Patents

Literature

31results about How to "Good fleece" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel textile downproof technology

InactiveCN105821670AIncrease productivityGood fleeceLight resistant fibresLiquid repellent fibresAdhesiveEngineering

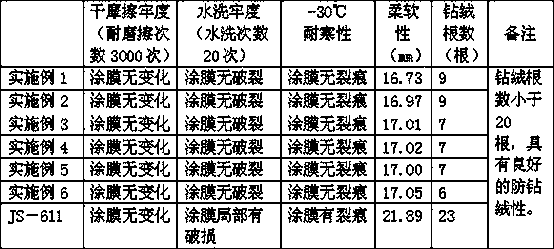

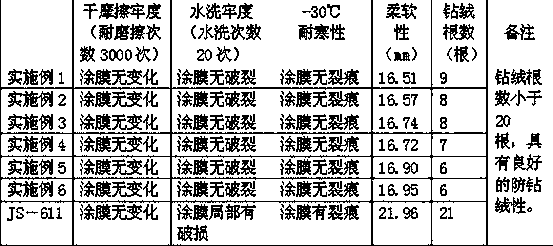

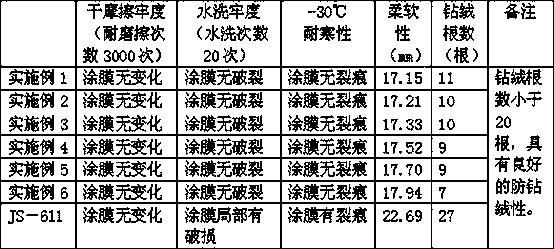

Disclosed is a novel textile downproof technology .The novel textile downproof technology comprises the following steps of 1, selecting a fabric, wherein the fabric is a plain weave fabric woven by nylon full-stretching silk, the yarn count is 20 D-40 D, and the density is 290 Tex-400 Tex; 2, performing water-repellency arrangement on the fabric, wherein the grade of getting wet is not smaller then 3; 3, performing calendering on the fabric obtained after water-repellency arrangement through a calender, wherein the pressure is 9-11 MPa, the temperature is 100-110 DEG C, and the speed is 30-40 m / min; 4, preparing a coating adhesive .The downproof effect is achieved through the good combination of a base fabric and the coating adhesive, particularly, the downproof effect at a sewing needle hole is achieved, meanwhile, the selected and prepared coating adhesive can ensure comprehensive indicators of downproofness, cold resistance, moisture penetrability, washing fastness, flexibility and the like of the fabric with the low weight increment, and the wearing comfort of the fabric is better on the premise of achieving functionality .

Owner:JIANGSU DONGBANG TECH

Environmentally friendly anti-siphon afterfinishing method for suede microfiber synthetic leather

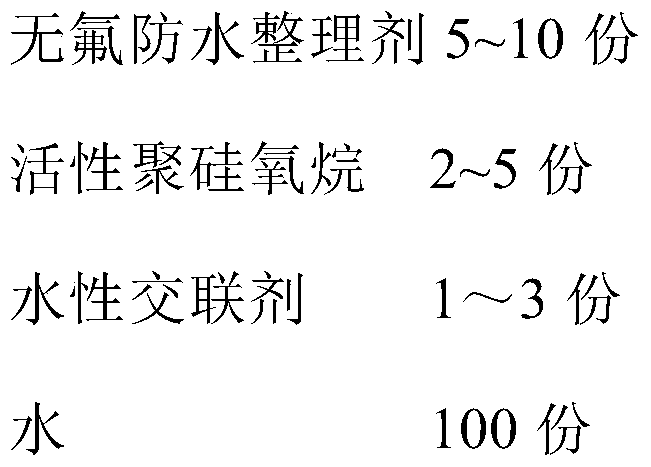

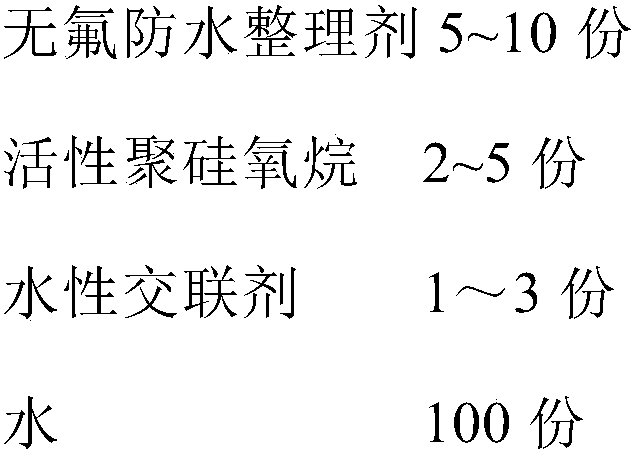

ActiveCN105463857AImprove the anti-siphon effectSpeed up penetrationFibre treatmentFluorine freeMicrofiber

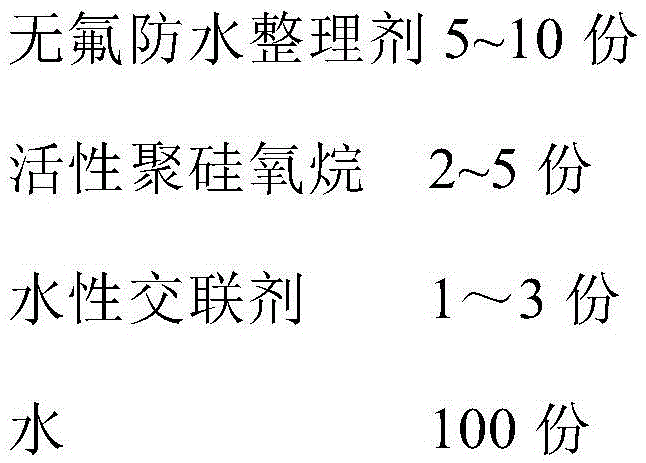

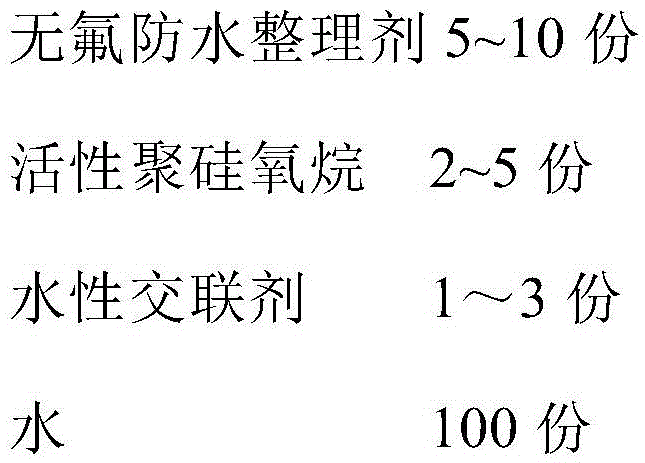

The present invention discloses an environmentally friendly anti-siphon afterfinishing method for a suede microfiber synthetic leather. The method is as below: (1) immersing the dyed microfiber synthetic leather into an anti-siphon treatment solution, and padding; (2) then drying the product obtained in the step (1), cooling, rolling and crumpling to obtain the anti-siphon suede microfiber synthetic leather. The anti-siphon treatment solution for suede microfiber synthetic leather has a pH value of 4-6, and comprises the following components by weight: 5-10 parts of a fluorine-free waterproof finishing agent, 2-5 parts of reactive polysiloxane, 1-3 parts of an aqueous crosslinking agent and 100 parts of water. The agent of the invention uses the fluorine-free environment-friendly waterproof finishing agent without APEO, PFOA or PFOS, and the ultrasonic technology; and the obtained microfiber synthetic leather achieves anti-siphon effect of rise of impregnating solution of less than 1cm after 2h immersion, and has good creases and velvety sense, so as to improve the grade of the suede microfiber synthetic leather.

Owner:HUAFON MICROFIBER SHANGHAI

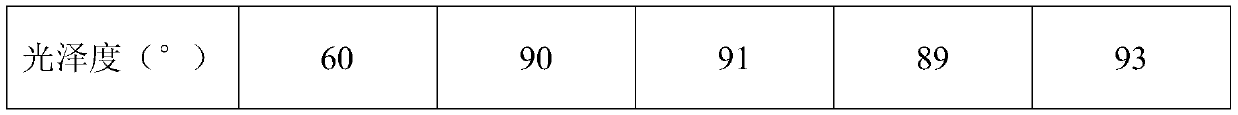

Water-based yangbuck with lustring effects and method for preparing water-based yangbuck

ActiveCN106436337AStrong sense of hierarchyClear texturePolyurea/polyurethane coatingsTextiles and paperWater basedEngineering

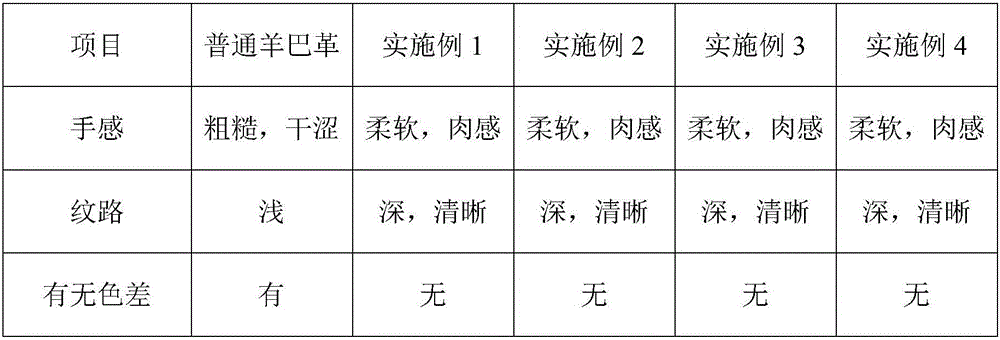

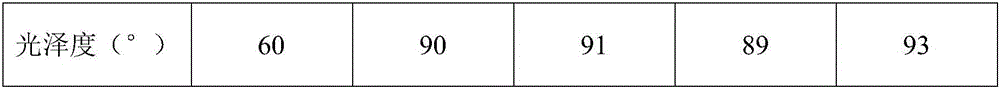

The invention provides a method for preparing water-based yangbuck with lustring effects. The method includes steps of 1), coating and scraping water-based wet base slurry on base cloth, transporting the base cloth into a coagulating tank, coagulating the base cloth and drying the base cloth by means of baking to obtain water-based base; 2), coating water-based yangbuck materials on release paper, drying the water-based yangbuck materials and the release paper to form yangbuck clinging surfaces, adhering the water-based base onto the yangbuck clinging surfaces, then drying the yangbuck clinging surfaces by means of baking, cooling the yangbuck clinging surfaces and peeling the release paper to obtain artificial leather by means of preparation; 3), placing the artificial leather in a baking oven and foaming the artificial leather at the high temperature to obtain yangbuck by means of preparation; 4), carrying out color change treatment on the yangbuck by the aid of a printing machine; 5), preparing lustring materials, adding the lustring materials into the printing machine and carrying out lustring treatment on the yangbuck. The method has the advantages that the surfaces of the water-based yangbuck are high in leather feeling and good in velvet feeling and feel soft, and the excellent lustring effects can be realized; the surfaces of the yangbuck are bulky, thick, smooth, straight and bright and have plump pile after lustring treatment is carried out on the yangbuck, and market requirements on high-grade yangbuck can be met.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD

Production method of Europa suede-feel polyurethane synthetic leather

InactiveCN101748614AGood market prospectGood moisture permeabilityLamination ancillary operationsPattern makingEnvironmental resistanceHigh polymer

The invention discloses a production method of Europa suede-feel polyurethane synthetic leather, which comprises the following steps: firstly, preparing semifinished synthetic leather by using a wet method; secondly, hot-joining the polyurethane slurry layer, which is formed after the pattern of release paper is transferred, onto the surface of the semifinished synthetic leather which is printed by the wet method, wherein the polyurethane slurry comprises the following raw materials in parts by weight: polyester-polyether copolymer resin SF-01, 3-7 parts of expanded micro particle, 8-12 parts of butanone, 5-10 parts of solvent-type pigment and 0.2-0.5 part of modified silicone high polymer BYK-95950; thirdly, embossing and foaming by using embossing rollers; and finally, crinkling. The invention enables the surface of the polyurethane synthetic leather to have strong suede feel and barbing effect. The polyurethane synthetic leather has the advantages of high wear resistance, high peeling, high cold resistance, high hydrolysis resistance and other physical properties. The polyurethane synthetic leather is exactly like leather and is high-quality environmental-protection high-grade synthetic leather. The whole process conforms to the requirements of environmental protection, and conforms to the development trend of professional shoe materials in modern times.

