Multifunctional insole and a manufacture method thereof

A manufacturing method and a technology for insole, which are applied in the fields of textile and hygiene, and can solve the problems of indurability, uncomfortable wearing, and poor durability of drug insole functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention are as follows,

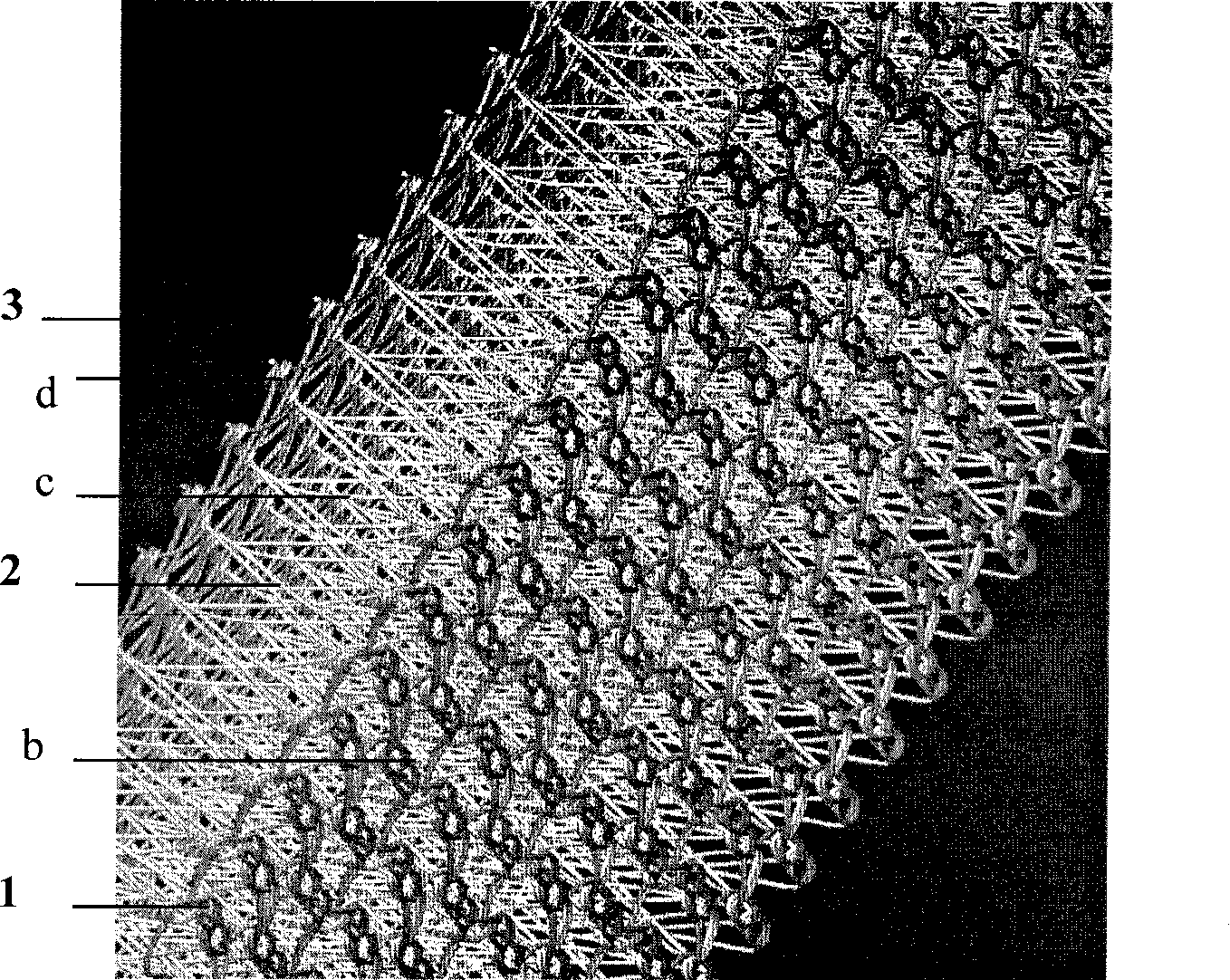

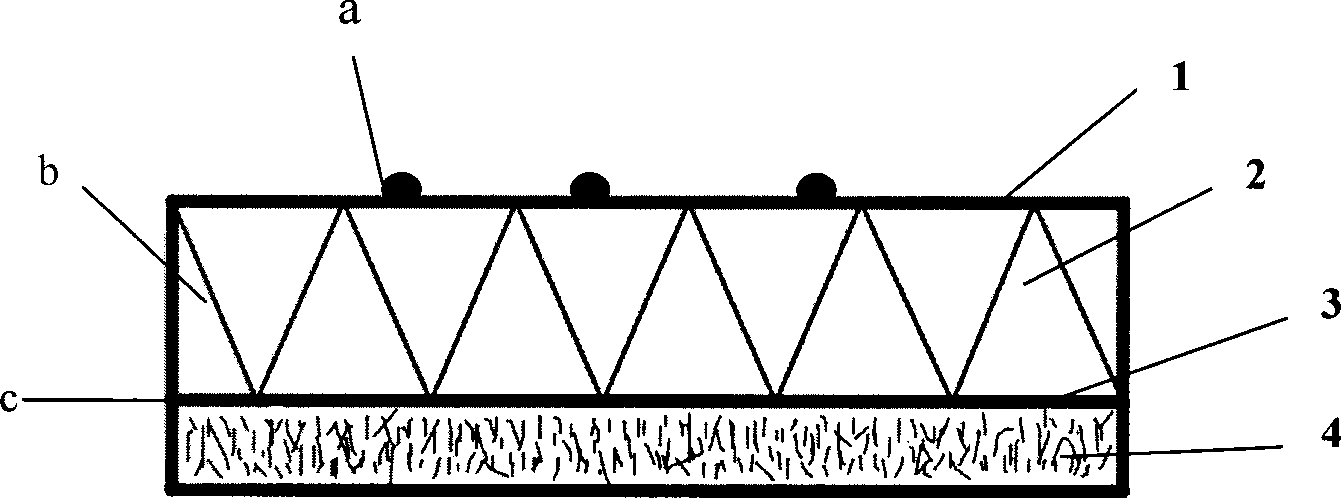

[0015] 1. Yarn preparation: use 250dtex bamboo charcoal yarn as the raw material for the surface fabric, use 33dtex polyester monofilament as the spacer yarn, and use 83dtex polyester yarn as the raw material for the bottom fabric;

[0016] 2. Yarn warping: 12 bamboo charcoal yarns with 230 ends of 21 inches, 6 polyester monofilaments with 460 ends of 21 inches, and 83dtex polyester yarn with 460 ends of 21 inches.

[0017] 3. On-machine weaving: Weaving is carried out on the E22 double-needle bed Raschel machine, among which GB1 and GB2 use two-thread and two-hole thread to thread bamboo charcoal yarn, GB3 full thread thread thread polyester monofilament, GB4 and GB5 full thread thread thread polyester 83dtex polyester yarn. Set the stripping board distance to 4 mm, and the pulling density to 14 coils / cm. The laying yarn organization of each bar is as follows:

[0018] GB1: 1-0-1-1 / 2-3-2-2 / 1-0-1-1 / 2-3-3-3 / 4-5-4-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com