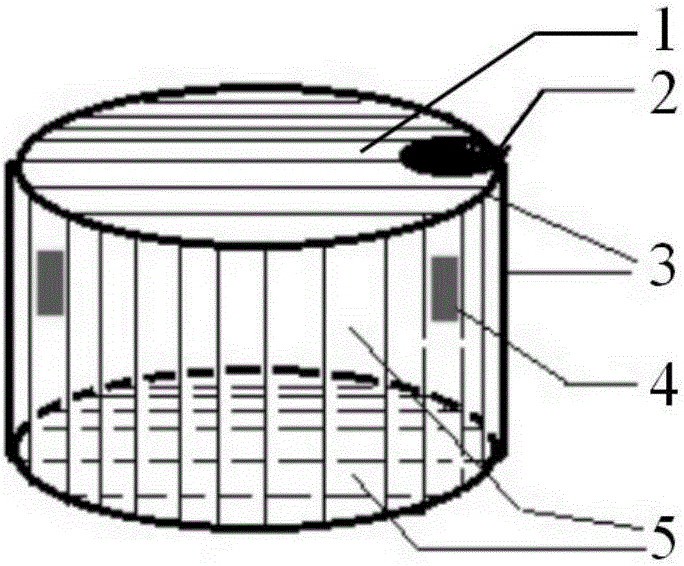

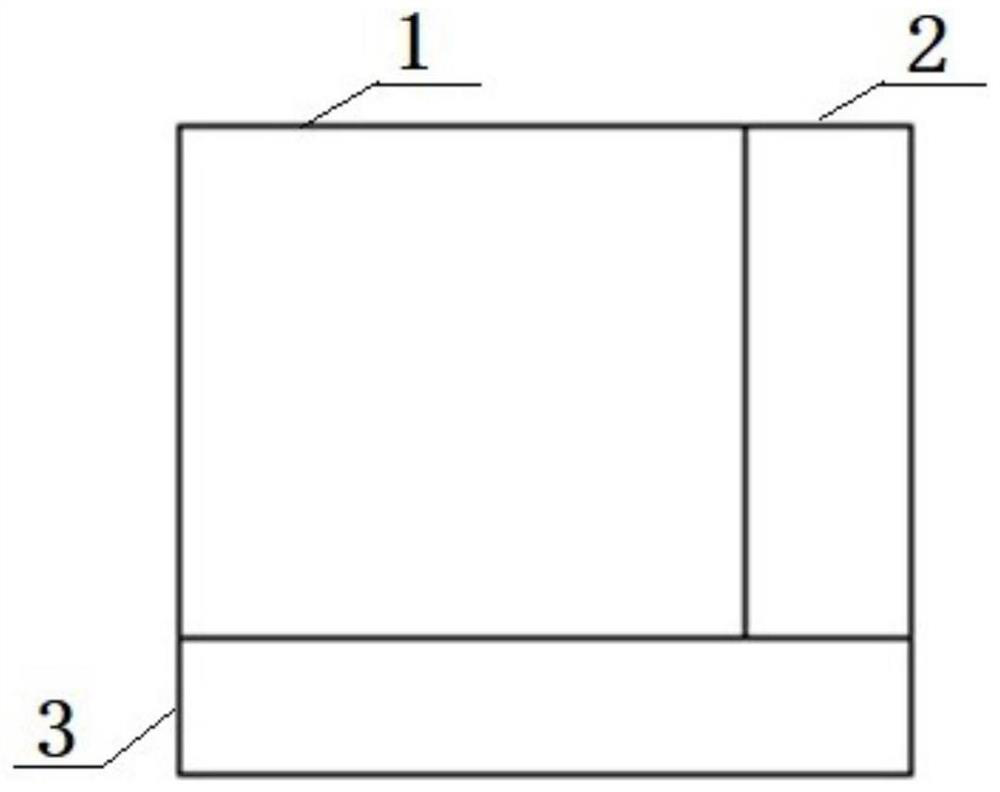

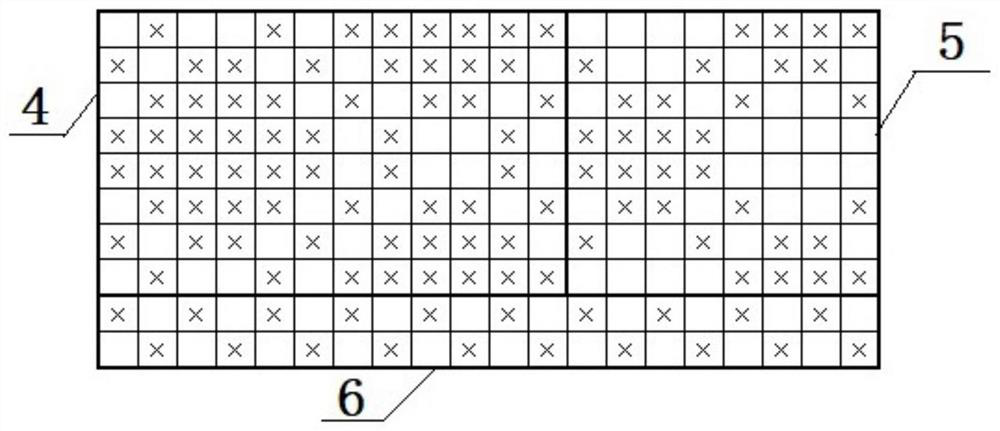

Environment-friendly preservation box and preservation method for instant fresh-cut fruits and vegetables

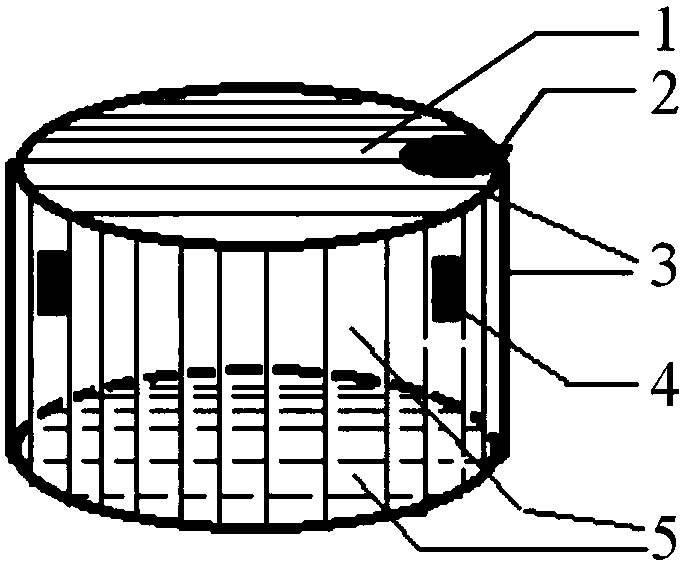

ActiveCN105775413AStrong breathability and moisture permeabilitySlow deterioration of fruits and vegetablesDomestic cooling apparatusLighting and heating apparatusFilling materialsEnvironmental resistance

The invention relates to an environment-friendly preservation box and a preservation method for instant fresh-cut fruits and vegetables, and belongs to the technical field of preservation of the fruits and vegetables. The environment-friendly preservation box for the instant fresh-cut fruits and vegetables comprises a box body and a cover body (1), the box body comprises a box body framework (3) and a double-layer surrounding body (5) covering the outer side of the box body framework, and silica gel windows (4) are arranged on the side wall of the box body; the cover body is provided with a top opening (2), and a gasket is arranged on the top opening and contains ethylene absorbing agents; the double-layer surrounding body (5) comprises an inner-layer surrounding body and an outer-layer surrounding body, wherein the inner-layer surrounding body is made of degradable plastic with high moisture permeability, the outer-layer surrounding body is made of PE preservation films, and the part between the inner-layer surrounding body and the outer-layer surrounding body is filled with foam. The environment-friendly preservation box for the instant fresh-cut fruits and vegetables is high in air permeability and moisture permeability, the deterioration speed of the fruits and vegetables is low, and freshness of the fruits and vegetables is guaranteed.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI

