Patents

Literature

90results about How to "Not easy to shed hair" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

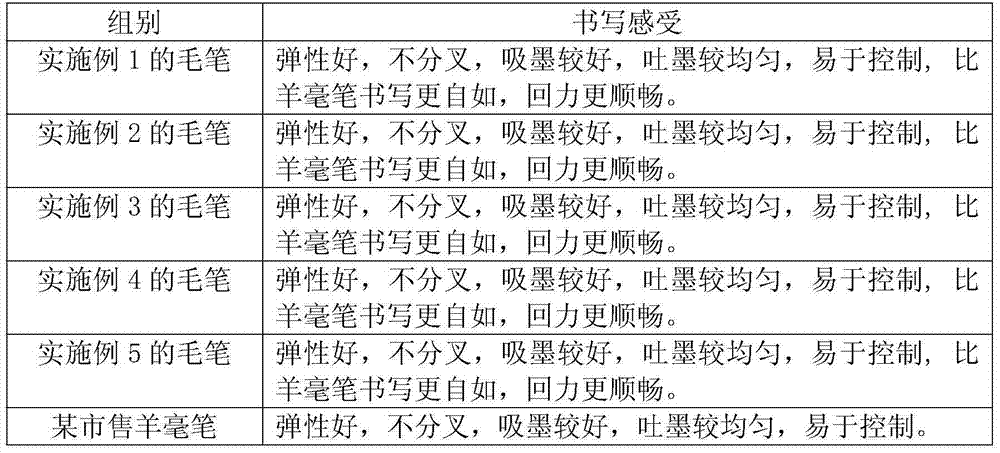

Method for producing writing brushes free of bristle falling

The invention discloses a method for producing writing brushes free of bristle falling. The method comprises the steps that (1) bristles are degreased with a high temperature ironing and pressing device; (2) the bristles are screened with a common screen primarily; (3) a bristle pile with peaks are put in an orderly way, and remaining strays are scrapped off with a dull knife; (4) the selected fine and soft bristle materials with peaks are used as raw material for producing brush tips, and the raw material of each brush tip is wrapped in a piece of paper; (5) one end of a wire is fixed, one end of the bottom of the raw material of each brush tip is held, an approximately circular shape is formed, the other end of the line penetrates through the circle along the diameter, the line is wound around the raw material by multiple circles, and after a coil of a certain weight is formed at the bottom of the brush tip, the end of the line is fixed and fastened; (6) finished writing brush tips are combed with a comb, after the brush tips are placed in glue and evenly coated with the glue, the brush tips are vertically taken up, each brush tip is bound with one line, one end of each line is held in the hand, the other end of each line is fixed, the other hand holds a brush holder, the corresponding line is pulled downward in an intersecting mode without knotting, and then the finished writing brushes are obtained after the glue is dry.

Owner:湖州南浔双颖湖笔有限公司

Wool-like all-cotton fabric and processing method thereof

ActiveCN104480613AImprove fluffiness and softnessGood warmth retentionSucessive textile treatmentsWoven fabricsYarnHair falling

The invention relates to wool-like all-cotton fabric and a processing method thereof and belongs to the field of home textiles. Both warp and weft of the wool-like all-cotton fabric is all-cotton yarn, yarn count of the yarn is 18-32s, twist factor is 350-405, fabric structure is six-variable satin weave, float of the weave is 5 weave points, step number is variable, and changing rules along the direction of interweaving points are to sequentially increase gradually and then decrease gradually. The processing method includes the following steps: weaving the warp and the weft according to the six-variable satin weave after warping, pulp sizing and palming and reeding; performing processes of singeing, desizing-scouring-bleaching, slight sanding, printing, ageing and washing, softening and shaping and pre-shrinking. By the processing method, the wool-like all-cotton fabric which is high in fluffy and soft degree, high in heat insulativity and less prone to hair falling can be formed and is especially suitable for being used as a bedding article in autumn and winter.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Multi-group color separation spinning and crocheting wool yarn and manufacturing method thereof

The invention discloses multi-group color separation spinning and crocheting wool yarn and a manufacturing method of the multi-group color separation spinning and crocheting wool yarn. The manufacturing method comprises the steps that elastic nylon or filaments are crocheted to be net-shaped yarn, drafted multi-group color separation spinning short fiber thick yarn wool tops are fed and enter false twisting hooks of hook wood ingots under the traction of the nylon filaments or the elastic filaments, 10-20 false twists are added on strands and the nylon filaments or the elastic filaments to form thick yarn to be attached to the net-shaped yarn of the nylon filaments or the elastic filaments, and the multi-group color separation spinning and crocheting wool yarn is obtained after untwisting. As the tape yarn is of a drafting type, the yarn has the advantages of being soft, fluffy, high in strength and the like, wool does not fall off easily, the yarn is applicable to sweater yarn of autumn and winter clothes, and good moisture absorption performance, the heat retention performance and the air permeability are achieved. The manufacturing method overcomes the defect that a traditional twisting machine is single in fiber mode, enriches the characteristics of multiple components of the yarn, subsequent dyeing is avoided, and the yarn is an environmentally friendly product.

Owner:JIANGSU LUGANG SCI & TECH

Shrink-proof wool core-spun yarn

The invention discloses a shrink-proof wool core-spun yarn, comprising: a core thread and a covering yarn; the core thread is a polyester thread, the covering yarn is a wool blended yarn made by twisting multiple wool fibers, cotton fibers and bamboo fibers, the wool blended yarn covers the polyester yarn, the wool fibers are special-shaped wool fibers having triangular cross section, and the cotton fibers are special-shaped cotton fibers having Y-shaped cross section. In this way, by covering the polyester core thread by using the wool blended yarn as the covering yarn with the wool blended yarn made by twisting the special-shaped wool fibers, the special-shaped cotton fibers and the bamboo fibers, the wool core-spun yarn is made which has excellent shrink-proof performance, good surface gloss, good softness and is resistant to picking and pilling.