Owner:ANHUI ANLI MATERIAL TECH

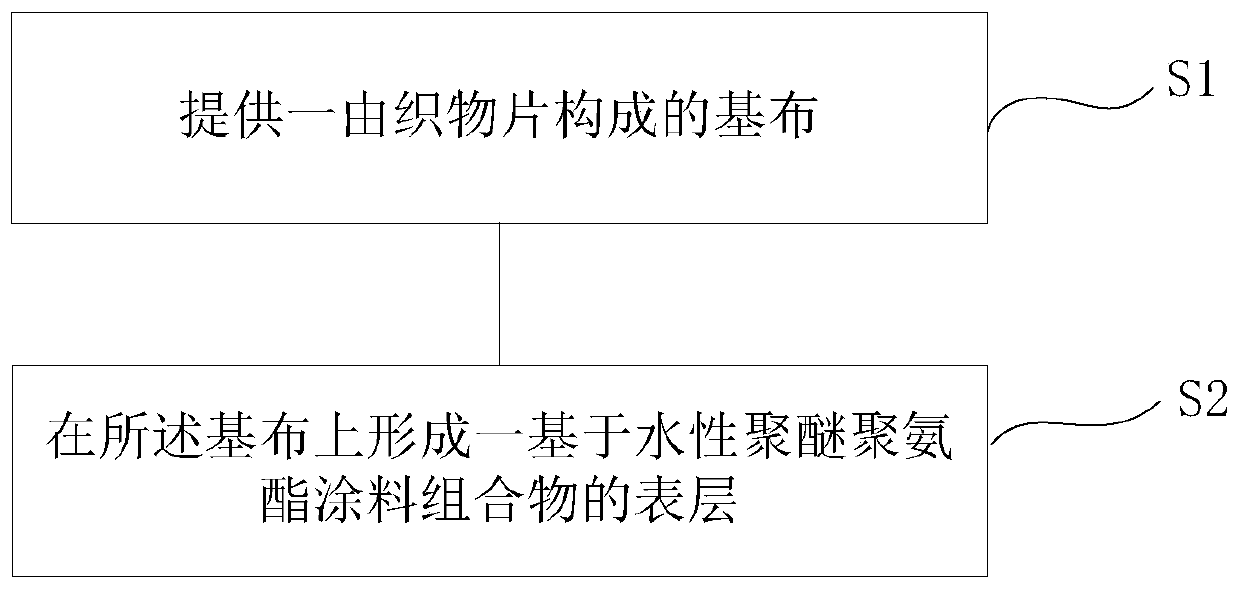

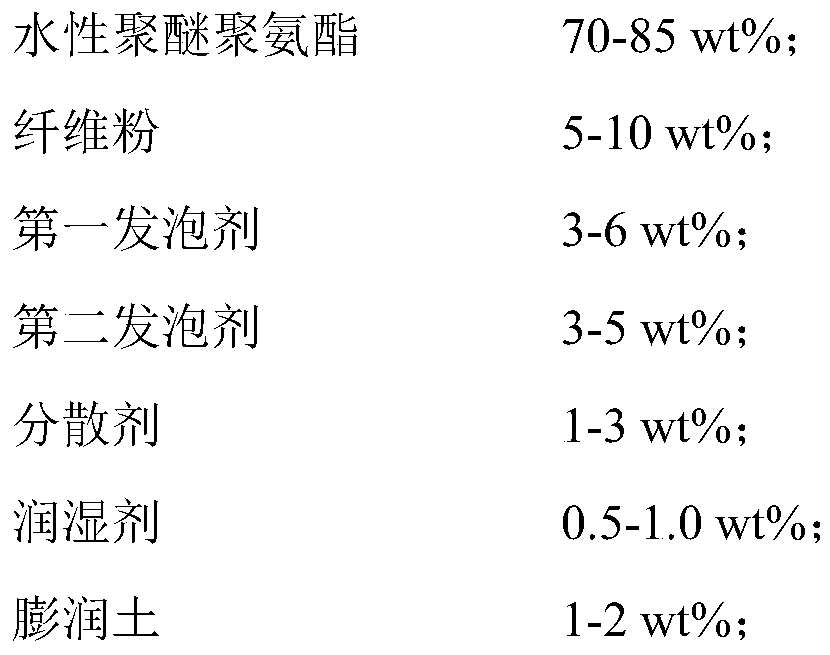

Wet-process Yangbuck synthetic leather and preparation method thereof

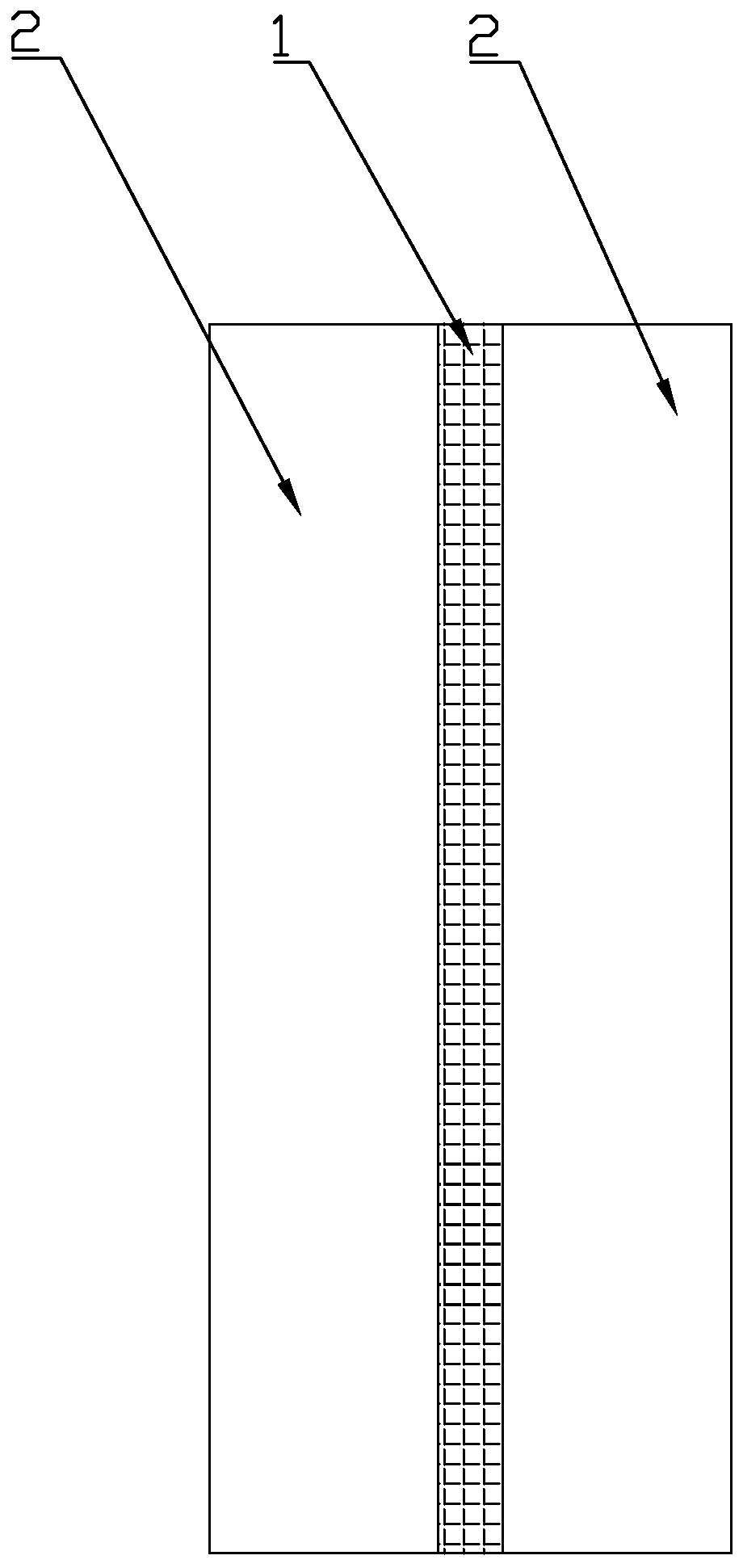

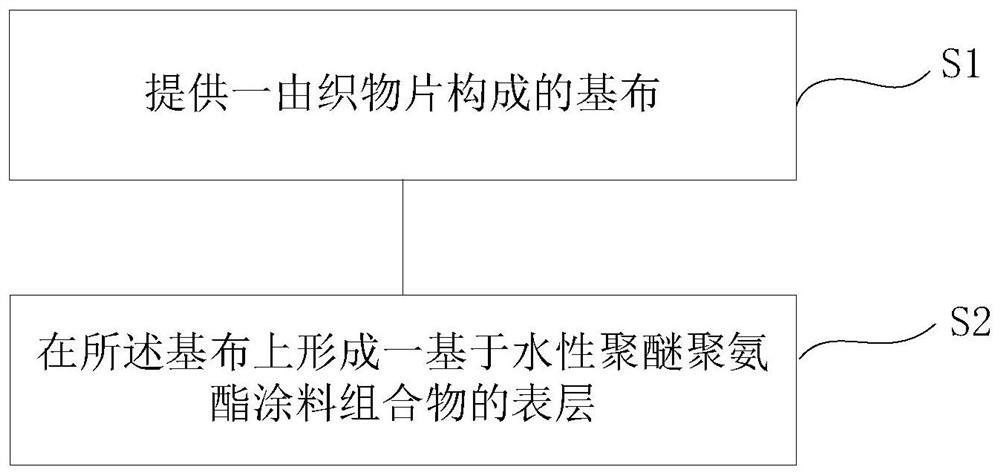

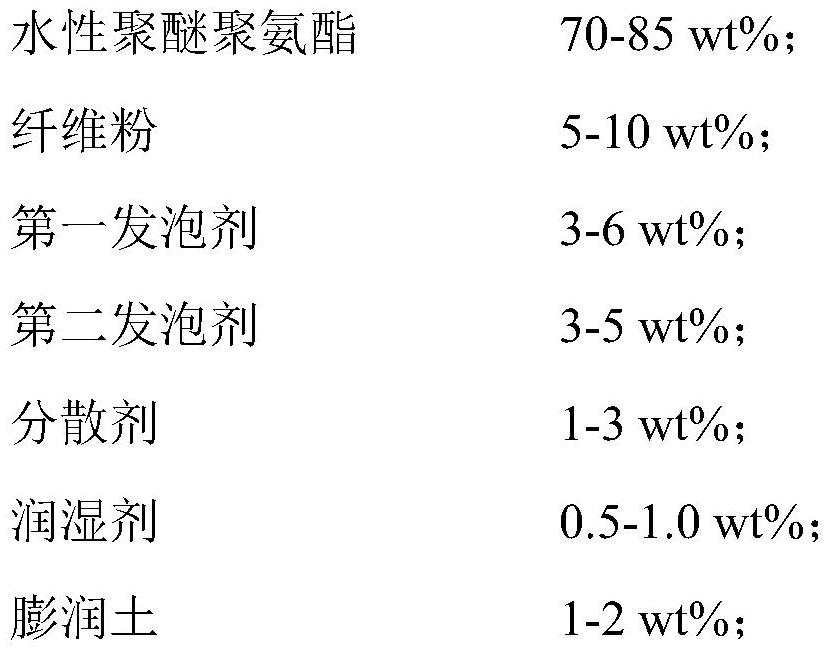

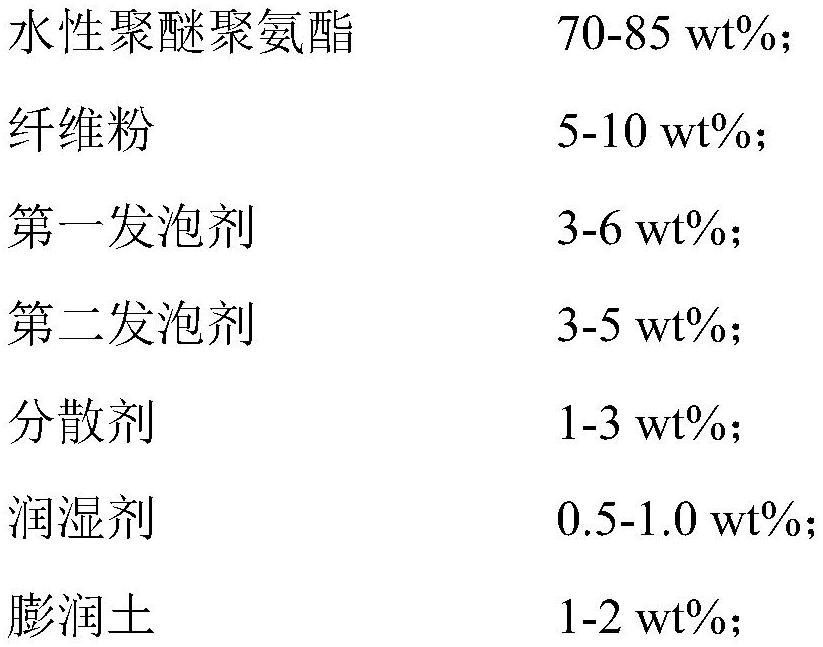

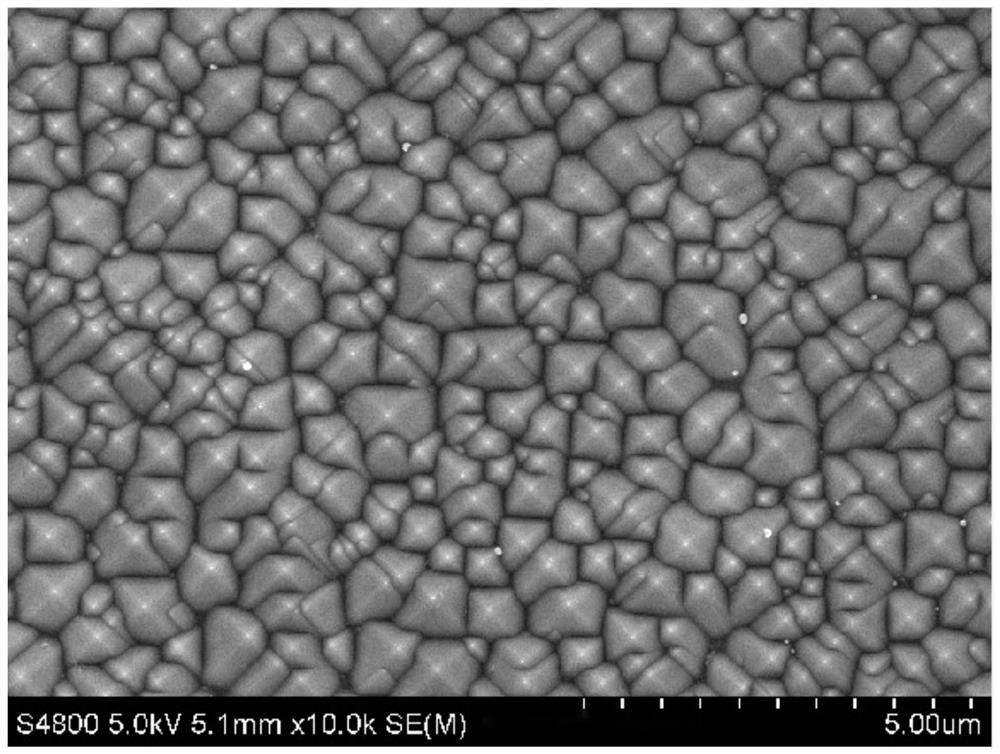

ActiveCN111206432AThe preparation method is simple, safe and reliableGood fleeceTextiles and paperCelluloseFiber

The present invention provides wet-process Yangbuck synthetic leather and a preparation method thereof. The wet-process Yangbuck synthetic leather comprises base cloth composed of fabric pieces and anaqueous polyether polyurethane coating composition based surface layer positioned on the base cloth. The surface layer has the porosity of 80-90%. The aqueous polyether polyurethane coating composition comprises 70-85wt% of aqueous polyether polyurethane, 5-10wt% of fiber powder, 3-6wt% of a first foaming agent, 3-5wt% of a second foaming agent, 1-3wt% of a dispersing agent, 0.5-1.0wt% of a wetting agent and 1-2wt% of bentonite, wherein the fiber powder consists of 95-97wt% of cellulose and 3-5wt% of fatty acid ester. The wet-process Yangbuck synthetic leather provided by the invention has excellent air permeability and moisture permeability, ideal yellowing resistance and delicate velvet surface.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +1

Rabbit tomentum blanket and production process thereof

The invention relates to a rabbit tomentum blanket and a production process thereof. The rabbit tomentum blanket comprises a blanket liner, wherein fillers are filled in the blanket liner, and a depilation preventing isolated layer is arranged between the fillers and the blanket liner. The fillers comprise the following raw materials in part by weight: 60 to 80 parts of rabbit tomentum, 10 to 30 parts of cashmere and 10 to 15 parts of low-melting point chemical fibers. The rabbit tomentum blanket has the advantages that: the problem of hair slip of the rabbit tomentum blanket is radically solved by improving the production process and production technology of the rabbit tomentum blanket, the rabbit tomentum blanket have good effects of hair slip prevention, depilation prevention and pilling prevention, excellent heat retention performance and remarkable health-care function; and the process develops and utilizes the rabbit tomentum widely, liberates and develops the breeding industry of long hair rabbits, elongates the breeding industry chain of the long hair rabbits, and improves additional values of rabbit hair products, so that the rabbit hair products begin to walk into thousands of households and serve the home life of people.