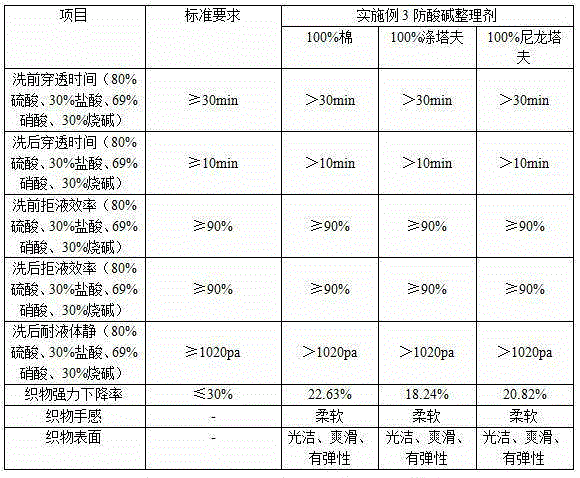

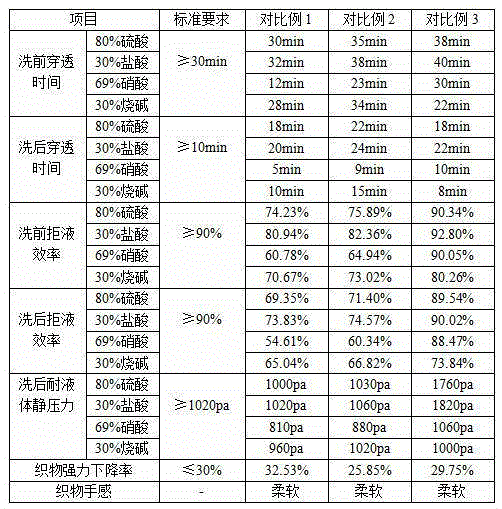

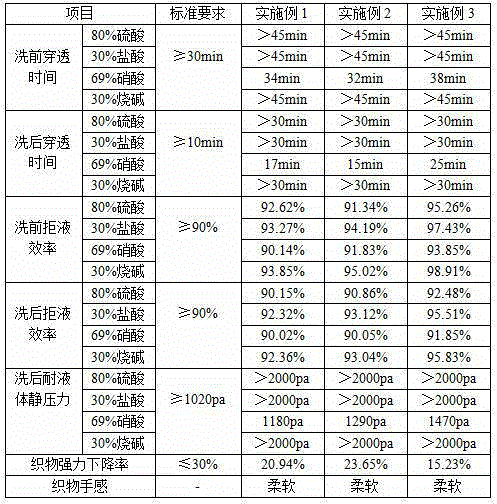

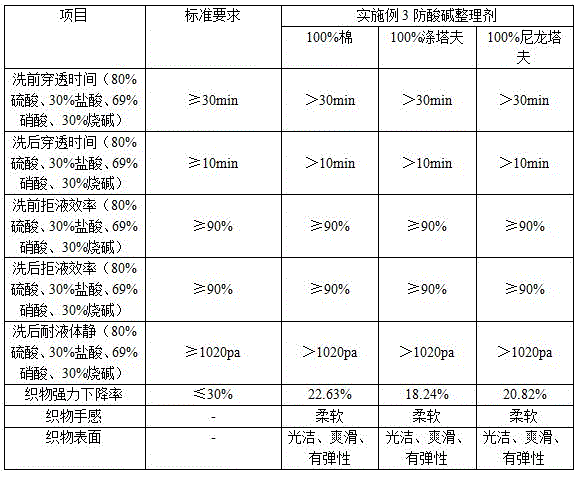

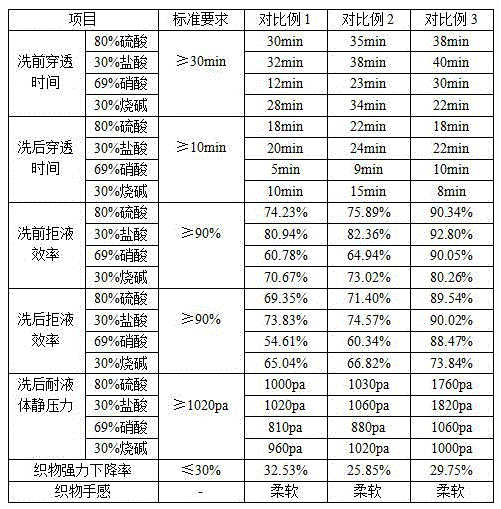

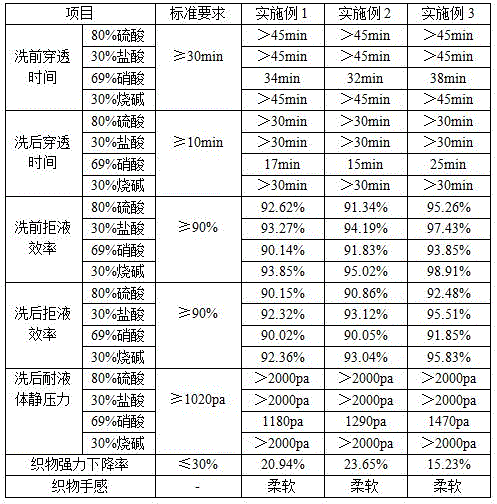

Acid and alkali resisting finishing agent and preparing method and application thereof

The invention discloses an acid and alkali resisting finishing agent and the preparing method and application thereof. The finishing agent is prepared from, by weight concentration, 80-120 g / L waterproof and oilproof finishing agent, 30-60 g / L reinforcing agent, and 10-20 g / L film formation catalyst. The waterproof and oilproof finishing agent is prepared from perluorooctyl acrylate, octadecyl acrylate, hydroxymethyl acrylamide, vinylidene chloride, an emulgator, a cosolvent, an initiator and water. Oxidized polyethlene wax emulsion serves as the reinforcing agent. The film formation catalyst is prepared from isocyanate trimer, end methyl polyethylene glycol, a sealing agent, an organic solvent and water. The acid and alkali resisting finishing agent is high in film-forming property and compression strength, can not be wetted or permeated by acid liquid, alkali liquid and various chemical substances, can resist strong acid, strong alkali and strong oxidants and has the advantages of being breathable, comfortable, soft, portable, easy to wash and the like.

Owner:珠海华大浩宏新材料有限公司

Combined fabric for uniforms

InactiveCN104287250AReduce wasteWith protectionGarment special featuresSynthetic resin layered productsPolyesterWater vapor permeability

The invention relates to combined fabric for uniforms, and belongs to the field of textile fabric. The combined fabric is formed by combining a base fabric layer, a TPU film layer and a Tricot polyester fabric layer, warp yarns of the base fabric layer are 250D polyester low stretch yarns, and weft yarns of the base material layer are 10S TC recuperated yarns. The combined fabric for uniforms has an air and water vapor permeability function, and excess water in uniforms can be drained out of the uniforms in the wearing process; the combined fabric further has a windproof function, temperature inside the uniforms can be effectively maintained, and a warm keeping effect is achieved when a wearer works in winter. The Tricot polyester fabric layer is then combined with the surface of a breathable film, the breathable film can be effectively protected and can not be damaged when the uniforms are worn in work, and therefore the uniforms and the functions are permanent and durable.