Owner:SUZHOU WEIJIE TEXTILE

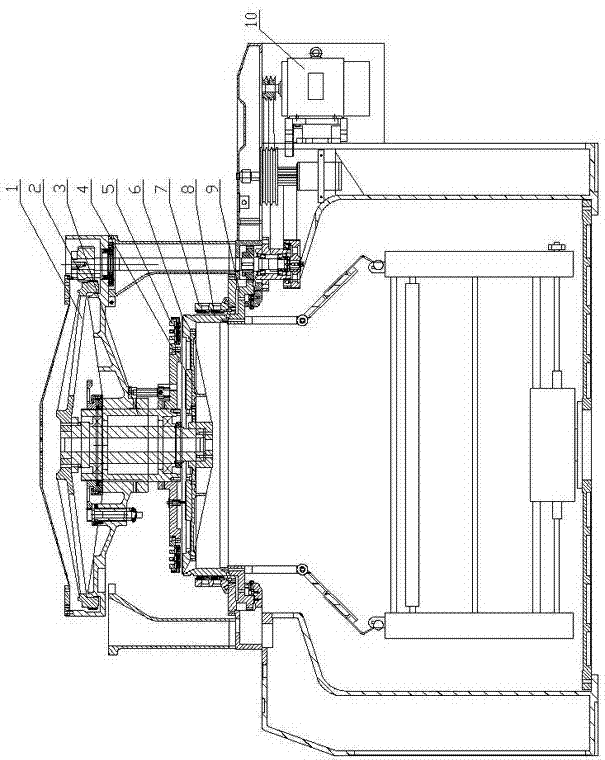

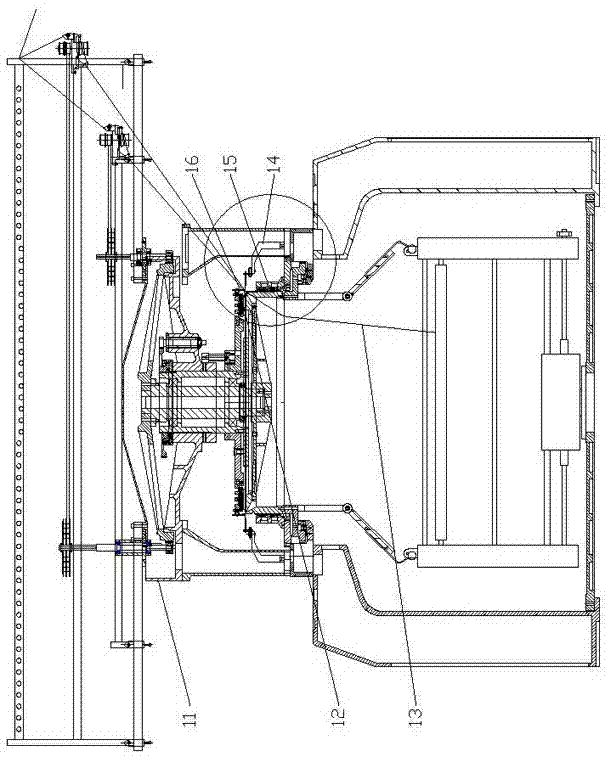

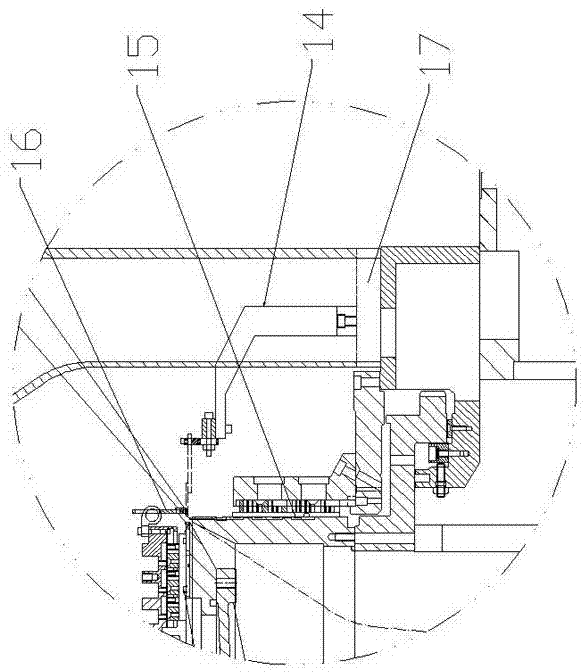

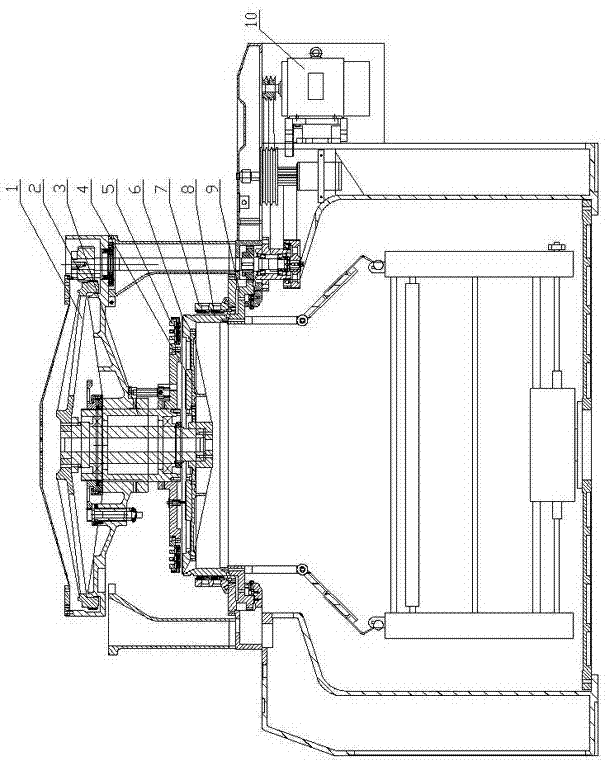

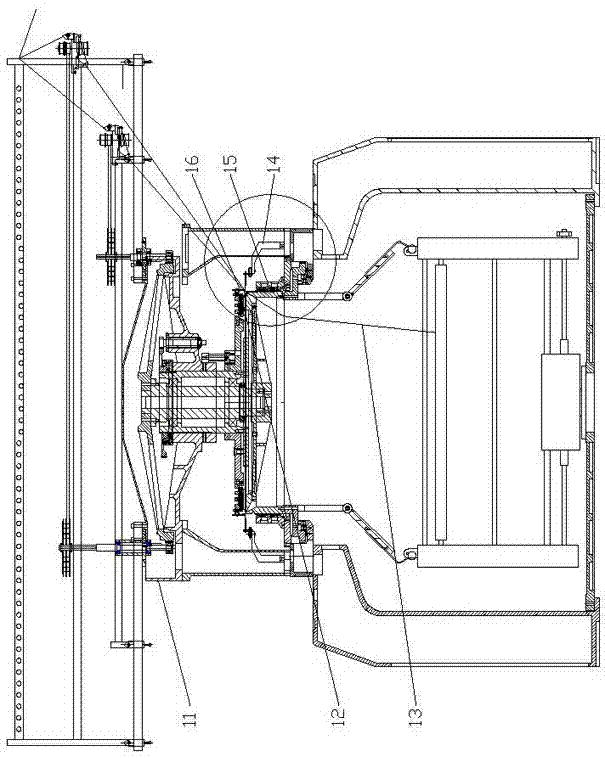

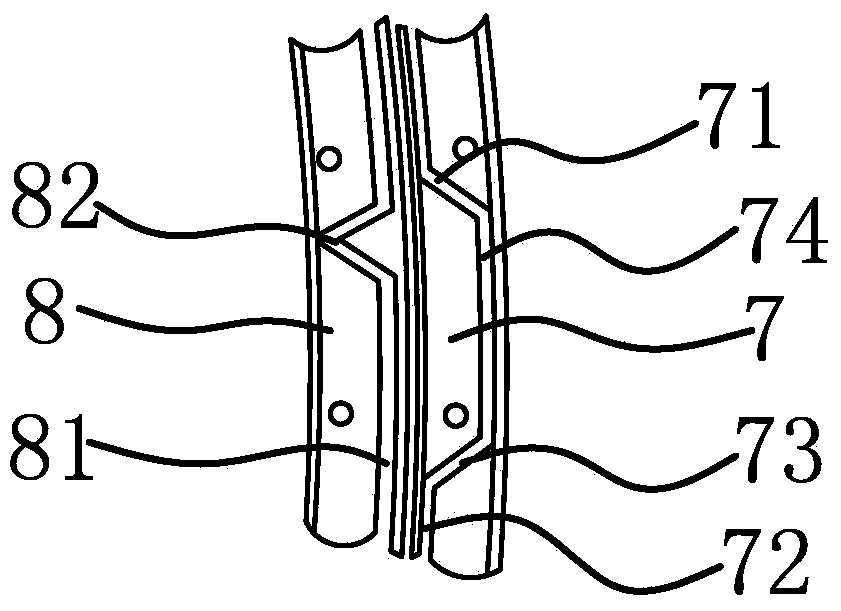

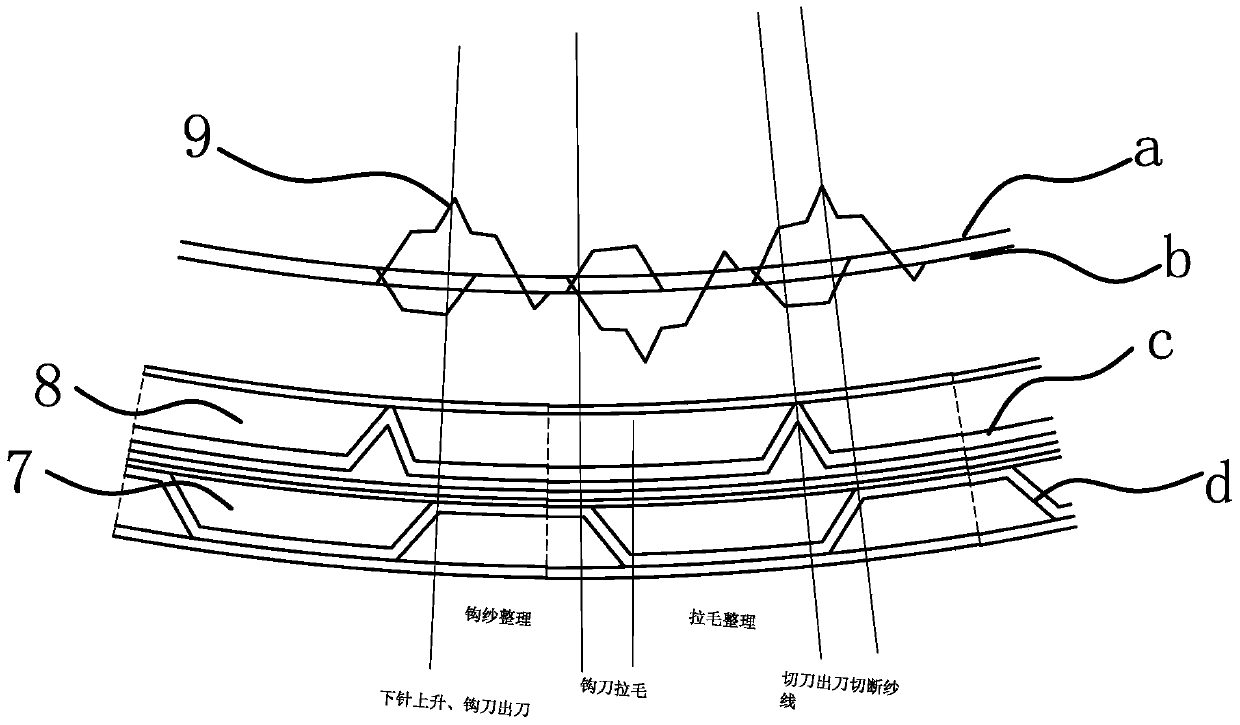

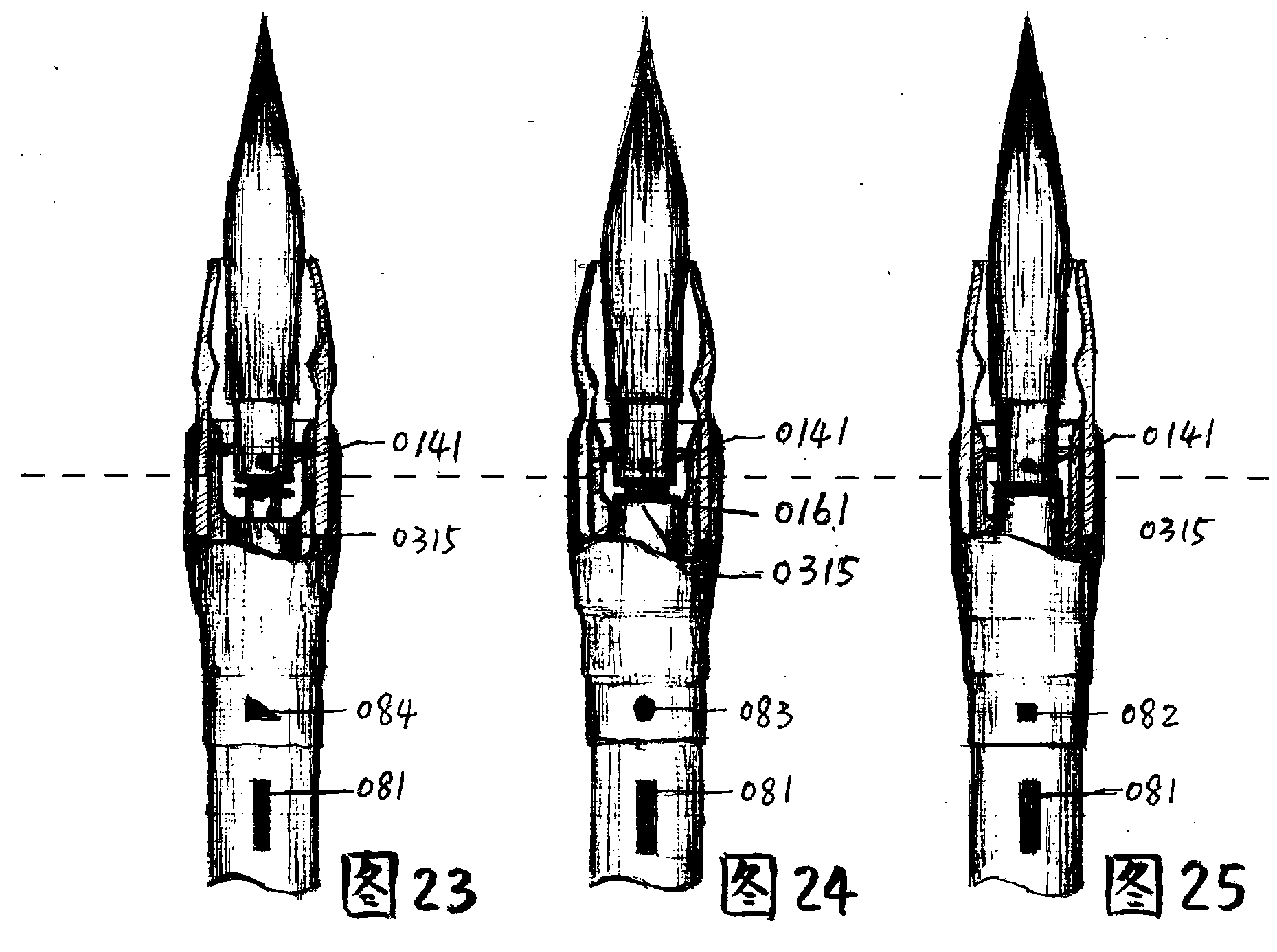

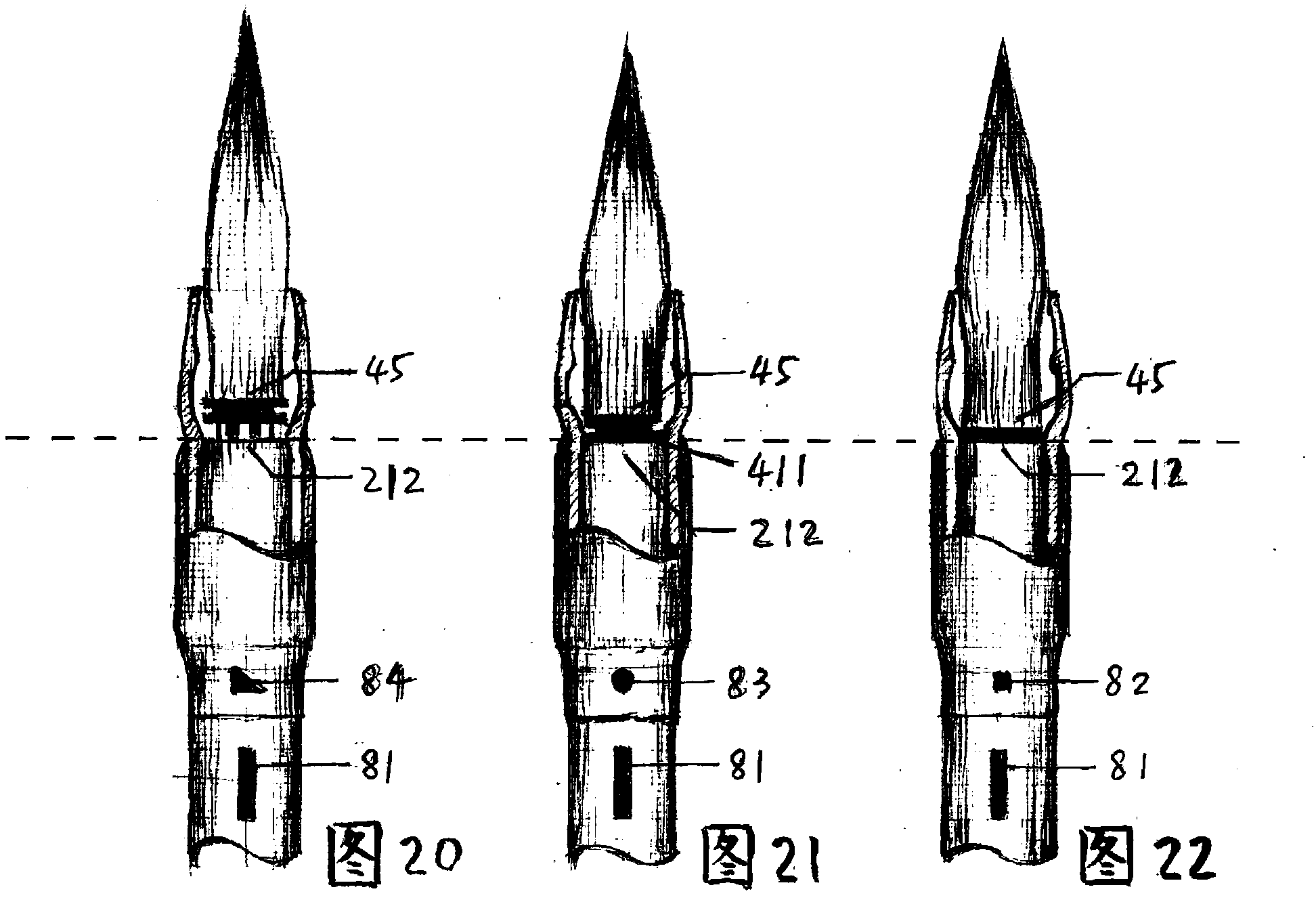

Loop-pile cutting circular machine

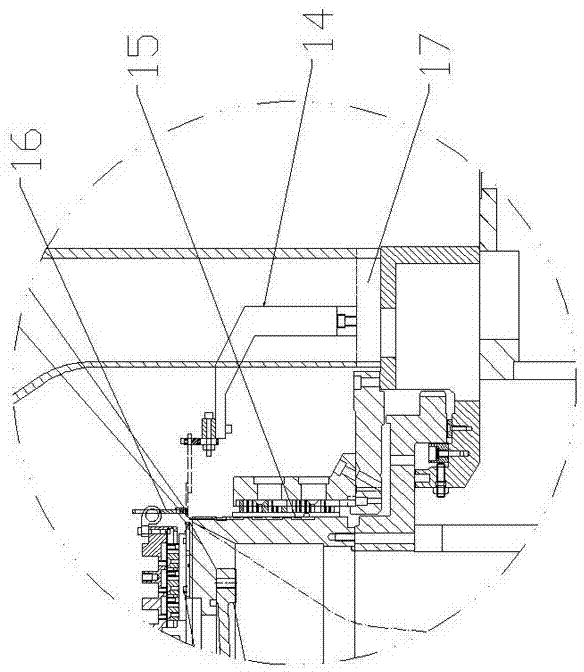

ActiveCN103938357ASolve the problem of uneven hair surface and hair end hookIncrease weaving speedCircular knitting machinesAfter treatmentEngineering

The invention provides a loop-pile cutting circular machine. A needle barrel is fixed on a large disc gear and sleeved by a lower disc saddle, a plurality of vertically-arranged needle triangles are arranged on the inner side of the lower disc saddle in the peripheral direction, and needle slots of the needle triangles of adjacent paths are connected to form knitting needle running tracks. A large tripod gear synchronously rotating with the large disc gear is installed on a large tripod, a knife disc tray is fixedly connected onto a lower shaft head of a gun barrel connected with the large tripod gear, a knife disc is arranged on the knife disc tray, a knife and hook assembly is installed on the knife disc, a knife disc saddle is arranged above the knife disc, and a knife and hook assembly triangle is arranged on the knife disc saddle. Fabrics woven by the loop-pile cutting circular machine are smooth in surface, free of hooked ends, high in hair side density, not prone to hair slip and soft in backing fabric, shearing, breaking and other after treatment steps can be omitted, and the production cost is greatly saved. The knife and hook assembly triangle adopts an arrangement mode that four paths form a group and is large in gap, not prone to shifting and good and stable in operation compared with arrangement modes of common machines.

Owner:LIANYUNGANG YUANFENG MACHINERY

Processing method of goat hair needle-punched nonwoven carpet

The invention discloses a processing method of a goat hair needle-punched nonwoven carpet. The processing method comprises using goat hair or a goat hair main body added with a certain proportion of hot melt fiber as a processing raw material, adding water and wool oil to the processing raw material, and then successively performing opening, mixing and wool covering treatment on the processing raw material; performing carding by using a carding machine, and outputting fiber webs from a card doffer; performing cross lapping on the obtained fiber webs; performing needle-punched reinforcing on the fiber web formed by cross lapping, and forming a goat hair needle-punched nonwoven fabric; and disposing the goat hair needle-punched nonwoven fabric in a drying oven to perform drying treatment, naturally cooling the goat hair needle-punched nonwoven fabric to room temperature after drying is completed, and obtaining the goat hair needle-punched nonwoven carpet. According to the processing method, the goat hair fiber is processed and manufactured by using a needle-punched nonwoven technology, and the goat hair fiber can be well utilized.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Mfg. process of medical moisture absorption paper point base paper

ActiveCN1861900AHigh tensile strengthGood flexibilityPaper/cardboard wound articlesReinforcing agents additionSoftwoodHot melt

The preparation method of base paper, it is used to produce medical moisture absorption paper tip. The 85-95% softwood pulp and 5-15% hot melt fibre are mixed and put into the pulp kneader to thiolysis, and then pumping them into primary pulp barn, sending them to mixture barn after duplex beating, then we can get the pulp, and adding intensifier the weight of which is 0.5 percent of the pulp. Delivering the pulp into header box after the pulp passes through the scummer, and continuously adding the dispersant agent the weight of which is 0.5 percent of pulp into the header box. Then the pulp gets into the net box, netting, and the pulp can form the wet paper after the pulp is molded and dehydrated in the net box. The wet paper dehydrates greatly in the pressing part, and then it is dried in the drying part. The paper tip can get through batching, rewinding and splitting. The base paper which is used to produce medical moisture absorption paper tip has the merits such as higher strength of extension, better softness and higher smoothness, and it is not easy to drop fur, the cost of it is low.

