Patents

Literature

32results about How to "Strong cashmere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Color fixed island composite short fiber and preparation method thereof

ActiveCN102650081AColorfulUniform colorFilament/thread formingConjugated synthetic polymer artificial filamentsLow-density polyethyleneCarding

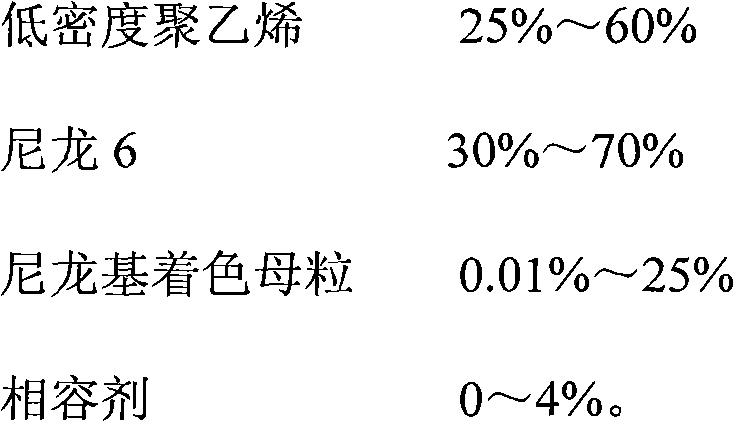

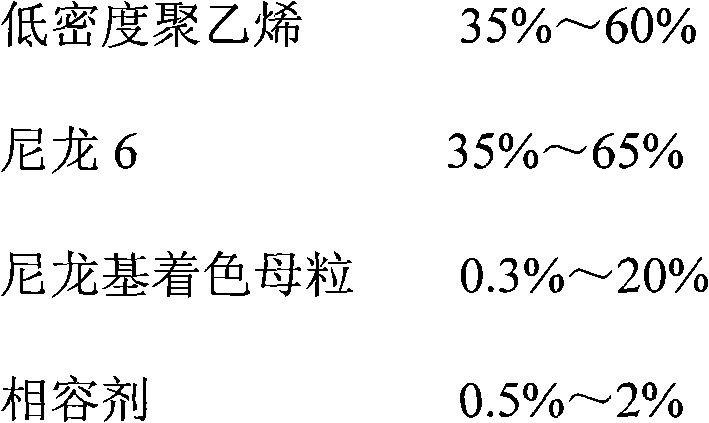

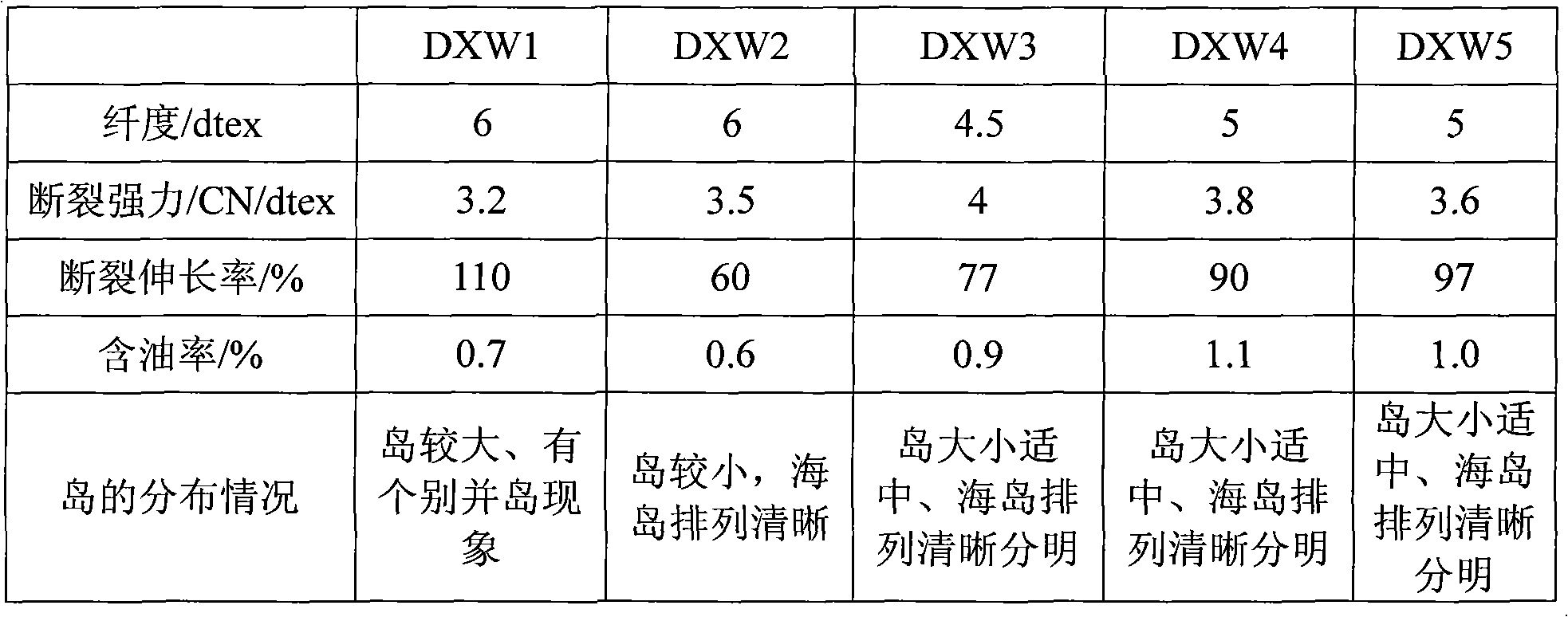

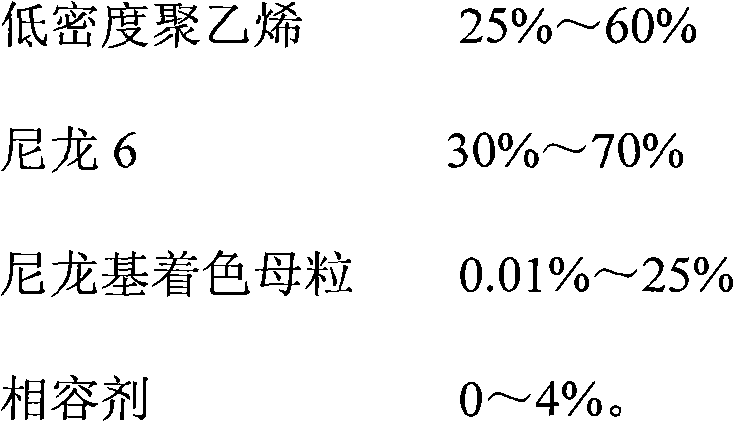

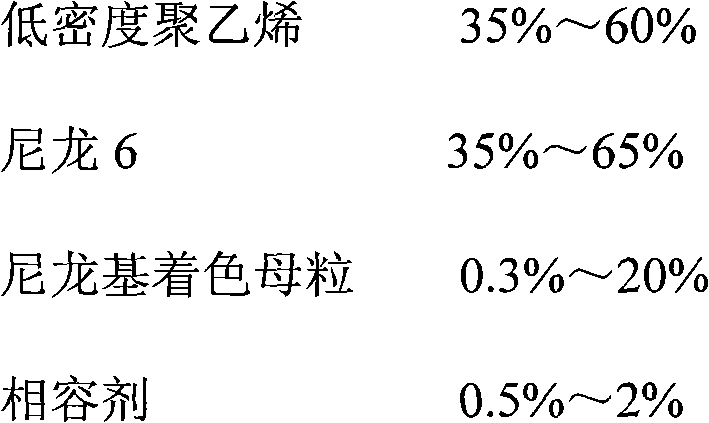

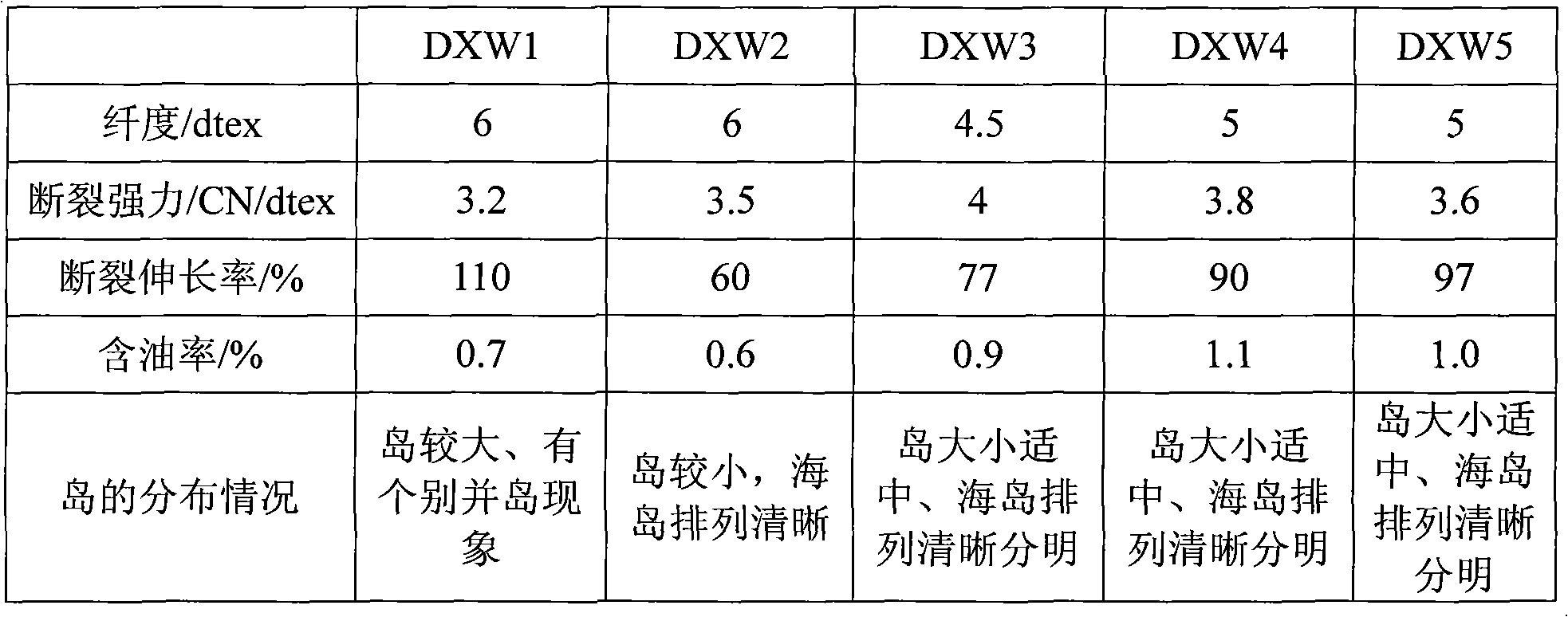

The invention provides a color fixed island composite short fiber and a preparation method thereof. The color fixed island composite short fiber comprises the following components by weight: 25-60 percent of low density polyethylene, 30-70 percent of nylon (6), 0.01-25 percent of nylon base coloring master batch and 0-4 percent of compatilizer. Compared with the prior art, the number of the islands of the color fixed island composite short fiber is fixed, as well as the size and the distribution of the short fiber are regular; color super-fine fiber synthetic leather prepared by adopting the preparation method has the advantages of bright and uniform color, high color fastness, no color difference between different batches, uniform carding, strong woolen sensation, high abrasion resistance, easiness in removing of dust after leather abrading, low probability of dust dropping during friction and the like; and besides, high energy consumption and high pollution dyeing process is simplified, and the preparation cost is reduced to a great extent.

Owner:HUAFON MICROFIBER SHANGHAI

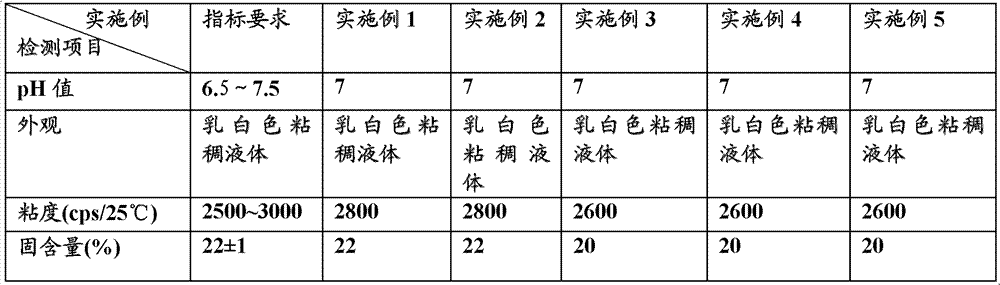

Velvet finishing agent for synthetic leather and preparation method thereof

The invention relates to a velvet finishing agent for synthetic leather and a preparation method thereof. The velvet finishing agent consists of the following raw materials in parts by weight: 80-120 parts of polyurethane resin, 3-10 parts of dry smooth wax powder, 2-8 parts of silicon dioxide extinction powder, 6-15 parts of glass microspheres with particle size of 5-60 microns, 1-6 parts of epoxidized soybean oil, 1-6 parts of phenmethyl silicon oil, 1-6 parts of plasticizer, 30-60 parts of dimethylformamide, 30-50 parts of butyl acetate, 20-40 parts of methylal and 20-40 parts of dimethylbenzene. The velvet finishing agent for synthetic leather provided by the invention has low cost and good velvet feel, can be used through multiple technologies such as roller painting, printing and the like, and is widely applicable. In the invention, a preparation technology of uniformly dispersing before grinding and filtering is adopted, and the prepared finishing agent can obtain more delicate velvet feel; and moreover, as the yangbuck powder requiring accurate temperature control and long-time foaming is not used, the preparation is easier.