Owner:枣庄甘霖实业有限公司

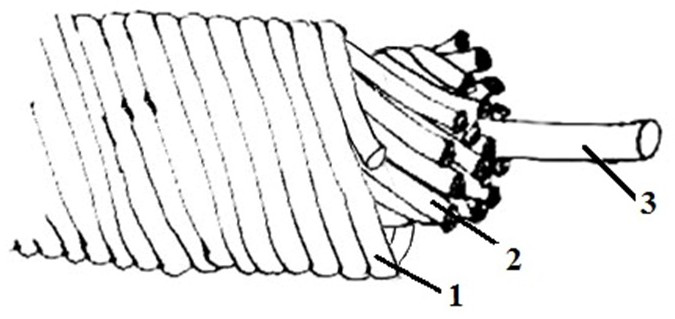

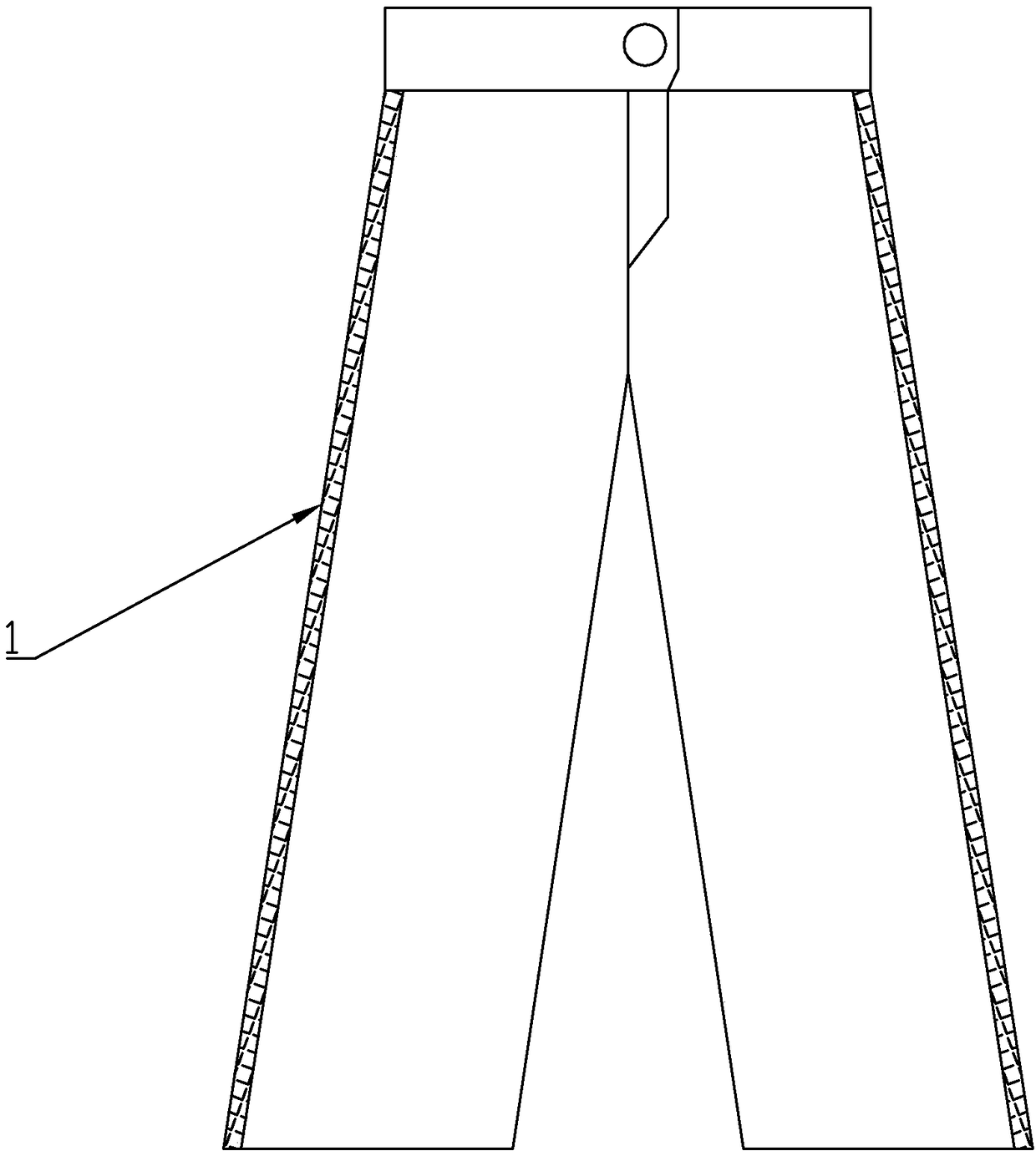

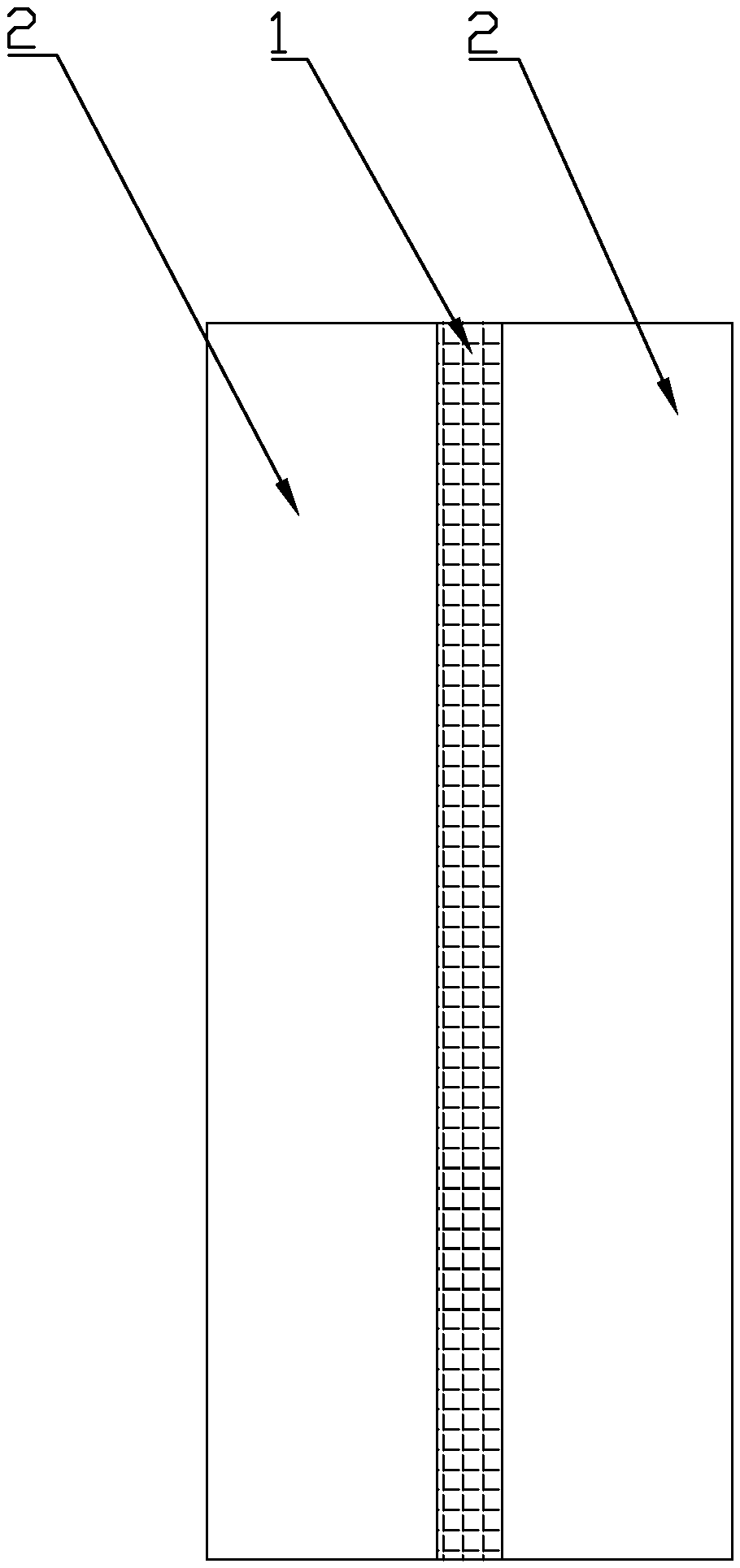

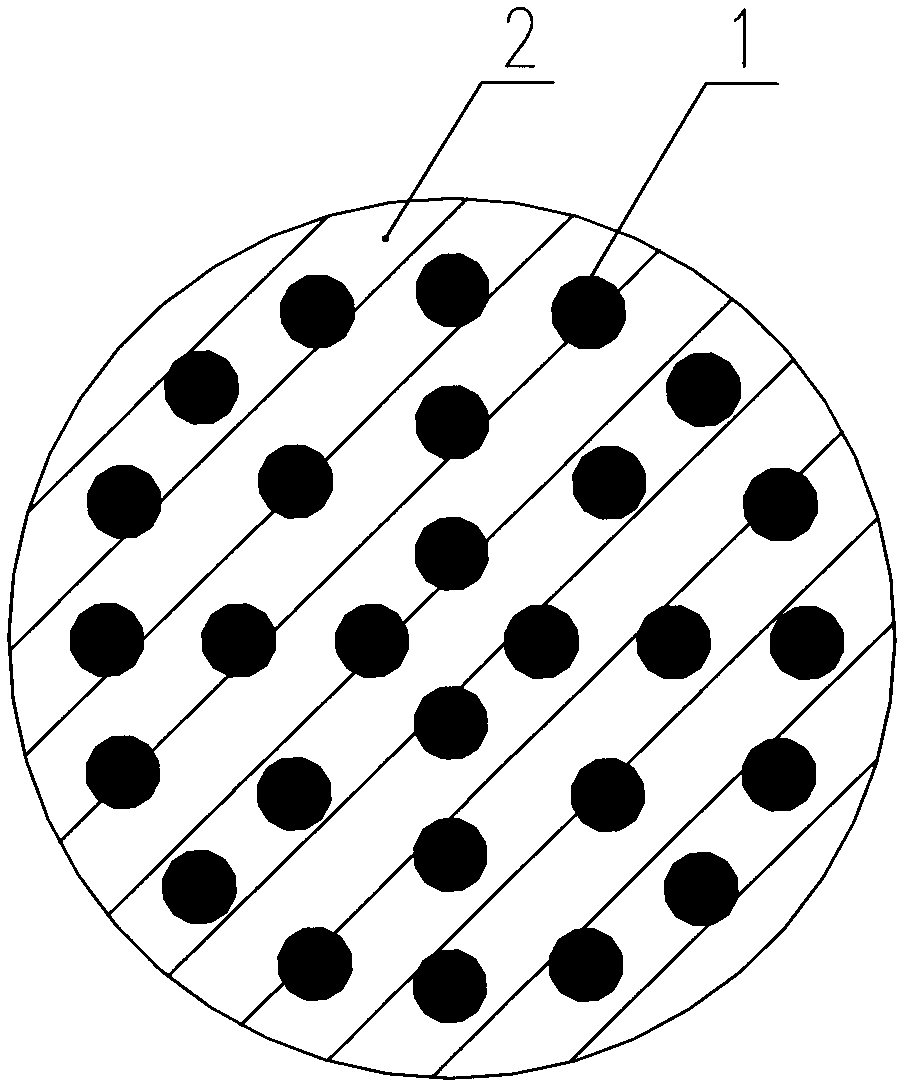

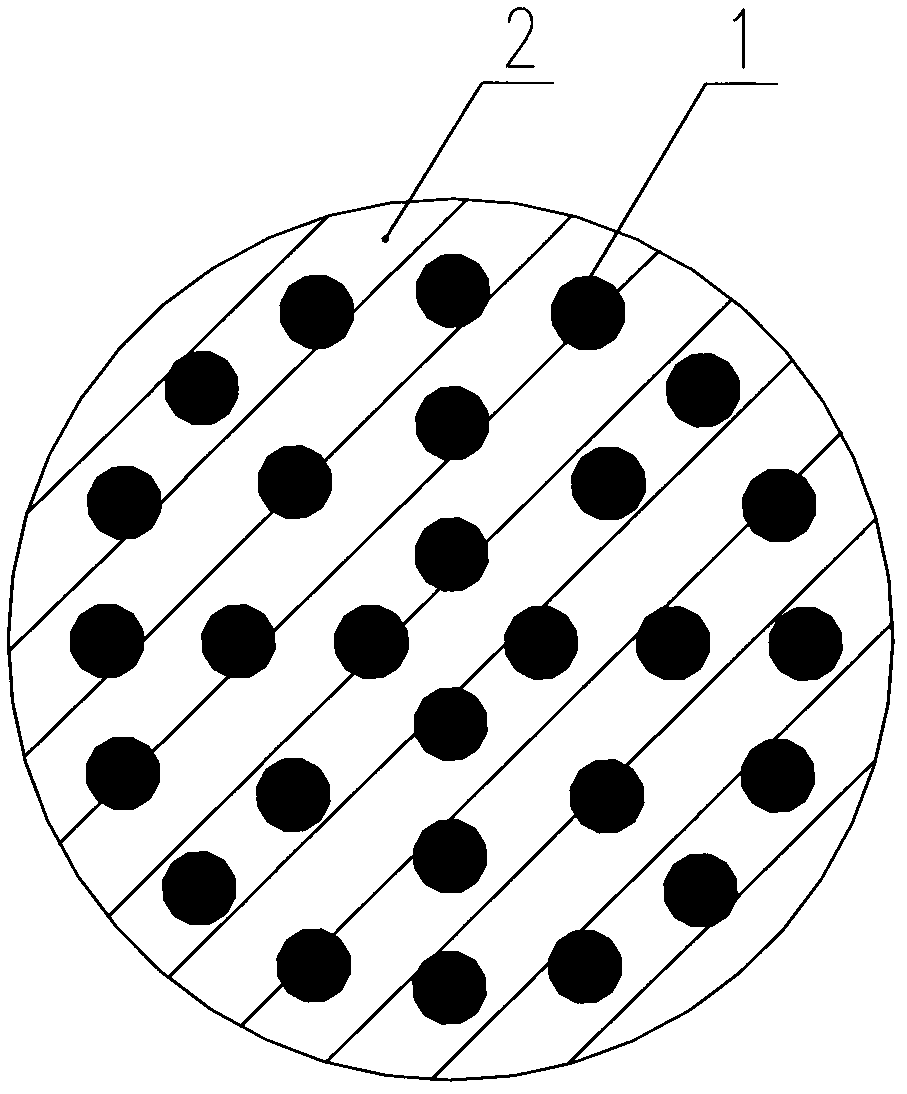

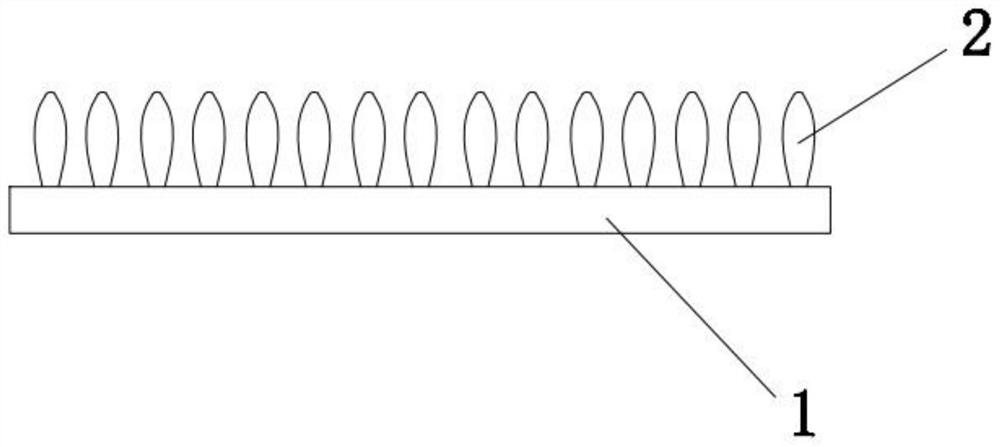

Jean fabric with coral fleece hand feeling and production method thereof

The invention provides a jean fabric with coral fleece hand feeling and a production method thereof. One side or both sides of the jean fabric with the coral fleece hand feeling forms or form a wool face or wool faces through opening ball wool. Warp or weft of the jean fabric with the coral fleece hand feeling adopts warm-keeping covering yarn. The warm-keeping covering yarn comprises middle-layershort fiber yarn 2 and outer-layer chemical fiber filaments 1. The chemical fiber filaments spirally cover the short fiber yarn. The short fiber yarn is the yarn formed by twisting cotton fiber and honeycomb polyester fiber. By adopting the warm-keeping covering yarn with short fiber yarn as the middle layer and the chemical fiber filaments as the outer layer, the jean fabric with the coral fleece hand feeling has good coral fleece feeling after opening ball wool, the vein feeling of the cloth is strong, the warm keeping effect can be guaranteed, and the fashionable requirement can be met.

Owner:GUANGDONG FORWARD DENIM

Bamboo fabric raw material production technology

InactiveCN105463673AImprove breathabilityImprove wear resistanceWeft knittingVegetable materialFiberEngineering

A bamboo fabric raw material production technology can provide bamboo fabric raw material having wet-absorbing and ventilating performance as flax and a characteristic of bright color such as chemical fibers and the bamboo fabric raw material can maintain features of bamboo fiber textile. With cooperation between the raw material and other raw material with various