Polyurethane resin for waterproof vapor permeable leather and preparation method thereof

A technology for polyurethane resin and leather, applied in the field of polyurethane resin, can solve the problems of no waterproof effect and decreased vapor permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

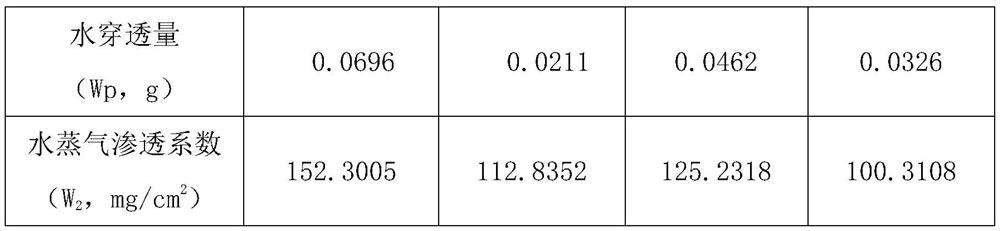

Embodiment 1

[0025] (1) Polybutylene adipate diol (0.05mol), polytetrahydrofuran ether diol (0.05mol), double-terminal hydroxyl long-chain alkyl silicone oil (0.01mol), solvent N,N-dimethyl Mix formamide (100ml), add 4,4'-diphenylmethane diisocyanate (0.088mol), and react at 75°C until the content of isocyanate groups is constant;

[0026] (2) Add ethylene glycol (0.23mol), N,N-dimethylformamide (80ml), add 4,4'-diphenylmethane diisocyanate (0.224mol), react at 75°C for 1 hour, add solvent Add 4,4'-diphenylmethane diisocyanate (0.032mol) to N,N-dimethylformamide (194ml), and stop adding when the viscosity reaches 120Pa·s (25°C). Methanol (0.003mol) was added to stop the reaction, and after 30 minutes, the temperature was lowered to 50°C and the material was discharged to obtain the polyurethane resin with a solid mass fraction of 30%.

Embodiment 2

[0028] (1) Polyhexamethylene adipate diol (0.08mol), polypropylene glycol (0.02mol), double-ended hydroxyl long-chain alkyl silicone oil (0.003mol), double-ended hydroxyl polytrifluoropropylmethylsilane Put oxane (0.002mol) and solvent N,N-dimethylformamide (100ml) into the reaction flask, mix well, put in 4,4'-diphenylmethane diisocyanate (0.08mol), react at 75°C until Constant isocyanate group content;

[0029] (2) After the prepolymerization is completed, add ethylene glycol (0.316mol), solvent N,N-dimethylformamide (80ml), add 4,4'-diphenylmethane diisocyanate (0.32mol), 75°C React for 1 hour, add the remaining solvent N,N-dimethylformamide (210g), continue to add 4,4'-diphenylmethane diisocyanate (0.02mol), the viscosity rises to 100Pa·s (25°C ) viscosity, stop adding. Methanol (0.003mol) was added to stop the reaction, and after 30 minutes, the temperature was lowered to 50°C and the material was discharged to obtain the polyurethane resin with a solid mass fraction of...

Embodiment 3

[0031] (1) Polybutylene adipate diol (0.04mol), polytetrahydrofuran ether diol (0.06mol), double-ended hydroxyl long-chain alkyl silicone oil (0.006mol), double-ended hydroxyl polytrifluoropropyl Add methylsiloxane (0.002mol) and solvent N,N-dimethylformamide (100ml) into the reaction flask, mix well, add 4,4'-diphenylmethane diisocyanate (0.339mol), and heat at 75°C Reaction until the isocyanate group content is constant;

[0032] (2) After the prepolymerization is completed, add ethylene glycol (0.271mol), solvent N,N-dimethylformamide (80ml), add 4,4'-diphenylmethane diisocyanate (0.272mol), 75°C React for 1 hour, add the remaining solvent N,N-dimethylformamide (200g), continue to add 4,4'-diphenylmethane diisocyanate (0.016mol), the viscosity rises to 80Pa·s (25°C) When viscosity is reached, stop adding. Methanol (0.003mol) was added to stop the reaction, and after 30 minutes, the temperature was lowered to 50°C and the material was discharged to obtain the polyurethane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com