Owner:SUZHOU DEERUN COMPOSITE MATERIALS

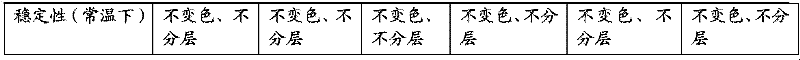

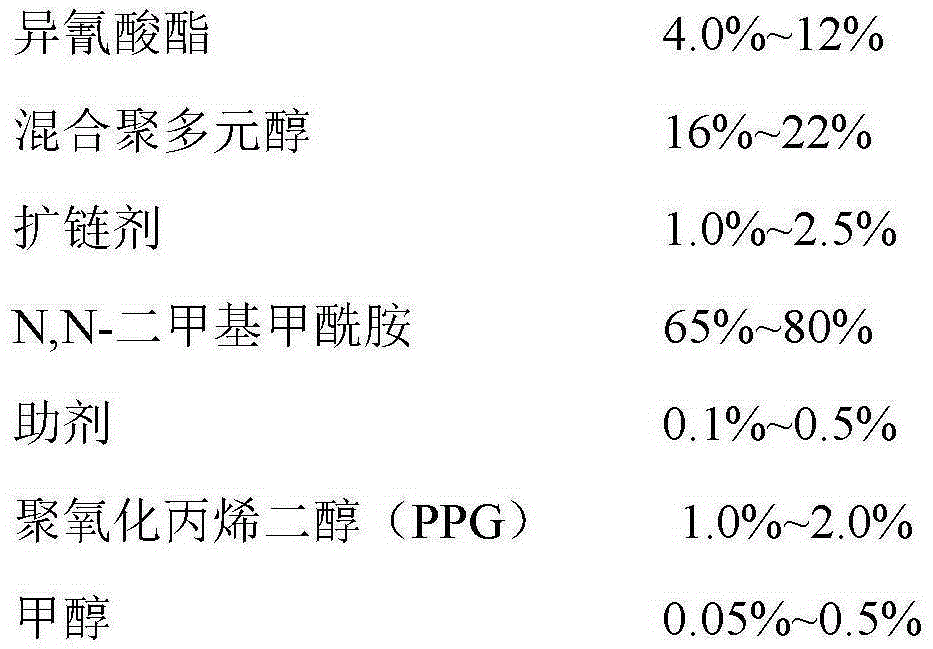

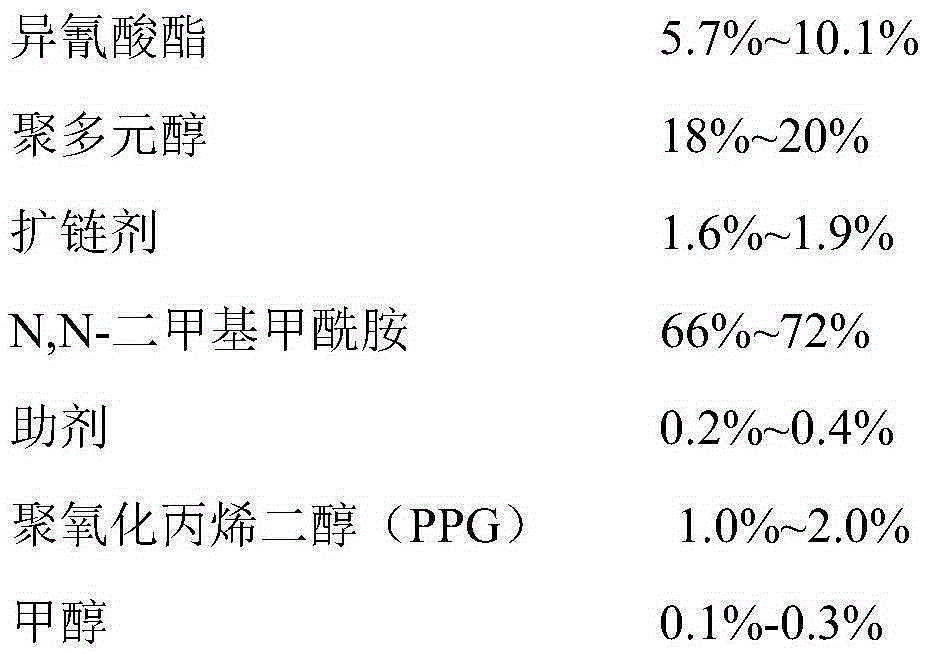

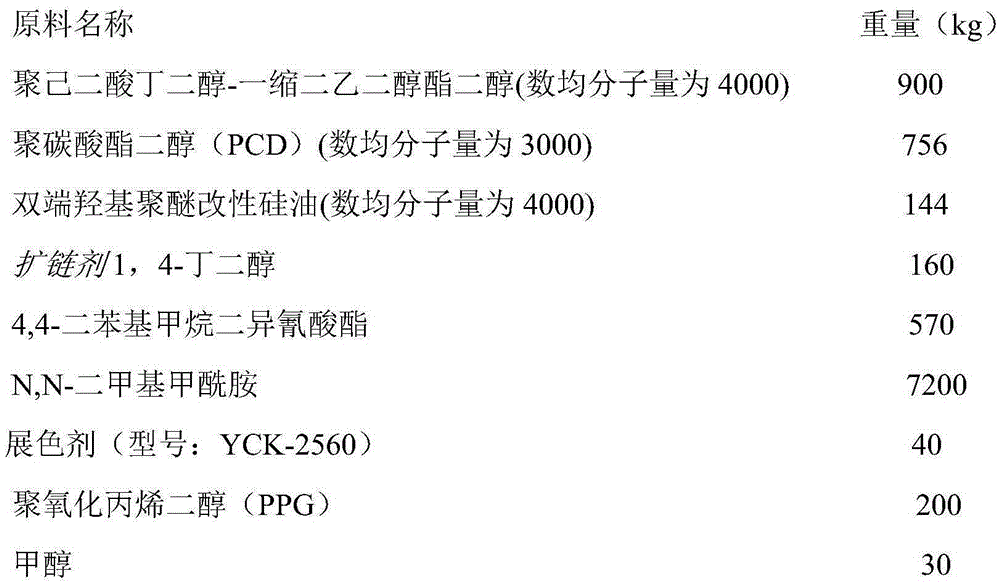

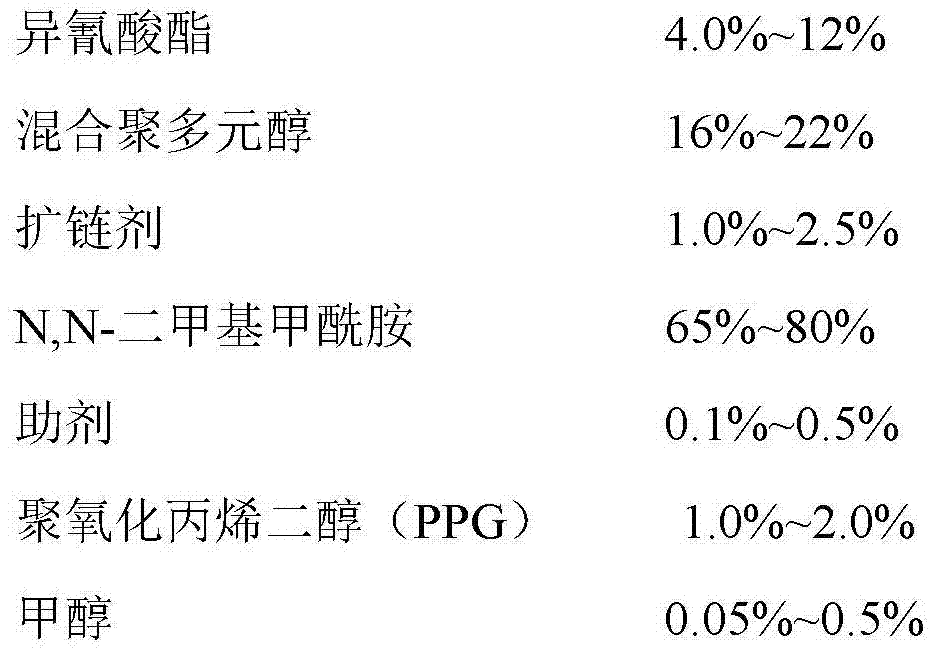

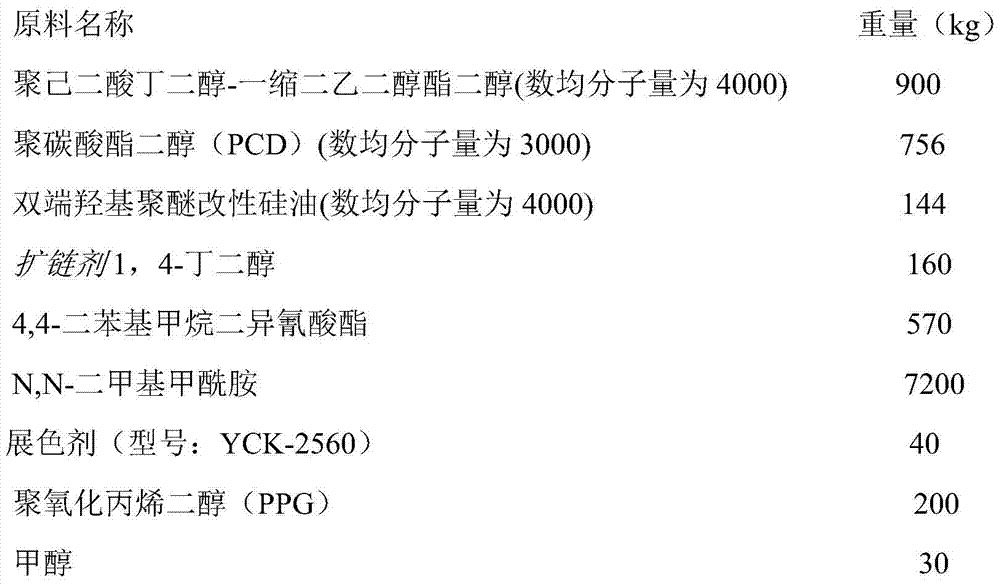

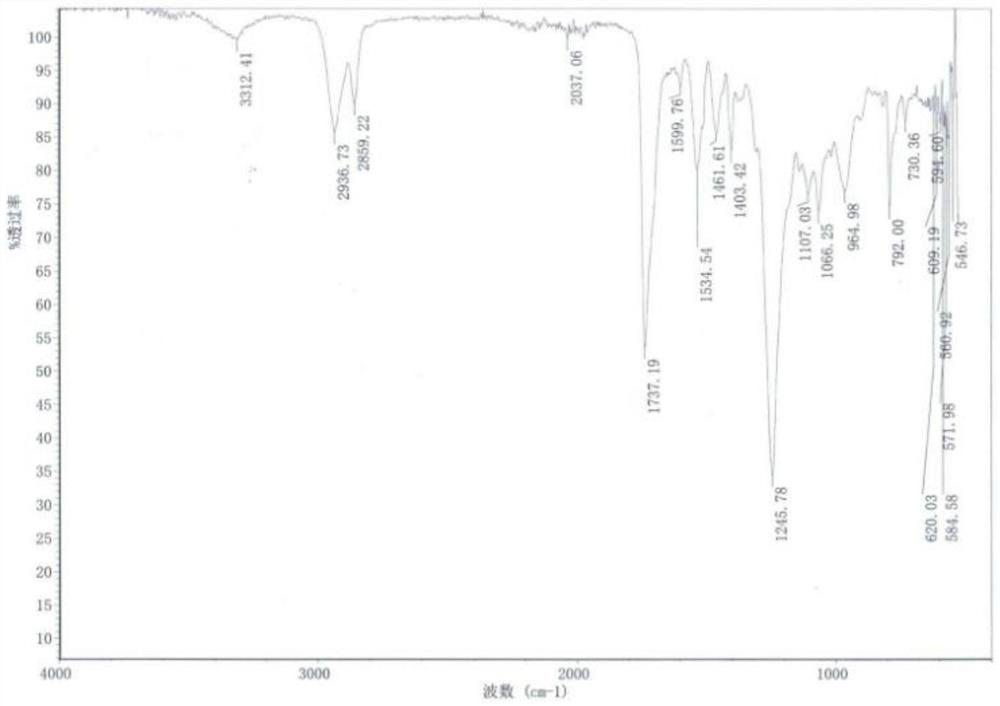

Polyurethane nubuck resin for high-resilience high-velvet-feeling clothing leather and preparation method of thereof

ActiveCN105330815AIncrease elasticityFine and vertical cellsTextiles and paperN dimethylformamidePolybutylene

The invention provides a polyurethane nubuck resin for high-resilience high-velvet-feeling clothing leather and a preparation method thereof. The polyurethane nubuck resin for the high-resilience high-velvet-feeling clothing leather is prepared from, by weight, 4.0-12% of isocyanate, 16-22% of mixed polyvalent alcohol, 1.0-2.5% of chain extender, 65-80% of N,N-dimethylformamide, 0.1-0.5% of auxiliary, 1.0-2.0% of polypropylene oxide glycol (PPG) and 0.05-0.5% of methyl alcohol. The polyurethane nubuck resin for the high-resilience high-velvet-feeling clothing leather is prepared through the synthesis technology of polybutylene adipate-diethylene glycol ester diol, polycarbonate diol, silicon oil, diisocyanate, other reactants and two midbodies in an independent chain growth mode, and the prepared resin is used for polyurethane nubuck leather. The prepared nubuck leather has the advantages of being high in resilience, uniform in bubble thickness, strong in velvet feeling, good in weather resistance and the like.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