Owner:MUDANJIANG HENGFENG PAPER CO LTD

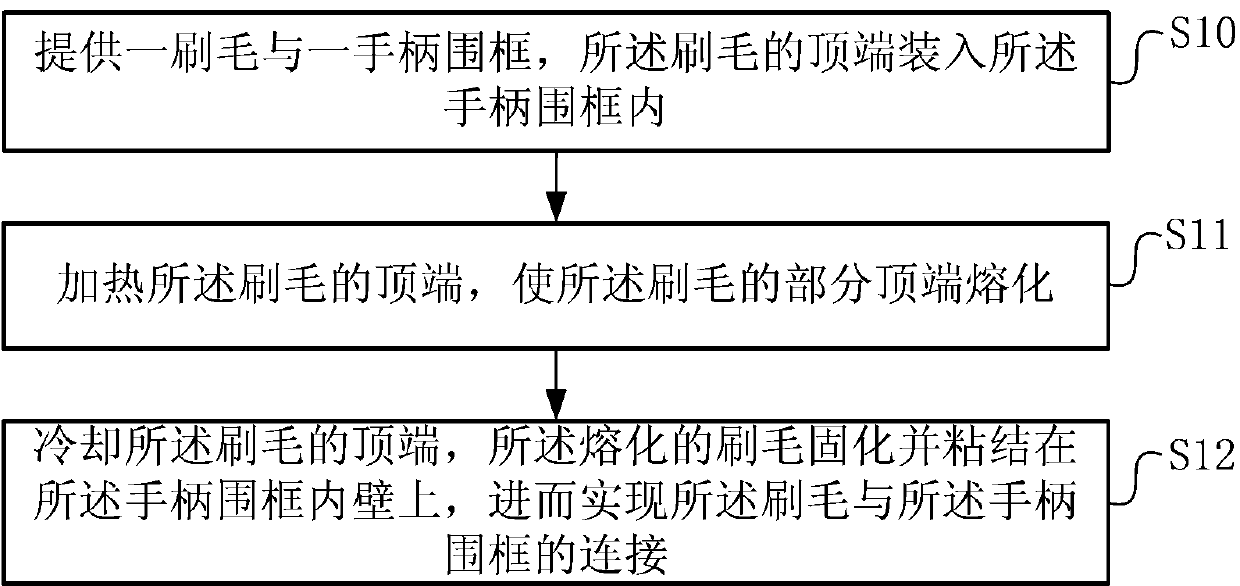

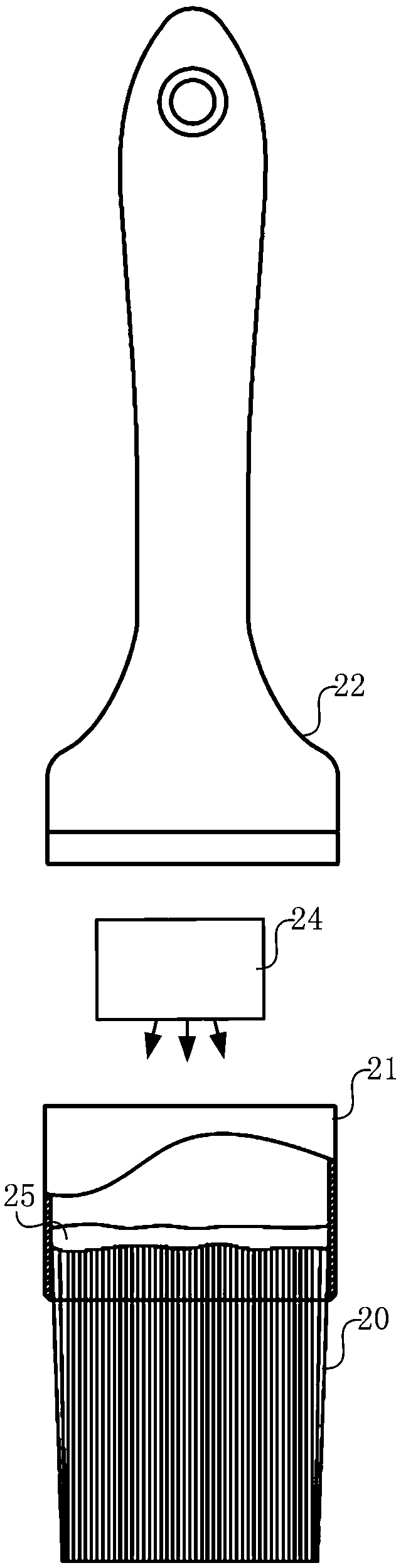

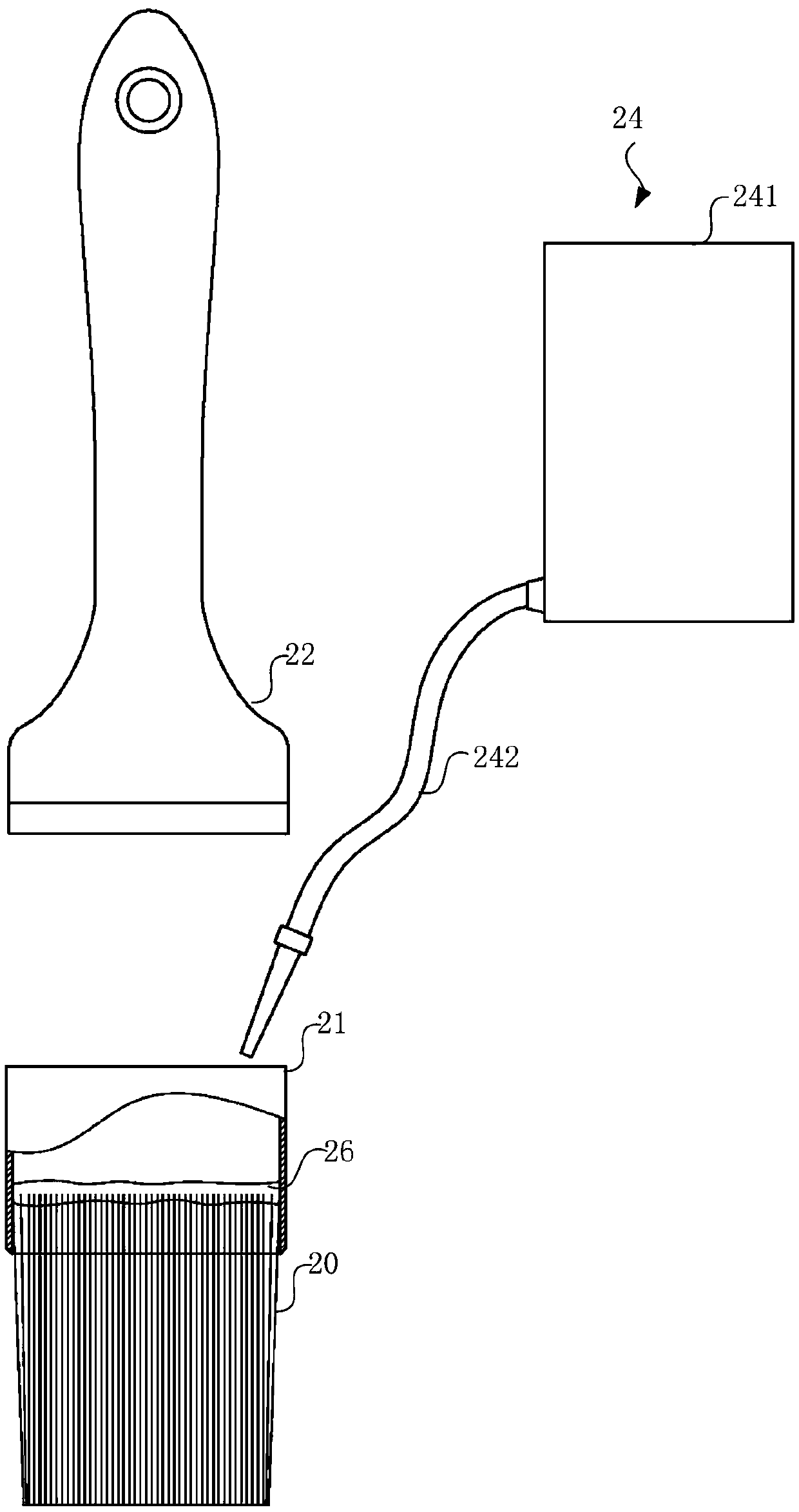

Method and device for connecting bristles and handle enclosure frame and brush manufactured through method

The invention provides a method and device for connecting bristles and a handle enclosure frame and a brush manufactured through the method. The method includes the following steps that the bristles and the handle enclosure frame are provided, and the top ends of the bristles are put into the handle enclosure frame; the top ends of the bristles are heated so that part of the top ends of the bristles can be molten; the top ends of the bristles are cooled, the molten parts of the bristles are solidified and bonded to the inner wall of the handle enclosure frame, and thus the bristles and the handle enclosure frame are connected. The method has the advantages that the bristles and the handle enclosure frame are connected in a hot-melting state, bonding is firm, fast, easy and convenient, the bristles do no shed, environmental friendliness is achieved as no bonder is used, and processing time is shortened; besides, the method is suitable for automatic production and reduces product cost.

Owner:SHANGHAI LEMAHE ELECTROMECHANICAL MFG CO LTD

Highly protective polyimide flame-retardant garment fabric and heat setting method thereof

InactiveCN106585026AImprove flame retardant performanceImprove antibacterial propertiesWeft knittingSynthetic resin layered productsYarnEngineering

The invention provides a highly protective polyimide flame-retardant garment fabric and a heat setting method thereof and relates to the technical field of flame-retardant fabrics. The highly protective polyimide flame-retardant garment fabric is prepared from an inner layer and an outer layer through sewing. The inner layer is prepared from polyimide fiber yarn and flame-retardant filaments through weaving. The outer layer is a cloth surface with raised grids and is prepared from polyimide fiber yarn and flame-retardant filaments through weaving. The highly protective polyimide flame-retardant garment fabric has good fire resistance and heat-insulating functions, can be used at a high temperature for a long time, is comfortable, and reduces hair slip. Through heat setting, the fabric is smooth and flat and size stability.

Owner:JIANGSU AOSHEN HI TECH MATERIALS CO LTD

Polyester Chenille yarn and textile technology and application of polyester Chenille yarn

The invention provides a textile technology of polyester Chenille yarn. The textile technology comprises the steps that firstly, low-melting-point hot-melting binder fibers and polyester fibers are blended, and center yarn is prepared; secondly, decoration yarn is sandwiched between the center yarn for spinning through twisting, and a semi-finished product of the polyester Chenille yarn is obtained, wherein the decoration yarn is made of polyester fibers; thirdly, the semi-finished product of the polyester Chenille yarn is heated at the temperature of 0-200 DEGC, and the polyester Chenille yarn is obtained. According to the polyester Chenille yarn, the center yarn is prepared in the mode that the low-melting-point hot-melting binder fibers and the polyester fibers are blended, the polyester fibers are used as the decoration yarn, and after heat treatment, the low-melting-point hot-melting binder fiber skin layer is melted while the central layer is not changed, so that point-like bonding structures are formed between the fibers, the binding power of the fibers is increased, the slippage phenomena of the fibers are reduced, and the picking-resistant effect is good. The polyester Chenille fabric prepared from the yarn is not prone to picking, and the original hand feeling and style are maintained; meanwhile, the textile technology is simple and easy to implement, no auxiliary equipment is needed, and the cost is low.

Owner:三问家居股份有限公司

Chicken feather pen and manufacturing method thereof

The invention discloses a chicken feather pen. A manufacturing method of the chicken feather pen comprises the steps of selecting a cock chicken feather, forming a notch at the tail end of a cock chicken feather tube through shearing, soaking preprocessed cock chicken feather into water added with alkaline to be heated, completely removing oil on the surface of the chicken feather, meanwhile cleaning blood and meat in the cock chicken feather tube, cleaning and flattening the degreased chicken feather, firstly putting the feather in order to form wisps, using threads to bind the wisps loosely and enable the feather not to fall, then flattening the feather, trimming a part of cock chicken feather tube and manufacturing a pen point. The cost of the chicken feather pen is lower than the cost of a traditional pen, feather resources are richer than wool and weasel's hair, and the chicken feather pen is excellent in quality. The pen point can suck more ink and discharge the ink evenly, commonly and averagely 4-5 characters can be written at a time, the feather does not easily drop, the elasticity of the chicken feather pen in writing is nearly the same as the elasticity of a wool pen and is basically unchanged, and the pen point is not bifurcate.

Owner:WUXI TONGCHUN NEW ENERGY TECH

Air yarn production process

The invention discloses an air yarn production process. The air yarn production process includes the steps of material preparation, arrangement, weaving, treatment and spraying. The surfaces of one-ply yakwool yarn, one-ply acrylic yarn and one-ply polyester stretch yarn are respectively sprayed with highly-elastic silicone coating adhesive, or the surface of filled rough yarn is sprayed with the highly-elastic silicone coating adhesive. By the means, the air yarn production process has the advantages that after spray of the highly-elastic silicone coating adhesive, the highly-elastic silicone coating adhesive is distributed on the surface of the filled rough yarn in a dotted manner, so that structural integrity and abrasion resistance of the filled rough yarn are improved, and produced clothes are less prone to linting, fluffy, soft, high in resilience and good in warmth.

Owner:ZHANGJIAGANG CHAFTA TEXTILE TECH

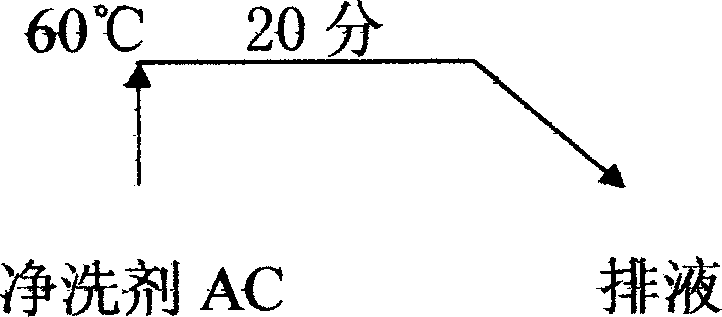

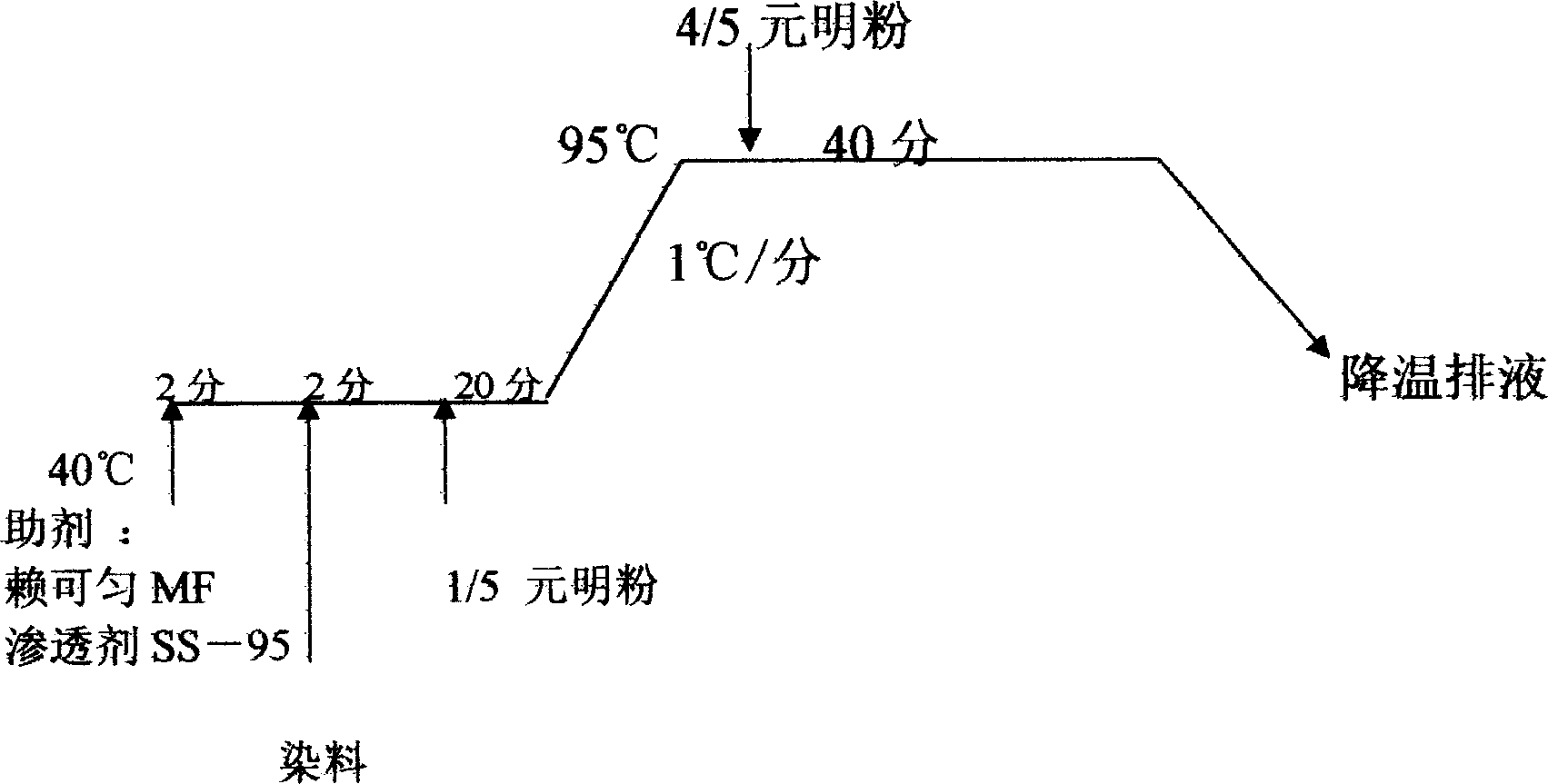

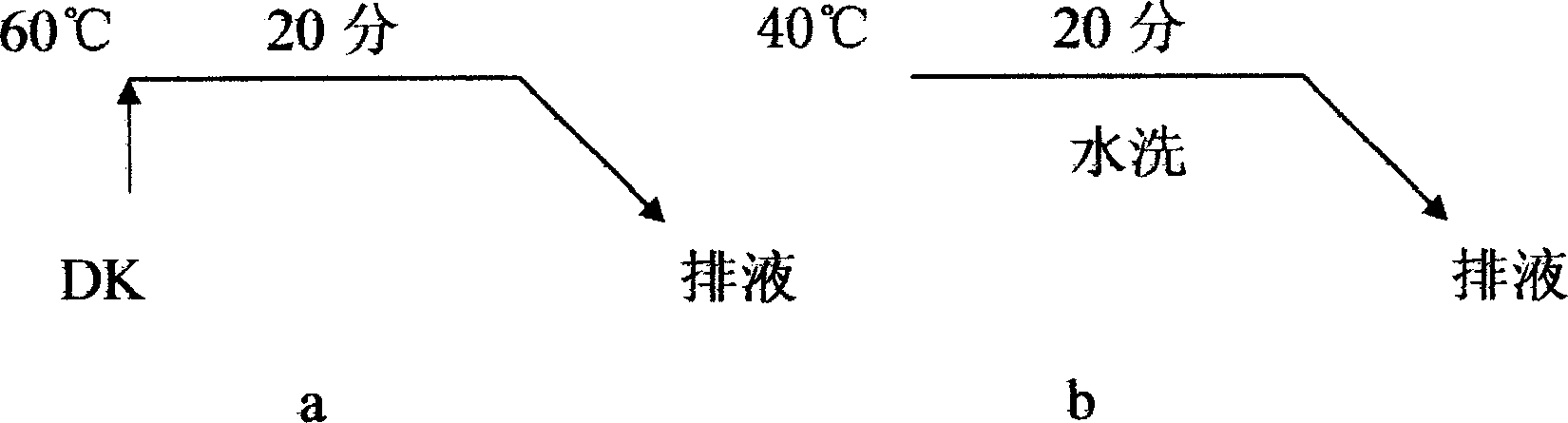

Manufacturing process of sanding cashmere sweater

The invention relates to a sand washing cashmere sweater making technology that contains the following steps: dying process: taking pre-processing, dying, adding assistant agent under 40 degree centigrade, whisking for 2 minutes, adding dye 20 minutes, heating at the speed of 1 degree centigrade per minutes, dying for 30 minutes at 95 degree centigrade, discharging; sand washing technology: dipping in positive ion and leavening agent for 25-35 minutes at 40 degree centigrade, sand washing for 15-20 minutes; inching, and adding floating stone, washing, softening, evaporating, drying. The invention has the advantages of unease balling up, strong wear resistance, etc.

