Method and device for connecting bristles and handle enclosure frame and brush manufactured through method

A technology of bristles and handles, applied to devices and brushes made by the method, a method field, which can solve the problems of long processing time, low efficiency, hair loss, etc., to shorten processing time, reduce product cost, and not easy to fall off hair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

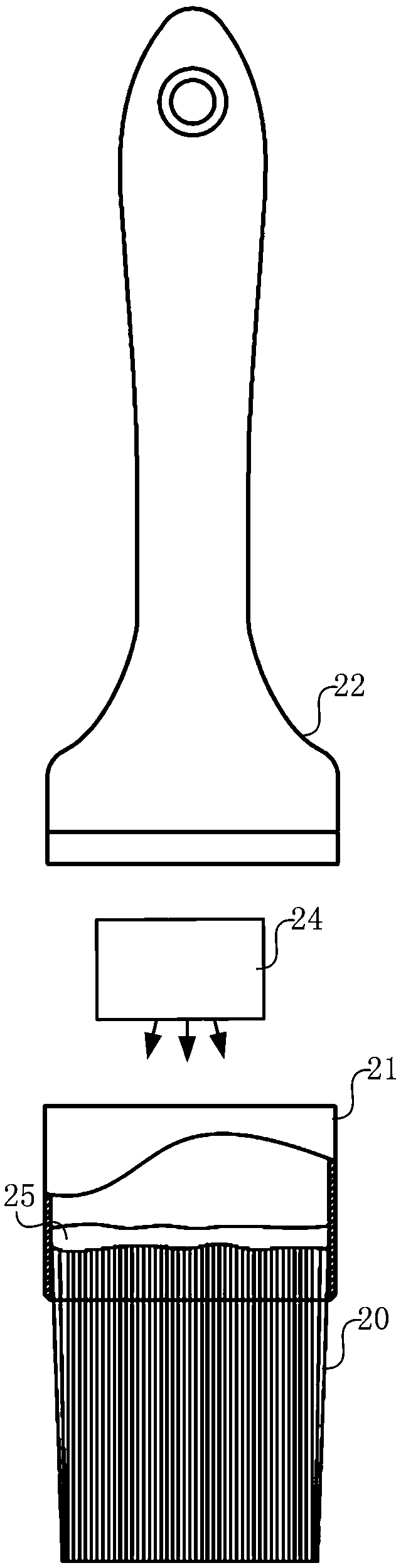

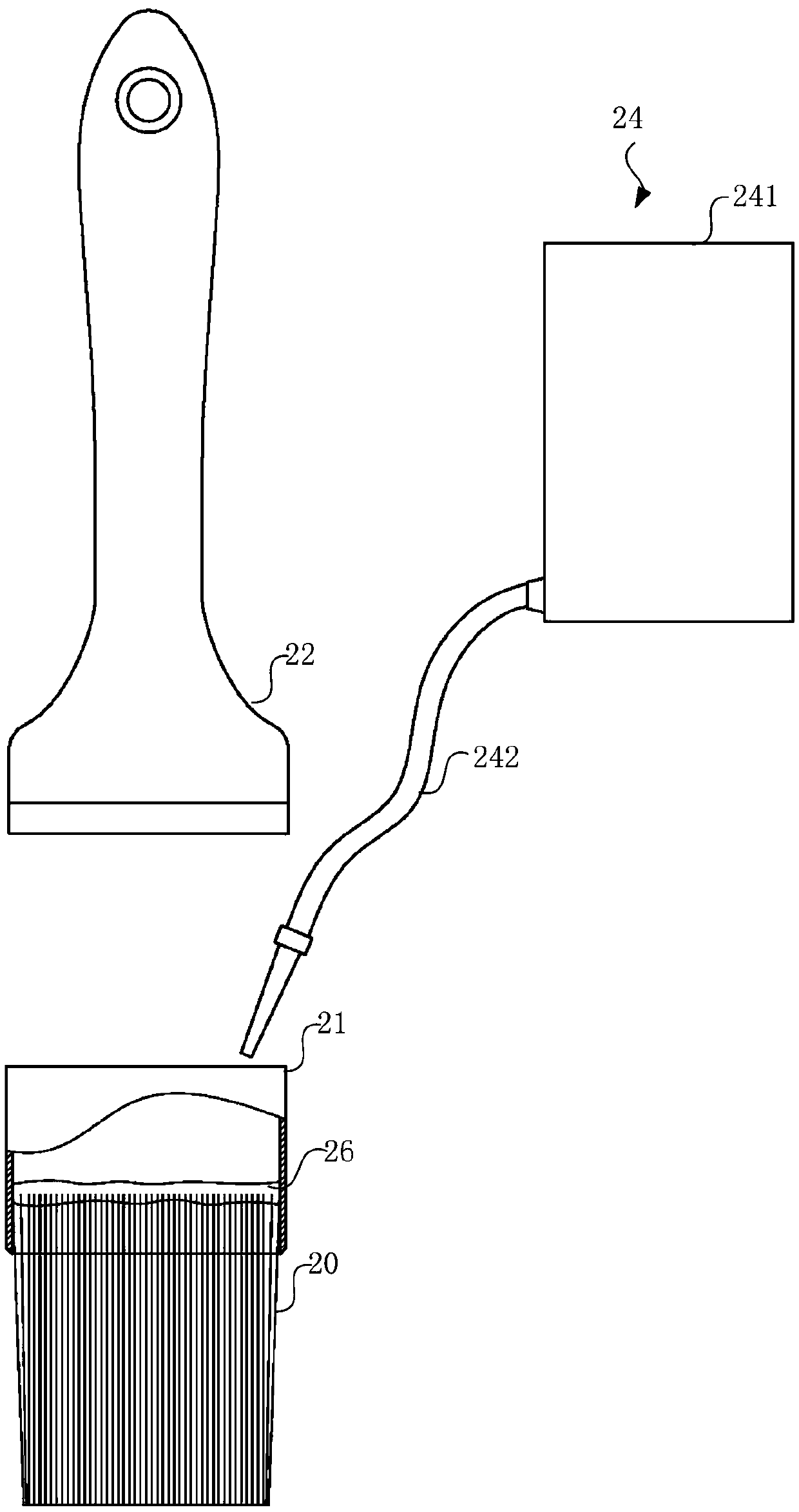

[0019] The method and device for connecting the bristles to the frame of the handle provided by the present invention and the specific implementation of the brush made by the method will be described in detail below in conjunction with the accompanying drawings. In order to