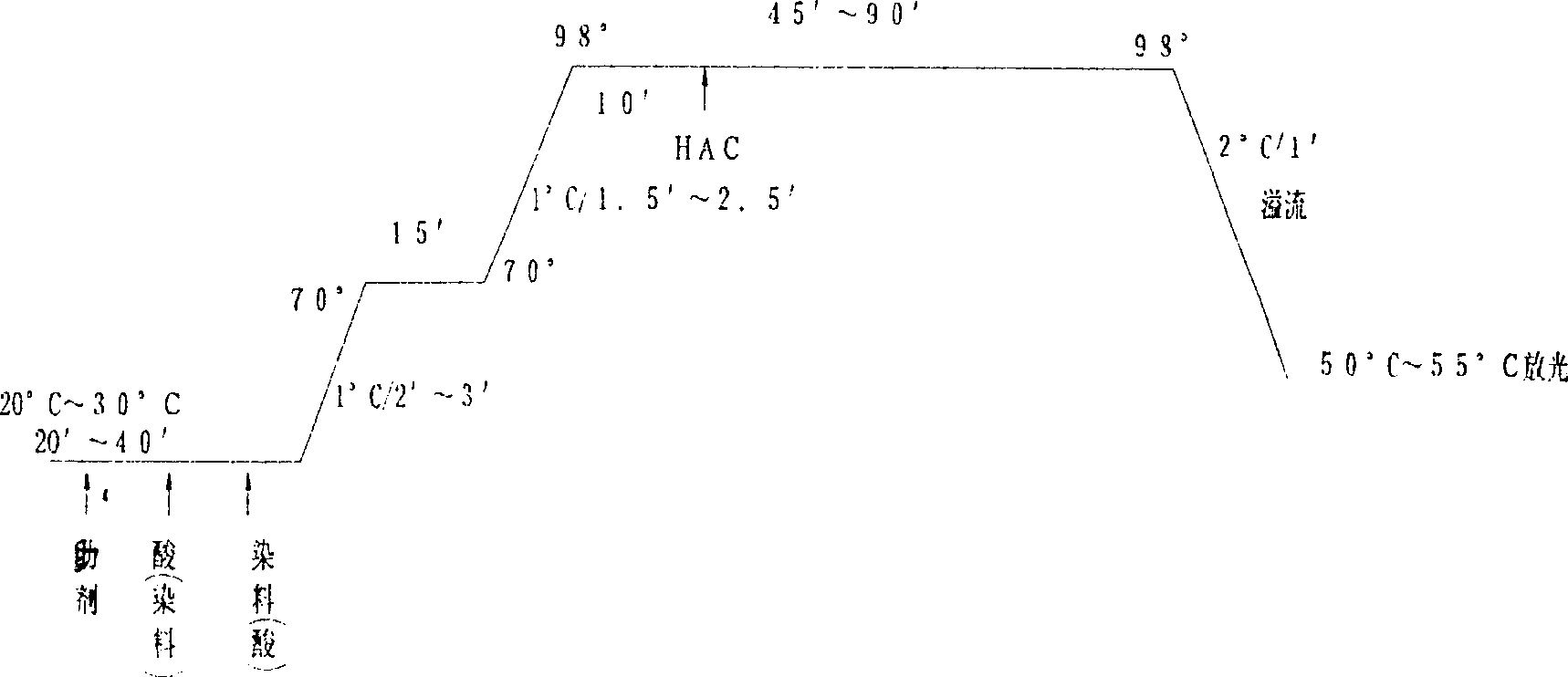

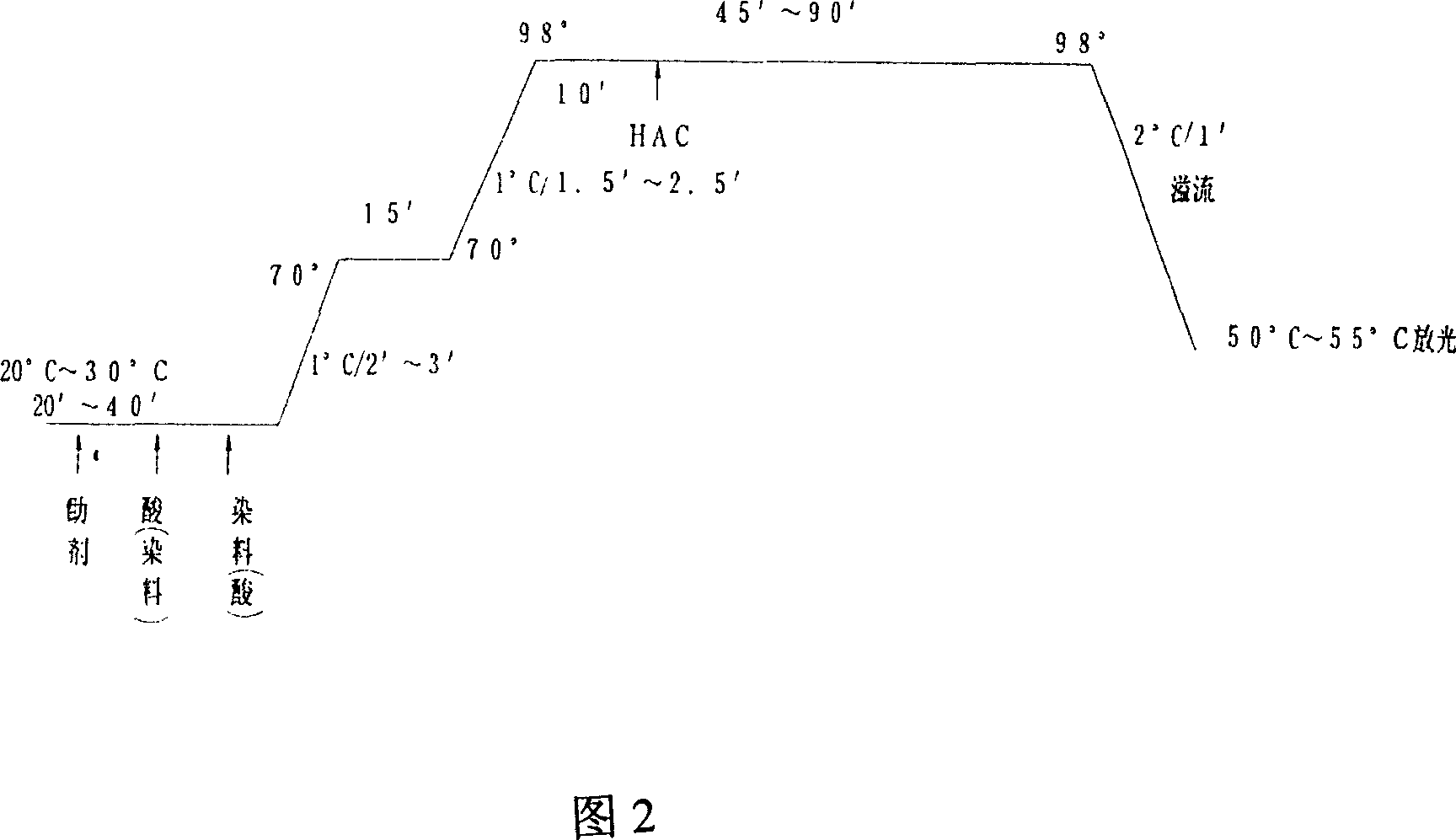

Preparation method of knitted wool-like warm fabric

InactiveCN105332155AGood dissipationHigh pectinWeft knittingBiochemical fibre treatmentYarnPolymer science

The invention relates to a preparation method of a knitted wool-like warm fabric. The preparation method comprises the following steps: (1) raw material selection; (2) spinning technology implementation; (3) weaving technology implementation; (4) printing, dyeing and after-finishing. The knitted wool-like warm fabric is formed by performing the after-finishing, such as knitting, dyeing, carbon grinding and softening, on hemp / cotton / polypropylene fiber blended yarns and polyolefin elastic fibers, namely confirmable elastic fibers, which serve as raw materials. By the adoption of hemp, a product can realize antibacterial, health care and anti-ultraviolet functions; cotton fibers are high in hygroscopicity and spinnability; the polypropylene fibers are poor in heat conductance and high in heat insulation property; by the blending of the three types of fibers, a product has the functions of heat insulation, moisture absorption, breathing, bacteria prevention and ultraviolet resistance; by the weaving of the polyolefin elastic fibers, the product is extremely high in elasticity and conformality. The product is soft, fine, breathable, relaxing, high in heat retention property and suitable for making high-end warm coats or skirts, is a high-quality antibacterial, health care and warm fabric which has a wide market development prospect.

Owner:JIANGSU YDTEX GRP LTD

Production method of low-shrinkage rate dacron complex fiber

InactiveCN105177783AObvious drapeApparent comfortArtificial filament heat treatmentMelt spinning methodsComing outFiber

The present invention relates to the field of polyester fiber production equipment, and especially discloses a production method of low-shrinkage rate dacron complex fibers. Semidull polyester melts enter into a static mixer, are then conveyed into a spinning manifold through a melt distributor, and are extruded onto a POY spinneret and an FDY spinneret; POY fibers coming out of the POY spinneret are cooled by cross air blow and oiled by an oil nozzle, pass a yarn guide, a pre-network and another yarn guide; FDY fibers coming out of the FDY spinneret are cooled by cross air blow and oiled by an oil nozzle, pass a yarn guide, a pre-network and a GR1 hot roller; and the POY fibers coming out of the yarn guide and the FDY fibers coming out of the GR1 hot roller enter into a stranding comb-shaped yarn guide together, and then pass a yarn guide disc, an intermediate network, a GR2 hot roller and a main network, thus to be rolled for shaping. According to the production method, the obtained fibers are different in boiling water shrinkage, and thus a shell fabric is good in velvet feeling, soft in hand feeling, firm, anti-wrinkle and wear-resisting.