performance, weaving raw material having different styles can be produced, so weaving product raw material can be diversified and performance of various fabric raw material can be utilized; and fabric with bright color, great hand feeling and velvet feeling, great elasticity and wet-absorbing and ventilating performance, excellent anti-wrinkling performance, low shrinkage rate and great wearability.

Owner:WUJIANG CITY JUNDA TEXTILE

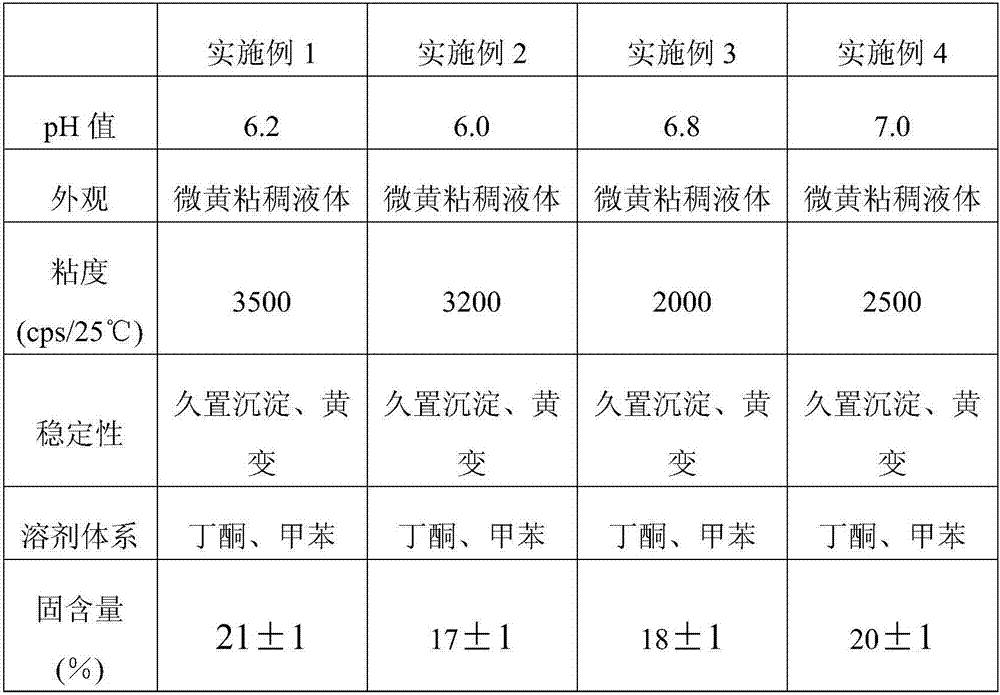

Acrylate coating layer emulsion capable of preventing down feather from escaping from needle holes, coating layer glue and preparation method of acrylate coating layer emulsion

ActiveCN109232794AReduce surface tensionImprove wear resistanceTextiles and paperIsooctyl acrylatePolymer science

The invention relates to an acrylate coating layer emulsion capable of preventing down feather from escaping from needle holes, coating layer glue and a preparation method of the acrylate coating layer emulsion. The acrylate coating layer emulsion contains the following raw materials in parts by weight: 9.5-10 parts of iso-tridecanol polyoxyethylene ether (40), 1-1.5 parts of sodium dioctyl sulfosuccinate, 2-2.5 parts of alcohol ether sulfosuccinate monoester disodium salt, 1-1.5 parts of itaconic acid, 2.5-3 parts of acrylamide, 3-3.5 parts of acrylic acid, 160-165 parts of n-butyl acrylate,40-43 parts of iso-octyl methacrylate, 24-27 parts of acrylonitrile, 3-3.5 parts of hydroxyethyl methylacrylate, 3-3.5 parts of an acrylic acid modified reaction type slip agent, 0.7-1.2 parts of 3-(2,3-epoxypropoxy)propylmethyldiethoxysilane, 4-4.5 parts of hydroxyethyl acrylamide, 0.8-1.2 parts of ammonium persulfate, 0.2-0.4 parts of sodium hydrogen sulfite and 280-300 parts of deionized water.A polymer emulsion formed through the polymerization of a seed emulsion is particularly suitable fortaffeta, cotton and nylon fabrics.

