Additives for Monocrystalline Silicon Wafer Chain Texturing and Its Application

A single crystal silicon wafer and additive technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of lengthening the length of the texturing machine, increasing the reflectivity of the silicon wafer, shortening the texturing time, etc. Achieve good conversion efficiency, increase productivity, and uniform appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Mix 1 part by mass of polyethyleneimine 1800, 5 parts by mass of fucoidan, 0.2 part by mass of polyacrylamide (molecular weight: 8 million), 0.5 part by mass of polyetheramine D230, and 93.3 parts by mass of deionized water to prepare the additive solution; then add additives, potassium hydroxide and deionized water sequentially according to the mass ratio of 1:4:100, stir evenly to make texturing liquid; put monocrystalline silicon wafers flat into the chain texturing equipment, and use the prepared The texturing liquid is used for chain-type texturing of monocrystalline silicon wafers, the texturing temperature is 90°C, and the reaction time is 3.5 minutes. The average reflectance of the textured sheet was measured to be 11.24 after the texturing was completed.

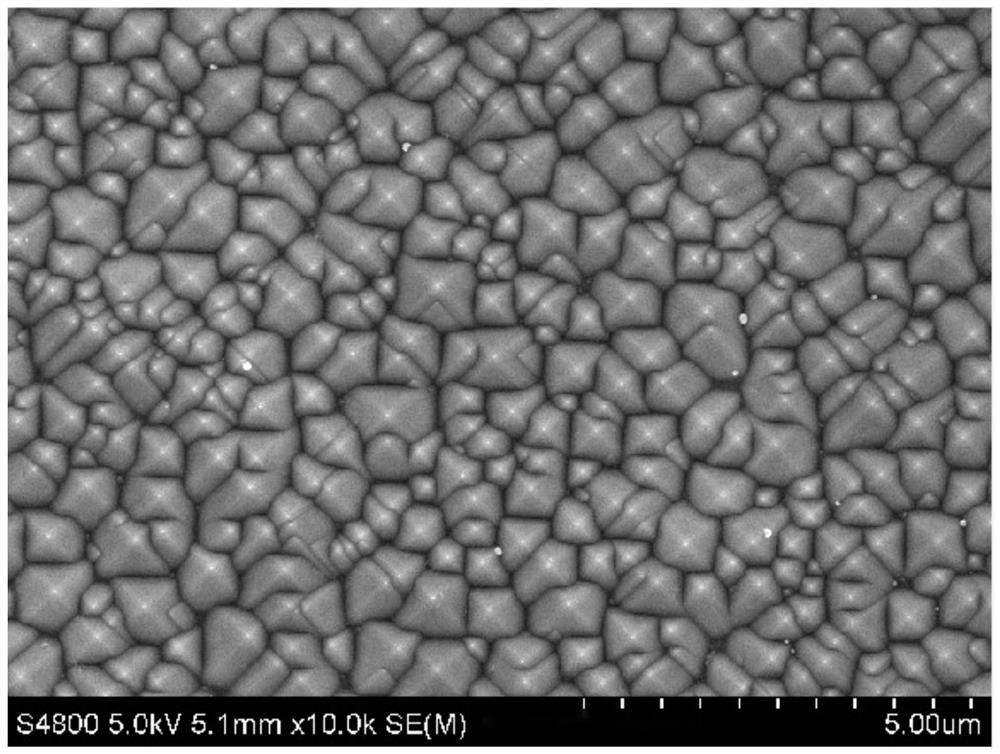

[0026] The suede surface appearance of the obtained suede sheet of embodiment 1 is as attached figure 1 As shown, the size of the textured pyramids is small, the density of the piles is high, and the pyramid...

Embodiment 2

[0028] Mix and stir 1 part by mass of polyethyleneimine 1800, 10 parts by mass of fucoidan, 0.2 part by mass of polyacrylamide (molecular weight: 8 million), 0.5 part by mass of polyetheramine D230, and 88.3 parts by mass of deionized water to make an additive solution; then according to the mass ratio of 1:4:100, add additives, potassium hydroxide and deionized water in sequence and stir evenly to make a texturing solution; put the monocrystalline silicon wafer into the chain texturing equipment, and use the prepared The texturing solution is used for chain texturing of monocrystalline silicon wafers, the texturing temperature is 90°C, and the reaction time is 3.5 minutes. The average reflectance of the textured sheet was measured to be 11.63 after the texture was finished.

Embodiment 3

[0030] 0.5 parts by mass of polyethyleneimine 1800, 0.5 parts by mass of polyethyleneimine 70000, 5 parts by mass of fucoidan, 0.2 parts by mass of polyacrylamide (molecular weight 8 million), 0.5 parts by mass of polyetheramine D230, 93.3 parts by mass Mix and stir deionized water evenly to make an additive solution; then add additives, potassium hydroxide and deionized water in sequence according to the mass ratio of 1:4:100, stir evenly to make a texturing solution; put the monocrystalline silicon wafer flat into the chain In the type texturing equipment, the prepared texturing liquid is used for chain texturing of monocrystalline silicon wafers, the texturing temperature is 90°C, and the reaction time is 3.5 minutes. After the texturing was completed, the average reflectance of the texturized sheet was measured to be 11.30.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com