Multifunctional protective fabric

A multi-functional, fabric technology, applied in protective clothing, clothing, special outerwear, etc., can solve the problems of burning holes, roughness, and bulky products, and achieve the effects of low cost, ideal effect and simple production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

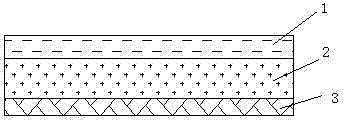

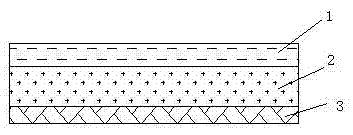

[0014] Such as figure 1 Shown, a kind of multifunctional protective fabric, comprises barrier layer 1 and comfort layer 2, and isolation layer 1 is ceramic aluminum oxide metal film layer, and comfort layer 2 is the knitted fabric layer of natural fiber or man-made fiber through flame-retardant treatment, so The ceramic aluminum oxide metal film layer described above is sprayed on the comfort layer 2, thereby increasing the heat reflectivity, antistatic performance and waterproof performance of the multifunctional protective fabric of the present invention, and the comfort layer 2 of the present invention is a stock solution flame-retardant glue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com