Owner:桐昆集团浙江恒盛化纤有限公司

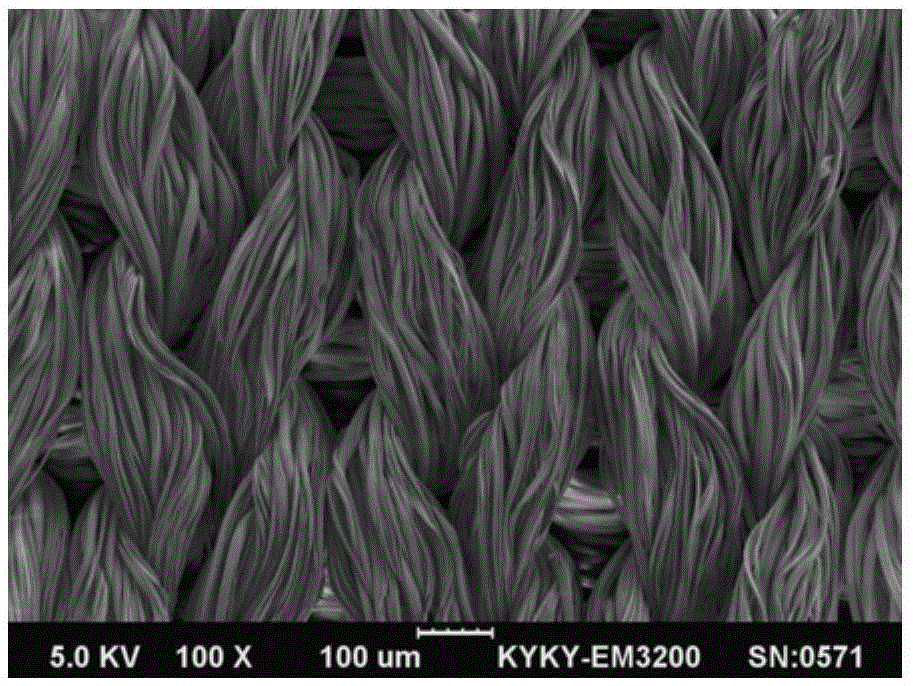

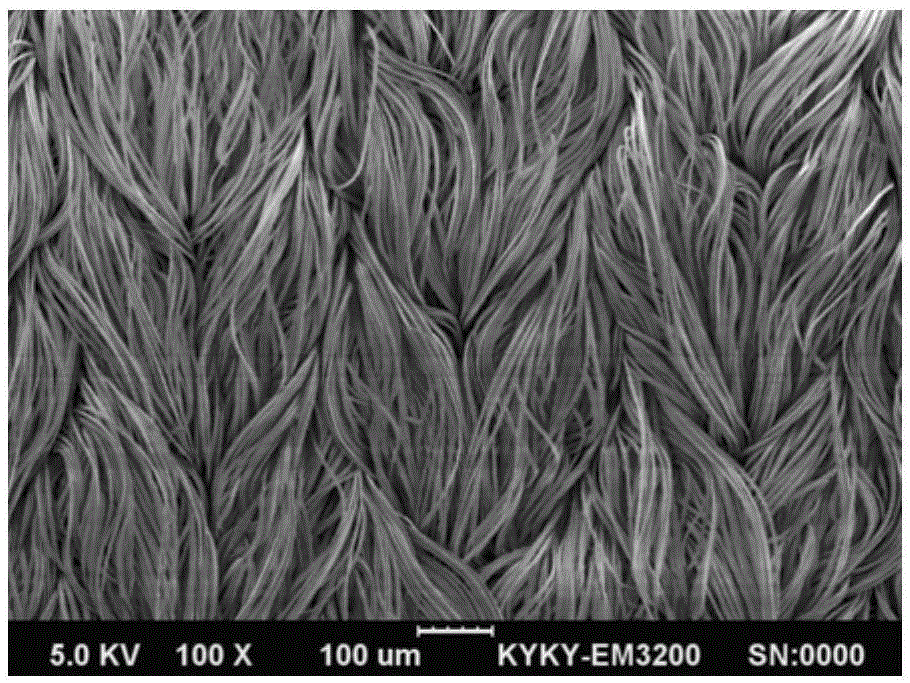

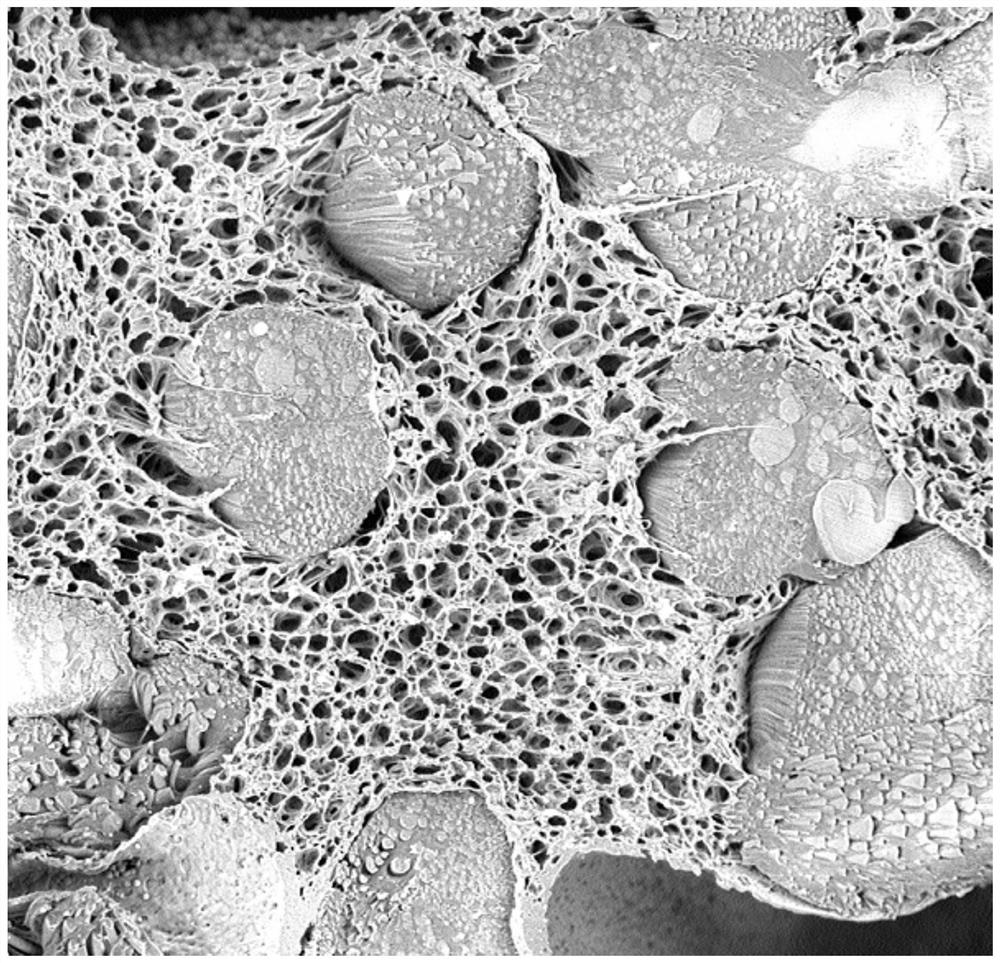

Figured sea-island superfine fiber suede leather with writing effect and preparation method thereof

ActiveCN103741497AStrong cashmereFeel fullPattern makingLiquid/gas/vapor textile treatmentAlcoholEmery paper

The invention discloses figured sea-island superfine fiber suede leather with a writing effect and a preparation method thereof. The preparation method comprises the following steps: (1) impregnating a superfine fiber polyurethane synthetic leather base cloth into a raising finishing agent to be padded, and then drying and setting the product to prepare superfine fiber suede leather with an oriented nap effect, wherein the raising finishing agent comprises the following components in parts by weight: 1-8 parts of pilling agent and 100 parts of deionized water; the pilling agent is a polyvalent alcohol interfacial agent compound; (2) unidirectionally polishing the two sides of the product obtained in the step (1) with raw emery paper, and then unidirectionally polishing the two sides with fine emery paper, wherein the polishing directions of the raw emery paper and the fine emery paper are consistent; (3) rubbing the product in the step (2) to generate grains, thus obtaining the figured sea-island superfine fiber suede leather with the writing effect. The suede leather has full hand feeling, writing effect, beautiful appearance, good genuine leather imitating effect and high added value.

Owner:HUAFON MICROFIBER SHANGHAI

Production method of Europa suede-feel polyurethane synthetic leather

InactiveCN101748614AGood market prospectGood moisture permeabilityLamination ancillary operationsPattern makingEnvironmental resistanceHigh polymer

The invention discloses a production method of Europa suede-feel polyurethane synthetic leather, which comprises the following steps: firstly, preparing semifinished synthetic leather by using a wet method; secondly, hot-joining the polyurethane slurry layer, which is formed after the pattern of release paper is transferred, onto the surface of the semifinished synthetic leather which is printed by the wet method, wherein the polyurethane slurry comprises the following raw materials in parts by weight: polyester-polyether copolymer resin SF-01, 3-7 parts of expanded micro particle, 8-12 parts of butanone, 5-10 parts of solvent-type pigment and 0.2-0.5 part of modified silicone high polymer BYK-95950; thirdly, embossing and foaming by using embossing rollers; and finally, crinkling. The invention enables the surface of the polyurethane synthetic leather to have strong suede feel and barbing effect. The polyurethane synthetic leather has the advantages of high wear resistance, high peeling, high cold resistance, high hydrolysis resistance and other physical properties. The polyurethane synthetic leather is exactly like leather and is high-quality environmental-protection high-grade synthetic leather. The whole process conforms to the requirements of environmental protection, and conforms to the development trend of professional shoe materials in modern times.

Owner:ANHUI ANLI MATERIAL TECH

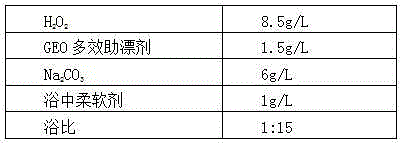

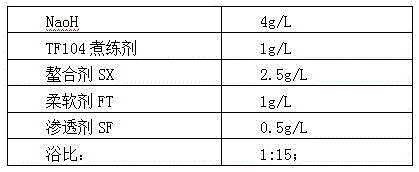

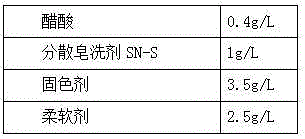

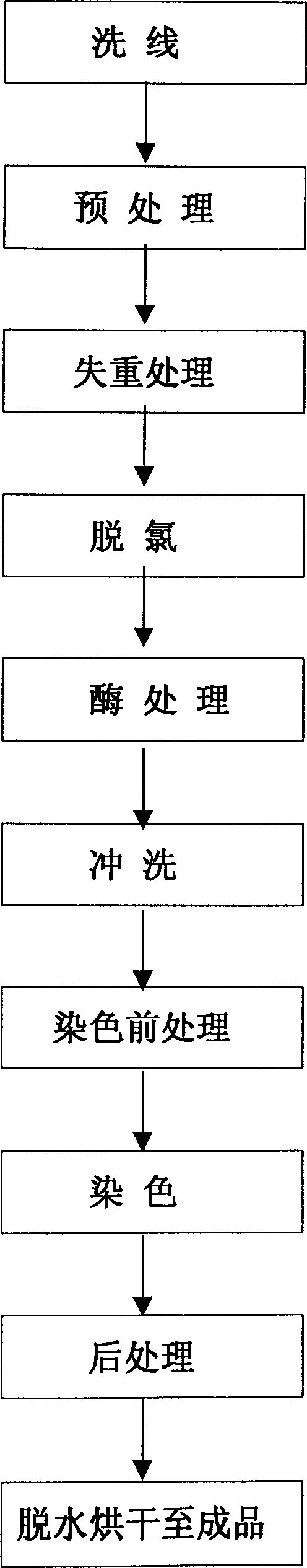

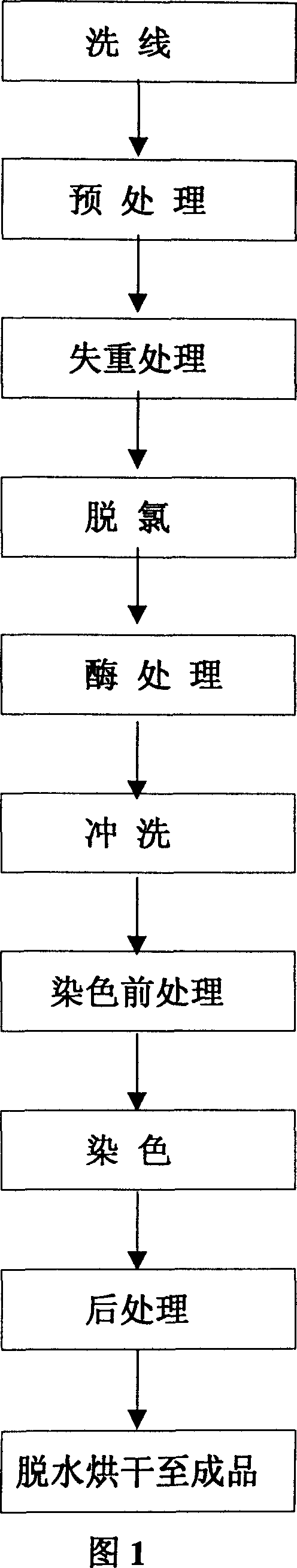

Machine washable snow-velvet and its preparation process

InactiveCN1664180ALittle strengthOvercome defectsBiochemical fibre treatmentAnimal materialWeightlessnessNatural state

This invention provide a snow floss and produce technics .The produce anti pilling is strong, still have excellent elasticity, droop capability, the trait of washed by machine. Especially the little ball rises after wear can be opened automatically after washed by machine and floss sense become better. This snow floss have trait: a, compare with common gauze of the same branch and slender, resist teaseling is better one level; b, compare with common gauze of the same branch and slender, flexibility is better about 20-80% and mightiness descend 15-20%; c, compare with former gauze fell branch heighten 3-15%, weightlessness about 10-40%,gauze branch boost 10-20; d, after washed by machine and washed by hand, the little ball can open automatically; e, after slopwork, the area minification is in 1.5-5%; f, in naturally state, the chubbiness is 115%-170% about former gauze. The technics process is: wash line - pretreatment- weightlessness manage-escaping from chlorine-enzyme manage -flush-coloration former manage-back settle -dehydrate and drying.

Owner:缪长春

Recycled polyester chenille yarn, manufacturing method thereof and method for manufacturing recycled polyester chenille yarn blanket

The invention discloses recycled polyester chenille yarn. The recycled polyester chenille yarn is obtained through plying of recycled DTY low-elastic interlaced yarn and recycled polyester plied yarn. The invention also discloses a manufacturing method of the recycled polyester chenille yarn. The invention further provides a method for manufacturing a recycled polyester chenille yarn blanket. The method for manufacturing the recycled polyester chenille yarn blanket comprises the steps of preparing the recycled polyester chenille yarn, and weaving the recycled polyester chenille yarn blanket from the recycled polyester chenille yarn in corresponding thickness. The spun recycled polyester chenille yarn is excellent in velvet feel, mellow and full, and not prone to lint falling. The recycled polyester chenille yarn is made from the PET waste material, waste material recycling is promoted, environment friendliness is realized, petroleum resources are saved, waste material treatment difficulty is reduced, and market prospects are broad. The manufactured recycled polyester chenille yarn blanket has a strong stereoscopic sense, a rich color, excellent elasticity and an excellent drape effect and is tolerant to machine washing.

Owner:常州英诺威家居用品有限公司

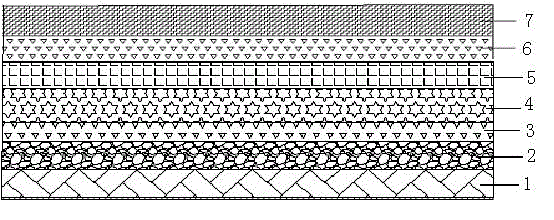

Water-based PU artificial leather with stereoscopic impression pattern

InactiveCN102943393AIncrease coverageSoft touchSynthetic resin layered productsTextiles and paperWater basedPolyurethane adhesive

The invention discloses a water-based PU artificial leather with a stereoscopic impression pattern. The artificial leather comprises a base cloth layer, a polyurethane PU layer coated on the base cloth layer, an aqueous polyurethane adhesive layer coated on the polyurethane PU layer, an aqueous PU resin layer coated on the aqueous polyurethane adhesive layer, modified polyurethane resin coated on the aqueous PU resin layer, crystal resin coated on the modified polyurethane resin and high solid polished resin coated on the crystal resin. The aqueous PU resin layer of the artificial leather provided by the invention is subjected to post high temperature PU treatment at 190 DEG C to gain strong concavo-convex crystal stereoscopic impression, better stereoscopic impression and unique effect. The high solid polished resin is a PU artificial leather post treatment resin with high solid content, and has characteristics of high gloss and high brightness; and the high solid polished resin cooperates with the crystal resin mutually to obtain synthesized leather with advantages of smoothness, scratch resistance and strong sense of cashmere.

