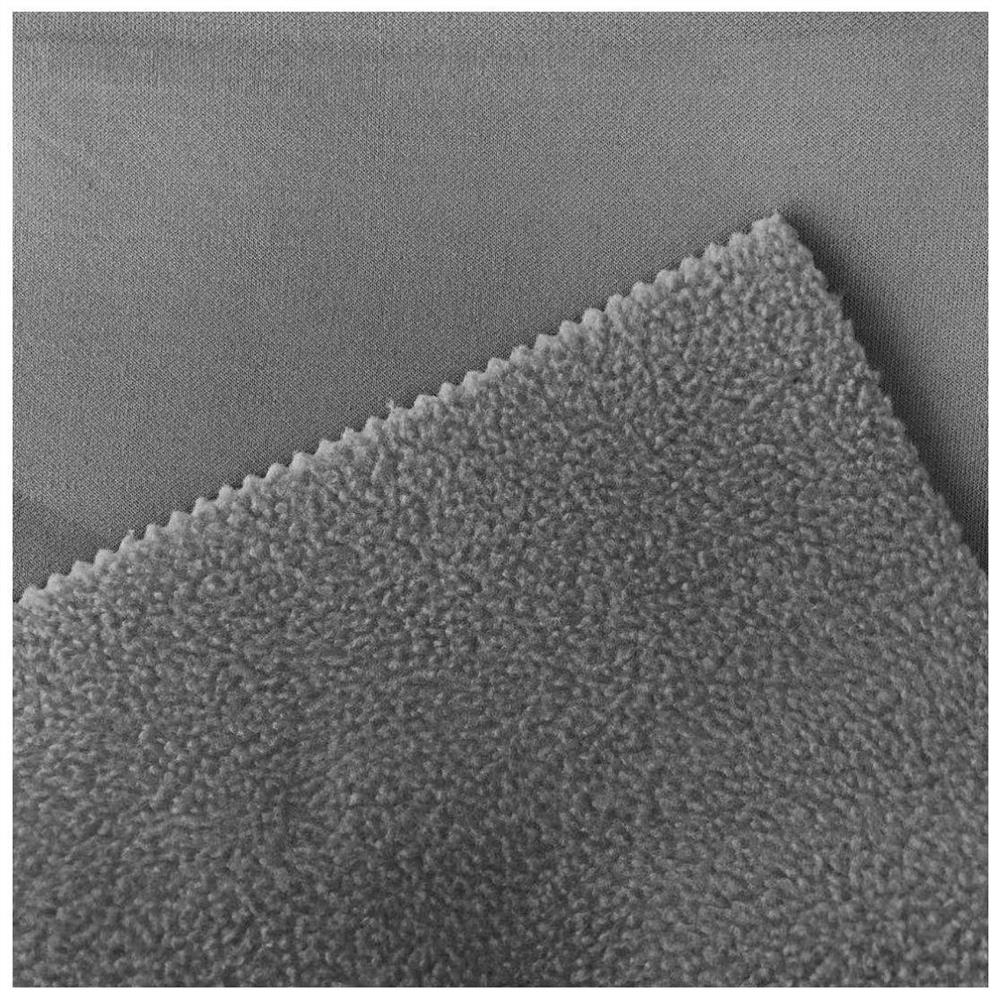

A kind of weft-knitted sandwich polar fleece fabric, gray cloth and production method thereof

A technology of sandwich polar fleece and a production method, which is applied in the directions of weft knitting, fabric surface trimming, knitting, etc., can solve the problems of short service life, thin cloth body, poor heat preservation, etc., and achieves increased service life and thicker fabric body. , good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: the production of a kind of weft-knitted sandwich polar fleece gray cloth and polar fleece fabric

[0038] Production of weft-knitted sandwich polar fleece fabric:

[0039] It is obtained by circular weaving with 8 stitches on a weft-knitting double-sided jacquard machine, and the model is 34”24G72F

[0040] The dial and the needle cylinder of the weft-knitting double-sided jacquard machine all adopt the needle row mode of 12121212;

[0041] Among them, the triangle configuration is as follows:

[0042] ∪∨───∨──

[0043] ──∨─∪─∨─

[0044] ───∧∩──∧

[0045] ∩──∧───∧;

[0046] The 1st and 5th routes use semi-white 40D / 1F polyester monofilament; the 2nd and 6th routes use semi-white 50D / 72F polyester light mesh plus 30D spandex; the 3rd and 7th routes use semi-white 150D / 288F polyester composite yarn (T-Z Burn 75D / 144F+T-S burn 75D / 144F); the 4th and 8th roads use semi-white 50D / 72F light mesh mixed with 30D spandex.

[0047] The 1st and 5th roads form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com