Acrylate coating layer emulsion capable of preventing down feather from escaping from needle holes, coating layer glue and preparation method of acrylate coating layer emulsion

An acrylate and water-based acrylate technology, applied in textiles and papermaking, etc., can solve the problems that the acrylate coating emulsion is difficult to meet the requirements, and the production technology of acrylate coating emulsion has not been reported, and achieves the improvement of emulsion conversion. rate, enhance wear resistance, improve the effect of compactness and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

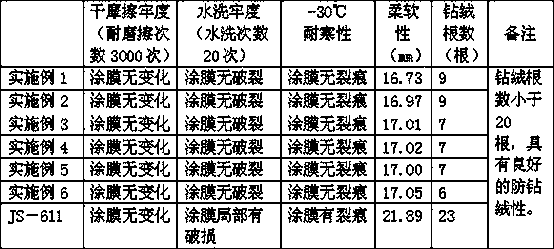

Examples

Embodiment 1

[0032] (1) Add deionized water 115, isomerized tridecyl alcohol polyoxyethylene ether (40) 9.5, dioctyl sodium sulfosuccinate 1, alcohol ether sulfosuccinic acid monoester disodium salt 2 into the pre-milk kettle In, fully stir to dissolve;

[0033] Then itaconic acid 1, acrylamide 2.5, acrylic acid 3, butyl acrylate 160, isooctyl acrylate 40, acrylonitrile 24, hydroxyethyl methacrylate 3, acrylic acid modification reaction slip agent 3,3-( 2,3 Glycidoxy) Propylmethyldiethoxysilane 0.7 was added to the pre-emulsion kettle, fully stirred and emulsified to obtain pre-emulsion A;

[0034] (2) Mix 9% by weight of pre-emulsion A with hydroxyethylacrylamide 4 to obtain pre-emulsion B;

[0035] (3) Mix ammonium persulfate 0.8 and deionized water 15 to obtain ammonium persulfate aqueous solution, which is set aside;

[0036] (4) Mix sodium bisulfite 0.2 and deionized water 5 to obtain an aqueous solution of sodium bisulfite for use;

[0037] (5) Add deionized water 145 to the react...

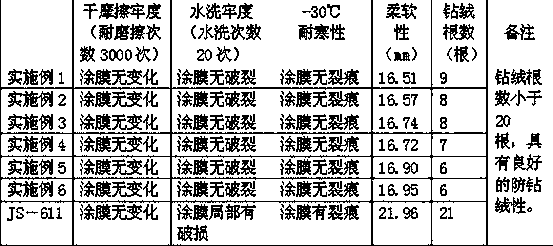

Embodiment 2

[0042] (1) Add deionized water 117, isomerized tridecyl alcohol polyoxyethylene ether (40) 9.6, dioctyl sodium sulfosuccinate 1.1, alcohol ether sulfosuccinic acid monoester disodium salt 2.1 to the pre-milk kettle In, fully stir to dissolve;

[0043] Then itaconic acid 1.1, acrylamide 2.6, acrylic acid 3.1, butyl acrylate 161, isooctyl acrylate 41, acrylonitrile 25, hydroxyethyl methacrylate 3.1, acrylic acid modification reaction slip agent 3.1, 3-( 2,3 glycidoxy) propylmethyl diethoxysilane 0.8 was added to the pre-emulsion kettle, fully stirred and emulsified to obtain pre-emulsion A;

[0044] (2) Mix 9.4% by weight of pre-emulsion A with hydroxyethylacrylamide 4.1 to obtain pre-emulsion B;

[0045] (3) Mix ammonium persulfate 0.88 and deionized water 15 to obtain ammonium persulfate aqueous solution, set aside;

[0046] (4) Mix sodium bisulfite 0.24 with deionized water 5 to obtain an aqueous solution of sodium bisulfite for use;

[0047] (5) Add deionized water 147 to...

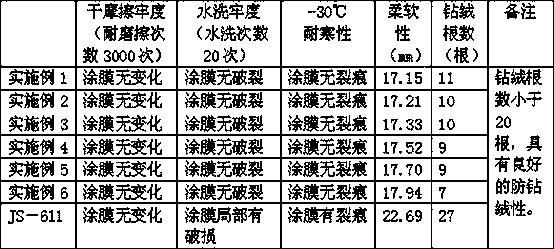

Embodiment 3

[0052] (1) Add deionized water 119, isomerized tridecyl alcohol polyoxyethylene ether (40) 9.7, dioctyl sodium sulfosuccinate 1.2, alcohol ether sulfosuccinic acid monoester disodium salt 2.2 to the pre-milk kettle In, fully stir to dissolve;

[0053] Then itaconic acid 1.2, acrylamide 2.7, acrylic acid 3.2, butyl acrylate 162, isooctyl acrylate 41.5, acrylonitrile 25.5, hydroxyethyl methacrylate 3.2, acrylic acid modification reaction slip agent 3.2, 3-( 2,3 glycidoxy) propylmethyl diethoxysilane 0.9 was added to the pre-emulsion kettle, fully stirred and emulsified to obtain pre-emulsion A;

[0054] (2) Mix 9.8% by weight of pre-emulsion A with hydroxyethylacrylamide 4.2 to obtain pre-emulsion B;

[0055] (3) Mix ammonium persulfate 0.96 and deionized water 15 to obtain ammonium persulfate aqueous solution, which is set aside;

[0056] (4) Mix sodium bisulfite 0.28 and deionized water 5 to obtain an aqueous solution of sodium bisulfite for use;

[0057] (5) Add deionized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com