Owner:LIAONING FIXED STAR FINE CHEM

Additive for chain type texturing of monocrystalline silicon wafers, and application thereof

ActiveCN111593412AImprove conversion efficiencyShorten the time of texturingPolycrystalline material growthAfter-treatment detailsCrystallographyPhysical chemistry

The invention discloses an additive for chain type texturing of monocrystalline silicon wafers. The additive comprises, by mass, 0.2-2.0% of polyethyleneimine, 0.5-10% of fucosan, 0.1-0.5% of polyacrylamide, 0.1-2.0% of polyether, amine and the balance of water. The additive disclosed by the invention is added into a texturing liquid for chain texturing of monocrystalline silicon wafers, so that the texturing time of chain texturing can be shortened to 3min, the productivity can be improved, the reflectivity of textured wafers can be kept at 11-12% and is basically equivalent to that of textured wafers obtained by groove texturing, and silicon wafers have better conversion efficiency.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

Rotary cup spinning process of polypropylene roving

ActiveCN1261628CStrong adhesionImprove spinnabilityContinuous wound-up machinesOpen-end spinning machinesOrganic chemical solventOrganic solvent

The present invention relates to rotary cup spinning process of polypropylene roving with short polypropylene fiber of fineness 4.5-6.5 dtex, length 51-76 mm, and surfactant of 0.6 %. The technological process includes carding, slivering, four times of needle combing and rotary cup spinning. The present invention adopts middle and long fiber with less depilation, good teasing and powerful adhesion, and wool spinning and semi-combing apparatus in fore spinning with favorable spinnabliltiy of middle and long fiber and no damage to the physical performance of fiber. The present invention produces middle and long polypropylene roving of 58.8-1100 tex, and the polypropylene roving is non-toxic, smell-less, not water absorbent, acid, alkali and organic solvent resistant, plumpy in hand feeling and fluffy, and may be used widely.

Owner:YANGZHOU YONGHUI TEXTILE TECH

Suede high-elasticity fabric structure

ActiveCN109304904AIncrease elasticityHigh rebound rateBiochemical fibre treatmentFibre typesHigh resistancePolyester

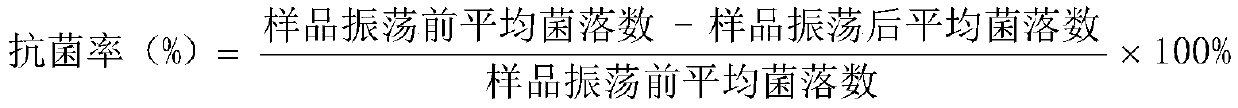

The invention discloses a suede high-elasticity fabric structure. The suede high-elasticity fabric structure is characterized by comprising down fabrics and a suede high-elasticity fabric for connecting two adjacent down fabrics; the suede high-elasticity fabric is prepared from the following materials: polyester fibers, polyurethane fibers, composite antibacterial agents and dipping glue. The suede high-elasticity fabric structure has the beneficial effects that the island-type ultrafine polyester fibers and the polyurethane fibers are woven into mixed fibers, thick fluffs can be formed on the surface of the fabric through the island-type ultrafine polyester fibers, and the napping effect is good; the fluffs are wash-resisting and wear-resisting, and can be dyed into different colors; thepolyurethane fibers have excellent elasticity and high resilience, can quickly restore to original shapes, and have high resistance to acid, alkali, sweat and dry cleaning; the composite antibacterial agents is immersed into tissues of the mixed fibers through dipping, and the antibacterial ability of the suede high-elasticity fabric structure is improved.

Owner:ZHEJIANG SEMIR GARMENT CO LTD

Down leakage preventing process for textiles

A down leakage preventing process for textiles is characterized by including the following steps: (1) selecting plain weave fabrics made of full-stretched yarns of chinlon, wherein the yarn count ranges from 20D to 40D, and the density ranges from 290Tex to 400Tex; (2) subjecting the fabrics to water repellent finishing, wherein the wetting grade is higher than or equal to grade 3; (3) by a calender, calendering the fabrics subjected to water repellent finishing under the pressure of 9-11 MPa and at the temperature of 100-110 DEG C, wherein the speed ranges from 30 m / min to 40 m / min; (4) preparing a coating adhesive. The down leakage preventing process has the advantages that the down leakage preventing effect, especially the down leakage preventing effect at sewing holes, is achieved through good combination of fabric base cloth with the coating adhesive; the selected coating adhesive can ensure the comprehensive indexes, such as down leakage resistance, cold resistance, moisture permeability, washability and softness, of the fabrics on the premise of low weight gain, so that the fabrics are highly comfortable while meeting the need for functionality.

Owner:泰州永和塑料包装有限公司

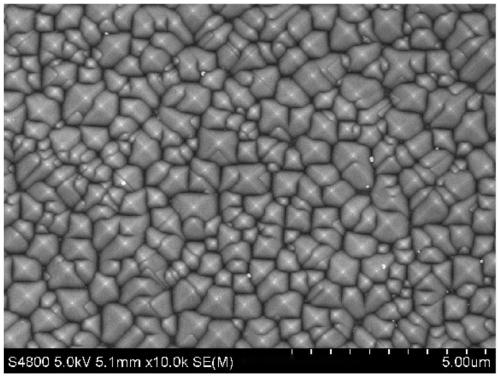

Wear-resistant scratch-resistant extraordinarily thick Yangba resin for synthetic leather and preparation method thereof

InactiveCN107354744AUniform cellsBright colorGrip property fibresAbrasion resistant fibresVeinProduction line

The invention relates to wear-resistant scratch-resistant extraordinarily thick Yangba resin for synthetic leather. The wear-resistant scratch-resistant extraordinarily thick Yangba resin is used for the front-stage process of the synthetic leather, and is prepared from the following ingredients: Yangba resin, butanone, methylbenzene, Yangba powder and polymethylphenyl siloxane fluid. The invention also relates to a preparation method of the wear-resistant scratch-resistant extraordinarily thick Yangba resin for the synthetic leather. All ingredients of the wear-resistant scratch-resistant extraordinarily thick Yangba resin for the synthetic leather are mutually coordinated and jointly acts; after the Yangba foaming, foam holes are uniform; the spreading color is bright-colored; the velvet effect is good; the wear-resistant scratch-resistant performance is high; the Yangba resin can be used for processes such as release paper imitation vein surface resin printing and roll coating. The wear-resistant scratch-resistant extraordinarily thick Yangba resin for the synthetic leather is a novel material of front-stage printing and can be used for the existing synthetic leather production line; the process is simple; the production equipment cannot be changed; the production cost cannot be increased.

Owner:JIANGSU BAOZE POLYMER MATERIAL

A kind of three-dimensional block corduroy fabric and its manufacturing method

ActiveCN105755648BSoft touchFluffyOrnamental textile articlesDyeing processEngineeringStructural engineering

Owner:FUJIAN LONGFENG TEXTILE TECH IND

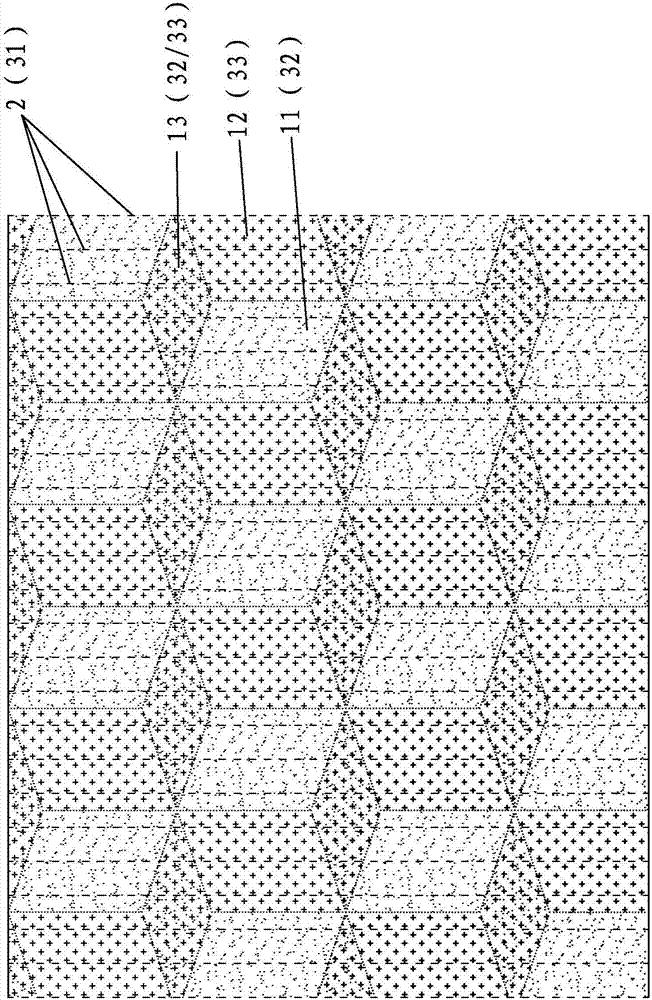

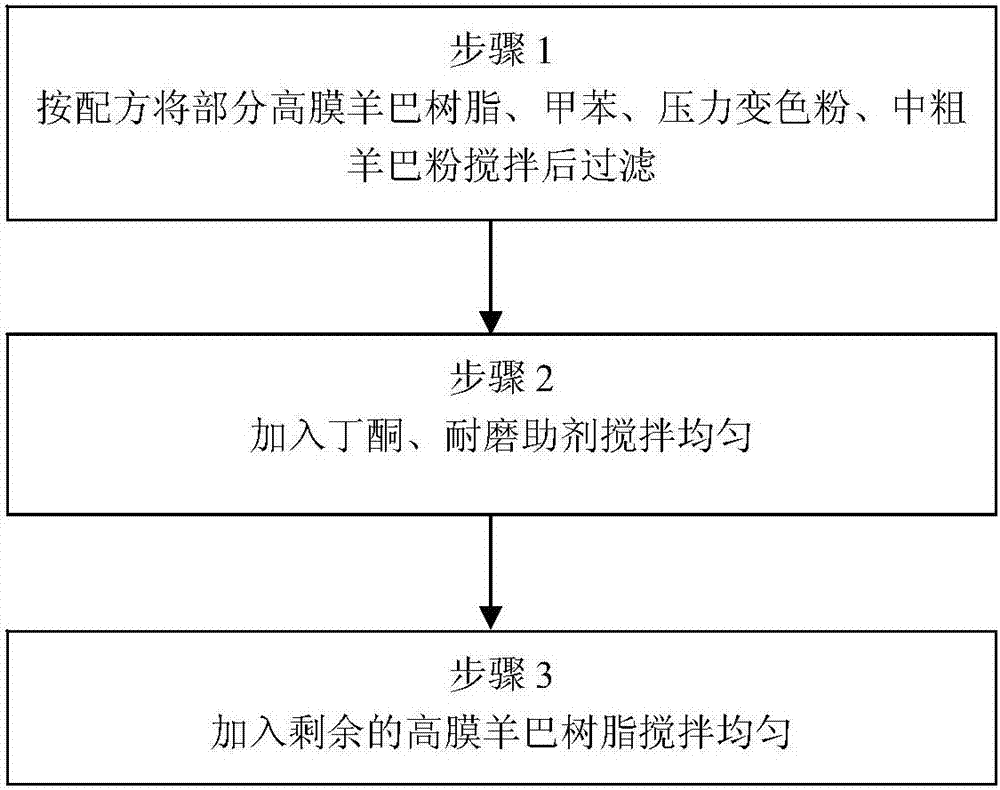

Medium-coarse Yangba pressure-change resin for synthetic leather and preparation method of medium-coarse Yangba pressure-change resin

The invention relates to medium-coarse Yangba pressure-change resin for synthetic leather. The medium-coarse Yangba pressure-change resin is prepared from the following raw materials in parts by weight: 50-52 parts of high-film Yangba resin, 20-22 parts of butanone, 16-18 parts of methylbenzene, 4-6 parts of a pressure toner, 2-4 parts of medium-coarse Yangba powder and 0-1 part of a wear-resistant additive. The invention further discloses a preparation method of the medium-coarse Yangba pressure-change resin for the synthetic leather. The method comprises the steps of mixing one part of high-film Yangba resin, the methylbenzene, the pressure toner and the medium-coarse Yangba powder according to the formula and filtering; adding the butanone and the wear-resistant additive and stirring evenly; and adding the remaining high-film Yangba resin, stirring evenly to obtain the medium-coarse Yangba pressure-change resin for the synthetic leather. Various components of the medium-coarse Yangba pressure-change resin coordinate with one another and work together, so that after Yangba is foamed, the medium-coarse Yangba pressure-change resin is uniform in cells, good in velvet hand feeling and obvious in color difference after hot stamping.

