Cashmere imitated tape yarn and production technology thereof

A production process, tape yarn technology, applied in the field of cashmere textile technology, can solve the problems of non-wear resistance, cost, high cost, waste, etc., and achieve the effect of strong wear resistance, not easy to pilling, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

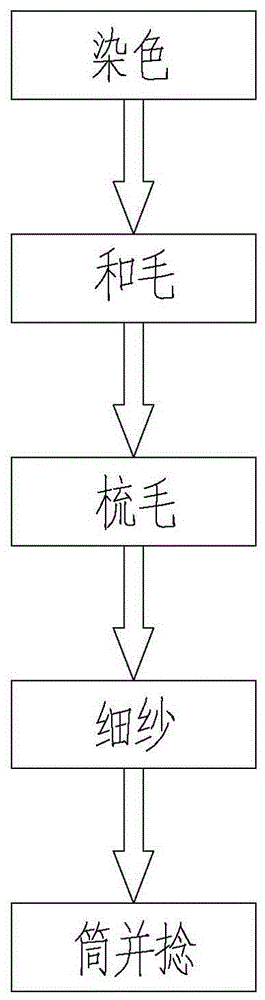

[0017] Example 1, such as figure 1 Shown, the production technology of cashmere imitation tape yarn comprises dyeing, wool and wool, carding, spun yarn and tube and twisting, and described tube and twisting process is carried out as follows; The first step, the single yarn of 1 / 26Nm to 1 / 28Nm Make double-ply yarn 2 / 26Nm to 2 / 28Nm, add 220 twist / m to 240 twist / m, "S" twist; the second step, first put 5 double-ply yarn 2 / 26Nm to 2 / 28Nm in parallel The twisting machine is divided into three types with different qualities to reduce concentrated joints, and then it is divided into three yarn paths on the twisting machine and paralleled. The division method is 2 strands, 1 strand, and 2 strands, and each yarn path uses the same Double-ply yarns of different quality specifications from 2 / 26Nm to 2 / 28Nm, the three yarn paths use three kinds of double-ply yarns of different qualities from 2 / 26Nm to 2 / 28Nm to form parallel yarns from 2 / 26Nm to 2 / 28Nm ; The third step is to add 60 twist...

Embodiment 2

[0028] Embodiment 2, this cashmere imitation belt yarn is made according to the following processes: dyeing, kneading, carding, spun yarn, tube and twisting, and the tube and twisting process is carried out as follows; in the first step, the single yarn is made To form a plied yarn, add 230 twists / m to 240 twists / m, and twist in the "S" direction; in the second step, the 5 strands of the plied yarn in the second step are divided into three yarn paths on the twisting machine to form a doubling yarn; in the third step, add 60 twists / meter to 70 twists / meter to the doubling yarn in the second step, and "Z" twists.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com