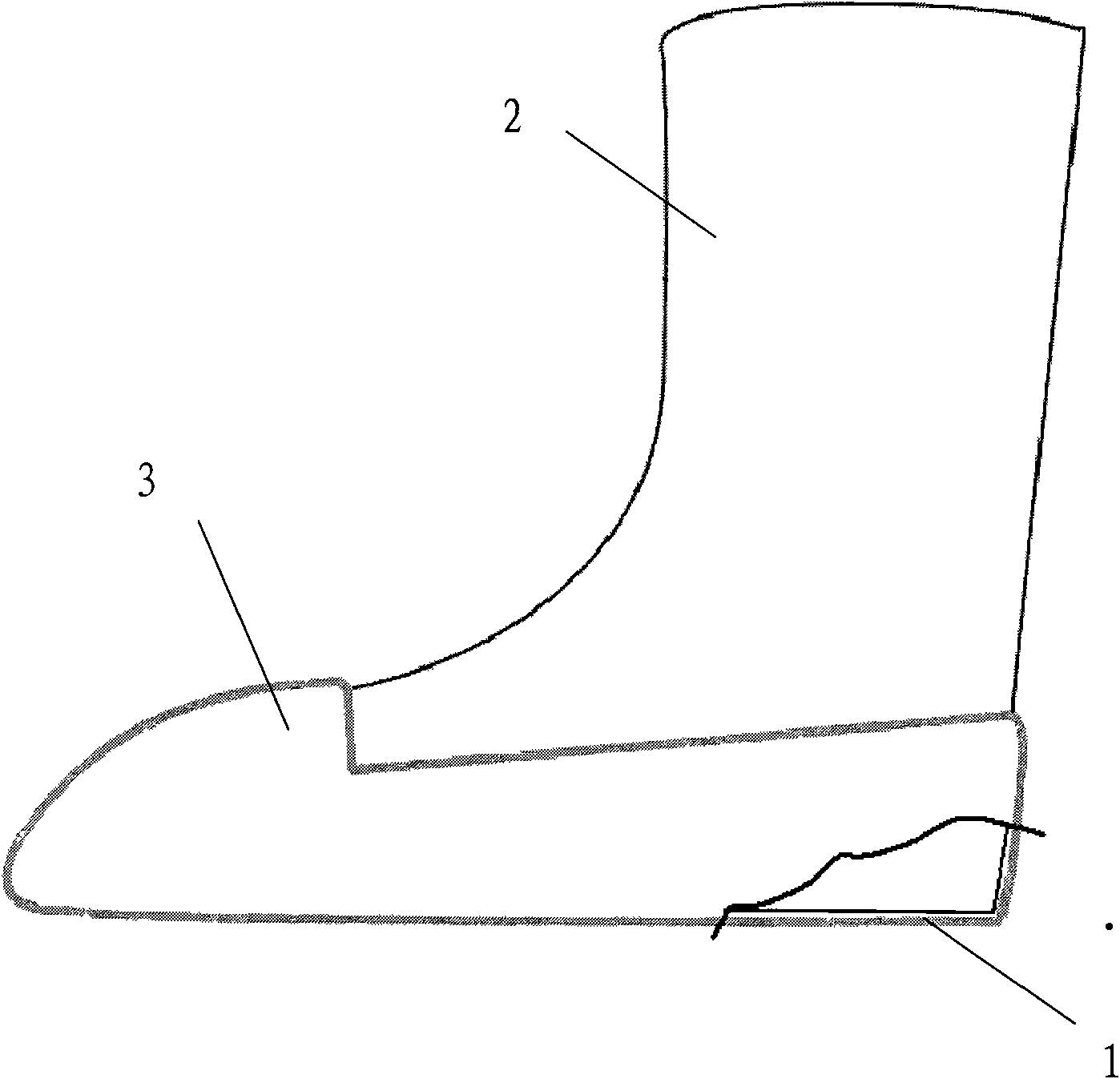

Felt shoe and production process thereof

A production process and technology of felt shoes, applied in footwear, clothing, applications, etc., can solve the problems of restricting the popularization and application of felt shoes, uneven thickness of raw wool, and difficult control of size and size, so as to increase the binding force and pulling force, The effect of good product shape and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Opening: select the carbonized wool, and beat the wool until it is completely loose with an opener;

[0038] (2) Combing: Use a carding machine to comb out the rough hair in the wool after opening in (1), and keep the wool with a fineness of 18-20 μm and a length of 20-50 mm as the raw material for making felt shoes, and keep the wool of wool combed into woolen nets;

[0039] (3) Modeling: Press the wool net into a flat felt shoe blank by hand;

[0040] (4) Steam pressure rubbing: put the made felt shoe blank into a steam pressure rubbing machine, pass water steam up and down, the steam pressure is 2 Pa, fumigate for 3 minutes, and press and rub at the same time;

[0041] (5) Kneading: Under the condition of 70°C-90°C, the steam-pressed felt shoe blanks are manually kneaded repeatedly until the surface is smooth. The thickness of the obtained product is 3mm, and the tensile force is 588N;

[0042] (6) Drying of the shape: place the shoe last in the felt shoe blank...

Embodiment 2

[0045] (1) Opening: select the carbonized wool, and beat the wool until it is completely loose with an opener;

[0046] (2) Combing: Use a carding machine to comb out the rough hair in the wool after opening in (1), and keep the wool with a fineness of 23-25 μm and a length of 50-60 mm as the raw material for making felt shoes, and keep the wool of wool combed into woolen nets;

[0047] (3) Modeling: use a press to punch the wool net into a flat felt shoe blank;

[0048] (4) Steam pressure rubbing: put the felt shoe blank made into a steam pressure rubbing machine, pass water steam up and down, the steam pressure is 5 Pa, fumigate for 3 minutes, and press and rub at the same time;

[0049] (5) Rubbing: Under the condition of 70°C-90°C, use a shrinking machine to repeatedly rub the steam-pressed felt shoe blank until the surface is smooth. The thickness of the obtained product is 5mm, and the tensile force is 784N;

[0050] (6) Drying of the shape: place the shoe last in th...

Embodiment 3

[0053] (1) Opening: choose carbonized wool, and manually beat the wool until it is completely loose;

[0054] (2) Combing: Use a carding machine to comb out the rough hair in the wool after opening in (1), and keep the wool with a fineness of 20-23 μm and a length of 60-70 mm as the raw material for making felt shoes and keep the wool The wool is combed into a woolen web;

[0055](3) Modeling: Use a punch to punch the wool net into a flat felt shoe blank;

[0056] (4) Steam pressure rubbing: put the made felt shoe blank into a steam pressure rubbing machine, pass water steam up and down, the steam pressure is 3 Pa, fumigate for 3 minutes, and press and rub at the same time;

[0057] (5) Rubbing: Under the condition of 70°C-90°C, manually rub the steam-pressed felt shoe blank repeatedly until the surface is smooth. The thickness of the obtained product is 4mm (and the tensile force is 686N;

[0058] (6) Drying of the shape: place the shoe last in the felt shoe blank after rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com