Owner:JIANGSU BAOZE POLYMER MATERIAL

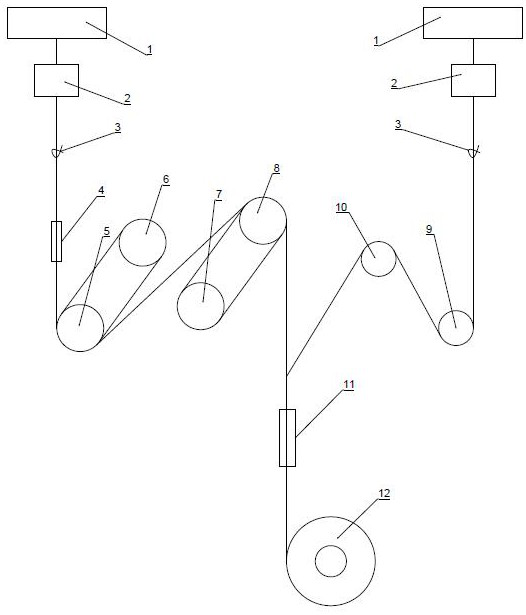

Bright ITY fiber production device and production method

The invention relates to the technical field of fiber production, in particular to a bright ITY fiber production device comprising spinning assemblies, a cooling device and an oiling device, wherein part of the spinning assemblies are used for producing FDY fibers, and the other spinning assemblies are used for producing POY fibers. The invention discloses a bright ITY fiber production method. Theproduction method specifically comprises the following steps of S1, spinning FDY nascent fibers by the spinning assemblies; S2, spinning POY nascent fibers by the spinning assemblies; S3, stranding the FDY fibers output from a third hot roller and a fourth hot roller and the P1OY fibers output from a second draw-off godet, then feeding the stranded fibers into a main interlacer and finally feeding the obtained product into a winding mechanism for winding and forming so as to obtain a bright ITY fiber product. According to the bright ITY fiber production device and production method, originalFDY equipment is modified to be used for producing the bright ITY fibers, and the contractibility of the FDY fibers is different from that of the POY fibers, so that unique style hand feeling can be generated after the two types of fibers are stranded, and the fabric has excellent drapability, velvet feeling and crepe feeling.

Owner:新凤鸣集团股份有限公司 +1

A suede high elastic fabric structure

ActiveCN109304904BIncrease elasticityHigh rebound rateBiochemical fibre treatmentFibre typesPolyesterPolymer science

Owner:ZHEJIANG SEMIR GARMENT CO LTD

A kind of wet method yangba synthetic leather and preparation method thereof

ActiveCN111206432BThe preparation method is simple, safe and reliableGood fleeceTextiles and paperCelluloseFiber

The invention provides a wet-processed yambar synthetic leather and a preparation method thereof. The wet-processed yambar synthetic leather comprises: a base cloth composed of a fabric sheet; a surface layer based on a water-based polyether polyurethane coating composition, the surface layer is located on the On the base cloth, the surface layer has a porosity of 80-90%, and the water-based polyether polyurethane coating composition comprises: water-based polyether polyurethane 70-85wt%; fiber powder 5-10wt%; first foaming agent 3 -6wt%; second foaming agent 3-5wt%; dispersant 1-3wt%; wetting agent 0.5-1.0wt%; bentonite 1-2wt%; wherein, the fiber powder is composed of 95-97wt% cellulose and 3-5wt% fatty acid ester composition. The wet-process yambar synthetic leather provided according to the present invention has excellent air and moisture permeability, ideal yellowing resistance, and a fine and velvety surface.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +1

Textile down-proof process

InactiveCN110886097ASolve a series of problems such as environmental protection, efficiency, and poor cashmere resistanceIncrease productivityTextile shapingPolymer scienceAdhesive

A textile down-proof process is characterized by including the steps: (1) fabric selection: selecting a plain weave fabric woven with fully-drawn nylon yarns; (2) performing water repellent finishingon the fabric; (3) calendering the fabric after water repellent finishing by a calender at the pressure of 9-11MPa at the temperature of 100-110 DEG C and at the speed of 30-40m / min; (4) preparing a coating adhesive. The yarn count of the plain weave fabric is 20D-40D, the density of the plain weave fabric is 290Tex-400Tex, and water repellent grade is larger than or equal to 3. Fabric base clothis effectively combined with the coating adhesive to achieve a down-proof effect, the down-proof effect at a sewing needle hole is particularly achieved, by the aid of the selected coating adhesive, comprehensive indexes such as down-proof performance, cold resistance, moisture penetrability, washing fastness and softness of the fabric can be ensured by low weight increase, and the wearing comfortableness of the fabric is better on the premise of meeting functionality.

Owner:郝小培

Environment-friendly anti-siphon finishing method for suede microfiber synthetic leather

The present invention discloses an environmentally friendly anti-siphon afterfinishing method for a suede microfiber synthetic leather. The method is as below: (1) immersing the dyed microfiber synthetic leather into an anti-siphon treatment solution, and padding; (2) then drying the product obtained in the step (1), cooling, rolling and crumpling to obtain the anti-siphon suede microfiber synthetic leather. The anti-siphon treatment solution for suede microfiber synthetic leather has a pH value of 4-6, and comprises the following components by weight: 5-10 parts of a fluorine-free waterproof finishing agent, 2-5 parts of reactive polysiloxane, 1-3 parts of an aqueous crosslinking agent and 100 parts of water. The agent of the invention uses the fluorine-free environment-friendly waterproof finishing agent without APEO, PFOA or PFOS, and the ultrasonic technology; and the obtained microfiber synthetic leather achieves anti-siphon effect of rise of impregnating solution of less than 1cm after 2h immersion, and has good creases and velvety sense, so as to improve the grade of the suede microfiber synthetic leather.

Owner:HUAFON MICROFIBER SHANGHAI

Additives for Monocrystalline Silicon Wafer Chain Texturing and Its Application

ActiveCN111593412BGood adhesionImprove adsorption capacityPolycrystalline material growthAfter-treatment detailsCrystallographyPhysical chemistry

The invention discloses an additive for chain type texturing of monocrystalline silicon wafers. The additive comprises, by mass, 0.2-2.0% of polyethyleneimine, 0.5-10% of fucosan, 0.1-0.5% of polyacrylamide, 0.1-2.0% of polyether, amine and the balance of water. The additive disclosed by the invention is added into a texturing liquid for chain texturing of monocrystalline silicon wafers, so that the texturing time of chain texturing can be shortened to 3min, the productivity can be improved, the reflectivity of textured wafers can be kept at 11-12% and is basically equivalent to that of textured wafers obtained by groove texturing, and silicon wafers have better conversion efficiency.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

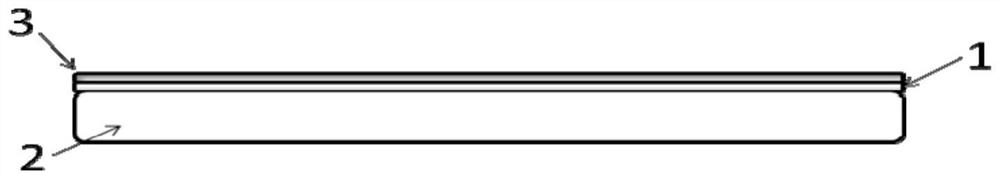

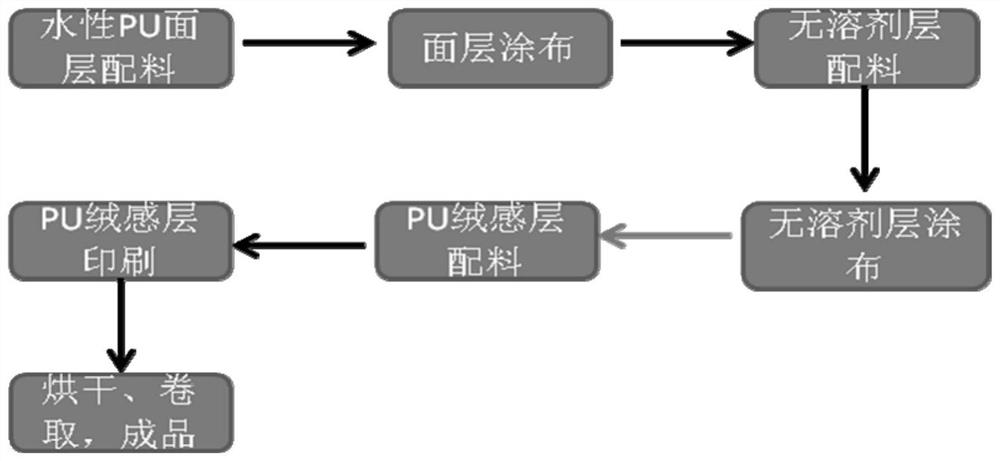

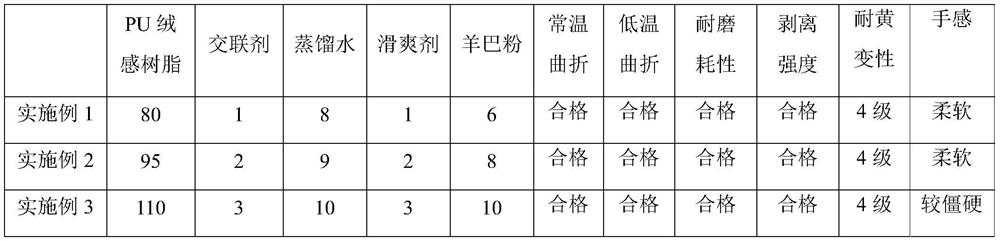

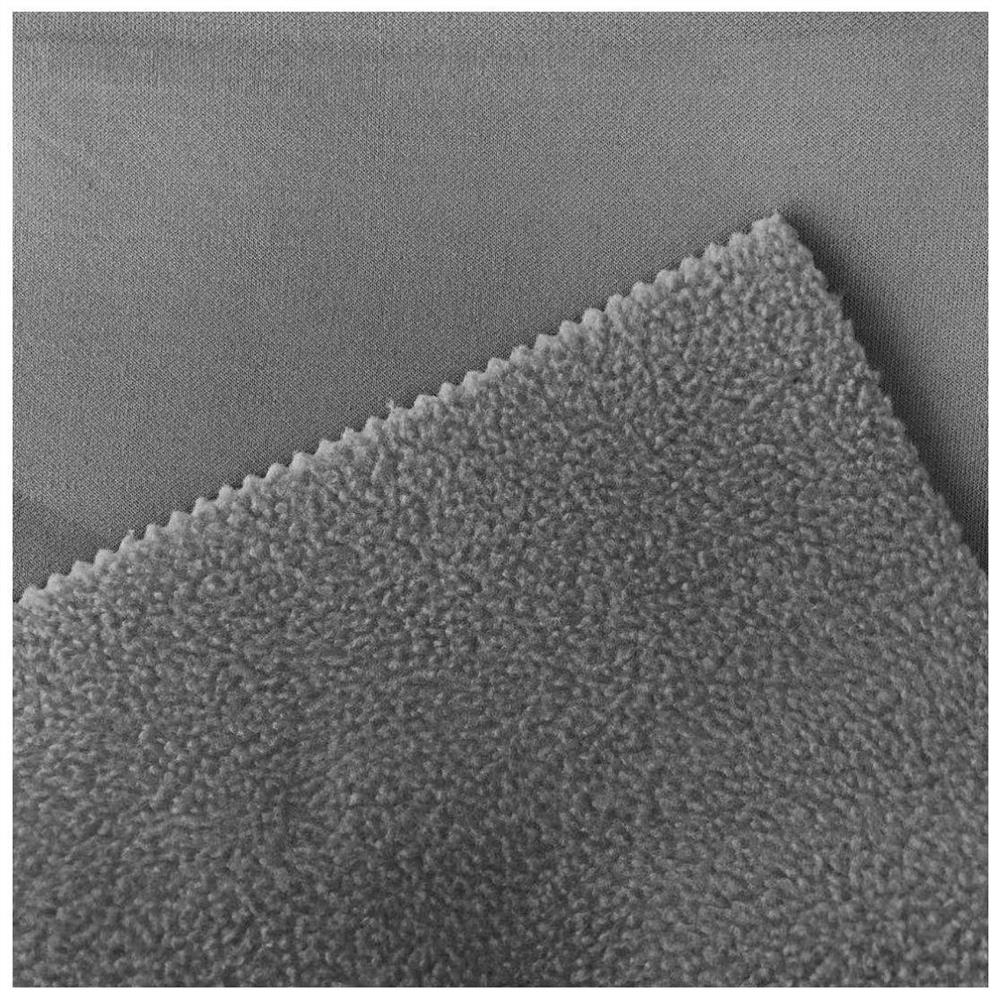

A kind of environment-friendly velvet film for shoes and preparation method thereof

ActiveCN110485169BGood fleeceGood physical propertiesFootwearTextiles and paperOrganic chemical solventPolymer science

The invention discloses an environment-friendly velvet film for shoes and a preparation method thereof, wherein the environmental-friendly velvet film for shoes sequentially comprises a surface velvet layer, a water-based PU surface layer and a thermosetting two-component solvent-free foaming layer from top to bottom. Floor. The invention adopts water-based PU resin and solvent-free resin, does not add other toxic and harmful organic chemical solvents, and is environmentally friendly. The film provided by the present invention is printed on the water-based PU velvet layer to improve the velvet feel of the surface layer of the film. On the premise of improving the velvet feel of the surface layer, a wear-resistant additive is added to the surface layer polyurethane to improve the wear-resistant and scratch-resistant performance. At the same time, the film itself has high hydrolysis resistance and high peel strength. It is a good substitute for four-way elastic synthetic leather for shoes.