Owner:SUZHOU ZHONGTAO TEXTILE

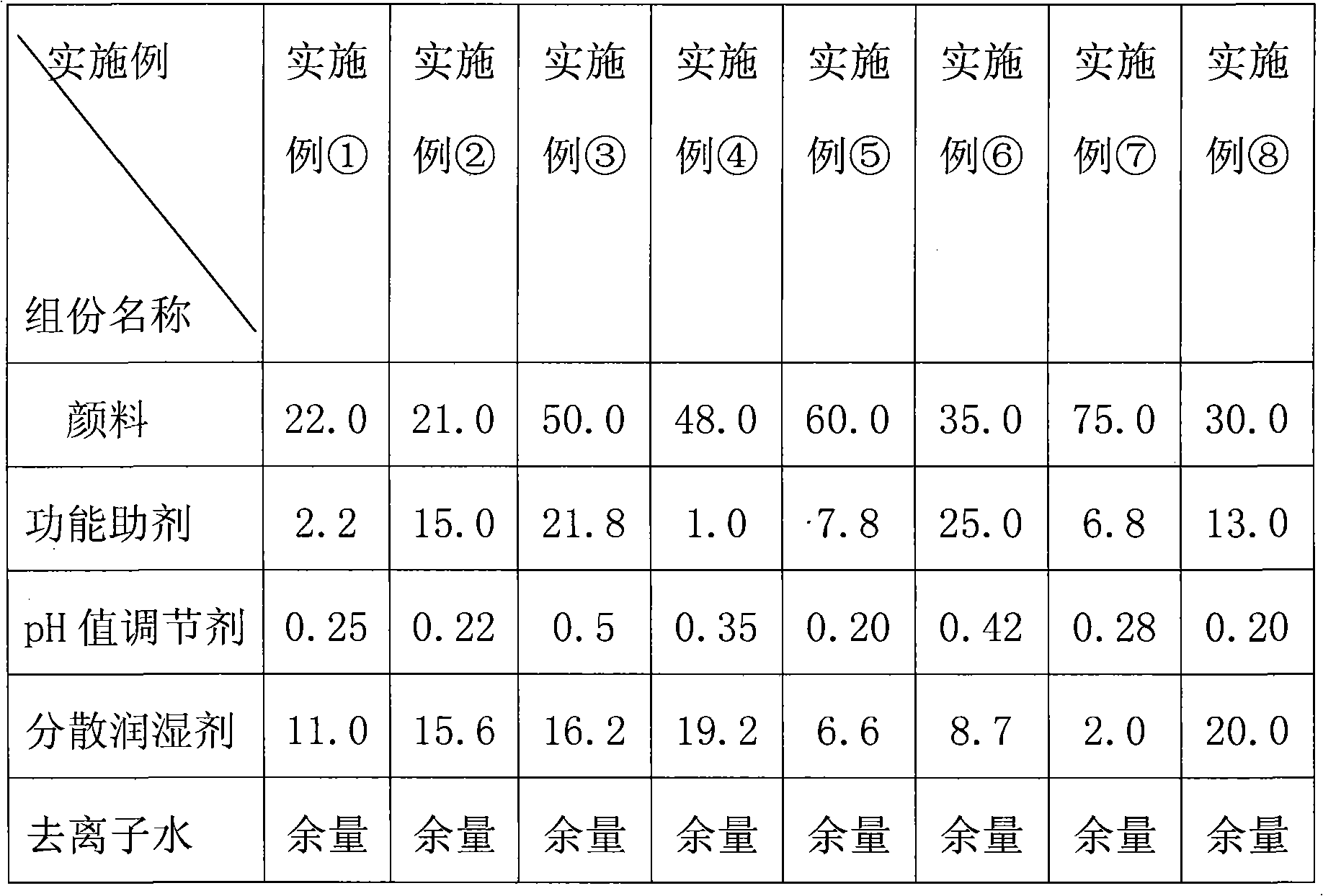

Ecotypic liquid pigment for synthetic leather and preparation method thereof

InactiveCN101942770ANo pollution in the processAppropriate ratioOrganic dyesDyeing processActive agentAlkylphenol

The invention discloses an ecotypic liquid pigment for synthetic leather, comprising the following raw materials in the total weight percentage: 21.0-75.0 percent of pigment, 1.0-25.0 percent of functional assistant, 0.2-0.5 percent of pH value regulator, 2.0-20.0 percent of dispersion wetting agent and the balance of deionized water. Quality detection, vacuum defoaming and filter packaging are carried out after all components are mixed and ground to finally obtain the required ecotypic liquid pigment for the synthetic leather. The ecotypic liquid pigment for the synthetic leather has the advantages of high stability, reasonable preparation process, low cost, simple production flow and easy industrial production, does not contain alkylphenol ethoxylates (APEO), polycyclic aromatic hydrocarbon (PHAs), heavy metal, formaldehyde, carcinogenic aromatic amide (AZO), ethylene glycol or a micromolecule surface active agent and is universal for a DMF (Dimethyl Formamide) system and an aqueous system.