Owner:JIANGSU BAOZE POLYMER MATERIAL

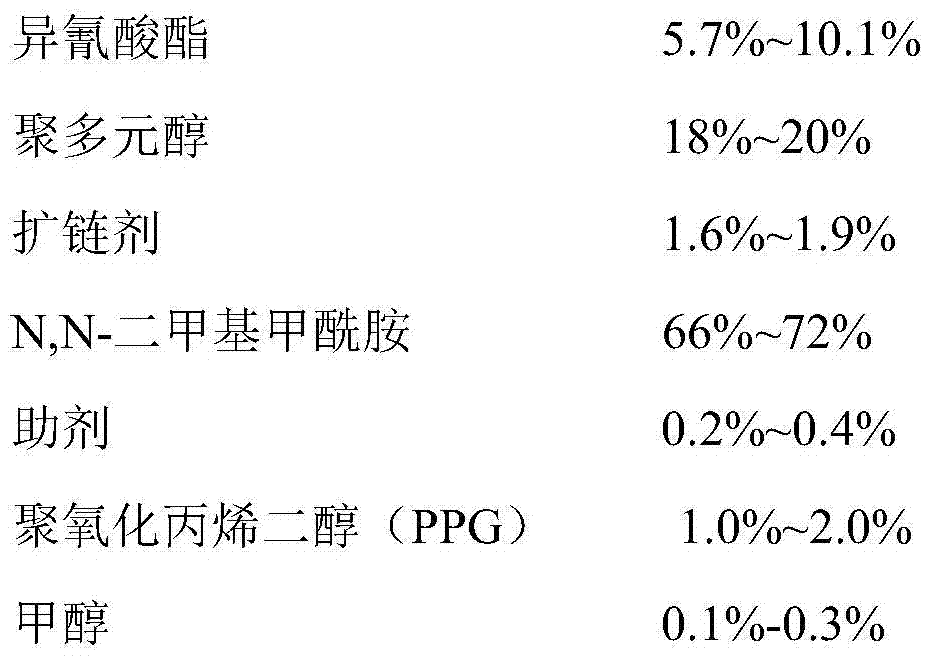

Polyurethane nubuck resin for high-resilience and high-fleece garment leather and preparation method thereof

ActiveCN105330815BIncrease elasticityFine and vertical cellsTextiles and paperN dimethylformamidePolybutylene

The invention provides a polyurethane nubuck resin for high-resilience high-velvet-feeling clothing leather and a preparation method thereof. The polyurethane nubuck resin for the high-resilience high-velvet-feeling clothing leather is prepared from, by weight, 4.0-12% of isocyanate, 16-22% of mixed polyvalent alcohol, 1.0-2.5% of chain extender, 65-80% of N,N-dimethylformamide, 0.1-0.5% of auxiliary, 1.0-2.0% of polypropylene oxide glycol (PPG) and 0.05-0.5% of methyl alcohol. The polyurethane nubuck resin for the high-resilience high-velvet-feeling clothing leather is prepared through the synthesis technology of polybutylene adipate-diethylene glycol ester diol, polycarbonate diol, silicon oil, diisocyanate, other reactants and two midbodies in an independent chain growth mode, and the prepared resin is used for polyurethane nubuck leather. The prepared nubuck leather has the advantages of being high in resilience, uniform in bubble thickness, strong in velvet feeling, good in weather resistance and the like.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

Processing method of natural fibre-like fabric

InactiveCN101994198ASoft touchFeel very slipperyDyeing processWoven fabricsWork in processEngineering

The invention relates to a processing method of a natural fibre-like fabric. Certain process changes are carried out on chemical fibre processing, and raw materials are mixed to make the visual sensation and the hand feeling of the fabric more approximate to the effect of a natural fibre, and a semi-finished product is manufactured by utilizing a twisting and sectional warping process; moreover, the problem of difficult dying of the products is solved and the dual-color effect is achieved, which is beneficial to the popularization of the natural fibre-like fabric; and meanwhile, the fabric also has the characteristics of soft, waxy, straight and smooth hand feeling, strong fluff feeling and good skin affinity.

Owner:YAYA

Machine washable snow-velvet and its preparation process

InactiveCN1309881CLittle strengthOvercome defectsBiochemical fibre treatmentAnimal materialProcess engineeringMechanical engineering

Owner:缪长春

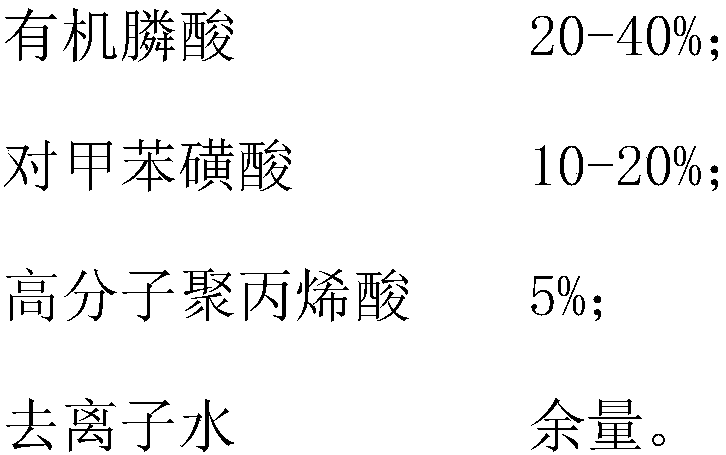

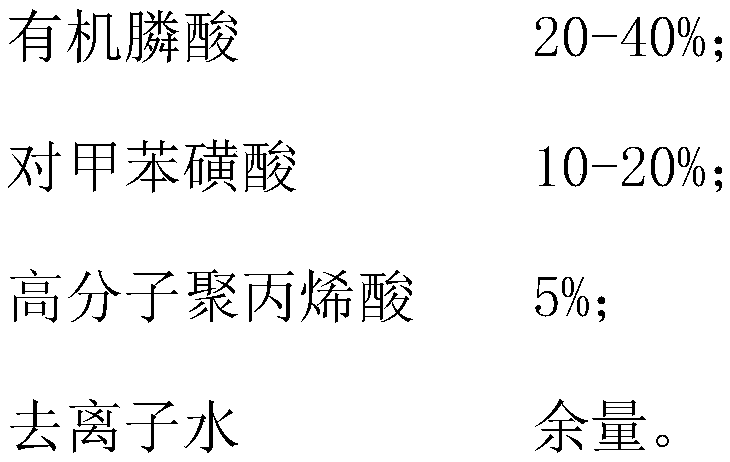

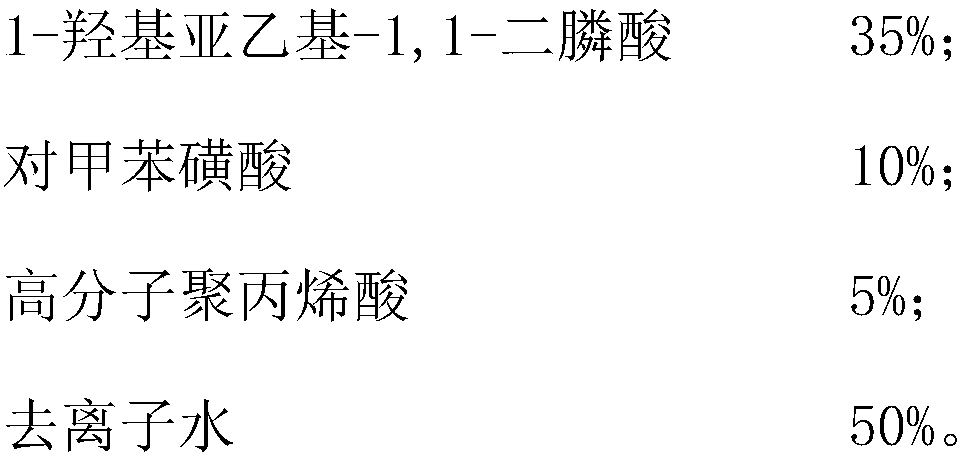

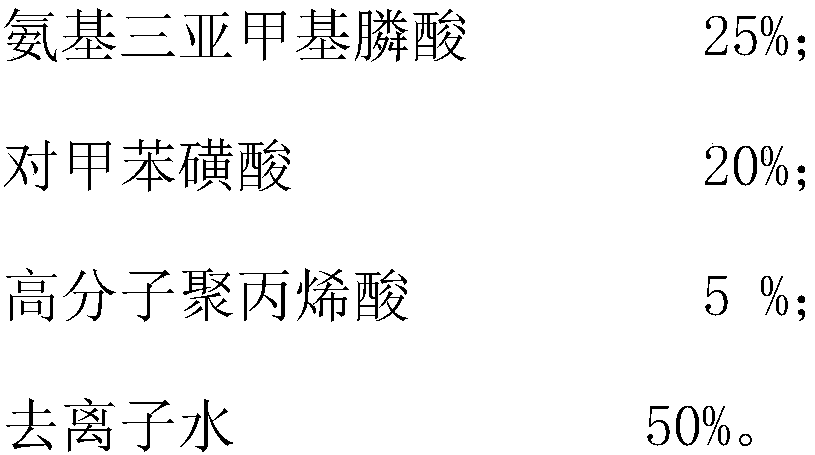

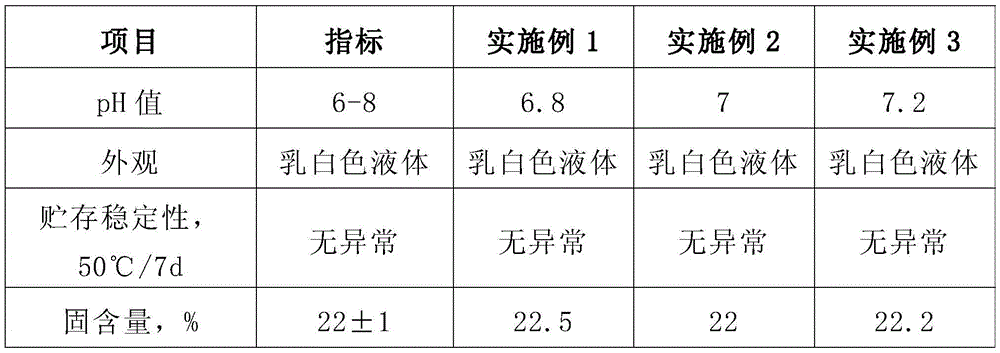

Modal fiber napping splitting agent with skin-core structure and preparation method of modal fiber napping splitting agent

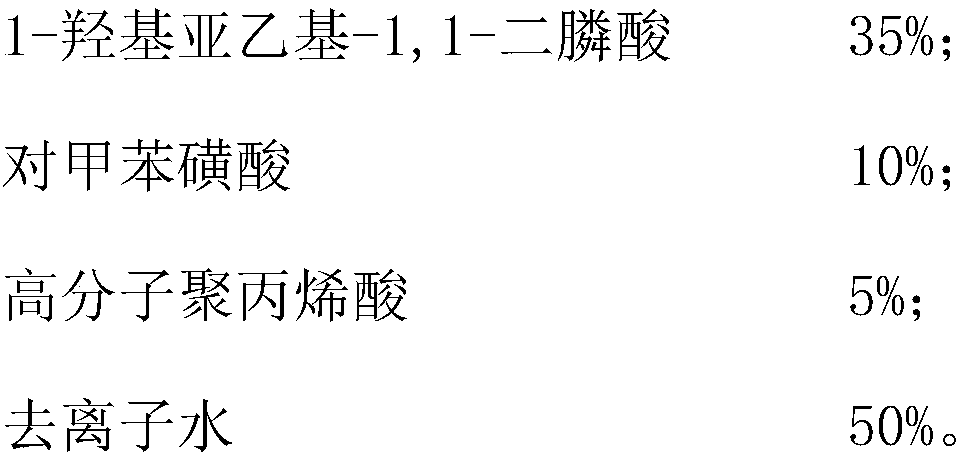

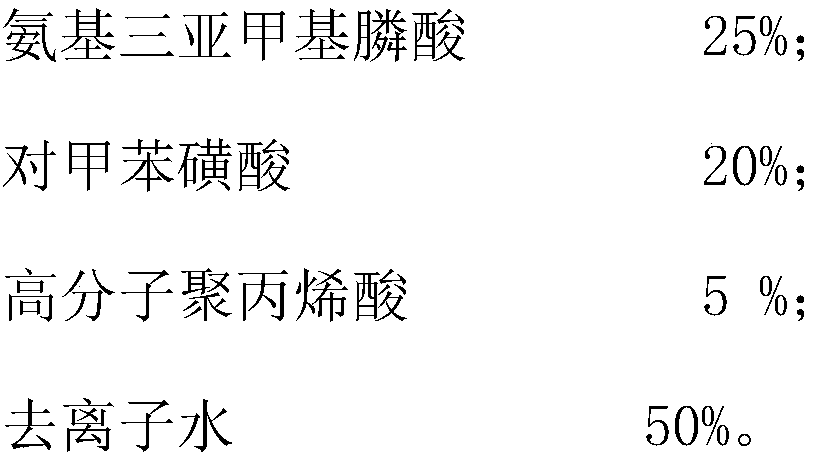

The invention relates to a splitting agent and a preparation method thereof and discloses a modal fiber napping splitting agent with a skin-core structure and a preparation method of the modal fiber napping splitting agent. The modal fiber napping splitting agent with the skin-core structure is prepared from components in percentage by mass as follows: 20%-40% of organic phosphonic acid, 10%-20% of p-toluenesulfonic acid, 5% of polymeric polyacrylic acid and the balance of deionized water. The modal fiber napping splitting agent has the advantages and effects as follows: not only can the napping splitting purpose be achieved, but also little influence is produced on strength of fabric, and a machine cylinder cannot be damaged.

