Polyurethane nubuck resin for high-resilience and high-fleece garment leather and preparation method thereof

A high-resilience, clothing leather technology, applied in textiles and papermaking, etc., can solve the problems of insufficient velvet feel, limited application, poor elasticity, etc., and achieve the effect of strong velvet feel, uniform cells, and high resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

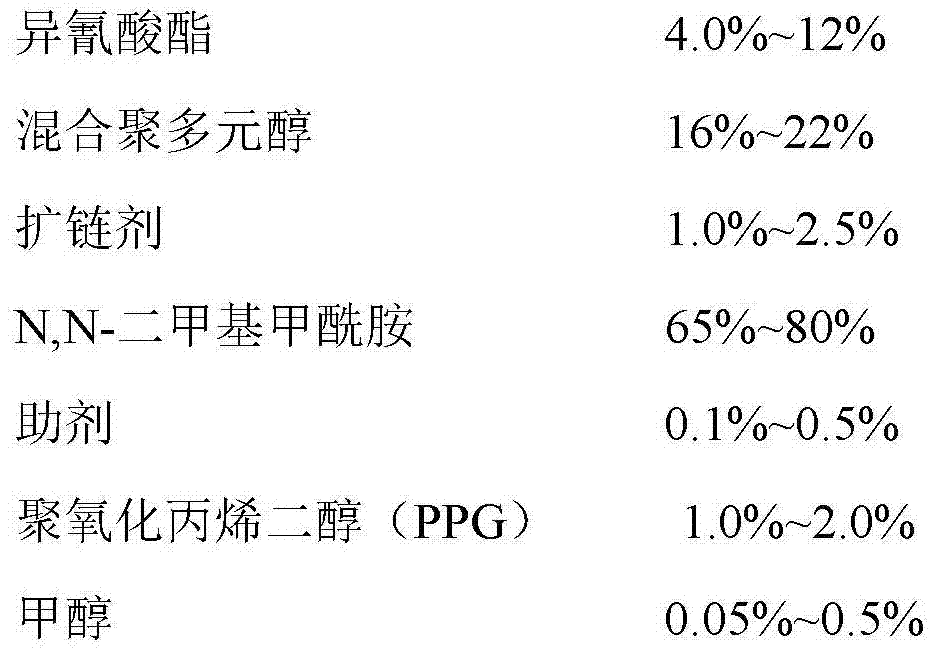

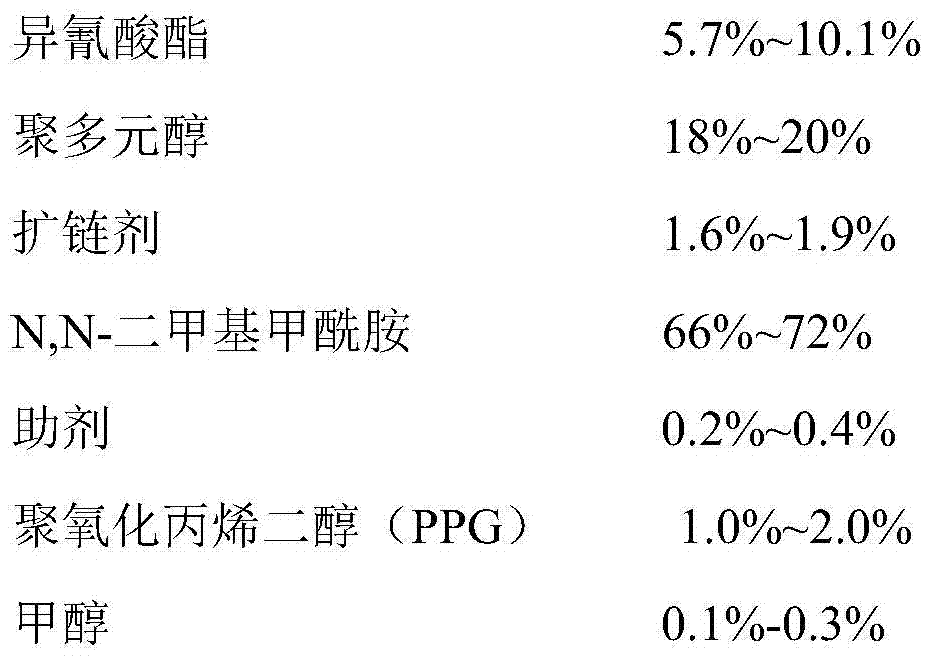

Method used

Image

Examples

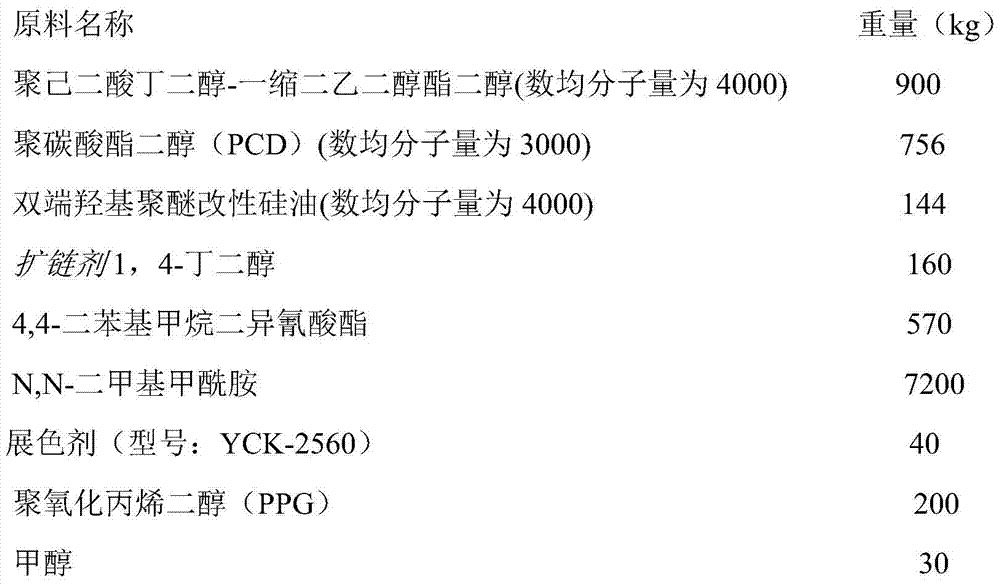

Embodiment 1

[0027]

[0028] Add 900kg of polybutylene adipate-diethylene glycol ester diol, 64kg of 1,4-butanediol, 798.7kg of dimethylformamide and 234kg of 4,4-diphenylmethane diisocyanate into the reaction The prepolymerization reaction was carried out in the kettle, and the reaction temperature was controlled at 70°C. After 3.0 hours of reaction, when the viscosity of the reaction solution reached 60Pa·s / 70°C, 756kg of polycarbonate diol (PCD) and double-terminated hydroxyl polyether were added to modify the reaction solution. 144kg of silicone oil, 64kg of 1,4-butanediol and 6401.3kg of N,N-dimethylformamide, after 40 minutes of reaction, 336kg of 4,4-diphenylmethane diisocyanate was added for chain growth reaction, and the viscosity of the reaction liquid reached 200Pa At s / 25°C, 30kg of methanol was added for capping, and at the same time, 40kg of vehicle and 200kg of polyoxypropylene glycol (PPG) were added to obtain polyurethane nubuck resin for garment leather with high resili...

Embodiment 2

[0030]