Owner:SUZHOU SUNMUN TECH CO LTD

Preparation method of sericin / polyvinyl alcohol compound membrane

The invention discloses a preparation method of a sericin / polyvinyl alcohol compound membrane. The preparation method is characterized by comprising the steps: using deionized water as a solvent, dissolving sericin and polyvinyl alcohol in a heating water bath to obtain a mixed solution of a certain concentration; drying the mixed solution to obtain a mixed protein membrane; treating the mixed protein membrane with an ethanol solution of certain concentration to induce change in structure, so as to obtain the sericin protein / polyvinyl alcohol compound membrane, which is non-soluble in water. The invention has mild preparation condition, short production cycle, and green and environment-friendly production process.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

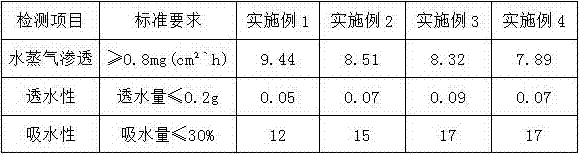

Preparation technology of printed base cloth synthetic leather with high transparency

InactiveCN107503166AHigh transparencyImprove printing effectDyeing processCLARITYMoisture permeability

The invention provides a preparation technology of printed base cloth synthetic leather with high transparency. The preparation technology comprises steps as follows: fabric base cloth is prepared firstly and coated with a transparent base layer, and then the transparent base layer is subjected to printing operation with special transparent printing paste, therefore, high transparency and excellent printing effect of the prepared synthetic leather can be guaranteed; besides, by means of strict control for setting temperature and setting time of the fabric base cloth, components and ratio of the components of the transparent printing paste as well as three-section color fixation treatment after printing, sufficient interaction of the components can be guaranteed, the synergistic interaction effect is achieved, excellent printing effect and transparency can be guaranteed while excellent base performance of the fabric base layer is guaranteed, the effects of air and moisture permeability, visual clarity and the like can be achieved, and the fabric has excellent glossiness.

Owner:丁彬彬

A kind of wet method yangba synthetic leather and preparation method thereof

ActiveCN111206432BThe preparation method is simple, safe and reliableGood fleeceTextiles and paperCelluloseFiber

The invention provides a wet-processed yambar synthetic leather and a preparation method thereof. The wet-processed yambar synthetic leather comprises: a base cloth composed of a fabric sheet; a surface layer based on a water-based polyether polyurethane coating composition, the surface layer is located on the On the base cloth, the surface layer has a porosity of 80-90%, and the water-based polyether polyurethane coating composition comprises: water-based polyether polyurethane 70-85wt%; fiber powder 5-10wt%; first foaming agent 3 -6wt%; second foaming agent 3-5wt%; dispersant 1-3wt%; wetting agent 0.5-1.0wt%; bentonite 1-2wt%; wherein, the fiber powder is composed of 95-97wt% cellulose and 3-5wt% fatty acid ester composition. The wet-process yambar synthetic leather provided according to the present invention has excellent air and moisture permeability, ideal yellowing resistance, and a fine and velvety surface.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +1

Down jacket and production method thereof

InactiveCN102524977BReduce stitchesTroubleshoot drilled issuesOvergarmentsClothes making applicancesComing outLaser cutting

