Acid and alkali resisting finishing agent and preparing method and application thereof

A finishing agent and anti-acid and alkali technology, which is applied in fiber treatment, textiles and papermaking, etc., can solve the problems of poor operator health and work efficiency, poor anti-acid and alkali performance, bulky and inconvenient clothing, etc., to avoid splashing and penetration , Acid-resistant and permeable for a long time, the effect of uniform protective film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

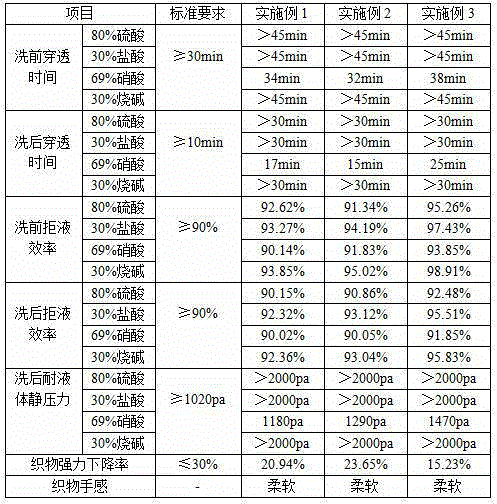

Embodiment 1

[0037] Embodiment 1, the anti-acid and alkali finishing agent of the present invention and its preparation

[0038] The anti-acid and alkali finishing agent of this embodiment is composed of the following components in weight concentration: waterproof and oil-proof finishing agent 80g / L, reinforcing agent 30g / L and film-forming catalyst 10g / L;

[0039] The waterproof and oil-repellent finishing agent is prepared from the following raw materials in parts by weight: 110 kg of trifluorooctyl acrylate, 130 kg of stearyl acrylate, 6 kg of methylol acrylamide, 70 kg of vinylidene chloride, 40 kg of emulsifier (fatty alcohol poly Oxyethylene ether AEO9 and octadecyltrimethylammonium chloride are mixed at a weight ratio of 2:1), diethylene glycol butyl ether 110kg, ammonium persulfate 0.6kg and water 450kg;

[0040] The reinforcing agent is oxidized polyethylene wax emulsion.

[0041] The film-forming catalyst is prepared from the following raw materials in parts by weight: 90 kg of i...

Embodiment 2

[0052] Embodiment 2, anti-acid and alkali finishing agent of the present invention and its preparation

[0053] The anti-acid and alkali finishing agent of this embodiment is composed of the following components by weight concentration: waterproof and oil-proof finishing agent 120g / L, reinforcing agent 60g / L and film-forming catalyst 20g / L;

[0054] The waterproof and oil-repellent finishing agent is prepared from the following raw materials in parts by weight: 130 kg of trifluorooctyl acrylate, 110 kg of stearyl acrylate, 3 kg of methylol acrylamide, 50 kg of vinylidene chloride, 50 kg of emulsifier (fatty alcohol poly Oxyethylene ether AEO9 and octadecyltrimethylammonium chloride are mixed at a weight ratio of 2:1), dipropylene glycol butyl ether 90kg, azobisisobutylamidine 0.65kg and water 550kg;

[0055] The reinforcing agent is oxidized polyethylene wax emulsion.

[0056] The film-forming catalyst is prepared from the following raw materials in parts by weight: 110 kg ...

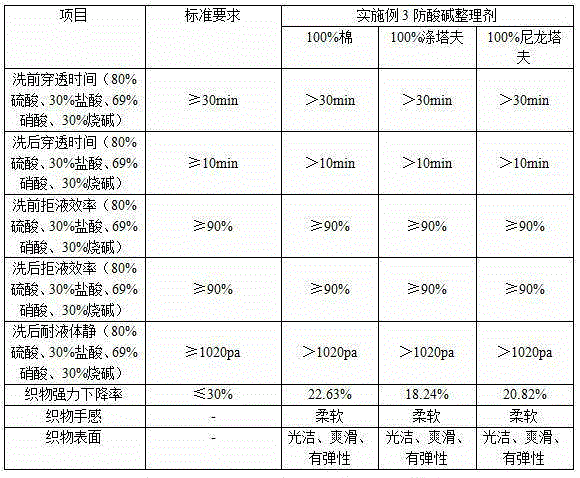

Embodiment 3

[0067] Embodiment 3, the anti-acid and alkali finishing agent of the present invention and its preparation

[0068] The anti-acid and alkali finishing agent of this embodiment is composed of the following components in weight concentration: waterproof and oil-proof finishing agent 100g / L, reinforcing agent 50g / L and film-forming catalyst 15g / L;

[0069] The waterproof and oil-repellent finishing agent is prepared from the following raw materials in parts by weight: 120 kg of trifluorooctyl acrylate, 120 kg of stearyl acrylate, 5 kg of methylol acrylamide, 60 kg of vinylidene chloride, 45 kg of emulsifier (fatty alcohol poly Oxyethylene ether AEO9 and octadecyltrimethylammonium chloride are mixed at a weight ratio of 2:1), diethylene glycol butyl ether 100kg, ammonium persulfate 0.65kg and water 500kg;

[0070] The reinforcing agent is oxidized polyethylene wax emulsion.

[0071] The film-forming catalyst is prepared from the following raw materials in parts by weight: 100 k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com