Owner:INNER MONGOLIA KINGDEER CASHMERE

Process for producing high soft and high elastic novel spun-laced clothing dressing

InactiveCN101397723AUnrestricted fiber requirementsSoft touchGarmentsCarding machinesInterliningCarding

The invention discloses a production technique of the dressing of high soft and elastic novel spunlaced clothes, which pertains to the technical field of textile materials. The technique essentially comprises the following steps: weighing and supplying, loosening mixed cotton, fine loosening, precise mixing, fine loosening, automatically leveling cotton supplied, porous drum-type fast carding, multistage rotary drum spunlaced tangling, drying, defect examination, winding, dividing and packaging. The production technique has few limitations to raw materials and can meet the production of different raw materials. A produced product has good performance of suspending weight, air permeability, soft touch feeling, small shrinking rate, high strength and wide thickness changing scope, is not easy to have fuzz or pick, does not contain chemical adhesives and is a relatively ideal base fabric for manufacturing the adhesive interlinings of high-grade clothes.

Owner:洪桂焕

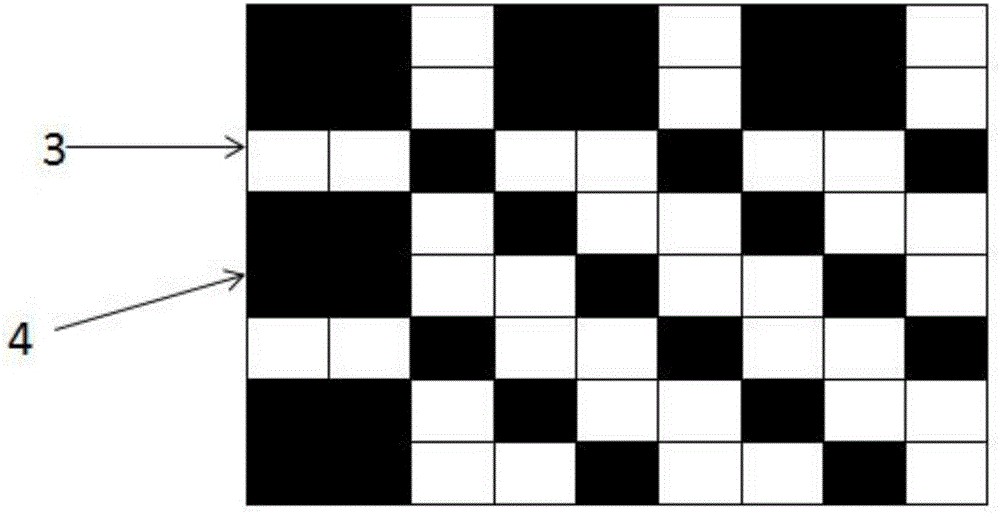

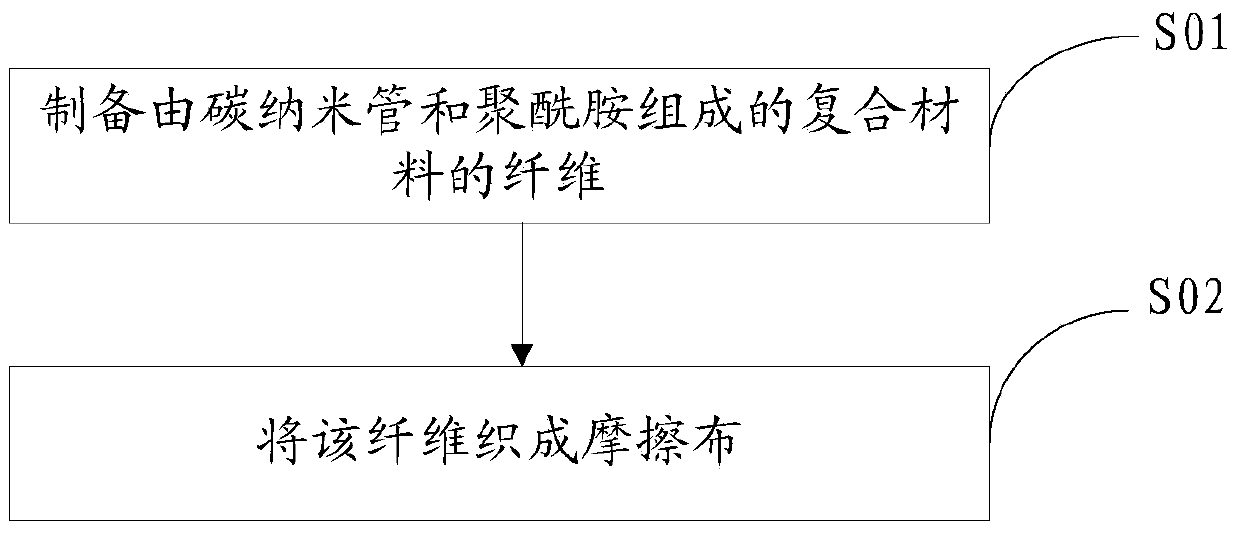

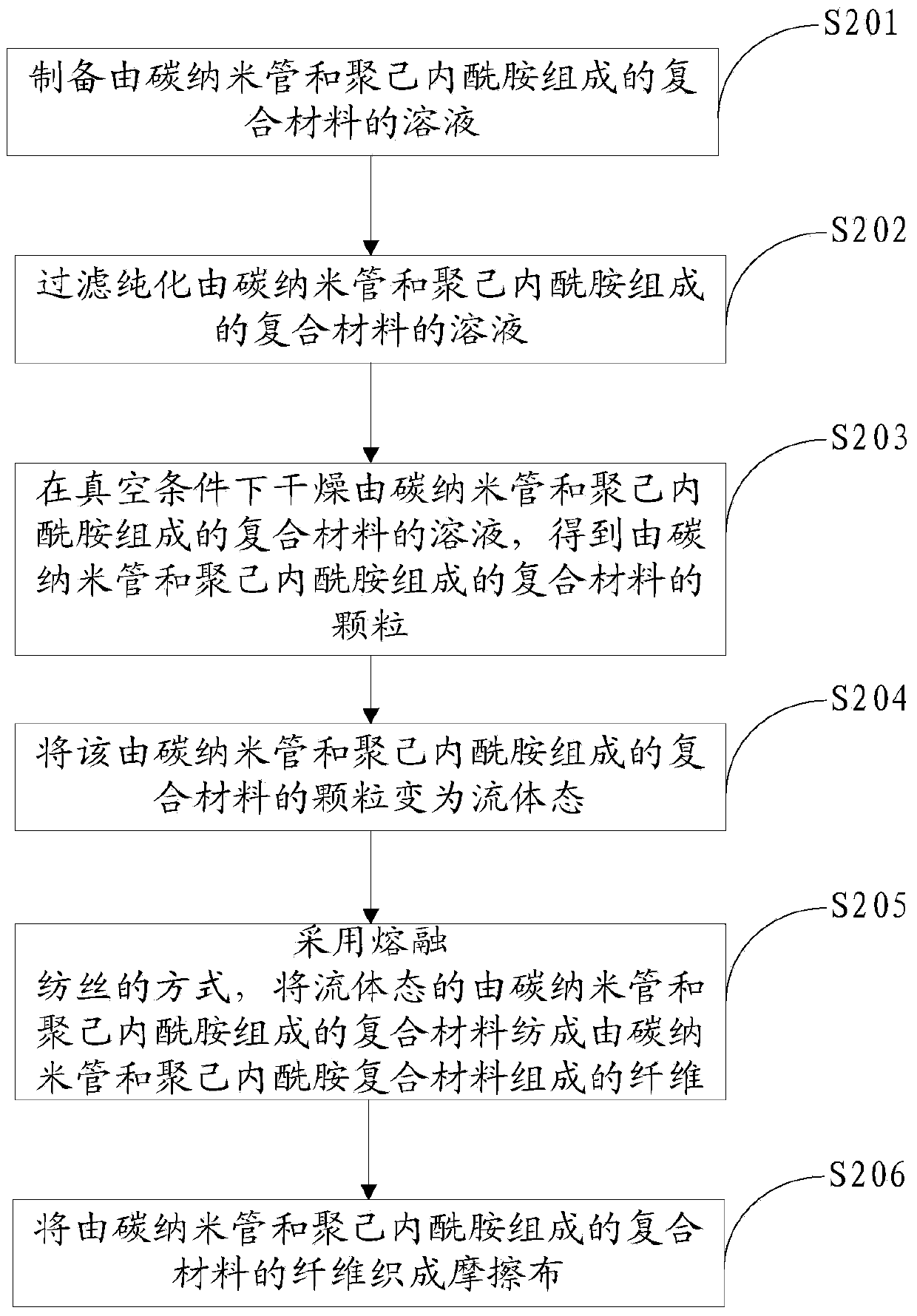

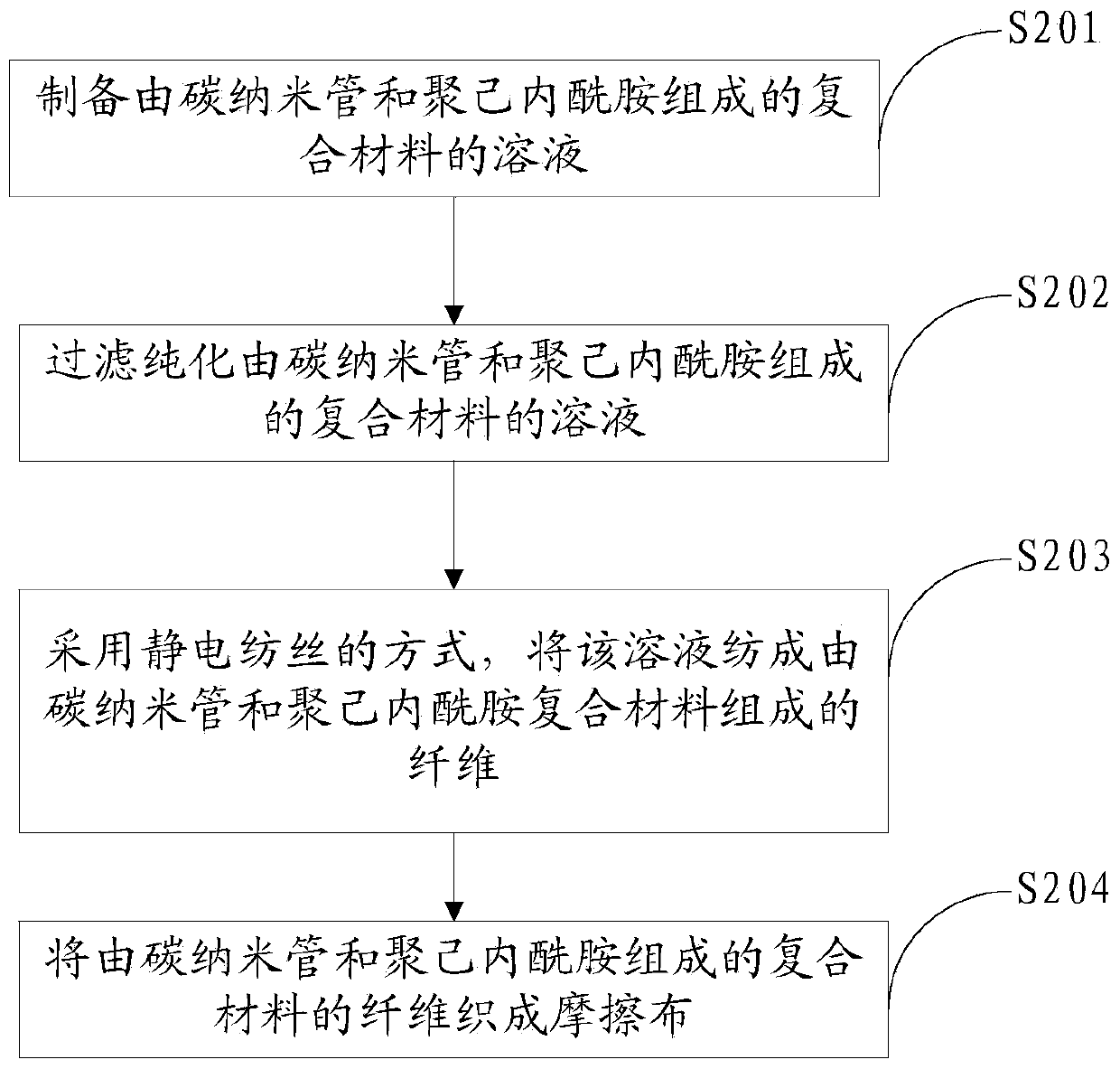

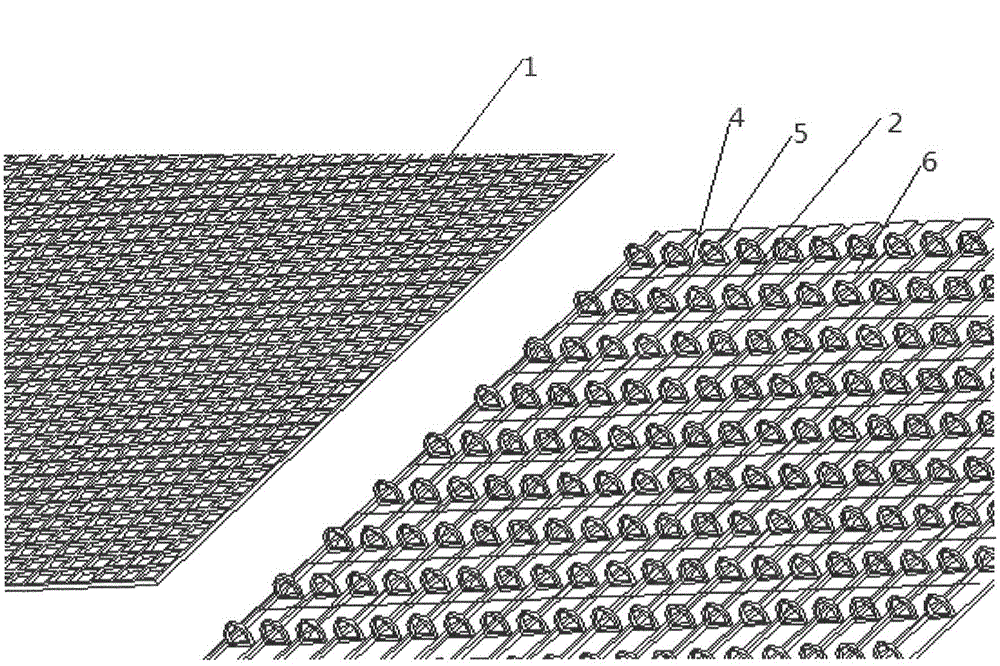

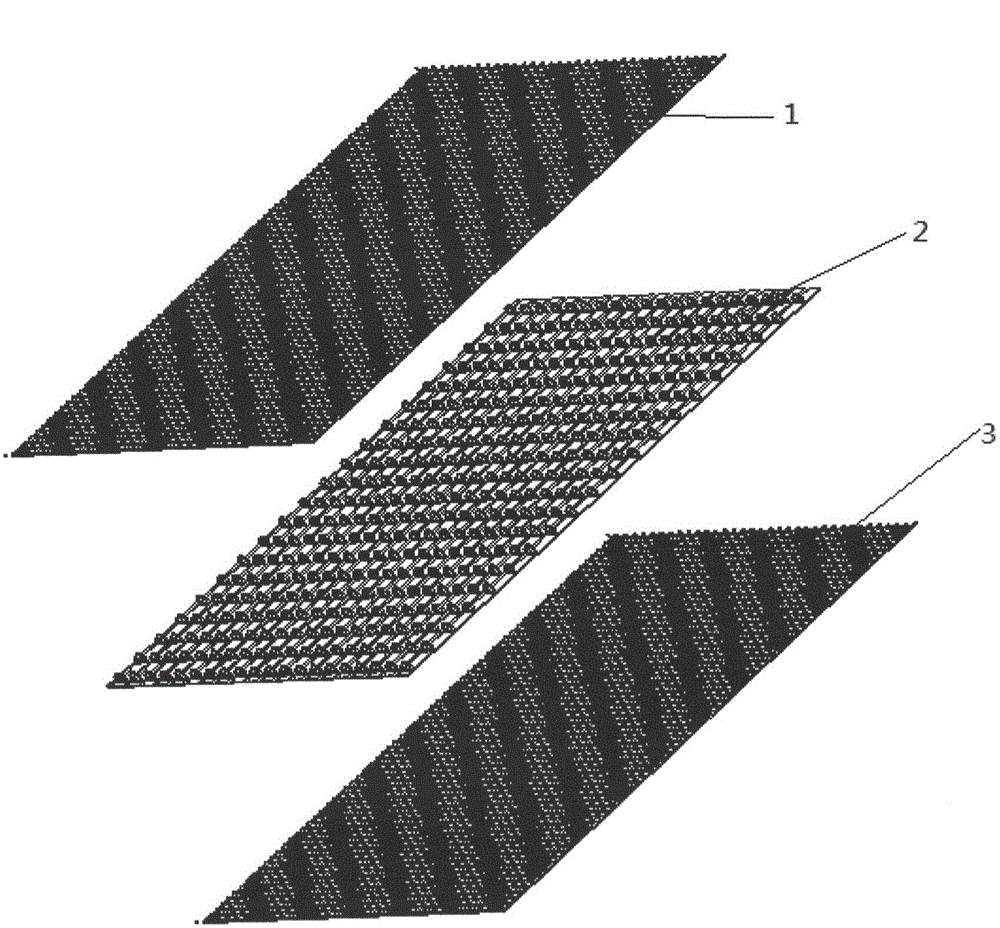

Rubbing cloth and preparation method and preparation device thereof

InactiveCN103472625AWarp and weft density is easy to controlNot easy to shed hairNon-linear opticsLiquid-crystal displayImaging quality

The invention discloses rubbing cloth and a preparation method and a preparation device thereof. The rubbing cloth is made of a composite material composed of carbon nano tubes and polyamide; since the carbon nano tubes have excellent antistatic property and the polyamide has excellent rubbing capability, the composite material composed of the carbon nano tubes and the polyamide has excellent antistatic property as well as excellent rubbing capability; moreover, as the composite material is an artificial material, wrap and weft density of the cloth are easily controlled during weaving, and further the rubbing cloth made of the composite material is high in uniformity; besides, the rubbing cloth made of the composite material is less prone to fur shedding. Therefore, the rubbing cloth is not only high in antistatic property and less prone to fur shedding, but also capable of realizing uniformity of orientation directions of orientation grooves under the condition of high rubbing strength, and further contrast and image quality of a liquid crystal display device are improved.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

Loop-pile cutting circular machine

ActiveCN103938357BIncrease weaving speedHigh densityCircular knitting machinesAfter treatmentEngineering

The invention provides a loop-pile cutting circular machine. A needle barrel is fixed on a large disc gear and sleeved by a lower disc saddle, a plurality of vertically-arranged needle triangles are arranged on the inner side of the lower disc saddle in the peripheral direction, and needle slots of the needle triangles of adjacent paths are connected to form knitting needle running tracks. A large tripod gear synchronously rotating with the large disc gear is installed on a large tripod, a knife disc tray is fixedly connected onto a lower shaft head of a gun barrel connected with the large tripod gear, a knife disc is arranged on the knife disc tray, a knife and hook assembly is installed on the knife disc, a knife disc saddle is arranged above the knife disc, and a knife and hook assembly triangle is arranged on the knife disc saddle. Fabrics woven by the loop-pile cutting circular machine are smooth in surface, free of hooked ends, high in hair side density, not prone to hair slip and soft in backing fabric, shearing, breaking and other after treatment steps can be omitted, and the production cost is greatly saved. The knife and hook assembly triangle adopts an arrangement mode that four paths form a group and is large in gap, not prone to shifting and good and stable in operation compared with arrangement modes of common machines.

Owner:LIANYUNGANG YUANFENG MACHINERY

Recycled polyester chenille yarn, manufacturing method thereof and method for manufacturing recycled polyester chenille yarn blanket