[0031] Add 1560kg of polybutylene adipate-diethylene glycol ester diol, 76kg of ethylene glycol, 1425kg of dimethylformamide and 501.5kg of 4,4-diphenylmethane diisocyanate into the reactor for pre-treatment. Polymerization reaction, the reaction temperature is controlled at 80°C, and after 2.0 hours of reaction, when the viscosity of the reaction solution reaches 80Pa·s / 70°C by sampling, add 360kg of polycarbonate diol (PCD), 80kg of double-terminated hydroxyl polyether modified silicone oil, and Diol 114kg and N,N-dimethylformamide 5245kg, after 20 minutes of reaction, add 4,4-diphenylmethane diisocyanate 508.5kg for chain growth reaction, measure the viscosity of the reaction solution when it reaches 280Pa·s / 25℃, add methanol 10kg end-capping, add color vehicle 20kg and polyoxypropylene glycol (PPG) 100kg simultaneously, obtain the polyurethane nubuck resin for clothing leather with high resilience and high cashmere feeling.

Embodiment 3

[0033]

[0034] Add 1200kg of polybutylene adipate-diethylene glycol ester diol, 68kg of ethylene glycol, 1078.1kg of dimethylformamide and 349.2kg of 4,4-diphenylmethane diisocyanate into the reaction kettle For prepolymerization, the reaction temperature is controlled at 70°C. After 3.0 hours of reaction, when the viscosity of the reaction liquid reaches 70Pa·s / 70°C, add 720kg of polycarbonate diol (PCD), 80kg of double-terminated hydroxyl polyether modified silicone oil, 102kg of ethylene glycol and 5706.9kg of N,N-dimethylformamide, reacted for 30 minutes, then added 505.8kg of 4,4-diphenylmethane diisocyanate to carry out the chain extension reaction, when the viscosity of the reaction solution reached 240Pa·s / 25℃ Add methyl alcohol 10kg capping, add color vehicle 30kg and polyoxypropylene glycol (PPG) 150kg simultaneously, obtain the polyurethane nubuck resin for clothing leather with high resilience and high velvet feel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com