Method for tanning Tan sheep skin with nano softening enzyme

A kind of sheepskin softening enzyme technology, applied in application, chemical treatment before tanning, small raw hide/big raw hide/leather/fur treatment, etc., can solve the problem of skin thickness, chrome tanning waste liquid pollution environment, aluminum salt and collagen fiber Combined with problems such as instability, it can reduce production costs, reduce environmental pollution, and reduce daily maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

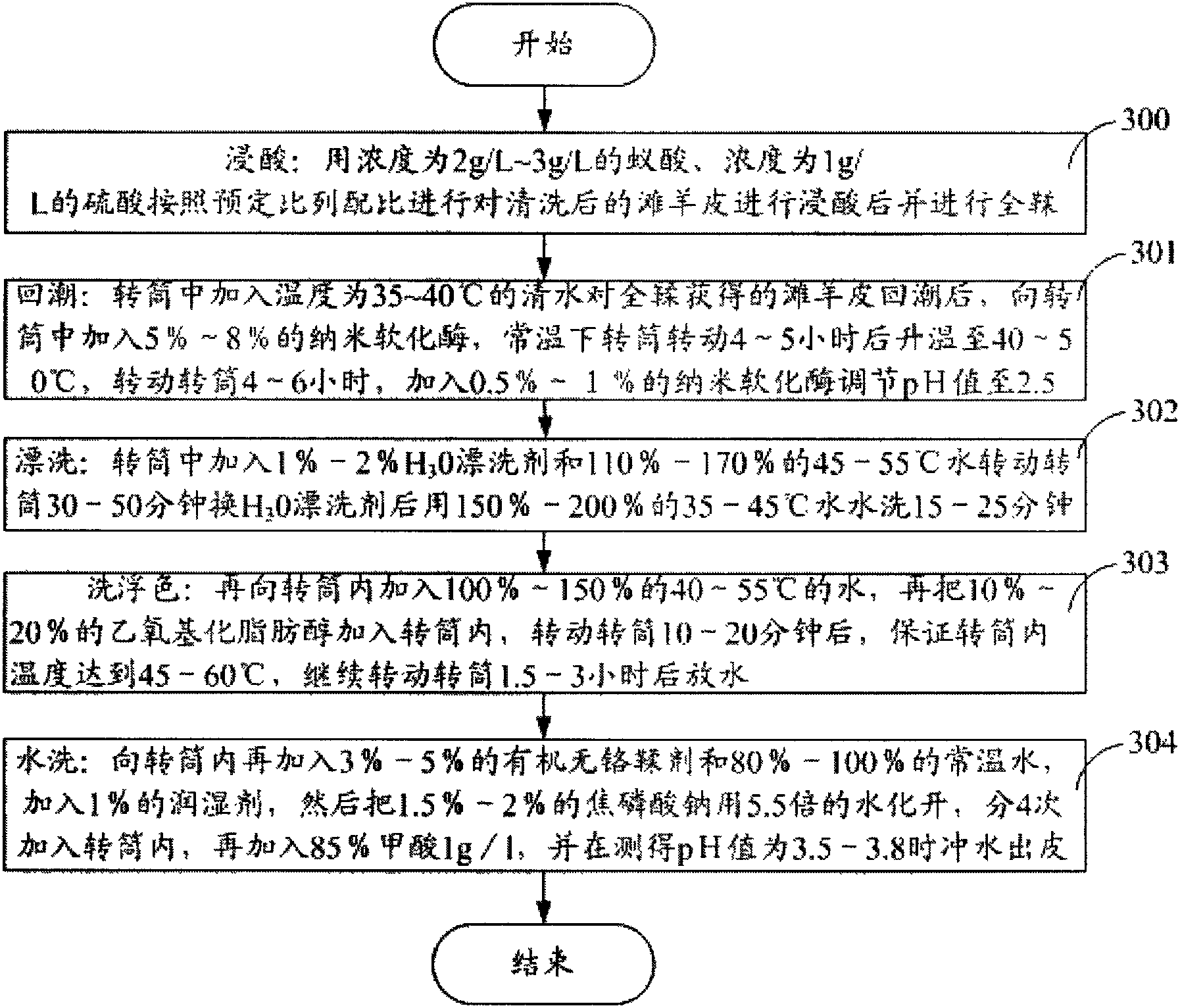

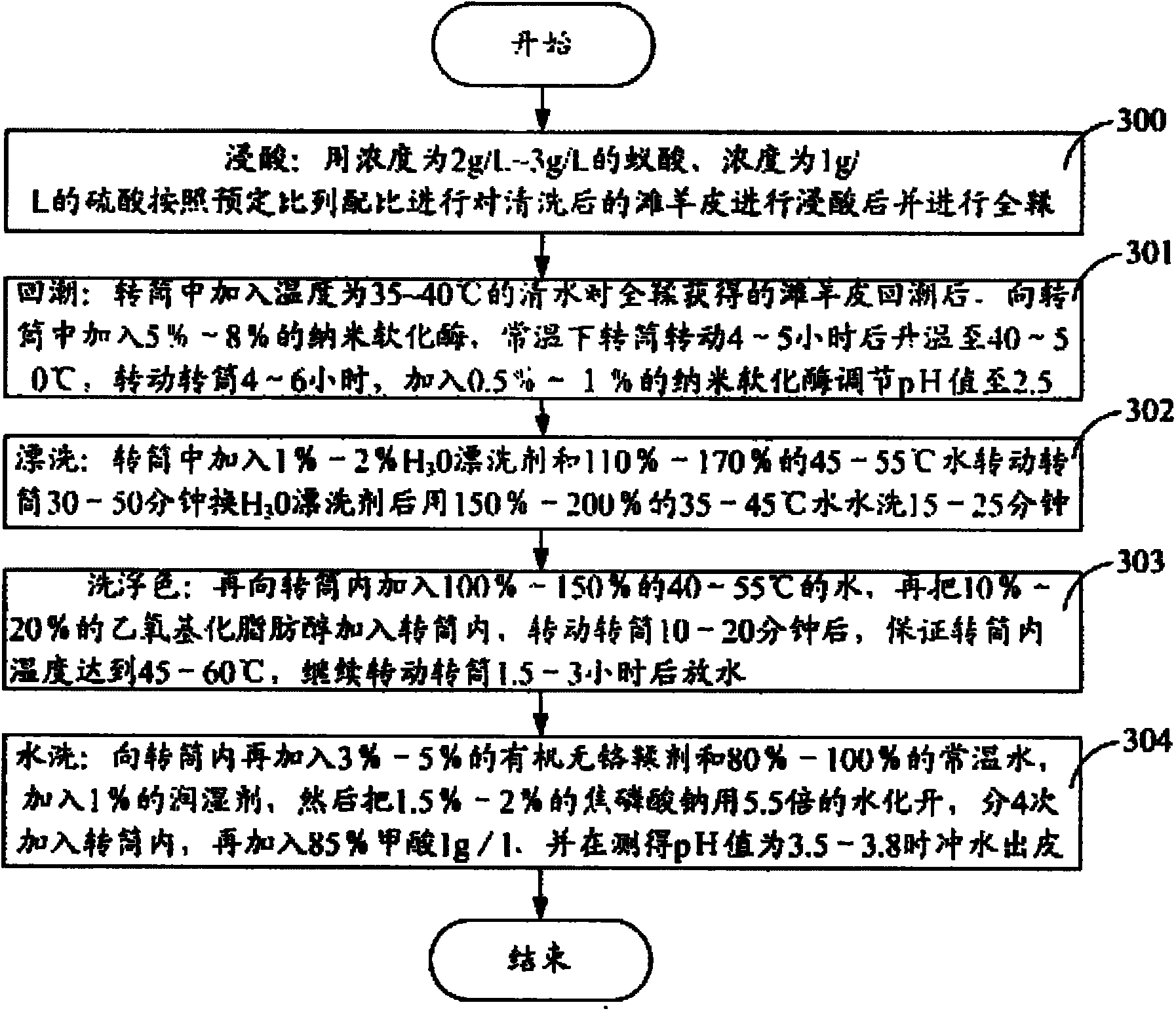

[0013] Please see also figure 1 A method for tanning sheepskin with nano softening enzymes, comprising the following steps:

[0014] Step S300, pickling: use formic acid with a concentration of 2g / L-3g / L and sulfuric acid with a concentration of 1g / L to carry out pickling and full tanning on the washed sheepskin according to a predetermined ratio.

[0015] Step S301, regaining moisture: adding water at a temperature of 35-40°C to the drum to rehydrate the fully tanned sheepskin, adding 5% to 8% of nano softening enzyme to the drum, and rotating the drum at room temperature for 4-5 After one hour, the temperature is raised to 40-50° C., and the drum is continued to be rotated for 4-6 hours, and 0.5% to 1% of nano-softening enzyme is added to adjust the pH value to 2.5, so that the drum stops rotating.

[0016] Step S302, rinsing: adding 1% to 2% H to the drum 3 O rinse agent and 110% to 170% of 45 to 55°C water (water relative to the dry weight of sheepskin), continue to rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com