High-temperature resistant ester-soluble printing ink

A printing ink and ester-soluble technology, which is applied in the field of high-temperature-resistant ester-soluble printing ink, can solve the problems of poor high-temperature resistance, solvent residue, and influence on curing effect, and achieve the effect of fast drying speed and less solvent residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

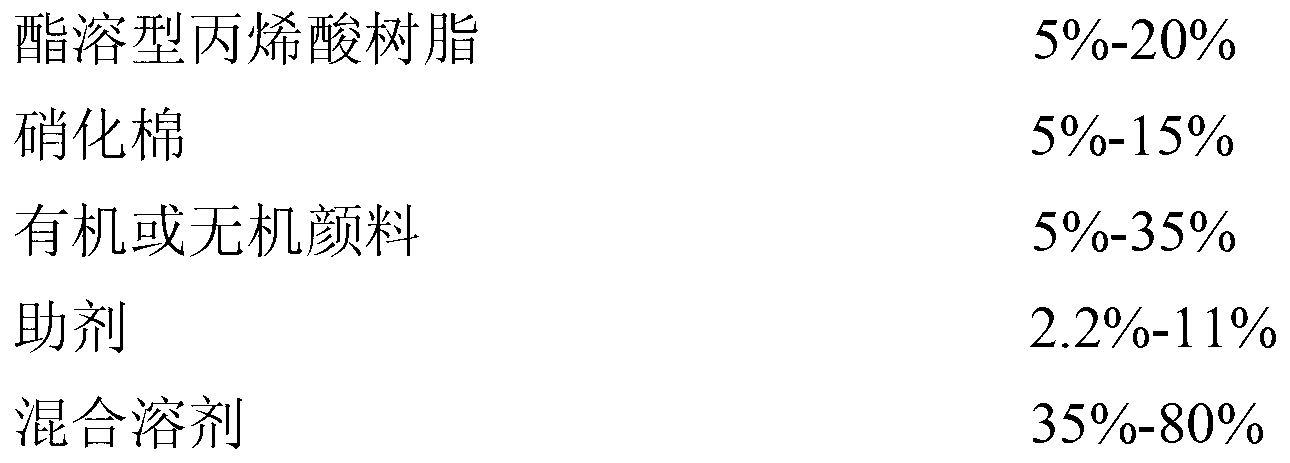

[0051] High temperature resistant type ester-soluble printing ink of the present invention is made of following components by weight percentage:

[0052] (Rohm and Haas, B-66) Ester-soluble acrylic resin 10%

[0053] (Northern Chemical Industry, 1 / 8) nitrocellulose 8%

[0054] (Ningbo Xinfu, R-606) rutile titanium dioxide 30%

[0055] (Nippon Paper 814) Ester-soluble adhesion enhancer 2%

[0056] (Maoming Petrochemical) tributyl citrate plasticizer 2%

[0057] Fumed silica 0.5%

[0058] Isopropanol 20%

[0059] N-Propyl Acetate 20%

[0060] Butyl acetate 7.5%

[0061] The high temperature resistant ester-soluble printing ink of the present invention can be obtained by mixing and stirring the components evenly.

Embodiment 2

[0063] High temperature resistant type ester-soluble printing ink of the present invention is made of following components by weight percentage:

[0064] (Rohm and Haas, B-66) Ester-soluble acrylic resin 12%

[0065] (Northern Chemical Industry, 1 / 8) nitrocellulose 8%

[0066] Phthalo blue 10%

[0067] (Nippon Paper, 814) Ester-soluble adhesion enhancer 2%

[0068] (Maoming Petrochemical) tributyl citrate plasticizer 2%

[0069] (Clariant, 3620) polyethylene micronized wax 0.5%

[0070] Isopropanol 20%

[0071] n-Butyl acetate 25.5%

[0072] Butyl acetate 20%

[0073] The high temperature resistant ester-soluble printing ink of the present invention can be obtained by mixing and stirring the components evenly.

Embodiment 3

[0075] High temperature resistant type ester-soluble printing ink of the present invention is made of following components by weight percentage:

[0076] (Rohm and Haas, B-66) Ester-soluble acrylic resin 16%

[0077] (Northern Chemical Industry, 1 / 8) nitrocellulose 10%

[0078] (Ningbo Xinfu, R-606) Rutile titanium dioxide 26%

[0079] (Nippon Paper, 814) Ester-soluble adhesion enhancer 2%

[0080] (US Shell, 828) epoxy plasticizer 2%

[0081] Fumed silica 0.5%

[0082] Isopropanol 16%

[0083] N-Propyl Acetate 18.5%

[0084] Butyl acetate 9%

[0085] The high temperature resistant ester-soluble printing ink of the present invention can be obtained by mixing and stirring the components evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com