Owner:绍兴海成化工有限公司

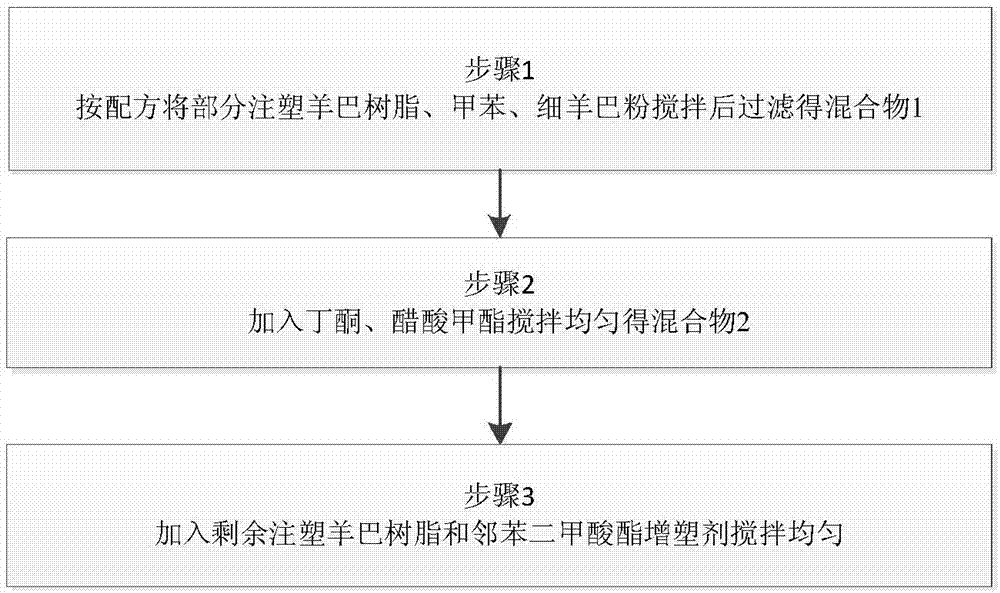

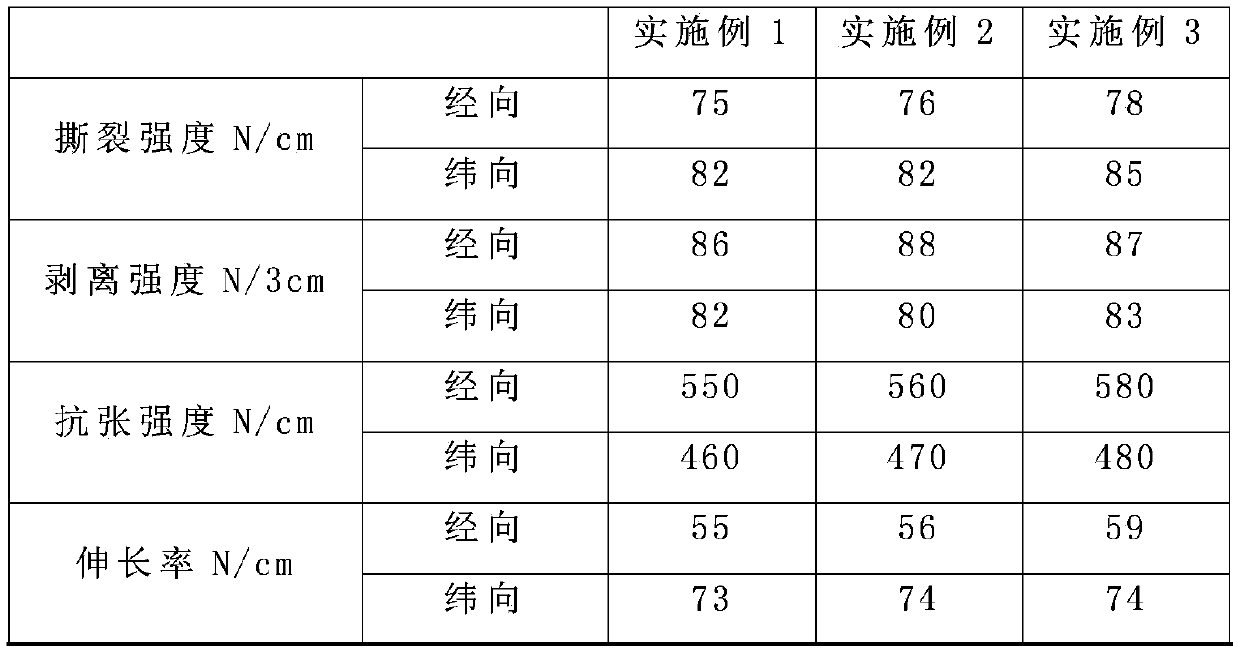

Injection molding fine Yangba resin for synthetic leather and preparation method thereof

InactiveCN107354743AUniform cellsStrong cashmereGrip property fibresProduction lineAdditive ingredient

The invention relates to injection molding fine Yangba resin for synthetic leather. Through being metered in parts by mass, the injection molding fine Yangba resin for synthetic leather is prepared from the following ingredients including 50 to 53 parts of injection molding Yangba resin, 13 to 15 parts of butanone, 10 to 12 parts of methylbenzene, 14 to 16 parts of methyl acetate, 2 to 3 parts of fine Yangba powder and 1 to 2 parts of phthalic acid ester plasticizing agents. The invention also discloses a preparation method of the injection molding fine Yangba resin for synthetic leather. The injection molding fine Yangba resin for synthetic leather prepared by the method has the advantages after the Yangba foaming, the foam holes are uniform; after the leather grinding, the velvet effect is high; the color spreading performance is good; the tactile sensation is unique; the injection molding effect is good. The injection molding fine Yangba resin can be used for processes of resin printing on the release paper vein surface, rolling coating and the like; the purposes are wide; the injection molding fine Yangba resin is applied to the existing synthetic leather production line; the process is simple; the injection molding fine Yangba resin for synthetic leather belongs to a novel material for front stage printing; the production equipment change and the cost increase are not needed.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Preparation method of novel waterproof microfiber superfine yangbuck leather

The invention discloses a preparation method of novel waterproof microfiber superfine yangbuck leather. The preparation method of the novel waterproof microfiber superfine yangbuck leather comprises the following steps of (1) preparing a coating slurry, dry-coating a base material through the prepared coating slurry, laminating the coated base material and fiber besleer, stripping the base material after drying and cooling, and reeling a finished product; (2) preparing a yangbuck treatment slurry, and coating a layer of yangbuck treatment slurry on the surface of the obtained finished product;(3) carrying out yangbuck foaming on the finished product treated through the step (2) at the temperature ranging from 170 to 180 DEG C, and obtaining a foamed yangbuck leather sample; and (4) graining and printing the yangbuck sample obtained by the treatment of the step (3), and obtaining a required yangbuck leather finished product. The yangbuck leather prepared by adopting the preparation method provided by the invention is dustproof and waterproof, has good oil resistance and wear resistance, and is not easy to scratch.

Owner:张家港嘉泰超纤科技有限公司

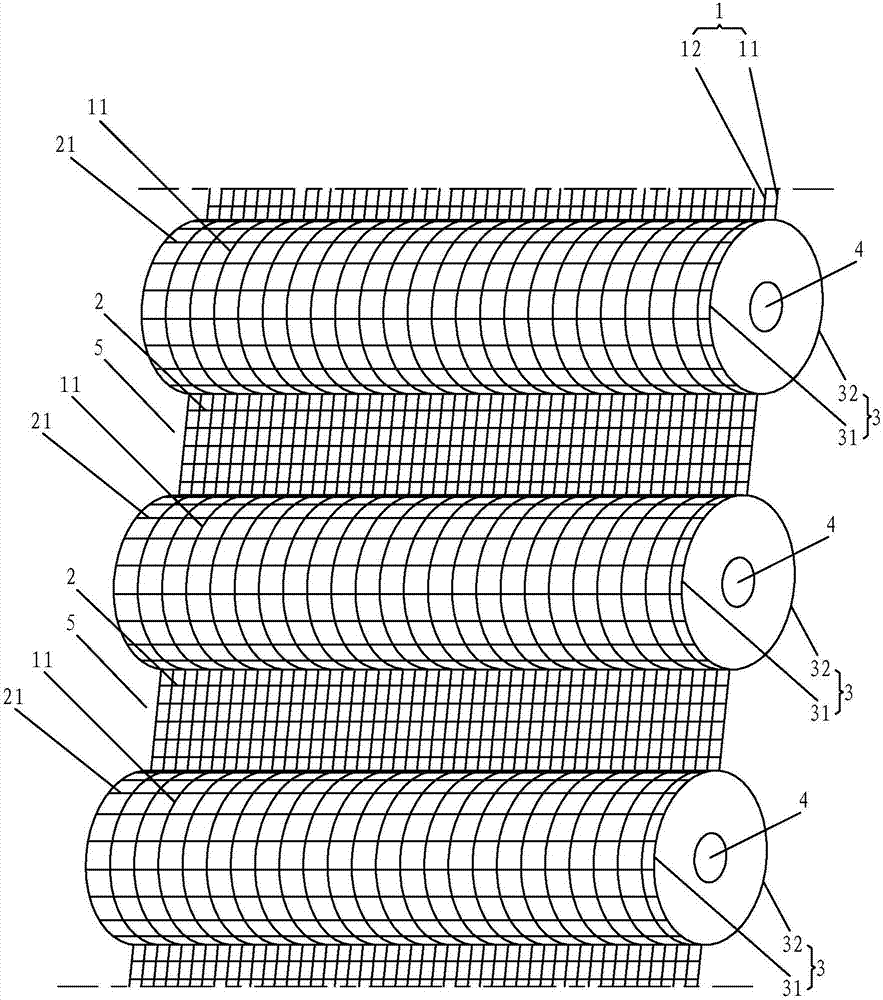

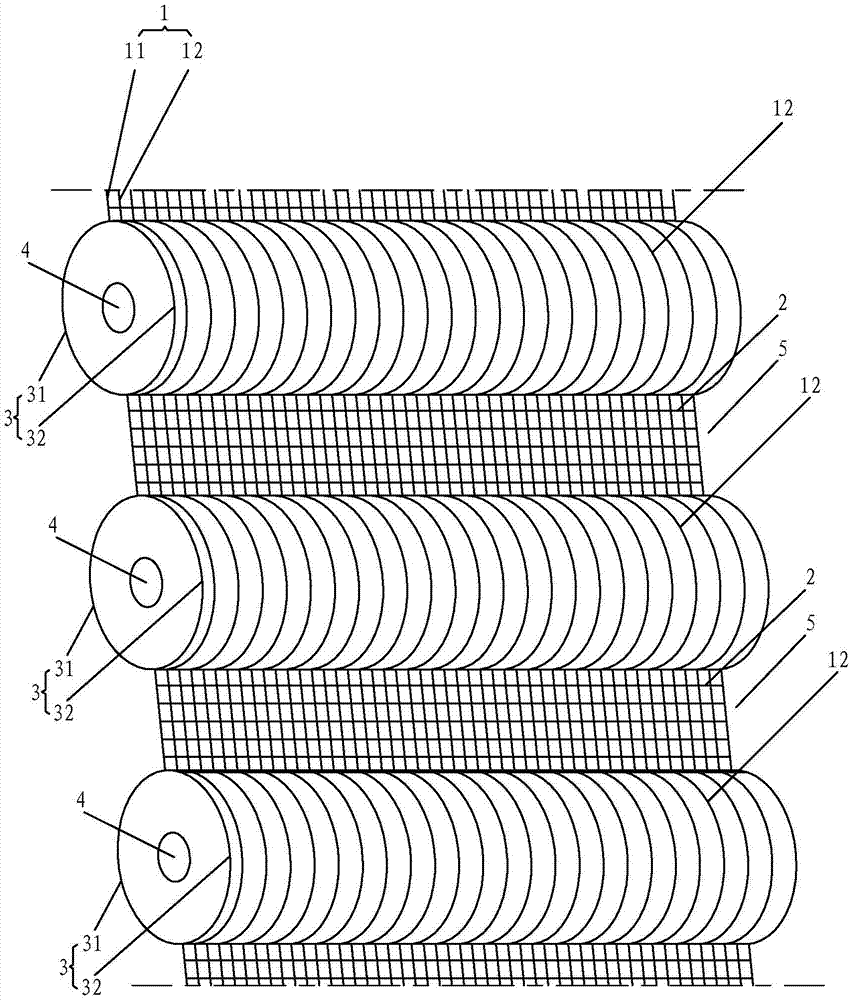

Third-dimensional tatting air layer suede fabric

InactiveCN107503020AStrong cashmerePlushOrnamental textile articlesMulti-ply fabricsEngineeringAir layer

The invention provides a third-dimensional tatting air layer suede fabric which comprises warp and weft. The warp and the weft form a plurality of fabric cylinders extending in the warp or weft direction. The fabric cylinders are filled with fabric filler. Accordingly, the structural mode of a traditional suede fabric is broken through, the front face has the obvious third-dimensional effect, the fabric is compact, the back face has the high suede sense, the third-dimensional effect is achieved, the middle adopts a hollow fabric cylinder formed by beating-up filling of the front face and the back face, the hollow fabric cylinder is filled with filer to form an air layer fabric, and the filler achieves the important supporting effect of ensuring existence of the fabric cylinder structure and forming the third-dimensional effect. Compared with the prior art, the third-dimensional tatting air layer suede fabric has the remarkable third dimension and suede sense and is compact, good in heat preservation and elasticity, simple in technology, firm in structure, novel and reasonable in structure and high in practicability.

Owner:FUJIAN SUNTION TEXTILE SCI & TECH

A fiber-opening process for modal woven fabrics

InactiveCN103952917BSoft touchStrong cashmereBiochemical fibre treatmentDry-cleaning apparatus for textilesFiberPulp and paper industry

The invention relates to a process for opening fibers of modal woven fabrics, which comprises the following process steps: using enzymes, desizing agents, scouring agents and penetrating agents to cold pile gray fabrics, washing with water and presetting; Pressure spraying treatment is carried out in the tank, the water level is selected to be controlled between 3.5~4.5 tons, and the bath ratio is 1:15~20; add sulfuric acid to the auxiliary tank to dilute and stir evenly, then slowly add it to the above-mentioned machine tank, heat up, and keep warm for pickling; the pickled fabric is then washed with water and neutralized with soda ash to obtain the fabric after opening. The opening fabric prepared by this process overcomes the shortcomings of the prior art and can make the cloth surface The impurity wool on the hairiness is removed cleanly, and the fabric feels soft and has a strong velvet feel. This process is simple and easy, and realizes the simultaneous progress of hair removal and fiber opening.

Owner:HANGZHOU XINSHENG PRINTING & DYEING

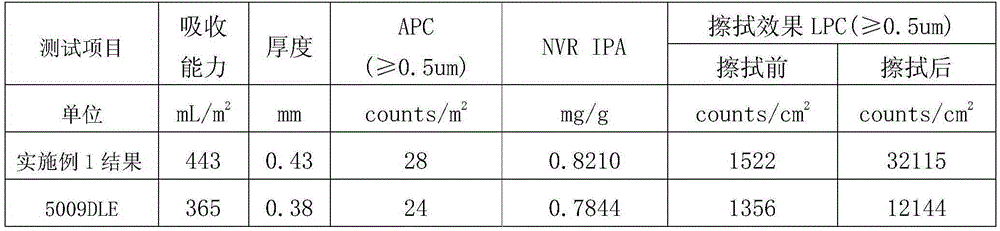

A kind of high-shrinkage and high-efficiency dust-free dust-free cloth and its production method

ActiveCN104074043BGood fiber opening effectFine clothFibre typesDry-cleaning apparatus for textilesPolyesterYarn

The invention provides a production method of dustless cloth with high shrinkage and high dust removing efficiency as well as the produced dustless cloth. The production method comprises the following main steps: polyester / nylon superfine fiber yarns are woven to gray cloth by using a knitting machine; the gram weight of the produced gray cloth is 130-180 g / m2; the gray cloth is poured in a dye vat by the bath ratio of 1: 5-7; penetrating agent, sodium hydroxide, EDTA-4Na and degreasing agent are added in the dye vat; the gray cloth is cleaned in a manner of discharging while washing; acetic acid is added for cleaning again; splitting agent is added for treating, and the cleaning is performed; soaping agent is added; and the gray cloth is cleaned again in the manner of discharging while washing. According to the production method of the dustless cloth with high shrinkage and high dust removing efficiency provided by the invention, the produced dustless cloth has excellent absorbability and good dust and dirt removing effect.