The invention discloses recycled polyester chenille yarn. The recycled polyester chenille yarn is obtained through plying of recycled DTY low-elastic interlaced yarn and recycled polyester plied yarn. The invention also discloses a manufacturing method of the recycled polyester chenille yarn. The invention further provides a method for manufacturing a recycled polyester chenille yarn blanket. The method for manufacturing the recycled polyester chenille yarn blanket comprises the steps of preparing the recycled polyester chenille yarn, and weaving the recycled polyester chenille yarn blanket from the recycled polyester chenille yarn in corresponding thickness. The spun recycled polyester chenille yarn is excellent in velvet feel, mellow and full, and not prone to lint falling. The recycled polyester chenille yarn is made from the PET waste material, waste material recycling is promoted, environment friendliness is realized, petroleum resources are saved, waste material treatment difficulty is reduced, and market prospects are broad. The manufactured recycled polyester chenille yarn blanket has a strong stereoscopic sense, a rich color, excellent elasticity and an excellent drape effect and is tolerant to machine washing.

Owner:常州英诺威家居用品有限公司

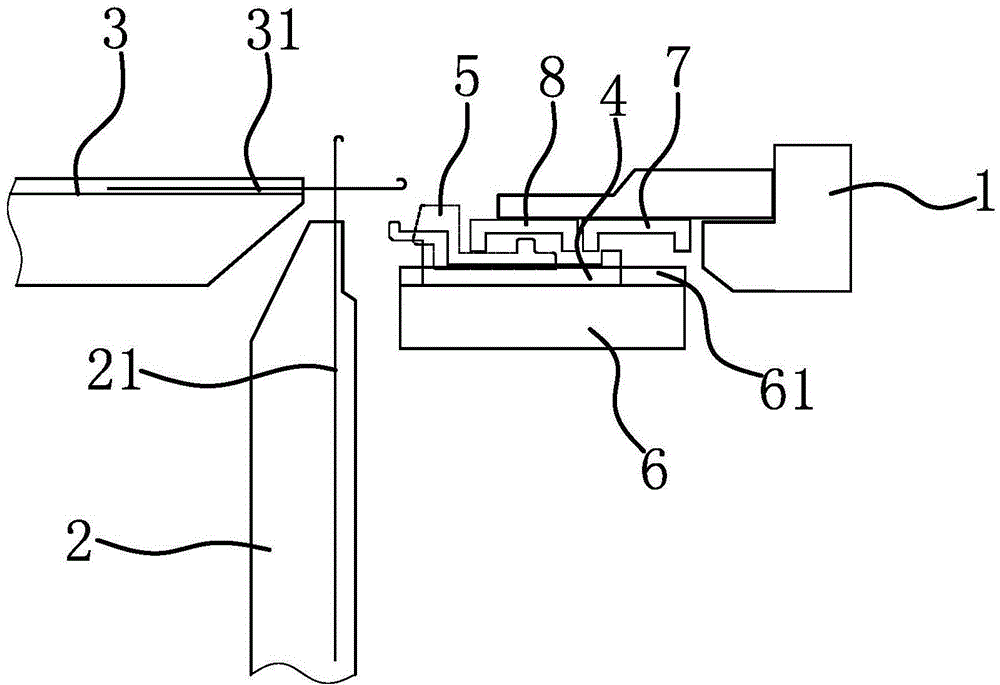

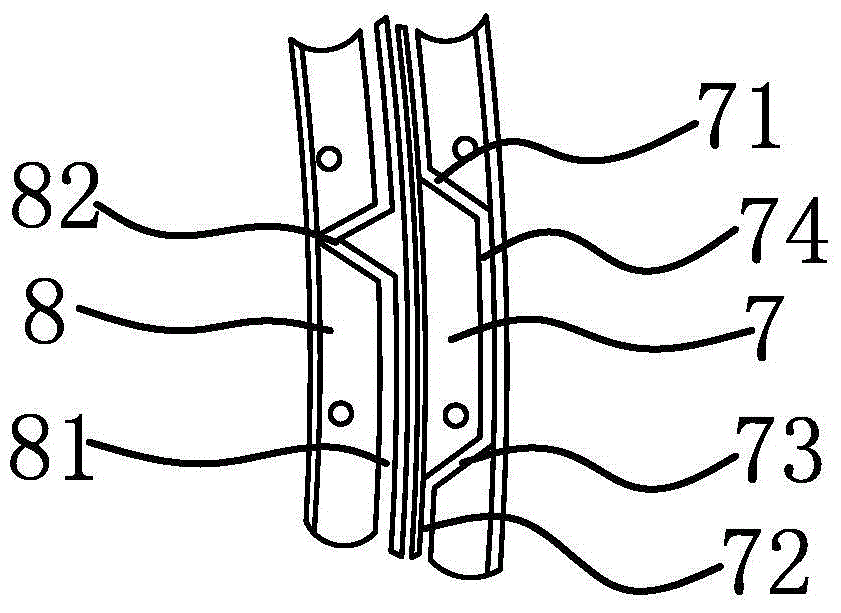

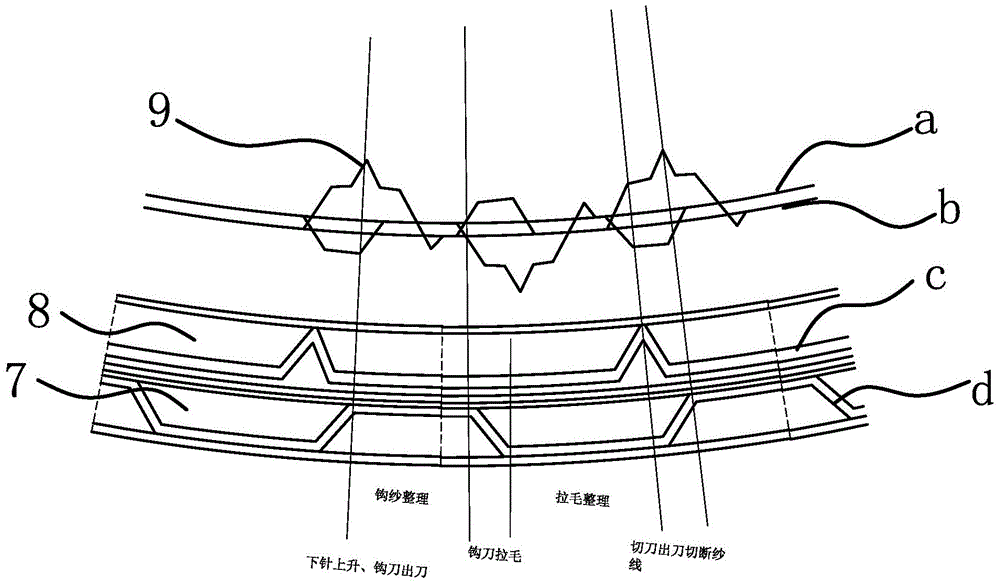

A double-side knitting and cropping integrated machine

The invention relates to a double-side knitting and cropping integrated machine and belongs to the technical field of textile machines. The machine solves the problem in the prior art that a circular knitting machine cannot perform napping during double-side knitting. The double-side knitting and cropping integrated machine is characterized in that the outer side of a needle cylinder is provided with hook cutters and cutters which are arranged radially along the needle cylinder. When lower knitting needles ascend, the hook cutters can hook yarn and pull the yarn out; when the yarn is pulled out, the cutters can cut the yarn; a rack is provided with a cropping mechanism driving the hook cutters and the cutters to perform yarn hooking, napping and cutting. Fabric knitted by the double-side knitting and cropping integrated machine has smooth surfaces without hook heads, is high in nap surface density, is high in gram weight, is not liable to nap falling, and has soft base fabric; the after-finishing steps of cropping and breaking are saved, so that the product cost is greatly saved.

Owner:SHAOXING BIAODIAN TEXTILE TECH

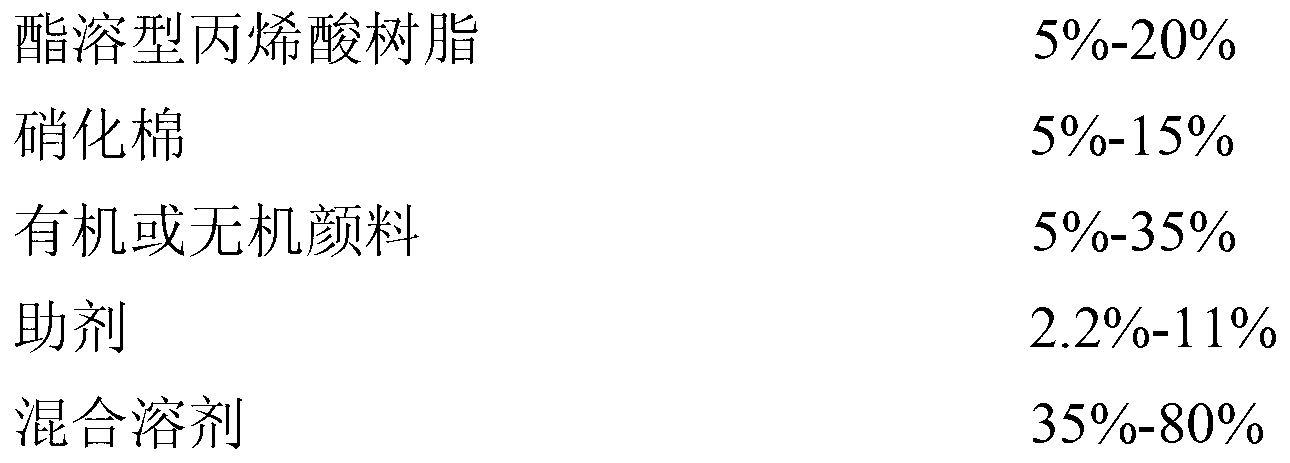

High-temperature resistant ester-soluble printing ink

The invention provides a high-temperature resistant ester-soluble printing ink, belonging to the field of ink printing. The ink comprises the following components in percentage by weight: 5-20% of ester-soluble acrylic resin, 5-15% of nitrocotton, 5-35% of organic or inorganic pigment, 2.2-11% of assistant and 35-80% of mixed solvent. The ink is mainly used for gravure food paper packages and has the following advantages of high gloss, good levelling and good printing color development performance; due to low viscosity, the ink hardly causes falling of paper fibers or stains paper when used for printing; due to high drying speed, no solvents such as benzene, ketone or the like and little solvent residue, the ink meets the requirements of human safety and environmental protection and suitable for food package printing; and due to the high-temperature resistance, the ink can resist 180 DEG C high temperature at most and is capable of sealing heat without losing color.

Owner:东莞市锐达涂料有限公司

Efficient and energy-saving shaping method for high-elasticity glue-free cotton with smooth and clean surface

The invention relates to an efficient and energy-saving shaping method for high-elasticity glue-free cotton with a smooth and clean surface. The shaping method sequentially comprises the steps of raw material preparing according to the ratio, mixing, opening, entering of a cotton box (a storage box), cotton carding, lapping, net laying, roasting in an oven, forming, rolling and packaging, wherein in net laying, different cotton nets on three lines are formed, and stacked and combined online. Three sets of design raw materials are mixed in different ratios, opened and carded to form the different cotton nets of three lines, the three sets of cotton nets are stacked and combined online through connecting bridges, baking in the oven, forming, rolling and packaging are carried out, and the subsequent line production is achieved. Elastic fibers are adopted in the inner layer of the composite, low-melting point fibers are adopted in the surface layer, and the glue-free cotton produced with the method is high in elasticity, and smooth and clean in surface, and the innovative method is efficient and capable of saving energy.

