Nuclear-radiation-protection yarn with temperature control function and production method thereof

A radiation protection and functional technology, applied in the field of nuclear radiation protection, can solve problems such as poor air permeability and moisture permeability, single radiation protection function, and poor wearing comfort, and achieve good mechanical strength and toughness, broad application prospects, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

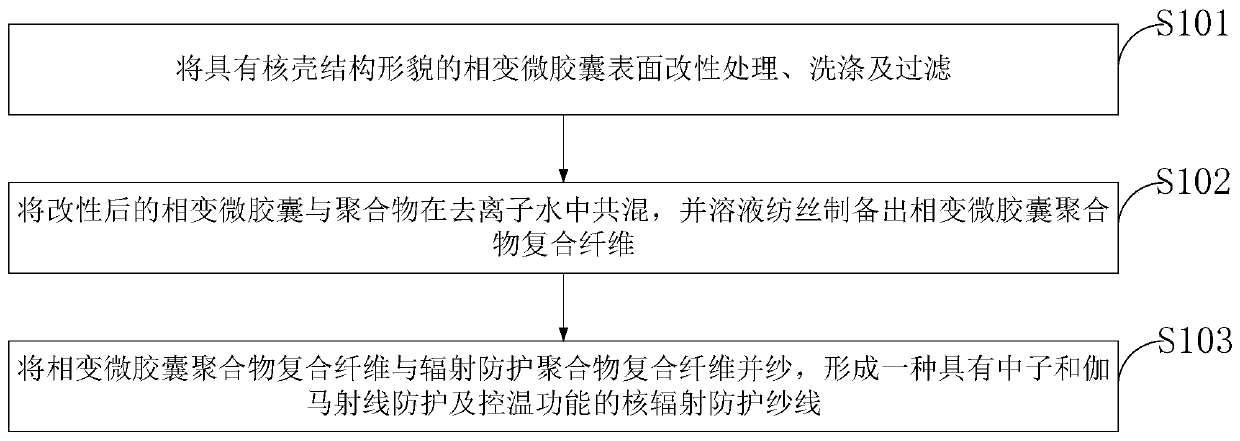

[0039] Such as figure 1 , the preparation method of nuclear radiation protection yarn with temperature control function provided by the embodiment of the present invention, comprising:

[0040] S101: modifying, washing and filtering the surface of the phase-change microcapsules having a core-shell structure.

[0041] S102: blending the modified phase-change microcapsules and the polymer in deionized water, and solution spinning to prepare phase-change microcapsule polymer composite fibers.

[0042] S103: combining phase change microcapsule polymer composite fiber and radiation protection polymer composite fiber to form a nuclear radiation protection yarn with neutron and gamma ray protection and temperature control functions.

[0043] As a preferred implementation of the present invention, the phase-change microcapsules in step S101 have a core-shell structure with a material having a nuclear radiation protection function as the shell and a material with a phase-change functi...

Embodiment 1

[0055] The method for preparing nuclear radiation protection yarn with temperature control function provided by the embodiment of the present invention comprises the following steps:

[0056] (1) Disperse the phase-change microcapsules whose shell is bismuth metal and paraffin wax core layer into a 200ml hydrogen peroxide solution flask, ultrasonically treat for 30mins, stir at 50°C for 48h, wash and filter to obtain surface hydroxylated phase-change microcapsules.

[0057] (2) blend the modified phase-change microcapsules with polyethylene glycol in deionized water (wherein the phase-change microcapsules are 1wt% of the polymer mass, and the concentration of the polymer aqueous solution is 5wt%), and then mix the solution Phase change microcapsule polymer composite fibers were prepared by spinning.

[0058] (3) Combining the phase-change microcapsule polymer composite fiber obtained in step (2) with boron carbide / polyester composite fiber (the ratio of shares is 1:1), to obta...

Embodiment 2

[0060] The method for preparing nuclear radiation protection yarn with temperature control function provided by the embodiment of the present invention comprises the following steps:

[0061] (1) Disperse phase-change microcapsules whose shell is lead oxide and core layer is calcium chloride hydrate salt into a 200ml hydrogen peroxide solution flask, ultrasonically treat for 30mins, stir at 50°C for 48h, wash and filter to obtain surface hydroxylation phase transition Microcapsules.

[0062] (2) Blending the modified phase-change microcapsules with polyacrylic acid in deionized water (wherein the phase-change microcapsules are 5wt% of the polymer mass, and the concentration of the polymer aqueous solution is 15wt%), and then solution spinning The phase change microcapsule polymer composite fiber was prepared.

[0063] (3) Combine the phase change microcapsule polymer composite fiber obtained in step (2) with the lead tungstate / nylon composite fiber (strand ratio 1:2) to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com