Preparation technology of printed base cloth synthetic leather with high transparency

A technology with high transparency and preparation technology, which is applied in the field of synthetic leather, can solve problems such as difficult production operations, darkening of gloss, and intolerance to yellowing, and achieve excellent transparency, excellent basic performance, and clear vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

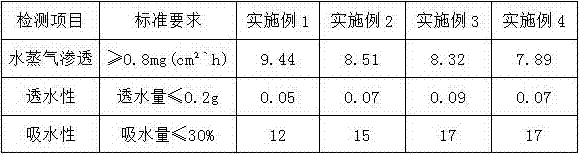

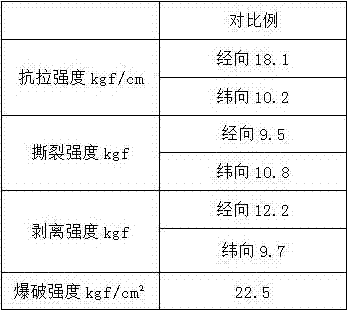

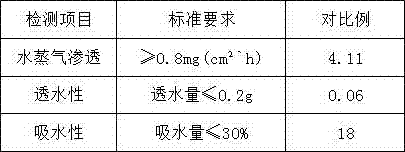

Examples

Embodiment 1

[0016] A preparation process of high-transparency printed base cloth synthetic leather, comprising the following steps:

[0017] 1) Prepare fabric base fabric: use polyurethane fiber as warp and weft yarn, wherein the warp yarn is 30D, and the weft yarn is 40D, and the fabric base fabric is processed by carding machine, web laying machine, and needle punching machine;

[0018] 2) Coating the transparent base layer: coating the PU glue layer on the fabric base fabric obtained in step 1), the thickness of the PU glue layer is 1.10mm, forming a transparent fabric base fabric;

[0019] 3) Heat setting: shape the transparent fabric base fabric obtained in step 3) at a temperature of 150°C, and the setting speed is 8m / min;

[0020] 4) Preparation of transparent printing paste: The transparent printing paste includes 14 parts by weight of polydimethylaminosiloxane, 32 parts of dimethylphenylbenzyl ammonium chloride disulfonic acid calcium salt, 13 parts of etherified starch parts, 1...

Embodiment 2

[0025] A kind of preparation technology of high-transparency printing base cloth synthetic leather as described in embodiment 1, wherein some steps can also adopt following technology:

[0026] In step 2), the thickness of the PU glue layer is 0.80mm.

[0027] In step 3), the setting temperature is 155°C, and the setting speed is 9 m / min.

[0028] In step 4), the transparent printing paste includes 18 parts by weight of polydimethylaminosiloxane, 25 parts of dimethylphenylbenzyl ammonium chloride disulfonate calcium salt, etherified starch 16 parts, 7 parts of galactomannan, 2 parts of HDI trimer curing agent, and 0.4 part of bismuth isooctanoate accelerator.

[0029] In step 4), the stirring time is 1.1 h, and the stirring temperature is 70°C.

[0030] In step 6), the dehydration temperature of the first stage of high-temperature color fixing is 152°C, the dehydration time is 5 minutes, the drying temperature of the second stage is 160°C, and the drying time is 5 minutes, a...

Embodiment 3

[0032] A kind of preparation technology of high-transparency printing base cloth synthetic leather as described in embodiment 1, wherein some steps can also adopt following technology:

[0033] In step 2), the thickness of the PU glue layer is 0.50mm.

[0034] In step 3), the setting temperature is 160° C., and the setting speed is 7 m / min.

[0035] In step 4), the transparent printing paste includes 10 parts by weight of polydimethylaminosiloxane, 40 parts of dimethylphenylbenzyl ammonium chloride disulfonate calcium salt, etherified starch 12 parts, 13 parts of galactomannan, 1 part of HDI trimer curing agent, and 0.6 part of bismuth isooctanoate accelerator.

[0036] In step 4), the stirring time is 1 h, and the stirring temperature is 80°C.

[0037] In step 6), the dehydration temperature of the first stage of the high-temperature color fixing is 140°C, the dehydration time is 7 minutes, the drying temperature of the second stage is 180°C, and the drying time is 5 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com