The invention discloses a down jacket and a production method thereof. The production method comprises a whole process from shell fabric forming to finished product forming. The production method comprises the following steps of: after sticking a breathable and moisture-permeable polyurethane film to the inner side of a warp-knitting or weft-knitting knitted fabric, carrying out laser cutting or ordinary cutting, at least carrying out a seamless plying-up process on a bodice part, then, filling eiderdown, and carrying out auxiliary sewing to form a knitted seamless down jacket. The knitted seamless down jacket can be next to the skin after being worn, is elastic and has a breathable and moisture-permeable function, so that the motion of a human body is greatly facilitated and the comfort is improved; furthermore, the advanced seamless hot-pressing technology is adopted, so that the sewing stitches are greatly reduced, and the problem that the eiderdown comes out from the sewing thread is solved; and the whole jacket is upgraded in both appearance and function.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

An environmentally friendly instant fresh-cut fruit and vegetable preservation box and preservation method thereof

ActiveCN105775413BBreathable and moisture-permeableKeep it deliciousDomestic cooling apparatusLighting and heating apparatusEnvironmental resistanceFilling materials

The invention relates to an environment-friendly preservation box and a preservation method for instant fresh-cut fruits and vegetables, and belongs to the technical field of preservation of the fruits and vegetables. The environment-friendly preservation box for the instant fresh-cut fruits and vegetables comprises a box body and a cover body (1), the box body comprises a box body framework (3) and a double-layer surrounding body (5) covering the outer side of the box body framework, and silica gel windows (4) are arranged on the side wall of the box body; the cover body is provided with a top opening (2), and a gasket is arranged on the top opening and contains ethylene absorbing agents; the double-layer surrounding body (5) comprises an inner-layer surrounding body and an outer-layer surrounding body, wherein the inner-layer surrounding body is made of degradable plastic with high moisture permeability, the outer-layer surrounding body is made of PE preservation films, and the part between the inner-layer surrounding body and the outer-layer surrounding body is filled with foam. The environment-friendly preservation box for the instant fresh-cut fruits and vegetables is high in air permeability and moisture permeability, the deterioration speed of the fruits and vegetables is low, and freshness of the fruits and vegetables is guaranteed.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI

A nuclear radiation protection yarn with temperature control function and preparation method thereof

The present invention belongs to the field of nuclear radiation protection technology, and a nuclear radiation protection yarn and its preparation method with temperature control function will be disclosed.After sexual phase change microcapsules and polymers, mixing the Chinese Communist Party of the ion water, and the solution spinning prepares a phase -changing microcapsule polymer composite fiber; the composite fiber and radiation protection polymer composite fiber of the phase transformer microcapsule polymer, Form a nuclear radiation protective yarn with neutron and gamma ray protection and temperature control functions.The invention prepared with temperature control function nuclear radiation protection yarns can further weave and form nuclear radiation protection textile fabrics and wearable radiation protection products. It has broad application prospects in the areas of nuclear operations, nuclear emergency and other fields, and provides easy operation, process, craftsmanshipNew methods with stable and low cost.

Owner:SOUTHWEAT UNIV OF SCI & TECH

A kind of anti-acid and alkali finishing agent and its preparation method and application

The invention discloses an acid and alkali resisting finishing agent and the preparing method and application thereof. The finishing agent is prepared from, by weight concentration, 80-120 g / L waterproof and oilproof finishing agent, 30-60 g / L reinforcing agent, and 10-20 g / L film formation catalyst. The waterproof and oilproof finishing agent is prepared from perluorooctyl acrylate, octadecyl acrylate, hydroxymethyl acrylamide, vinylidene chloride, an emulgator, a cosolvent, an initiator and water. Oxidized polyethlene wax emulsion serves as the reinforcing agent. The film formation catalyst is prepared from isocyanate trimer, end methyl polyethylene glycol, a sealing agent, an organic solvent and water. The acid and alkali resisting finishing agent is high in film-forming property and compression strength, can not be wetted or permeated by acid liquid, alkali liquid and various chemical substances, can resist strong acid, strong alkali and strong oxidants and has the advantages of being breathable, comfortable, soft, portable, easy to wash and the like.