Owner:河源市锦扬新材料有限公司

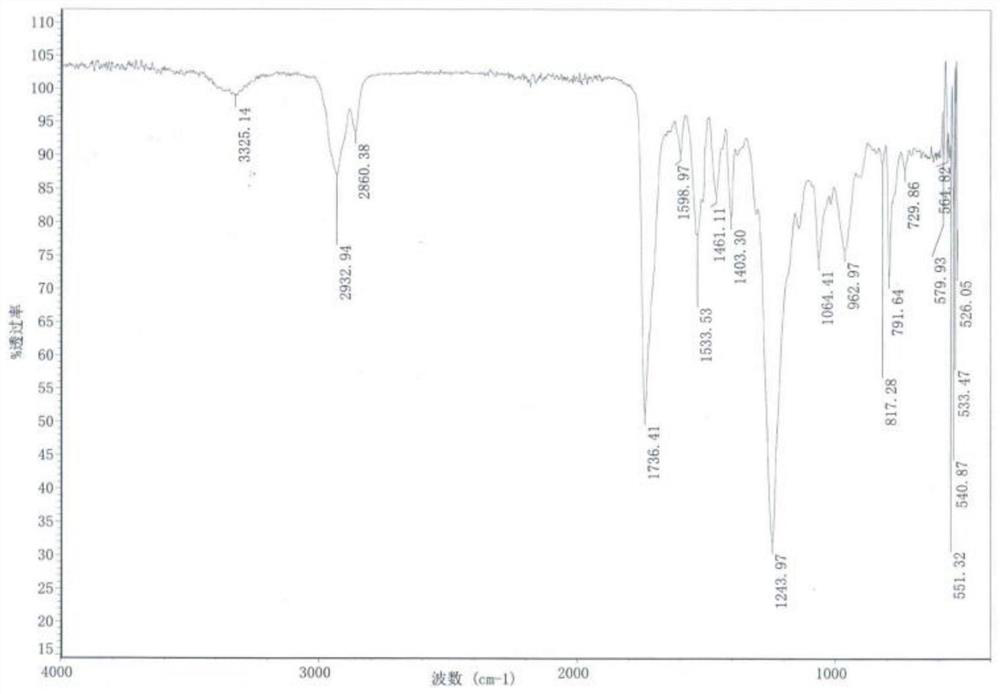

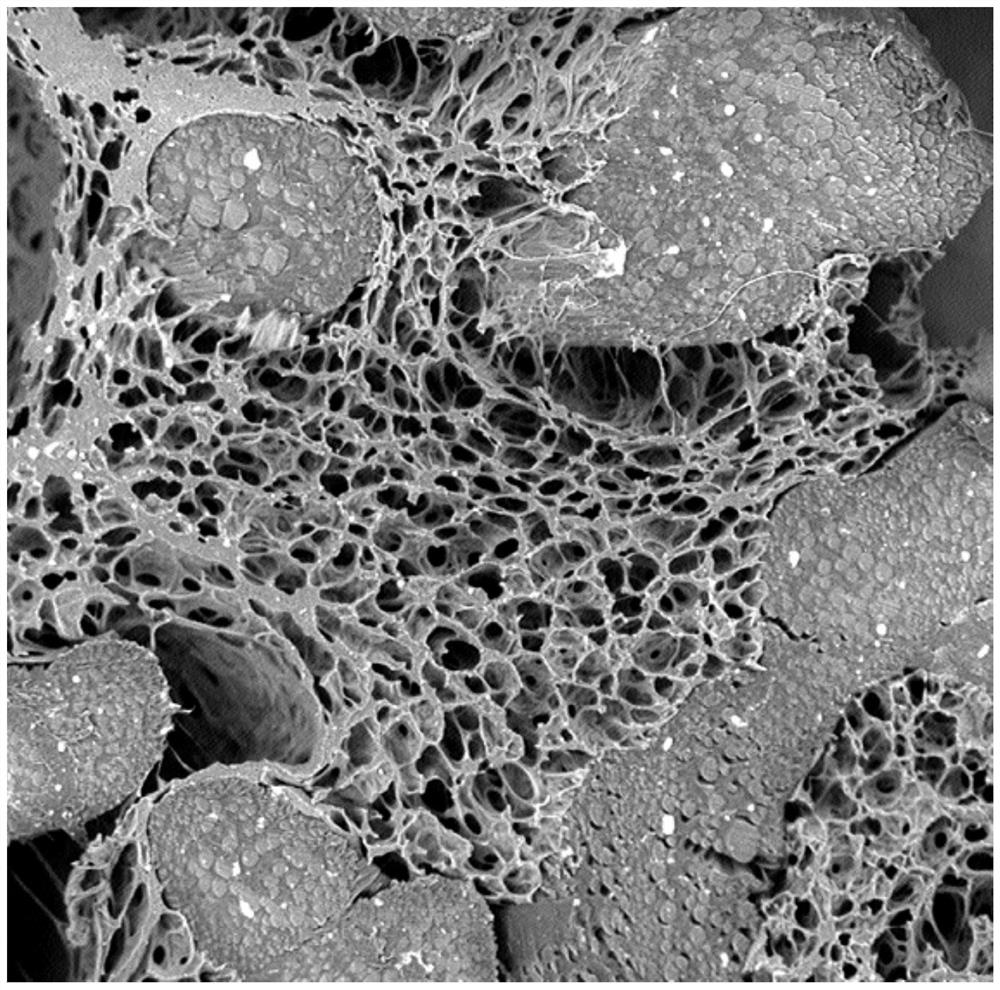

Weather-resistant island-and-island fiber base fabric and preparation method and application thereof

ActiveCN110952335BHigh color fastnessStrong cashmereFibre typesNon-woven fabricsPolyesterEnvironmental engineering

The invention discloses a weather-resistant island-setting sea-island fiber base fabric and a preparation method and application thereof. The weather-resistant island-setting sea-island fiber base fabric is prepared from the following components in parts by weight: polyester·90-60 parts, weather-resistant polyurethane resin·10-40 parts, the invention has a very good release structure, so that the microfiber base cloth has very excellent velvet feeling and fleshy feeling. At the same time, due to the introduction of urea group and aliphatic structure, the weather resistance of the product is greatly improved compared with conventional products, and the color fastness of the base fabric is high. Water waste. Described weather-resistant polyurethane resin is the polymer with structural segment shown in formula (1):

Owner:HUAFON MICROFIBER SHANGHAI

Waterproof and vapor-permeable superfine fiber suede and its preparation method and application

Owner:HUAFON MICROFIBER SHANGHAI

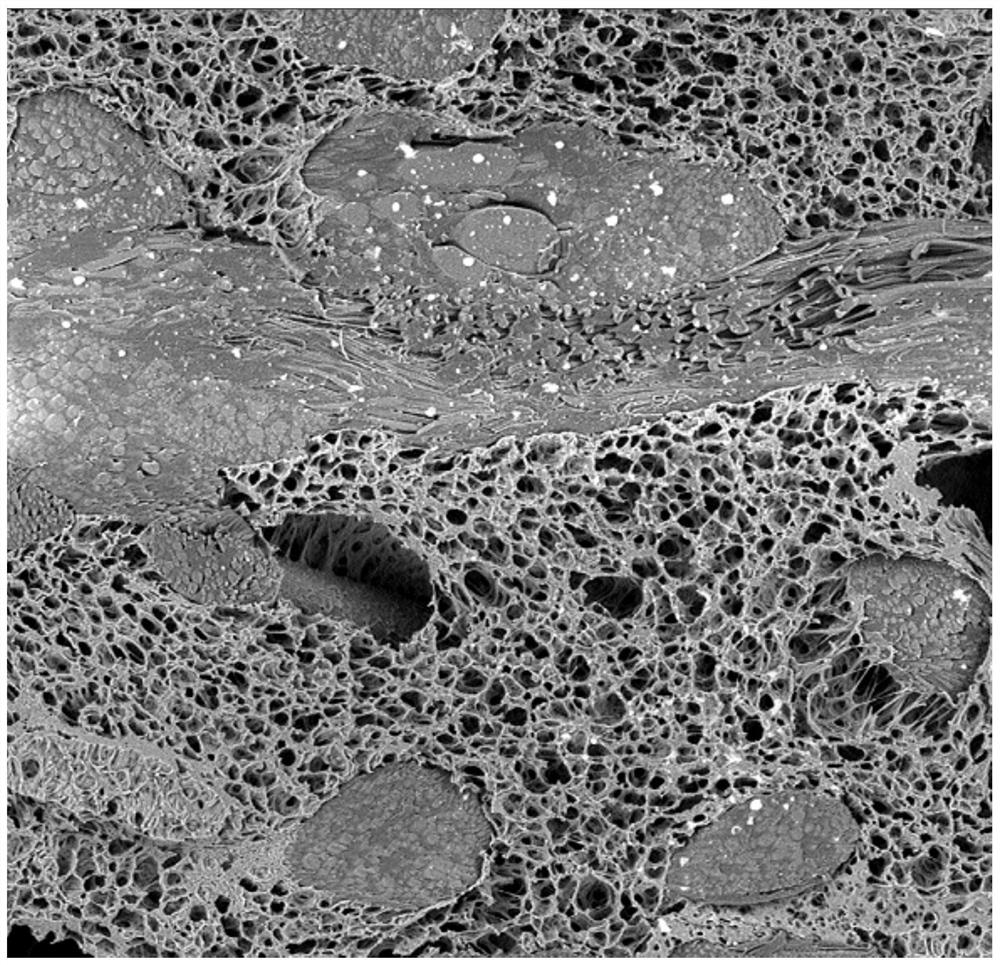

Sea-island ultrafine fiber, polyurethane leather and base fabric thereof and preparation method

ActiveCN101787586BFeel goodUniform feelFilament/thread formingTextile/flexible product manufactureLow-density polyethylenePolymer science

The invention discloses a sea-island ultrafine fiber, polyurethane leather and base fabric thereof and preparation method. The sea-island ultrafine fiber is composed of sea component and island component; wherein the sea component is low density polyethylene, the island component is polycaprolactam, and the mass ratio of the sea component and the island component is 70:30 to 75:25. The preparation method includes that the sea-island ultrafine fiber is composed of the components by the mass ratio and is prepared by conventional technology. The polyurethane leather and base fabric thereof related by the invention are all prepared by the sea-island ultrafine fiber of the invention, and conventional preparation technology is adopted. The sea-island ultrafine fiber of the invention can recyclerelated sea phase material and reduce production cost when being used for preparing polyurethane leather and base fabric thereof.

Owner:HUAFON MICROFIBER SHANGHAI

Color fixed island composite short fiber and preparation method thereof

ActiveCN102650081BColorfulUniform colorFilament/thread formingConjugated synthetic polymer artificial filamentsLow-density polyethyleneCarding

The invention provides a color fixed island composite short fiber and a preparation method thereof. The color fixed island composite short fiber comprises the following components by weight: 25-60 percent of low density polyethylene, 30-70 percent of nylon (6), 0.01-25 percent of nylon base coloring master batch and 0-4 percent of compatilizer. Compared with the prior art, the number of the islands of the color fixed island composite short fiber is fixed, as well as the size and the distribution of the short fiber are regular; color super-fine fiber synthetic leather prepared by adopting the preparation method has the advantages of bright and uniform color, high color fastness, no color difference between different batches, uniform carding, strong woolen sensation, high abrasion resistance, easiness in removing of dust after leather abrading, low probability of dust dropping during friction and the like; and besides, high energy consumption and high pollution dyeing process is simplified, and the preparation cost is reduced to a great extent.

Owner:HUAFON MICROFIBER SHANGHAI

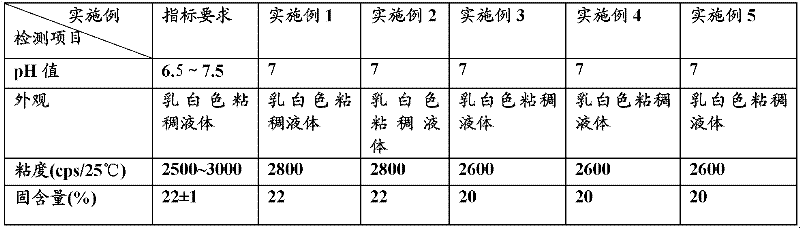

Velvet finishing agent for synthetic leather and preparation method thereof

The invention relates to a velvet finishing agent for synthetic leather and a preparation method thereof. The velvet finishing agent consists of the following raw materials in parts by weight: 80-120 parts of polyurethane resin, 3-10 parts of dry smooth wax powder, 2-8 parts of silicon dioxide extinction powder, 6-15 parts of glass microspheres with particle size of 5-60 microns, 1-6 parts of epoxidized soybean oil, 1-6 parts of phenmethyl silicon oil, 1-6 parts of plasticizer, 30-60 parts of dimethylformamide, 30-50 parts of butyl acetate, 20-40 parts of methylal and 20-40 parts of dimethylbenzene. The velvet finishing agent for synthetic leather provided by the invention has low cost and good velvet feel, can be used through multiple technologies such as roller painting, printing and the like, and is widely applicable. In the invention, a preparation technology of uniformly dispersing before grinding and filtering is adopted, and the prepared finishing agent can obtain more delicatevelvet feel; and moreover, as the yangbuck powder requiring accurate temperature control and long-time foaming is not used, the preparation is easier.