Owner:DANYANG YUSHENG TEXTILE NEW MATERIAL

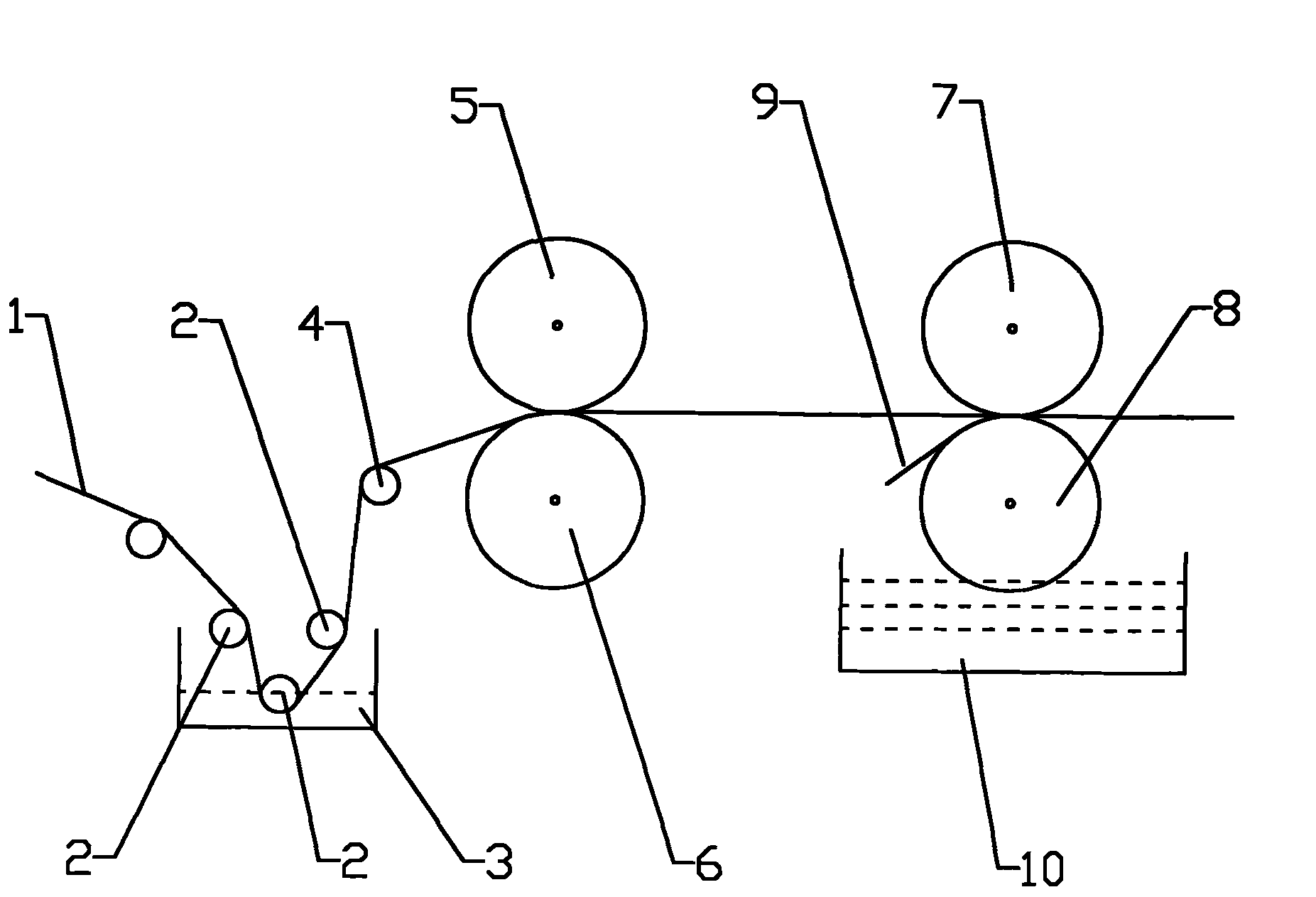

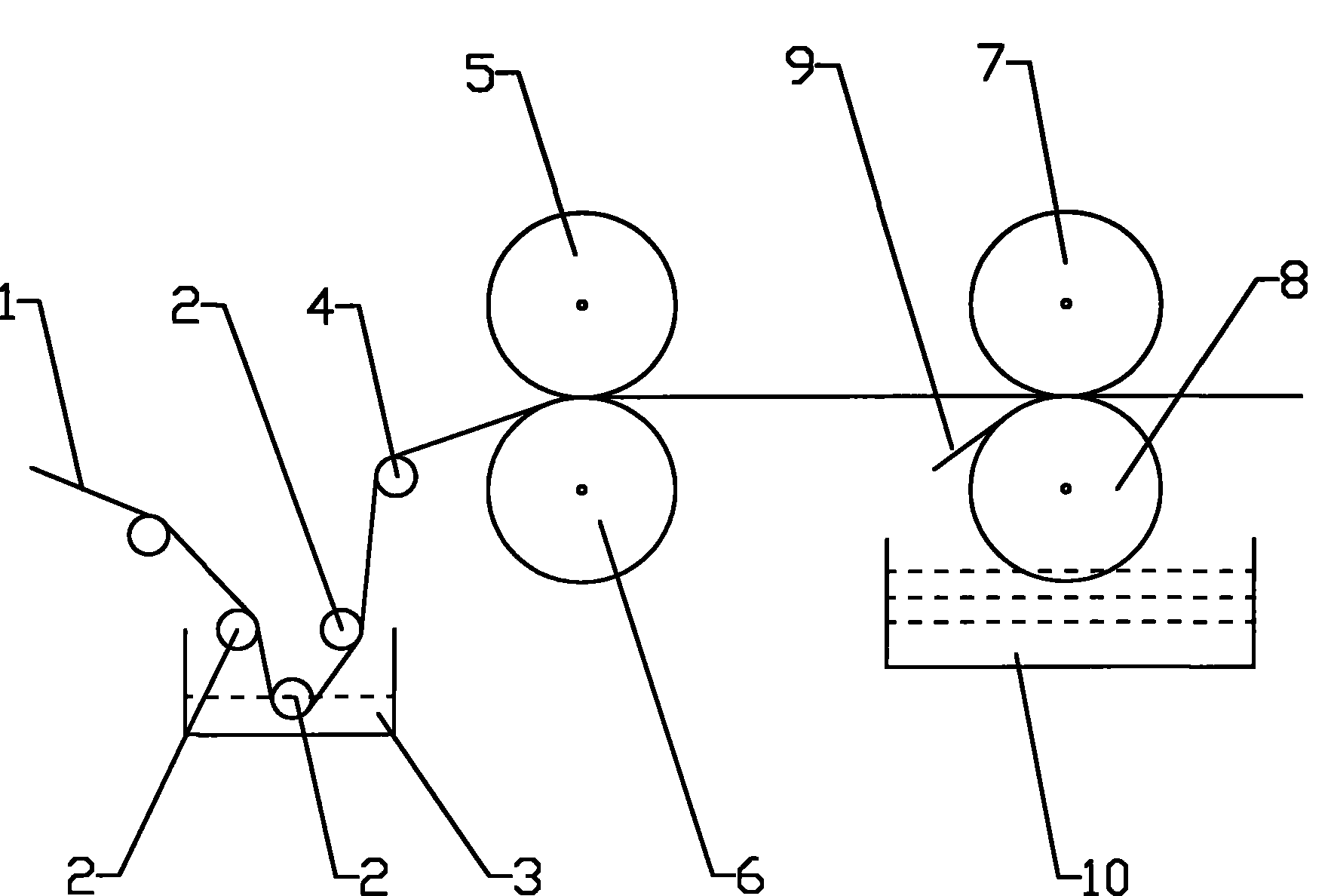

Equipment for producing printed spunlaced non-woven fabric

The invention relates to equipment for producing a printed spunlaced non-woven fabric. The equipment comprises an immersing device, a squeezing machine and a printing device. The immersing device comprises an immersing tank and a guide roll, wherein the guide roll is arranged in the immersing tank; slurry is contained in the immersing tank; and the guide roll is immersed in the slurry. The squeezing machine comprises an upper squeezing roll and a lower squeezing roll, wherein the central axes of the upper squeezing roll and the lower squeezing roll are parallel and the peripheries of the upper squeezing roll and the lower squeezing roll are tangential to each other. The printing device comprises a rubber roll and a printing roll which are arranged up and down; the central axes of the rubber roll and the printing roll are parallel; the peripheries of the rubber roll and the printing roll are tangential to each other; patterns are carved on the periphery of the printing roll; a slurry tank is arranged below the printing roll; the slurry is contained in the slurry tank; and a part of the printing roll is immersed in the slurry. After flowing through the immersing device, excessive slurry is discharged; and through the squeezing machine, the two surfaces of the spunlaced non-woven fabric are printed. The conformity of the patterns on the two surfaces is improved and the malposition of the patterns is avoided.