Owner:ANHUI ANLI MATERIAL TECH

Differential shrinkage composite fiber

InactiveCN102409459AIt has the effect of superfine single-filament finenessSoft touchTextiles and paperFiberPolyester

The invention discloses a differential shrinkage composite fiber which is composed of FDY (fully draw yarn) fiber yarn and POY (partially oriented yarn) fiber yarn by network stranding, and is characterized in that: the cross section of the FDY fiber yarn is of a sea island shape composed of polyester as an island component and water-soluble polyester as a sea component; and the cross section of the POY fiber yarn is of an orange valve shape in a structure as shown in Chinese character 'Mi', the component forming the Chinese character 'Mi' is the water-soluble polyester, and the component embedded in the Chinese character 'Mi' is the polyester. Because the FDY with a sea-island-shaped section and the POY with an orange-valve-shaped section are introduced to the differential shrinkage composite fiber, after splitting, the composite fiber has superfine monofilament titer; and after the superfine differential shrinkage composite fiber is treated by downstream splitting, the monofilament titer can reach 0.08dtex, the fiber monofilament titer reaches the superfine effect, and the fabric has soft hand feeling and excellent woolen feeling.

Owner:张家港保税区长江塑化有限公司

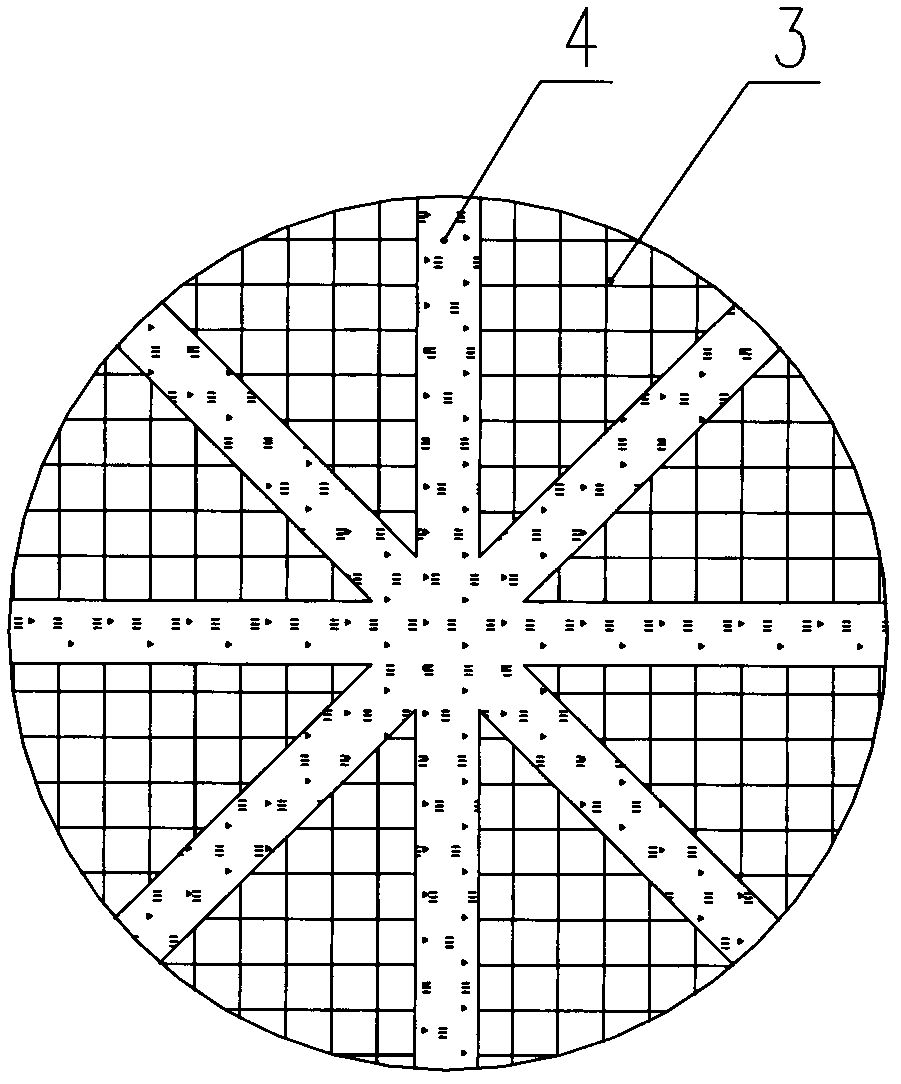

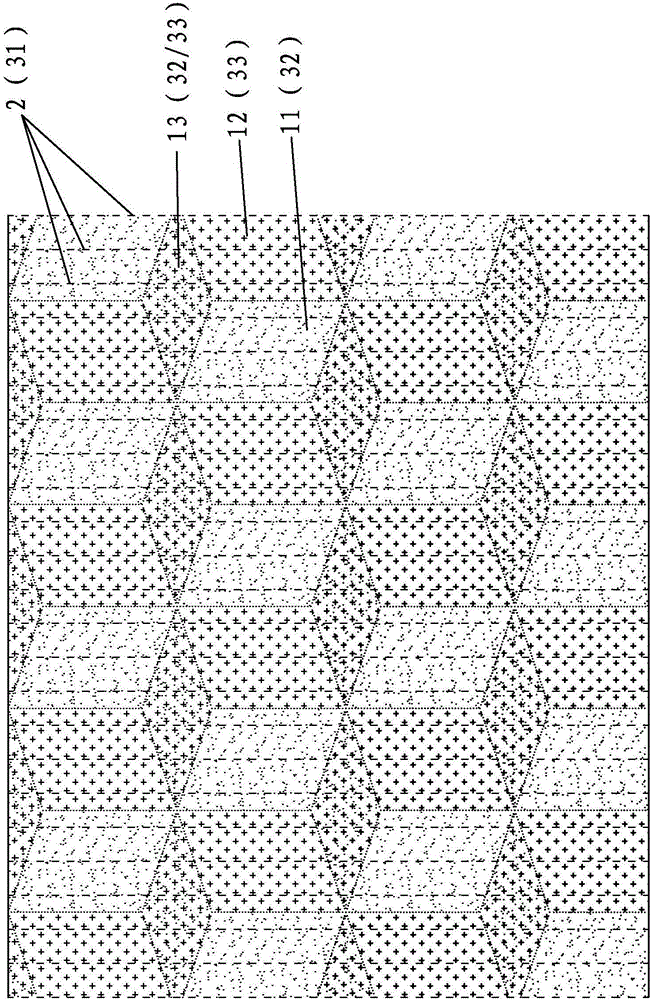

A kind of weft-knitted sandwich polar fleece fabric, gray cloth and production method thereof

The inventor provides a kind of production method of weft-knitted sandwich polar fleece gray cloth and cloth thereof, and described weft-knitted sandwich polar fleece gray cloth comprises upper surface, middle layer and lower surface; Described weft-knitted sandwich polar fleece gray cloth adopts weft Double-sided jacquard knitting machine 8-needle circular weaving; the dial and needle cylinder of the weft-knitting double-sided jacquard machine both adopt the needle arrangement of 12121212; wherein, the triangle configuration is as follows: ∪∨───∨──── ∨─∪─∨────∧∩──∧∩──∧───∧; wherein, the D values of the 3rd and 7th yarns are greater than the D values of the 2nd and 6th yarns. Different from the prior art, the technical solution above forms raised areas woven with thick yarns and non-fluffed areas woven with thin yarns arranged at intervals on the upper surface of the polar fleece fabric. After the structure is fluffed, the polar fleece fabric can be made more fluffy as a whole, has a strong fleece feeling, has good warmth retention property, and has a thicker fabric body, so that the service life can be increased.

Owner:FUJIAN HUAFENG NEW MATERIALS

A kind of water-based lambskin with scalding effect and preparation method thereof

ActiveCN106436337BStrong sense of hierarchyClear texturePolyurea/polyurethane coatingsTextiles and paperWater basedEngineering

The invention provides a method for preparing water-based yangbuck with lustring effects. The method includes steps of 1), coating and scraping water-based wet base slurry on base cloth, transporting the base cloth into a coagulating tank, coagulating the base cloth and drying the base cloth by means of baking to obtain water-based base; 2), coating water-based yangbuck materials on release paper, drying the water-based yangbuck materials and the release paper to form yangbuck clinging surfaces, adhering the water-based base onto the yangbuck clinging surfaces, then drying the yangbuck clinging surfaces by means of baking, cooling the yangbuck clinging surfaces and peeling the release paper to obtain artificial leather by means of preparation; 3), placing the artificial leather in a baking oven and foaming the artificial leather at the high temperature to obtain yangbuck by means of preparation; 4), carrying out color change treatment on the yangbuck by the aid of a printing machine; 5), preparing lustring materials, adding the lustring materials into the printing machine and carrying out lustring treatment on the yangbuck. The method has the advantages that the surfaces of the water-based yangbuck are high in leather feeling and good in velvet feeling and feel soft, and the excellent lustring effects can be realized; the surfaces of the yangbuck are bulky, thick, smooth, straight and bright and have plump pile after lustring treatment is carried out on the yangbuck, and market requirements on high-grade yangbuck can be met.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD

Stereoscopic-block corduroy fabric and manufacturing method thereof

The invention discloses stereoscopic-block corduroy fabric and a manufacturing method of the stereoscopic-block corduroy fabric. The stereoscopic-block corduroy fabric is woven by a group of warp yarn and three groups of weft yarn, wherein the three groups of weft yarn are respectively ground weft, first pile weft and second pile weft; the ground weft and the warp yarn are interwoven to form a fabric ground tint weave. The stereoscopic-block corduroy fabric is provided with two side surface units and one top surface unit which correspond to stereoscopic block patterns, wherein one side surface unit is used for enabling the first pile weft to float on a cloth cover and second pile weft to sink to be interwoven with the ground weft; the other side surface unit is used for enabling the second pile weft to flow on the cloth cover and the first pile weft to sink to be interwoven with the ground weft; the top surface unit is used for enabling the first pile weft and the second pile weft to float on the cloth cover to form mixed floating weft. Woven semi-finished fabric is subjected to dyeing treatment, thus finally obtaining the corduroy fabric, of which the two side surface units are in different colors and the top surface unit is in mixed color, capable of displaying stereoscopic-block double-color patterns. According to the stereoscopic-block corduroy fabric disclosed by the invention, traditional straight-strip corduroy is completely improved into patterns having stereoscopic block shapes, a multi-color sense is obtained, the performance is novel, a novel style idea is created for corduroy products, and individual diversified demands of publics are met.