Owner:SUZHOU DEERUN COMPOSITE MATERIALS

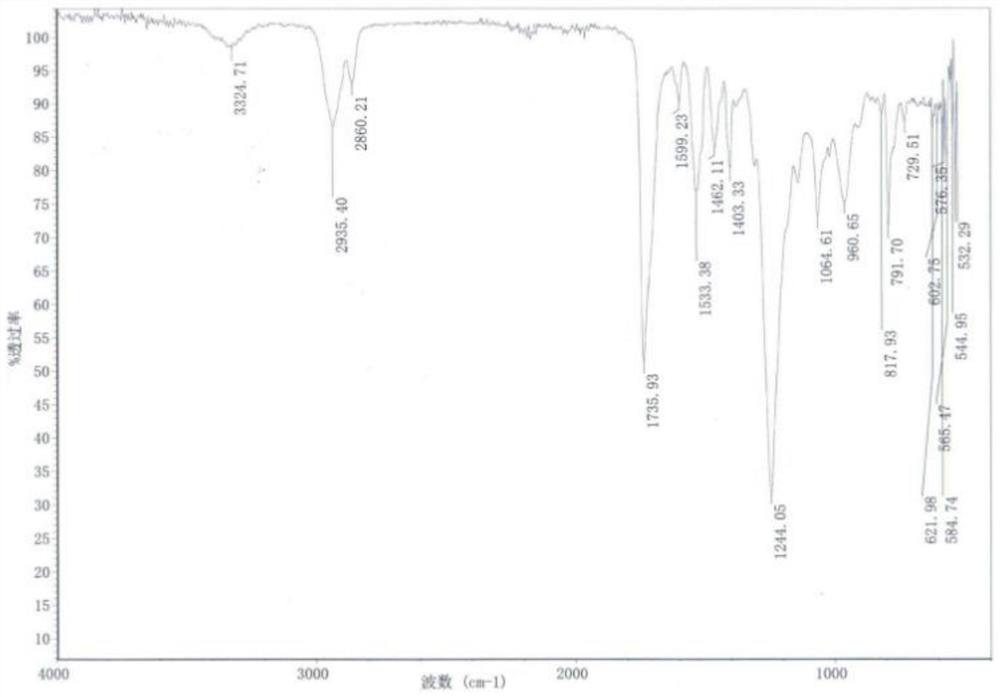

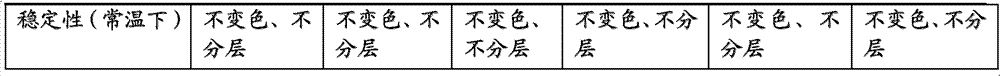

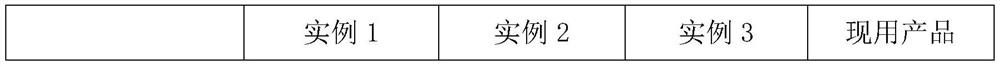

Polyurethane resin for waterproof vapor permeable leather and preparation method thereof

The invention discloses a polyurethane resin for waterproof and vapor-permeable leather and a preparation method thereof. The ratio of moles of polyol A and polyol B to polyol A and polyol B is 1.5:1 to 5:1; the moles of terminator are the moles of diisocyanate to moles of polyol A, polyol B and chain extender 2 times of the difference; the amount of solvent used is 65% to 80% of the total weight of polyol A, polyol B, diisocyanate, chain extender, terminator and solvent. The invention has excellent hydrophobicity, and at the same time ensures that the resin part forms a three-dimensional interpenetrating hole structure during the wet solidification process, and the diameter of the hole is small, allowing water vapor to easily pass through; when used in superfine fiber suede, it has very excellent suede Sensitive, sensual, production has the characteristics of simple and easy operation.

Owner:HUAFON MICROFIBER SHANGHAI

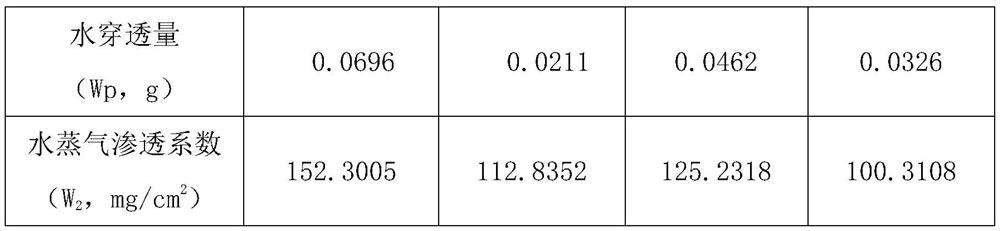

Dyeing and finishing method for fabric made from heat-absorbing and exothermic material

ActiveCN105256603BFeel comfortable and softNo more hair loss problemsHeating/cooling textile fabricsDry-cleaning apparatus for textilesYarnEngineering

Disclosed in the present invention is a dyeing and finishing method for manufacturing fabric by using a heat absorbable heating material. The method comprises the following specific steps: dyeing processing, softening, drying, raising and finished-product forming. In this way, according to the dyeing and finishing method for manufacturing fabric by using a heat absorbable heating material provided in the present invention, yarns are directly modified, a skin-core structure is selected, heat is continuously absorbed and released by means of sunlight adjustment, the heat balance of the body is implemented, the warmth retention effect is good, and the dyeing defect problem can also be well resolved; meanwhile, by means of a special wool drawing, wool cutting and fleece process as well as twice raising, the hand feeling warmth of the fabric is ensured, and the velvet feeling is strong, so that the handle of the fabric is more comfortable and softer, and the wool dropping problem of the surface of the fabric does not occur.

Owner:JIANGSU XINKAISHENG ENTERPRISE DEV

A kind of sheath-core structure modal fiber raising fiber opening agent and preparation method thereof

The invention relates to a splitting agent and a preparation method thereof and discloses a modal fiber napping splitting agent with a skin-core structure and a preparation method of the modal fiber napping splitting agent. The modal fiber napping splitting agent with the skin-core structure is prepared from components in percentage by mass as follows: 20%-40% of organic phosphonic acid, 10%-20% of p-toluenesulfonic acid, 5% of polymeric polyacrylic acid and the balance of deionized water. The modal fiber napping splitting agent has the advantages and effects as follows: not only can the napping splitting purpose be achieved, but also little influence is produced on strength of fabric, and a machine cylinder cannot be damaged.

Owner:绍兴海成化工有限公司

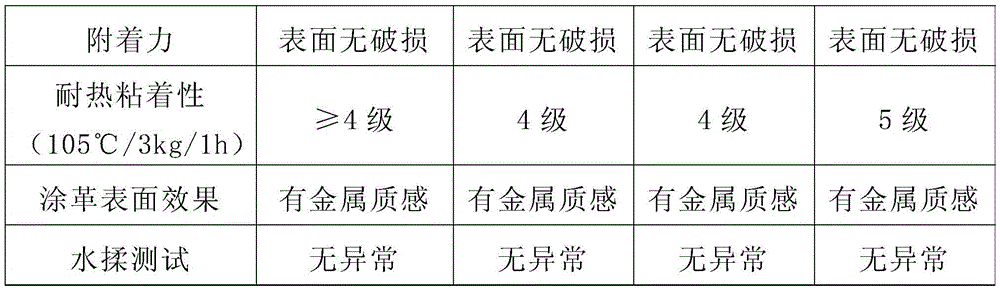

Water-based treatment agent for metal texture mist washing and brightening and preparation method thereof

The invention discloses a metallic fog-brightening water based treatment agent and a preparation method thereof. The preparation method comprises the steps: adding a wetting dispersant and a defoaming agent into waterborne polyurethane resin for mixing and stirring; then adding extinction powder and polytetrafluoroethylene wax powder, performing high-speed stirring for 20 minutes, adding a cosolvent, a wetting leveling agent and water, uniformly stirring the materials and performing filtration; adding a thickening agent into a mixture obtained by filtration, and adjusting the viscosity to 800-1,500 cps to obtain the metallic fog-brightening water based treatment agent. The metallic fog-brightening water based treatment agent disclosed by the invention is extremely high in haze and blackness; after being washed in water, the bottom of a trench and the top of leather are obviously different in glossiness, certain layering impression and high flocking impression are achieved; due to vision observation, the surface of the leather has a certain metallic color, so that the color is natural and soft. The product is prepared from a waterborne material, is safe and non-toxic and is a green and environment-friendly treatment agent.

Owner:LANZHOU SCISKY AQUEOUS POLYMER MATERIAL CO LTD

Regenerated polyester chenille yarn, manufacturing method and manufacturing method of regenerated polyester chenille yarn blanket

The invention discloses recycled polyester chenille yarn. The recycled polyester chenille yarn is obtained through plying of recycled DTY low-elastic interlaced yarn and recycled polyester plied yarn. The invention also discloses a manufacturing method of the recycled polyester chenille yarn. The invention further provides a method for manufacturing a recycled polyester chenille yarn blanket. The method for manufacturing the recycled polyester chenille yarn blanket comprises the steps of preparing the recycled polyester chenille yarn, and weaving the recycled polyester chenille yarn blanket from the recycled polyester chenille yarn in corresponding thickness. The spun recycled polyester chenille yarn is excellent in velvet feel, mellow and full, and not prone to lint falling. The recycled polyester chenille yarn is made from the PET waste material, waste material recycling is promoted, environment friendliness is realized, petroleum resources are saved, waste material treatment difficulty is reduced, and market prospects are broad. The manufactured recycled polyester chenille yarn blanket has a strong stereoscopic sense, a rich color, excellent elasticity and an excellent drape effect and is tolerant to machine washing.

Owner:常州英诺威家居用品有限公司

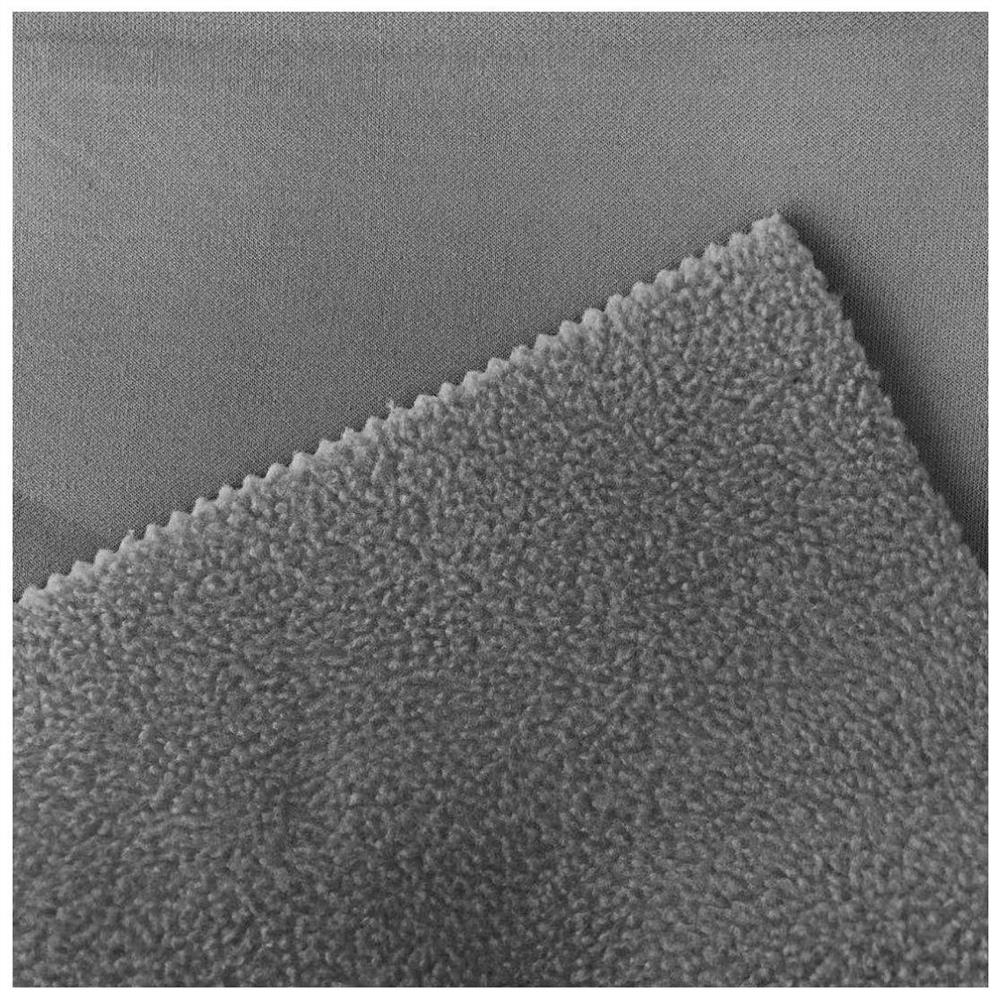

A kind of weft-knitted sandwich polar fleece fabric, gray cloth and production method thereof

The inventor provides a kind of production method of weft-knitted sandwich polar fleece gray cloth and cloth thereof, and described weft-knitted sandwich polar fleece gray cloth comprises upper surface, middle layer and lower surface; Described weft-knitted sandwich polar fleece gray cloth adopts weft Double-sided jacquard knitting machine 8-needle circular weaving; the dial and needle cylinder of the weft-knitting double-sided jacquard machine both adopt the needle arrangement of 12121212; wherein, the triangle configuration is as follows: ∪∨───∨──── ∨─∪─∨────∧∩──∧∩──∧───∧; wherein, the D values of the 3rd and 7th yarns are greater than the D values of the 2nd and 6th yarns. Different from the prior art, the technical solution above forms raised areas woven with thick yarns and non-fluffed areas woven with thin yarns arranged at intervals on the upper surface of the polar fleece fabric. After the structure is fluffed, the polar fleece fabric can be made more fluffy as a whole, has a strong fleece feeling, has good warmth retention property, and has a thicker fabric body, so that the service life can be increased.

Owner:FUJIAN HUAFENG NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com