Method for producing writing brushes free of bristle falling

A production method and brush technology, which can be applied to other ink pens, printing, writing utensils, etc., can solve the problem of easy hair loss on the brush head, and achieve the effects of quick glue distribution, simplified hair selection process, and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

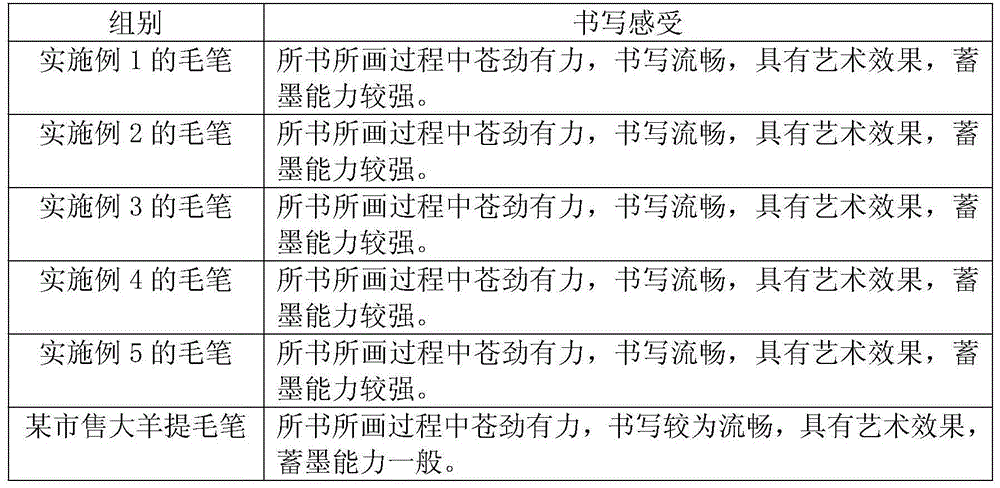

Examples

Embodiment 1

[0026] A method for making a goat hair brush head, the steps are as follows:

[0027] (1) High-temperature degreasing: select the upper part of goat hair with a length of 3 cm, spread the wool on the paper, sprinkle with straw ash, and then use an iron of appropriate size to iron evenly for 5-10 minutes to perform high-temperature degreasing;

[0028] (2) Preliminary selection of sieve: sieve the degreased wool with a 190-mesh sieve for primary selection of wool, because the wool without peaks is harder than the wool with peaks, and the sieve will just sieve the hard peaks The wool is brushed out, and the good ones will be left without peaks. This operation is faster than the general material selection and it is not easy to waste the good materials with peaks;

[0029] (3) Fine selection: tidy up the hair piles with peaks selected from the primary selection, scrape off the remaining miscellaneous hairs with a blunt knife, and repeat 1-2 times as needed;

[0030] (4) Selection...

Embodiment 2

[0036] A method for making a goat hair brush head, the steps are as follows:

[0037] (1) High-temperature degreasing: select the upper part of goat hair with a length of 7 cm, spread the wool on the paper, sprinkle with straw ash, and then use an iron of appropriate size to iron evenly for 9-12 minutes for high-temperature degreasing;

[0038] (2) Preliminary selection of sieve: Sieve the degreased wool with a 160-mesh sieve for primary selection of wool, because the wool without peaks is harder than the wool with peaks, and the sieve will just sieve the hard peaks The wool is brushed out, and the good ones will be left without peaks. This operation is faster than the general material selection and it is not easy to waste the good materials with peaks;

[0039] (3) Fine selection: tidy up the hair piles with peaks selected from the primary selection, scrape off the remaining miscellaneous hairs with a blunt knife, and repeat 1-2 times as needed;

[0040] (4) Selection of bru...

Embodiment 3

[0046] A method for making a rabbit hair brush head, the steps are as follows:

[0047](1) High-temperature degreasing: select the upper 2cm length of rabbit hair, spread the wool on the paper, sprinkle with straw ash, and then use an iron of appropriate size to iron evenly for 6-7 minutes for high-temperature degreasing;

[0048] (2) Preliminary selection of sieve: sieve the degreased wool with a 190-mesh sieve for primary selection of wool, because the wool without peaks is harder than the wool with peaks, and the sieve will just sieve the hard peaks The wool is brushed out, and the good ones will be left without peaks. This operation is faster than the general material selection and it is not easy to waste the good materials with peaks;

[0049] (3) Fine selection: tidy up the hair piles with peaks selected from the primary selection, scrape off the remaining miscellaneous hairs with a blunt knife, and repeat 1-2 times as needed;

[0050] (4) Selection of brush head raw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com