Owner:FUJIAN LONGFENG TEXTILE TECH IND

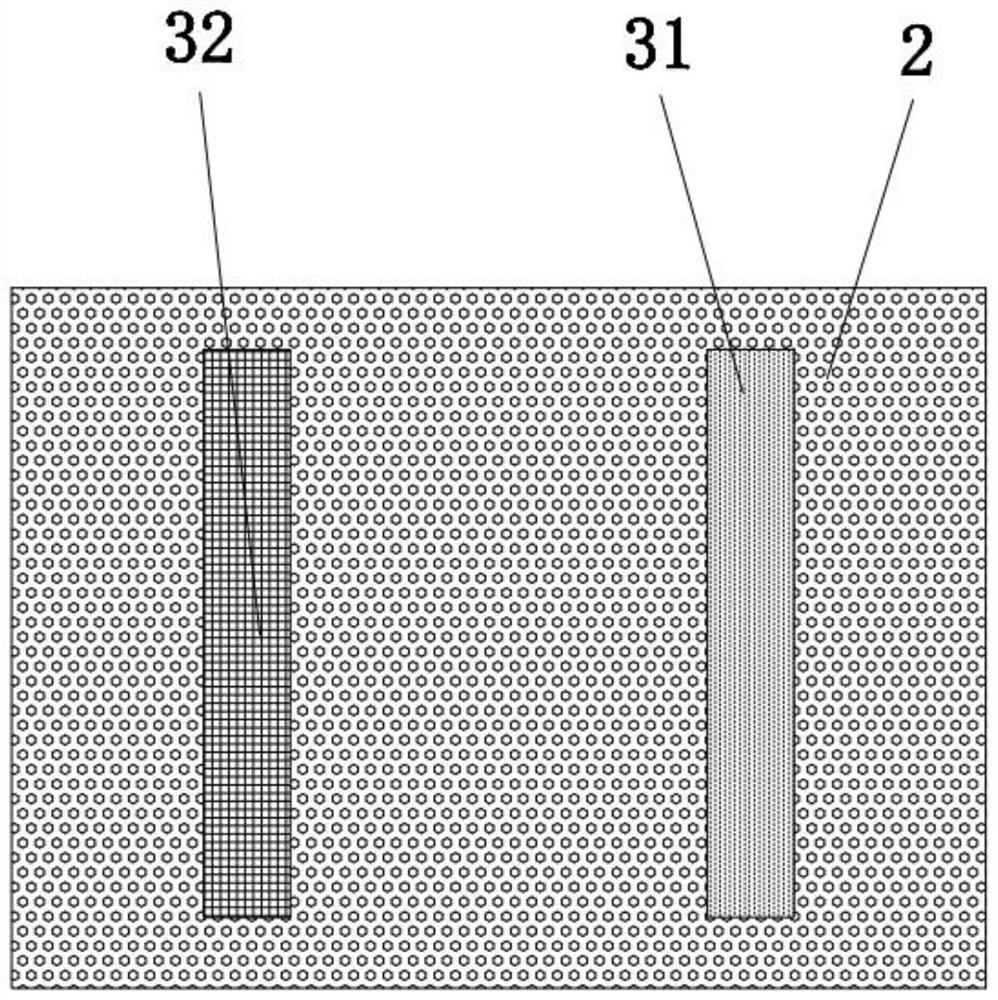

Variable raised warp knitted fabric and knitting method

The invention provides a variable raised warp knitted fabric and a knitting method, and relates to the field of spinning. The raised warp knitted fabric comprises a raised knitted fabric body which is integrally knitted by a double-needle bar warp knitting jacquard machine; the raised knitted fabric body comprises a surface layer and a raised layer which are integrally knitted; the surface layer is woven by a ground bar GB2, a ground bar GB4 and a ground bar GB5; and the raised layer is woven by a jacquard bar JB3.1 and a jacquard bar JB3.2. According to the invention, each guide bar is designed through a reasonable process; by fully utilizing the advantages of jacquard and combining with empty threading change of the guide bars, precise design and matched use of raw material chemical fibers, two-dimensional raised screen cloth which is skin-friendly, soft, light and thin, high in performance, variable and stable in structure and capable of being raised at will is produced; the characteristics of the jacquard are fully utilized, so that the fabric is stereoscopic, stable in structure, soft in hand feeling, high in wear resistance, light and thin; raising is attractive and skin-friendly; and the raising process is a great innovation and breakthrough in the jacquard.

Owner:福建利港新材料科技有限公司

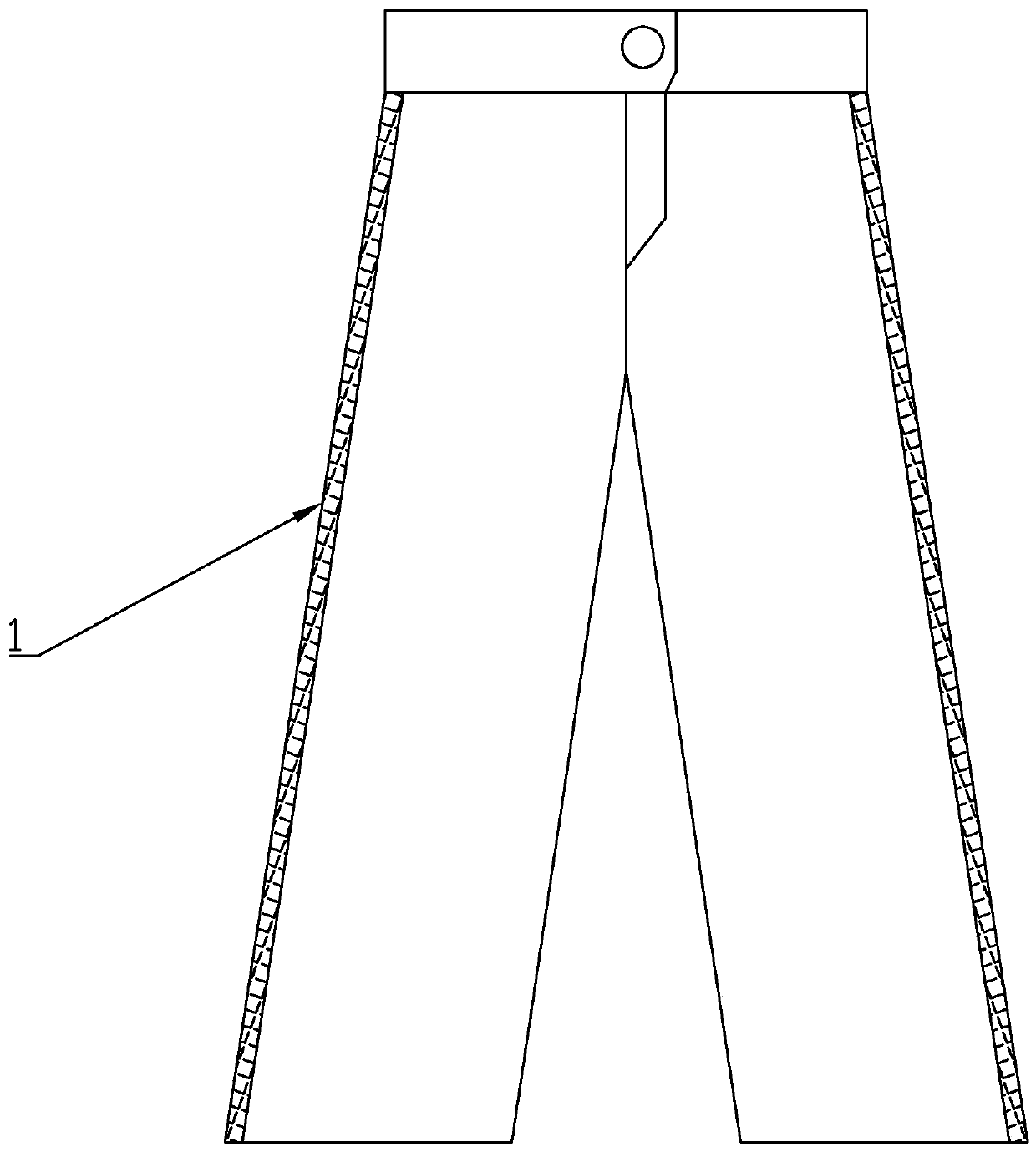

3D strip-attached filled fabric

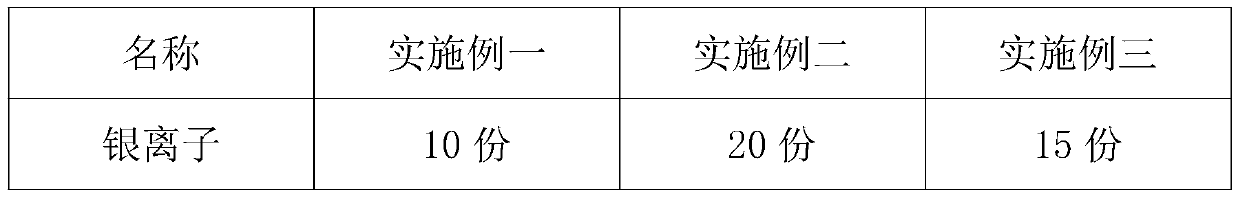

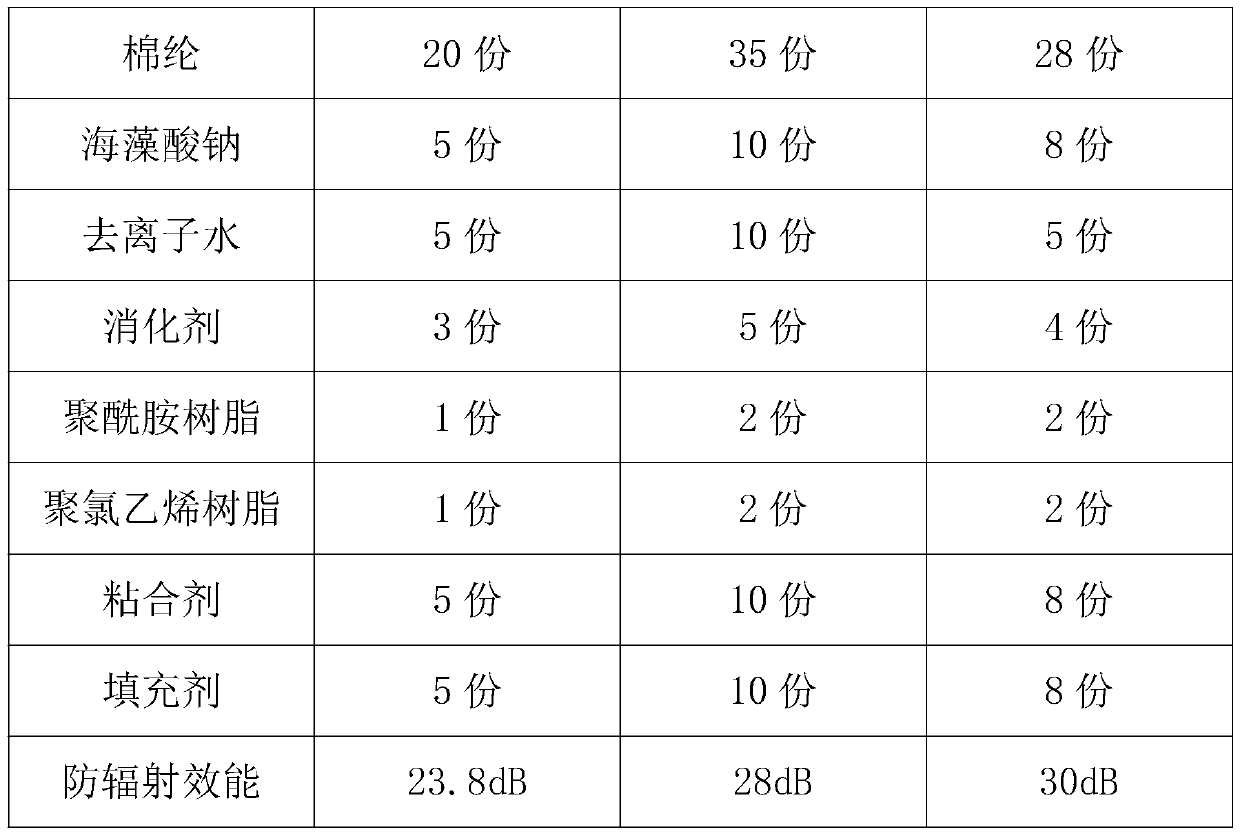

InactiveCN110359160AQuality improvementImprove radiation protection performanceElectroconductive/antistatic filament manufacturePattern makingFiberHigh volume manufacturing

The invention belongs to the technical field of fabrics and discloses a 3D strip-attached filled fabric. The 3D strip-attached filled fabric comprises silver ions, polyamide, sodium alginate, deionized water, a digestion agent, polyamide resin and polyvinyl chloride resin and further comprises an adhesive and a filling agent. By adoption of all-silver fibers and sodium alginate solution, great radiation resistance of the fabric is realized; by adding of polyamide resin and polyvinyl chloride resin, softness, smoothness and silkiness of the fabric are achieved, skin damages caused in use of thefabric are avoided, comfort in use is improved, and quality and usability of the fabric are improved. In addition, a processing process is simple and convenient, and the fabric is low in cost and suitable for mass production.

Owner:吴江市盛泽万利涂层厂

Super-soft nylon carpet and processing technology thereof

InactiveCN111671288AGood fleeceSoft and comfortableLiquid/gas/vapor article treatmentLiquid/gas/vapor removalSpinningSingle fiber

The invention discloses a super-soft nylon carpet and a processing technology thereof. The super-soft nylon carpet is formed by weaving nylon carpet yarns with the single fiber fineness of 850 d-1000detx through a tufting machine, wherein the nylon carpet yarns are spun by a spinneret plate with the spinning hole number of 200-300 F; the number of machine bobbins of the tufting machine is 1400-1600, the effective production width is 3.6-4.2 m, the yarn content per square meter is 1000-2500 g / m<2>, the suede height is 8-20 mm, and the nylon carpet yarns are formed by twisting two strands of nylon yarns after twisting the nylon yarns by 180-300 twists / m. The super-soft nylon carpet processed through adopting the processing technology is good in softness, keeps good stiff and smooth performance and is good in rebound rate.

Owner:ZHEJIANG JIAYUAN CARPET IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com