Owner:珠海华大浩宏新材料有限公司

A kind of pure cotton soft mat fabric and preparation method thereof

ActiveCN110983555BTight textureHas moisture absorption and heat absorptionFabric breaking/softeningSucessive textile treatmentsTextile printerPolymer science

The invention discloses a pure cotton soft mat fabric and a preparation method thereof. The fabric is composed of basic units arranged circularly. Three areas; the basic unit is formed by the interweaving of warp A yarn, warp B yarn and weft yarn; the weaves of the first area, the second area and the third area are heavy warp weave, open hole weave and plain weave respectively; warp A yarn is ply yarn, The warp yarn B yarn and the weft yarn are single yarns. The manufacturing method of the above-mentioned fabric comprises the following steps: (1) before the warp yarn A yarn is plyed, the single yarn is subjected to scouring and bleaching pretreatment; (3) singeing, desizing, printing or dyeing the gray cloth, and softening the gray cloth; placing the printed or dyed product in the softening finishing solution for beating treatment. The pure cotton soft mat fabric of the present invention has tight texture, delicate touch, moisture absorption and heat absorption, and is breathable and moisture permeable.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Reusable natural antibacterial China-hemp-based protective fabric and processing method thereof

PendingCN113858722AReduce pollutionShort processing flowLamination ancillary operationsSynthetic resin layered productsHemp fiberComposite material

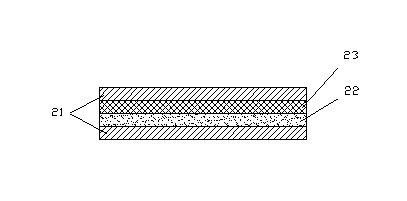

The invention discloses a reusable natural antibacterial China-hemp-based protective fabric. The protective fabric is composed of three layers, namely an outer layer, a middle layer and an inner layer, the outer layer is an antibacterial China-hemp fabric subjected to waterproof and oil-proof functional finishing, the middle layer is a functional isolating membrane layer, and the inner layer is an antibacterial China-hemp lining subjected to moisture absorption and sweat releasing functional finishing. The protective fabric is composed of the outer layer, the middle layer and the inner layer, takes the China hemp fiber as a basic raw material, has the properties of natural antibacterial property, air and moisture permeability, antistatic property, skin friendliness, comfort and the like, does not need additional antibacterial and antistatic finishing processing, is a functional and environment-friendly protective fabric, has durable usability, can be repeatedly used after being washed with water, can effectively reduce environmental pollution caused by disposable protective fabrics which are discarded after being used, and is especially suitable for production of protective fabrics in the fields of chemical defense, medical treatment, power stations and the like. The protective fabric is compounded through one-step hot pressing, the processing flow is short, the technology is simple, and the processing efficiency is high.

Owner:NINGBO YOUNGOR YINGCHENG UNIFORM +2

Processing technology of soft fading-prevention denim

InactiveCN107938100AExcellent discoloration effectBreathable and moisture-permeableWoven fabricsYarnYarnPolyester

The invention discloses a processing technology of soft fading-prevention denim. The processing technology comprises the steps of preparation of modified polyester fiber, preparation of yarn and yarnintertwining. The denim processed through the processing technology has an excellent fading-prevention effect; meanwhile, the soft fading-prevention denim has the advantages of being air and water vapor permeable, tender in hand feeling, and comfortable to wear; the processing technology is simple, low in cost and high in automated degree; meanwhile, in the processing process, fiber resources arefully utilized, and the requirement for environmental protection is met.

Owner:HAIYAN SHUOCHUANG CLOTHING RES INST

Coral fleece blended fabric

The invention provides a coral fleece blended fabric which is composed of cotton fiber, coral fleece, dacron, acetate fiber, soybean fiber, gabardine, plush and camel wool. The fabric made by the formula has the advantages of a fine and smooth texture, a soft hand feeling, high comfort, warmth-keeping performance, air and water vapor permeability, and bacteria resistance and bacteriostasis. The fabric has the advantages that hair slip, pilling and fading do not happen; water absorption performance is excellent and three times the water absorption performance of all-cotton productions; stimulation and irritability are not brought to skin; appearance is nice; and colors are abundant.

Owner:RUGAO WEIBAO SUIT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com