Owner:CHTC HELON

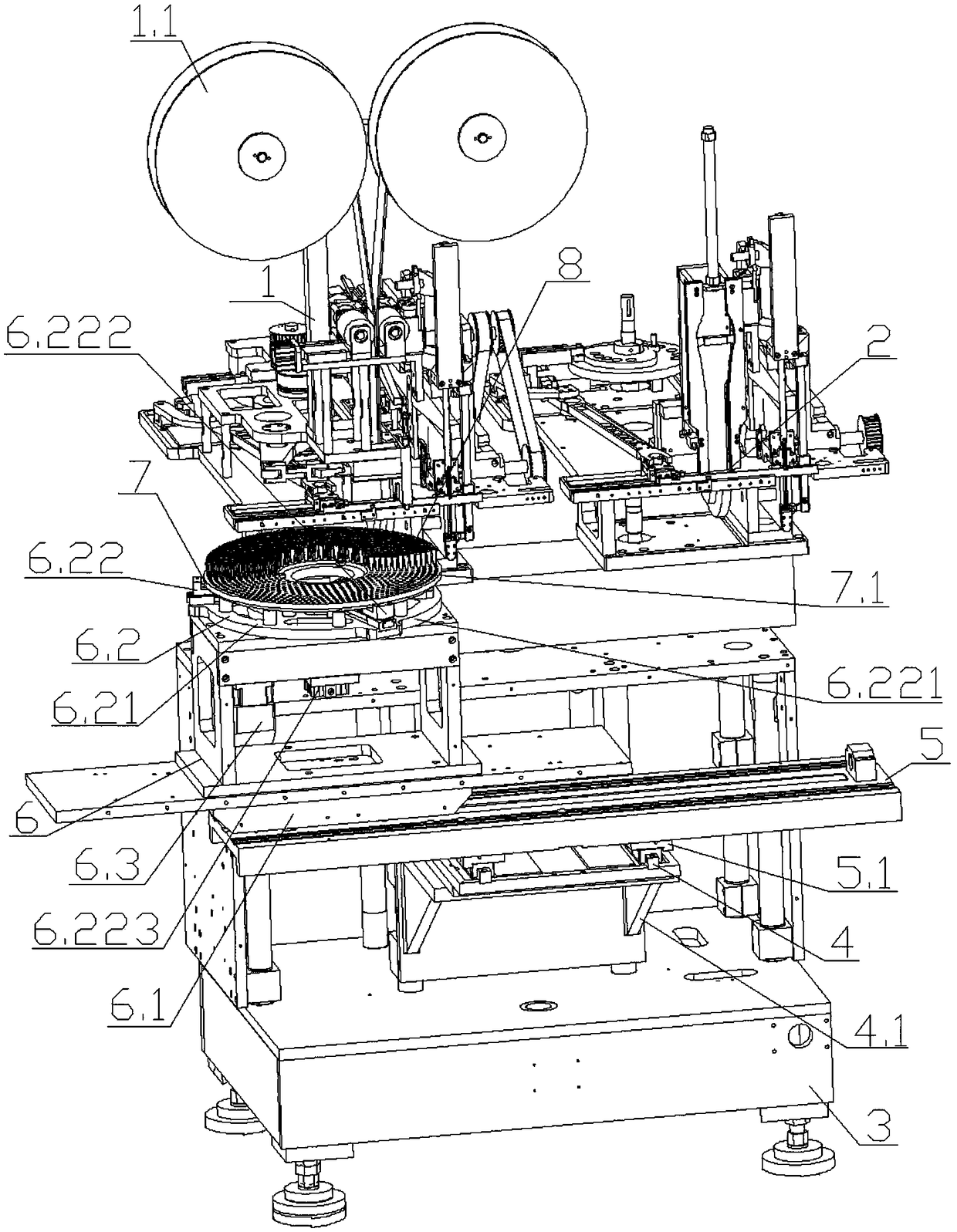

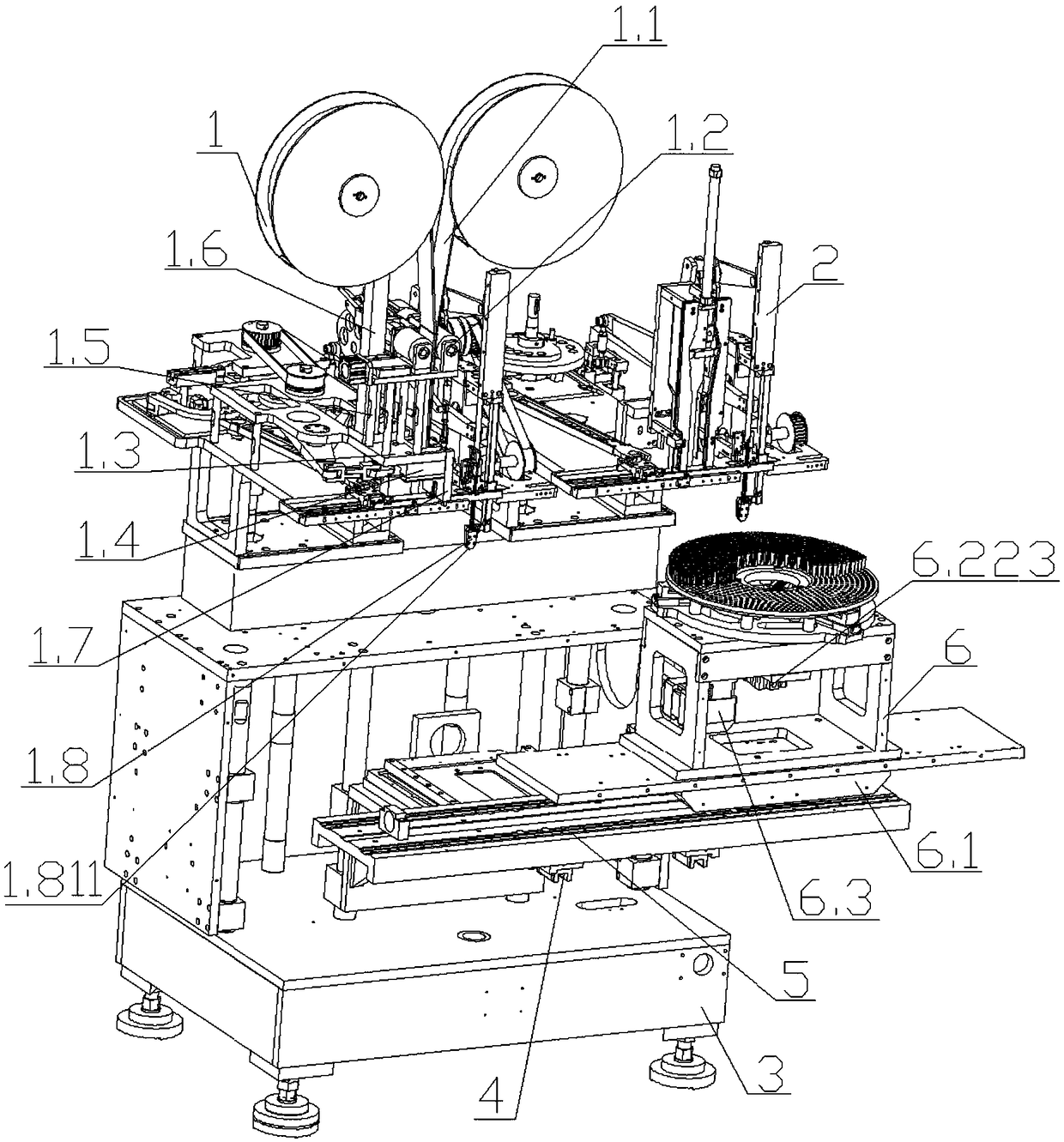

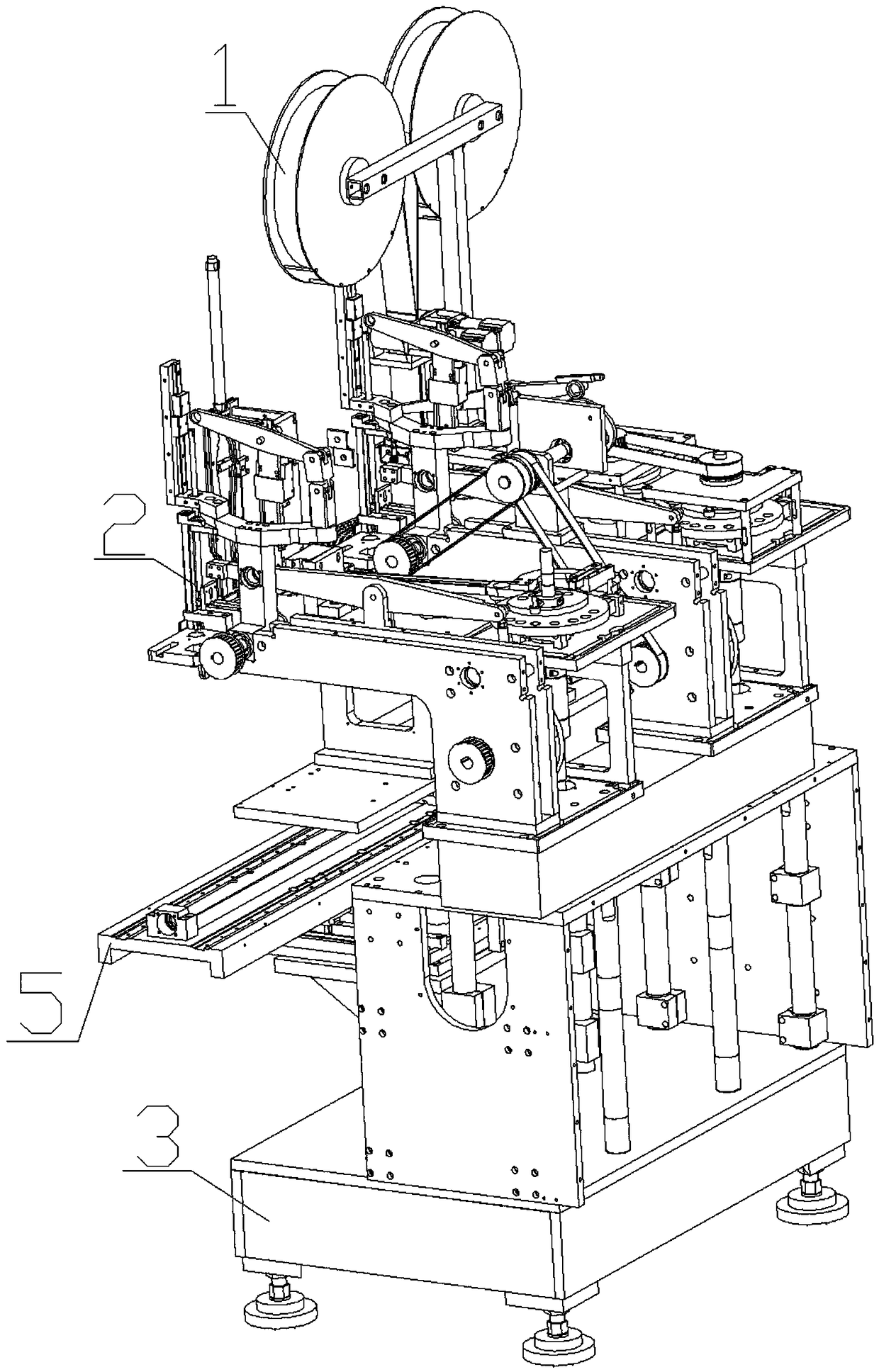

Automatic reciprocating hair planting machine for woolens of different materials and hair planting method thereof

ActiveCN109349789AStrong tensionReduce corrosionBrush bodiesAgricultural engineeringStructural engineering

The invention discloses an automatic reciprocating hair planting machine for woolens of different materials. The hair planting machine comprises a first hair planting mechanism and a second hair planting mechanism, a working platform and a base, a Y axis guiding rail is arranged on the base through a first supporting structure, an X axis sliding rail is slidably connected with the Y axis guiding rail through a first sliding block, and the lower end of the working platform is provided with a second sliding block which cooperates with the X axis guiding rail. The hair planting machine has the advantages that stagger hair planting can be conducted on a handle brush by adopting multiple woolens, hair does not easily fall, the working efficiency is high, labor force consumption is lesser, and the cost is lower. The invention further discloses a hair planting method of the automatic reciprocating hair planting machine for the woolens of different materials.

Owner:HUBEI C P NC MACHINERY

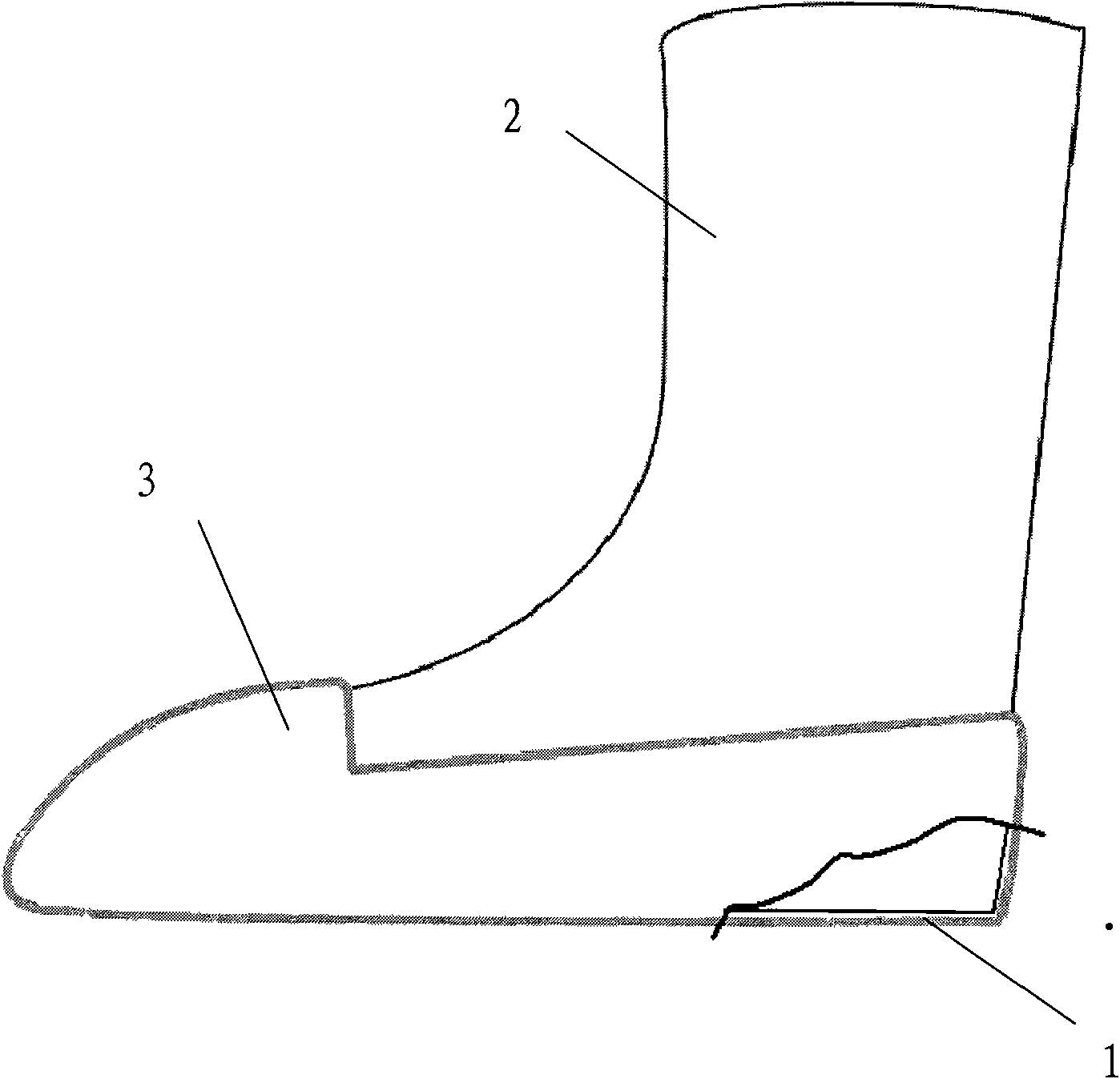

Felt shoe and production process thereof

The invention relates to a felt shoe and a production process thereof. The production is carried out by adopting processes of opening, combing, modeling, steam pressure twisting, striking and kneading, sizing and drying, and bottom adding. The produced felt shoe comprises a sole and an upper vamp, wherein the sole and the upper vamp have an integrated structure, a shoe cover is arranged on the sole, the front end of the shoe cover is wrapped on the upper end face of the upper vamp, and the back end of the shoe cover is wrapped on the back end face of the upper vamp. The sole and the upper vampare made from complete carbonized wools of which fineness is 18 to 25 mum and of which length is 20 to 70 millimeters. The felt shoe manufactured by the process can be worn indoors and outdoors, hasthe advantages of even thickness, high tensile force and binding force among the wools, high product strength, deformation prevention, softness and comfort, warm keep and foot fitness, various beautiful colors, good air permeability, abrasion resistance, environmental protection and cleaning convenience, is applied to various groups, and is suitable for popularization and application.

Owner:马世京

A double-sided knitting and shearing machine

The invention relates to an integrated machine for double-sided knitting and shearing, which belongs to the technical field of textile machinery and solves the problem in the prior art that large circular knitting machines cannot perform napping when double-sided knitting. The outer side of the needle cylinder of this double-knitting and shearing machine is equipped with a hook knife and a cutter set along the radial direction of the needle cylinder, and when the lower knitting needle rises, the hook knife can hook the yarn and pull the yarn out. The cutter can cut the yarn when it is out, and the frame is equipped with a shearing mechanism that drives the hook knife and the cutter to hook yarn, pull and cut. The fabric woven by this double-sided knitting and shearing integrated machine has a smooth surface without hooks, high density on the wool surface, high grammage, and is not easy to shed. Cost of production.

Owner:SHAOXING BIAODIAN TEXTILE TECH

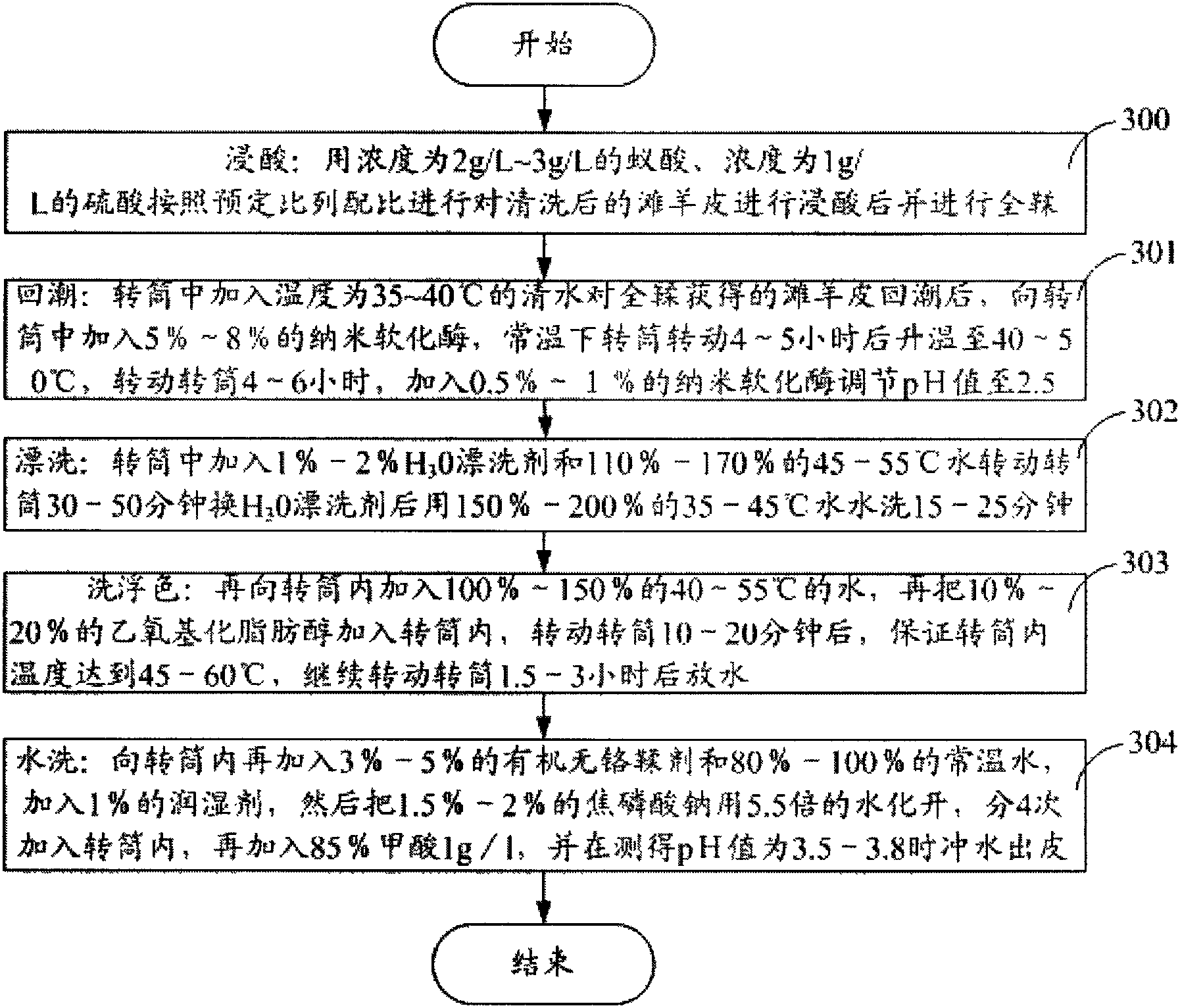

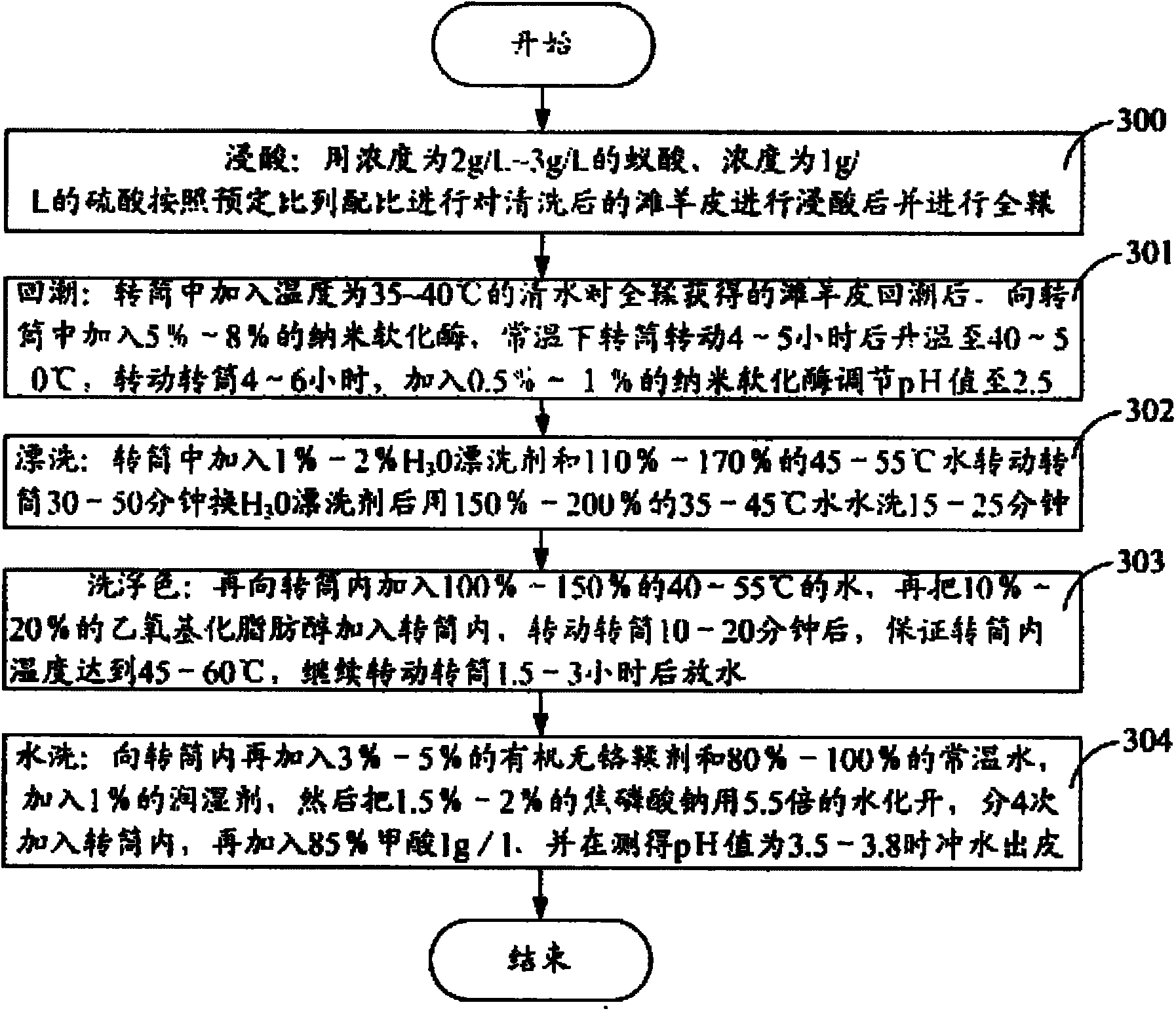

Method for tanning Tan sheep skin with nano softening enzyme

InactiveCN102534057ANot easy to shed hairEffective solubilityTanning treatmentPre-tanning chemical treatmentFiberSheep skin

