Manufacturing process of sanding cashmere sweater

A production process and technology for cashmere sweaters, which are applied in the field of sand-washed cashmere sweaters to achieve the effects of being full of the atmosphere of the times, stable in sand-washing effect and soft to the touch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Example: pure cashmere yarn 3126 / 2, the raw material used is 100% cashmere, the twist of single yarn is 450T / M, and the twist of double yarn is 240T / M. Use a 12G flat knitting machine to weave plain stitches and 1-1 ribs on the hem and cuffs. The garments will not be washed, shrinked, or ironed, and the garments will be dyed. The blue dyeing process is as follows:

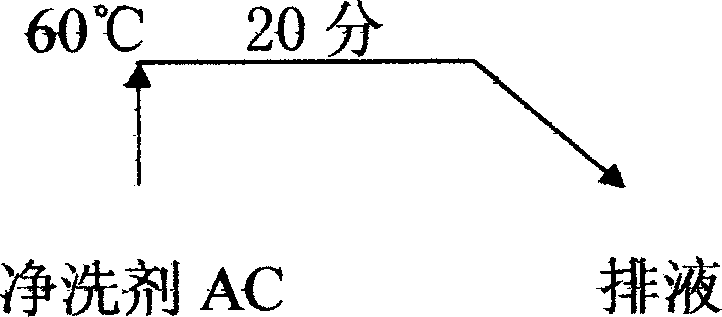

[0027] (1) Pretreatment

[0028] Use detergent AC: 0.5g / L, water temperature: 40°C, treat for 20 minutes, overflow wash water;

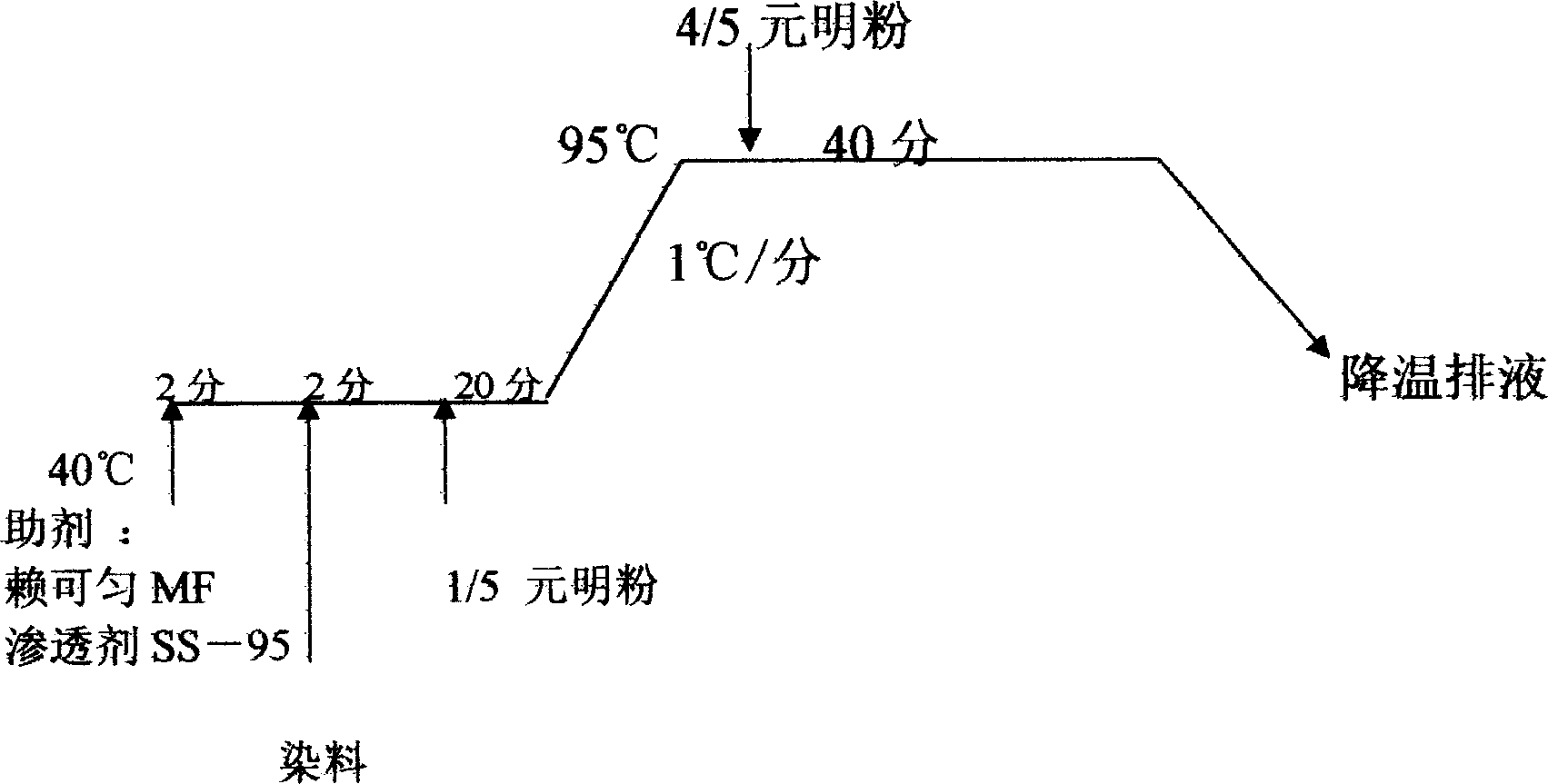

[0029] (2) Dyeing

[0030] Dye: Salafinier Solophenyl Blue FGLE 1%

[0031] Salafinier Solophenyl Blue BFF 1.2%

[0032] Additive: Lai Keyun MF 1.5%

[0033] Penetrant SS-95 1.5%

[0034] Yuanmingfen 50g / L

[0035] Process: add Lai Keyun MF and penetrant SS-95 auxiliary agent at a water temperature of 40°C, and run for 2 minutes; then add the above-mentioned dyes, and run for 2 minutes; then add 1 / 5 Yuan Mingfen, run for 20 minutes, and start to heat up. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com