clearly explain the present invention, the figure 2 , image 3 and Figure 4 The handle frame is shown in partial cutaway view.

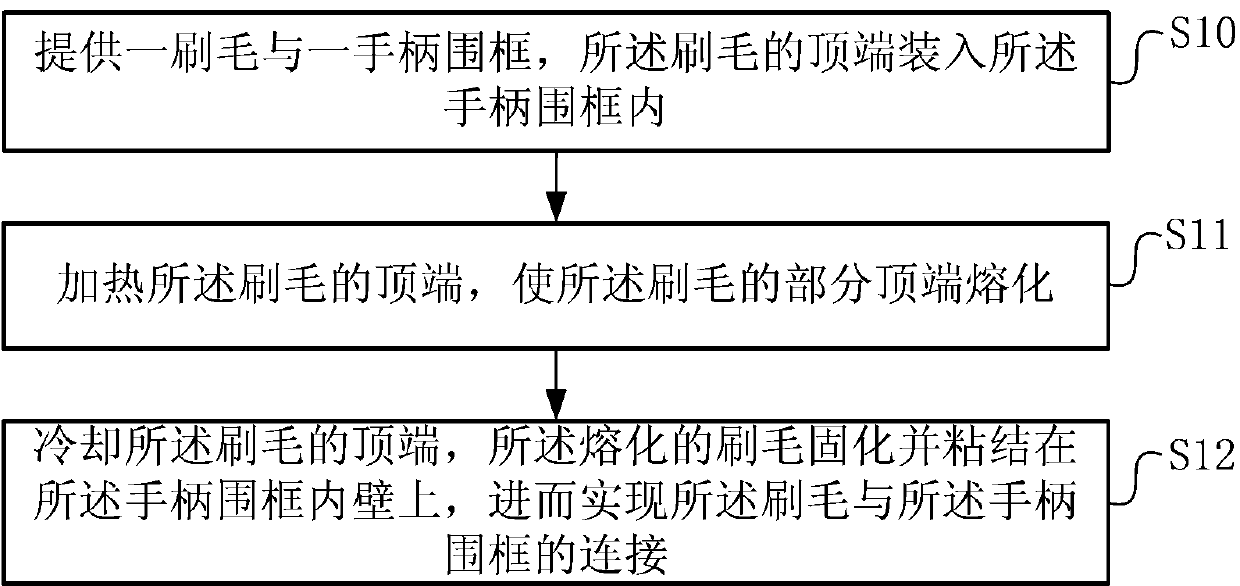

[0020] see figure 1 , the method that the bristle of the present invention is connected with the handle surrounding frame comprises the steps:

[0021] Step S10: providing a bristle and a handle frame, and the top of the bristle is put into the handle frame.

[0022] The top ends of the bristles can be fixed by a fixed structure and then packed into the handle frame. The handle frame can be made of metal or plastic material.

[0023] Step S12: heating the tips of the bristles to melt part of the tips of the bristles.

[0024] In one embodiment of the present invention, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com