Machine washable snow-velvet and its preparation process

A silk velvet, production process technology, applied in biochemical fiber treatment, dyeing, textiles and papermaking, etc., can solve problems such as bulkiness, poor elasticity, poor directionality, poor pilling resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

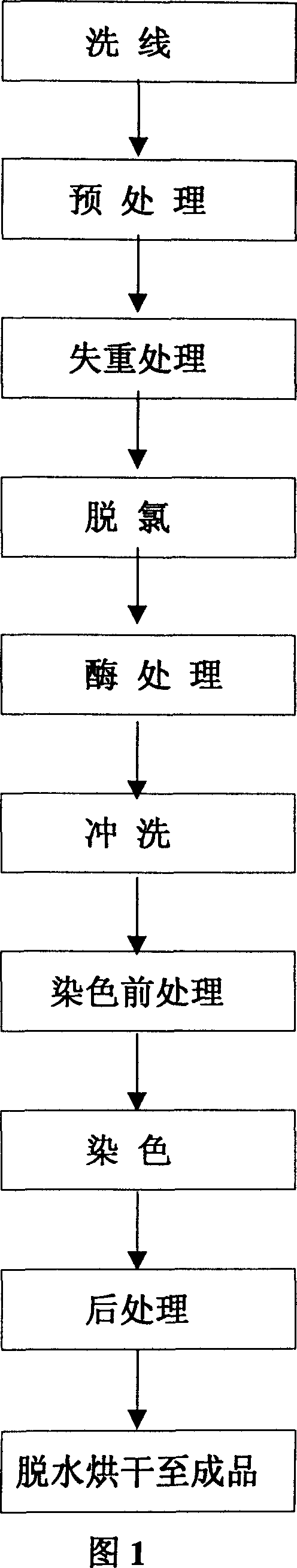

[0061] As shown in Figure 1, the production process of the machine washable Silk fleece of the present invention, the technological process is as follows:

[0062] (1) Washing line:

[0063] Use 64 S The yarn count spun from the above wool is 16 s 100 kilograms of raw wool yarn is put into the dyeing vat of Y600 open-door wool dyeing machine. The capacity of Y600 is 200 kilograms, and the optimum processing capacity is 120 kilograms of wool yarn. Add water to the water level, add 2 kilograms of non-ionic lotion 105 for washing, and control the temperature at 40°C, wash the thread for 15 minutes, then rinse, lighten the water, and control the oil content below 0.5%;

[0064] (2) Pretreatment:

[0065] Use additives to reduce the surface tension of wool, so that sodium dichloroisocyanurate, etc. can easily enter the scale layer, the outer layer of cutin, and the cortex to the intercellular substance. In addition, use acylated phthalein and its derivative wool protectant to ma...

Embodiment 2

[0095] 1) Washing line:

[0096] Use 70 S The yarn count spun from wool is 26 s Put 100 kg of yarn into the dyeing vat of Y600 open-door wool dyeing machine. The capacity of Y600 is 200 kg, and the optimal processing capacity is 120 kg. Water is added to the water level, and non-ionic lotion JU is added for washing. The dosage is equivalent to that of wool yarn The percentage of billet weight is 4.5%, the temperature is controlled at 48-50°C, the thread is washed for 15-20 minutes, then rinsed, the water is lighted, and the oil content is controlled below 0.5%;

[0097] (2) Pretreatment:

[0098] Soak the washed woolen yarn to the water level, add 4 kilograms of penetrating agent JFC and 14 kilograms of acylated phthalein derivative colloid protective agent respectively in water (this derivative is that the second carbon position in the acylated phthalein structure increases a hydroxyl group, Add a hydroxyl amino group to its ortho position), then adjust the pH value to wea...

Embodiment 3

[0126] (1) Washing line:

[0127] Use 80 S Wool spun yarn count 32 s Put 60 kg of raw yarn yarn into the dyeing vat of Y300 open-door wool dyeing machine. The capacity of Y300 is 100 kg. Add water to the water level, add 1.2 kg of non-ionic lotion 105 for washing, and control the temperature at 65-70 °C. 12 minutes, then rinse, lighten the water, and control the oil content below 0.5%;

[0128] (2) Pretreatment:

[0129] Soak the washed woolen yarn to the water level, add 0.9 kg of penetrant JFC and 4.8 kg of colloidal protective agent acylated phthalein to the water, then adjust the pH value to weak acidity with glacial acetic acid, control the water temperature at 25°C to 30°C, and treat for 35 ~40 minutes;

[0130] (3) Weightlessness treatment:

[0131] Then add 10 kilograms of sodium dichloroisocyanurate with a total weight of 4 times in the dye vat, and its molecular formula is C 3 Cl 2 N 3 o 3 Na, the reaction temperature is 20-25°C, measure the end point with p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com