The invention relates to a method for tanning Tan sheep skin with a nano softening enzyme, which comprises the following steps: pickling; dampening; adding 5-8% of nano softening enzyme into a rotating drum; after the rotating drum is rotated for 4-5 hours at ordinary temperature, heating to 40-50 DEG C, continuing rotating the rotating drum for 4-6 hours, and adding 0.5-1% of nano softening enzyme to regulate the pH value to 2.5; rinsing; washing out loose color; and washing with water. Under the actions of the nano softening enzyme and acidic condition, elastic fibers and excess colloids in the skin can be effectively dissolved and removed; and since the action of the nano softening enzyme is mild, the invention can ensure the low hair slipping tendency and fullness of the Tan sheep skin. In addition, no chromium or aluminum salt is used, thereby relieving the environmental pollution, reducing the control and routine maintenance cost for waste water and lowering the production cost.

Owner:宁夏西部皮草有限公司

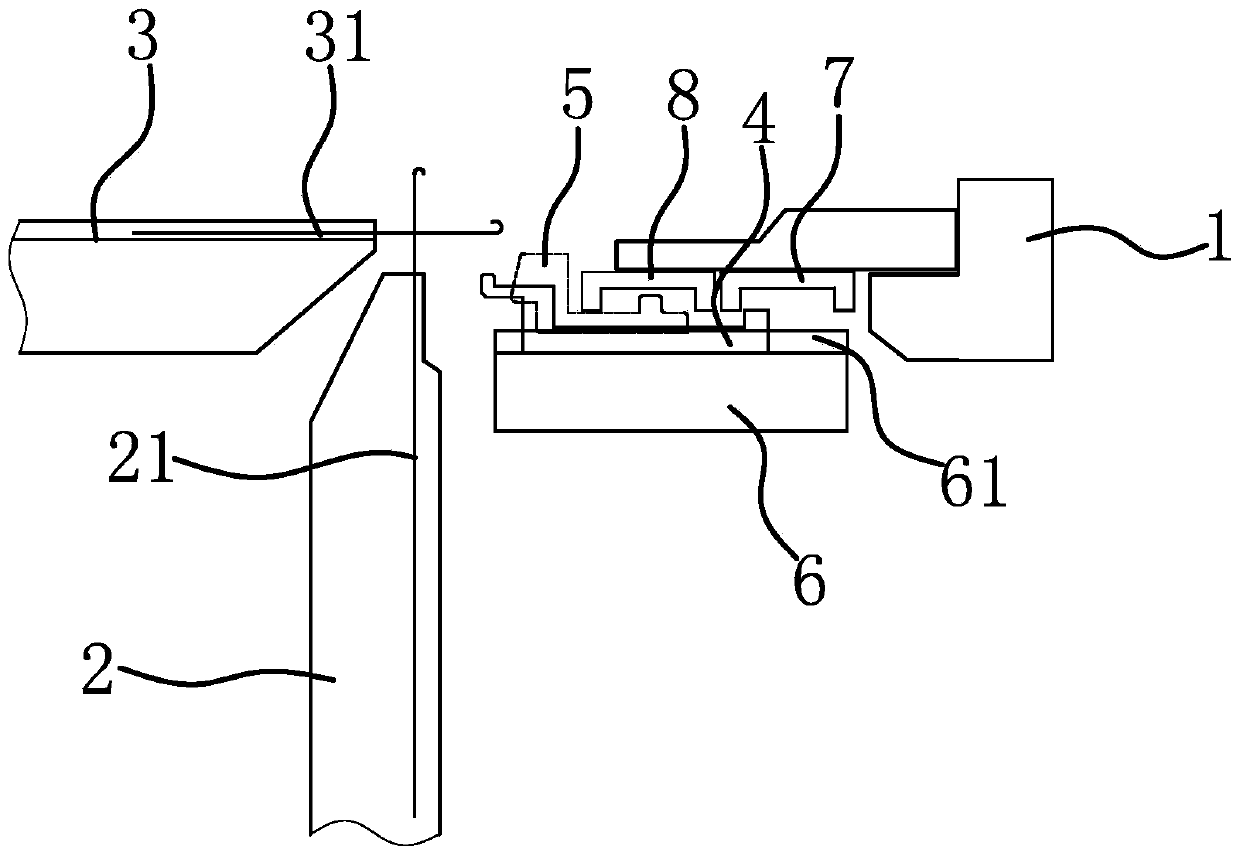

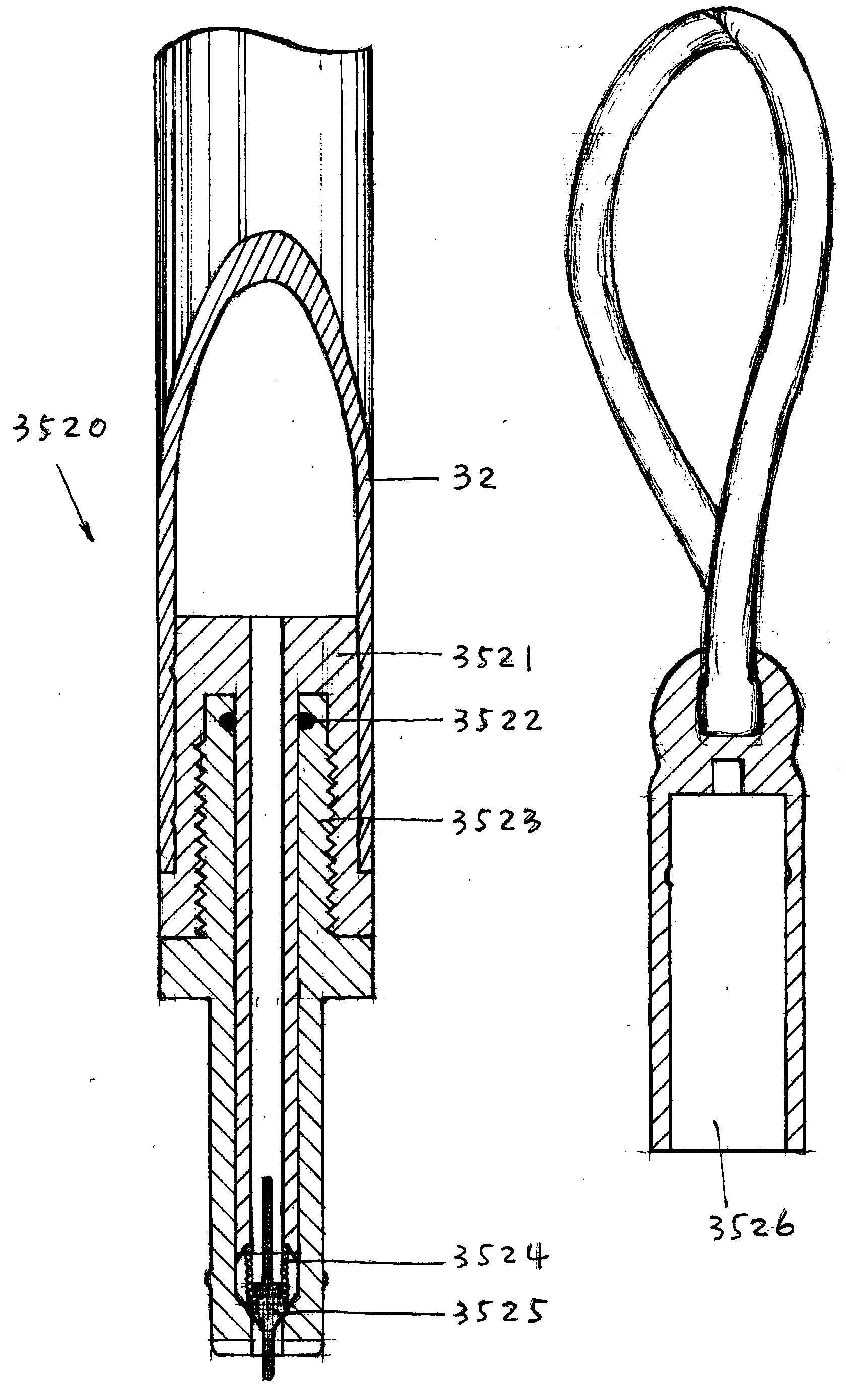

Writing brush with ink rod and fine adjustment function

InactiveCN103407310ASolution to short lifeNot perishable and smellyOther pensEngineeringMechanical engineering

The invention provides a writing brush with an ink rod and the fine adjustment function. The writing brush with the ink rod and the fine adjustment function is simple in structure, can absorb Chinese ink, contains the Chinese ink, is accurate in adjustment, natural in control and convenient to use, and can be maintained. The writing brush with the ink rod and the fine adjustment function comprises a writing brush rod assembly, a writing brush hopper assembly and a writing brush head assembly, wherein a liquid-air containing cavity is formed in the writing brush rod assembly, and the writing brush head assembly comprises a writing brush head. The writing brush with the ink rod and the fine adjustment function further comprises a movable flow-adjusting part, wherein the movable flow-adjusting part is used in cooperation with the writing brush rod assembly, the writing brush hopper assembly and the writing brush head assembly to form a fluid channel, the liquid-air containing cavity is communicated with the writing brush head through the fluid channel, the fluid channel can be opened and be closed, and the flow of the fluid channel can be changed. The fluid channel comprises a flow-adjusting part ink passing channel formed in the movable flow-adjusting part, and flow-adjusting part air passing channels which are formed between the movable flow-adjusting part and the writing brush rod assembly and between the movable flow-adjusting part and the writing brush hopper assembly, wherein the flow-adjusting part ink passing channel is communicated with the flow-adjusting part air passing channels through a sidewise exhaust channel. The writing brush rod assembly and the writing brush hopper assembly are connected in the mode that relative rotation can be carried out.

Owner:谢庆

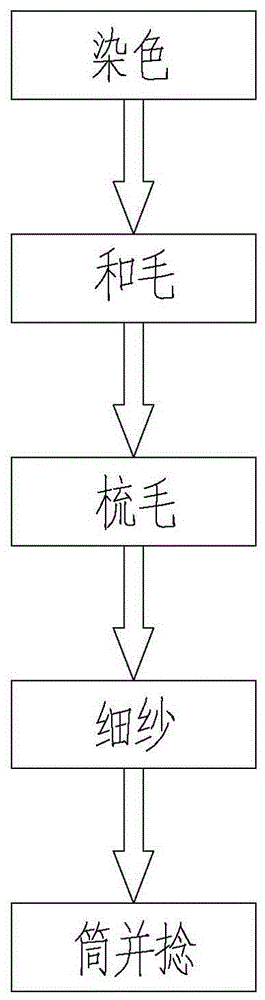

Cashmere imitated tape yarn and production technology thereof

The application relates to a cashmere textile technology, in particular to cashmere imitated tape yarn and a production technology thereof. The production technology of the cashmere imitated tape yarn comprises dyeing, mixing, combing, spinning, and winding and twisting; the process of winding and twisting is carried out according to the following method: step one, single yarn is made into twisted yarn, 220 T / M is added to 240 T / M, and S twist is adopted. According to the application, the cashmere imitated tape yarn can be obtained, common cashmere yarn production equipment is utilized for processing and formation, the cashmere imitated tape yarn can be woven to form a cashmere sweater by handwork or a flat knitting machine, and the woven product has the characteristics of being soft, smooth, rugged and luxurious; compared with the common cashmere sweater, the woven product is higher in strength and abrasive resistance, and is not likely to pill, felt, lose hair or deform; various colors and various models of the cashmere imitated tape yarn are combined, thereby meeting the leisure and natural trend of the times and diversified individual requirements; excellent performance, relatively low cost and rich appearances endow the cashmere imitated tape yarn with good practicability and popularization, and demands of different customers can be met.

Owner:新疆天山纺织服装有限公司

Three-layer cloth towel fabric and weaving method thereof

The invention discloses a three-layer cloth towel fabric and a weaving method thereof. One side of the towel is provided with a layer of first plain gauze, the other side of the towel fabric is provided with a layer of second plain gauze, binding nodes are arranged between the first plain gauze and the towel fabric, and binding nodes are arranged between the second plain gauze and the towel fabric. The towel fabric is soft, comfortable, good in permeability and water imbibition without hair slip. At the same time, the invention further discloses a weaving method of the three-layer cloth towel fabric, the weaving method can ensure three layers as while as form binding nodes according to needs at the same time.

Owner:高阳县卫东巾被厂

Glassine base paper production method

ActiveCN103821026AStrong anti-penetrationReduce dosageNon-fibrous pulp additionSpecial paperSurface strengthFilm coating

The invention discloses a Glassine base paper production method, which comprises the following steps: a, bleached sulfate softwood pulp is selected and used as a raw material; b, an alkylketene dimmer synthetic glue and paper making special starch with a weight percentage of 5% are added in the bleached sulfate softwood pulp; c, a net part is formed via double-faced bidirectional dehydration, and positive contrast is reduced; d, press dewatering is performed after the formation; e, a front drying part performs drying after dewatering; f, a paper page enters a large roller radial pressing area and passes through a soaking solution, and a certain quantity of adhesive films cover the surface of the paper page; g, the drying part performs shaping and drying after film coating; h, the processed paper is further treated by a steel roller in high-temperature calendaring intermediate; y, the paper is cut and packed by a rewinding machine. Compared with the prior art, the Glassine base paper production method has the technical characteristics of strong infiltration resistance, reduction of the use amount of silicon oil, increment of the surface strength of the paper pages and low probability of linting, and can greatly improve the production efficiency.

Owner:ZHEJIANG HUACHUAN IND GRP

Processing method for goat hair-three-dimensional-crimped-fiber-compounded needling nonwoven carpet

The invention discloses a processing method for a goat hair-three-dimensional-crimped-fiber-compounded needling nonwoven carpet. The processing method includes the steps that hot melting fibers, the three-dimensional crimped fibers and washed goat hair are mixed to form mixed fibers; water and wool oil are added into the mixed fibers, the mixed fibers are opened and mixed, and pretreated fibers are obtained; the pretreated fibers are carded through a carding machine, and a fiber web is output; the fiber web is subjected to cross lapping; the fiber web subjected to cross lapping is needled and reinforced, and a goat hair-three-dimensional-crimped-fiber-compounded needling nonwoven cloth is formed; the goat hair-three-dimensional-crimped-fiber-compounded needling nonwoven cloth is put into a drying oven and dried, and is naturally cooled to be at the room temperature after drying is completed, and the goat hair-three-dimensional-crimped-fiber-compounded needling nonwoven carpet is obtained. According to the processing method, the goat hair, the hot melting fibers and the three-dimensional crimped fibers are mixed, the nonwoven cloth for the carpet is processed with the needling nonwoven technology, and good using of goat hair fibers is achieved.

Owner:MUNSELL GARMENTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com