Wool-like all-cotton fabric and processing method thereof

A processing method and technology for cotton fabrics, applied in the direction of fabric surface trimming, textile material processing, continuous processing of textile materials, etc., can solve problems such as hardening, easily causing human respiratory diseases and allergic phenomena, environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

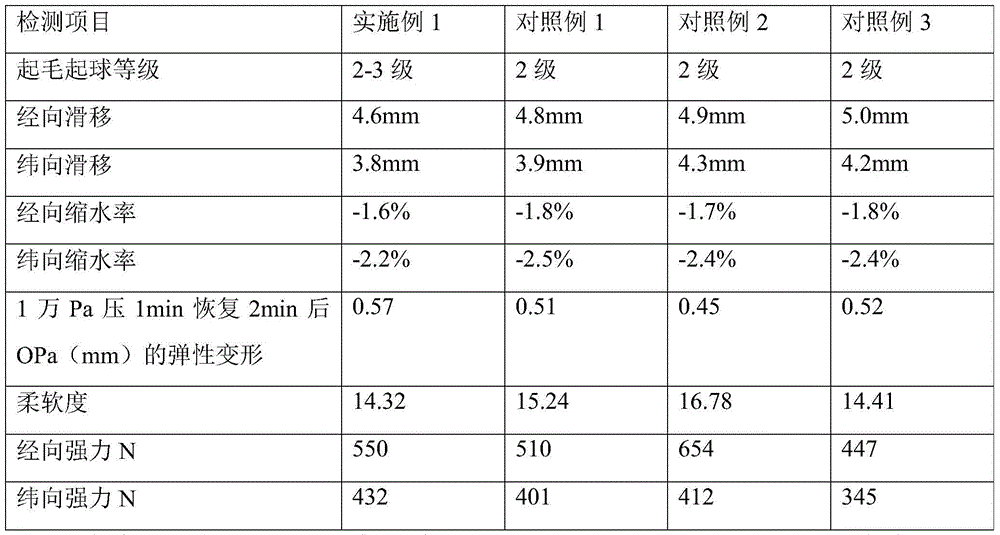

Embodiment 1

[0031] Specifications: The warp yarn is 32S siro-spun cotton yarn, the twist coefficient is 380, the single yarn breaking strength is 16cN / tex-17cN / tex, and the 3mm hairiness index is less than 8%. The weft yarn is 21S ring-spun cotton yarn with a twist coefficient of 375, a single yarn strength of 16cN / tex to 16.5cN / tex, and a 3mm hairiness index of less than 10%. The gray cloth has a width of 105 inches, a specification of 32S*21S / 133*60, a weave structure of six warp satin weaves, and the numbers of fly are 2, 3, 3, 2, 1, 1 respectively.

[0032] Its production method includes the following steps: winding → warping → sizing → threading of warp → threading of warp stopper → threading of brown silk → inserting reed → machine weaving → gray fabric singeing → desizing, scouring, bleaching → light sanding →Printing→Steaming and washing→Soft setting→Pre-shrinking.

[0033] When sizing, phosphate starch slurry is used, and a small amount of propylene and wax flakes are added.

...

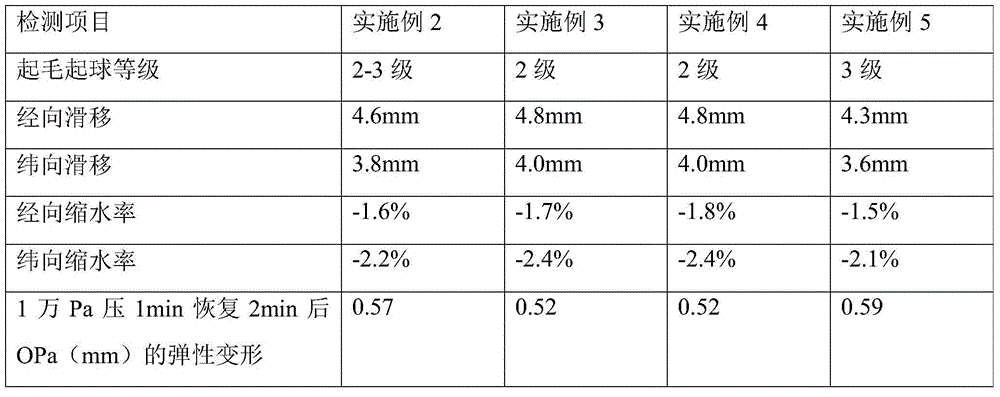

Embodiment 2

[0047] Specifications: The warp yarn is 32S siro-spun cotton yarn, the twist coefficient is 395, the single yarn breaking strength is 16.5cN / tex-17cN / tex, and the 3mm hairiness index is less than 8%. The weft yarn is 18S ring-spun cotton yarn with a twist coefficient of 380, a single yarn strength of 16cN / tex to 16.5cN / tex, and a 3mm hairiness index of less than 10%. The gray cloth has a width of 105 inches, the specification is 32S*18S / 133*58, the weave structure is a satin weave on the warp surface with six pieces, and the flying numbers are 2, 3, 3, 2, 1, 1 respectively.

[0048] Its production method includes the following steps: winding → warping → sizing → threading of warp → threading of warp stopper → threading of brown silk → inserting reed → machine weaving → gray fabric singeing → desizing, scouring, bleaching → light sanding →Printing→Steaming and washing→Soft setting→Pre-shrinking.

[0049] The singeing process adopts two fronts and one reverse, the vehicle speed...

Embodiment 3

[0053] The difference from Example 2 is that the sanding process of the carbon roller is not used.

[0054] Specifications: The warp yarn is 32S siro-spun cotton yarn, the twist coefficient is 395, the single yarn breaking strength is 16.5cN / tex-17cN / tex, and the 3mm hairiness index is less than 8%. The weft yarn is 18S ring-spun cotton yarn with a twist coefficient of 380, a single yarn strength of 16cN / tex to 16.5cN / tex, and a 3mm hairiness index of less than 10%. The gray cloth has a width of 105 inches, the specification is 32S*18S / 133*58, the weave structure is a satin weave on the warp surface with six pieces, and the flying numbers are 2, 3, 3, 2, 1, 1 respectively.

[0055] Its production method includes the following steps: winding → warping → sizing → threading of warp → threading of warp stopper → threading of brown silk → inserting reed → machine weaving → gray fabric singeing → desizing, scouring, bleaching → light sanding →Printing→Steaming and washing→Soft sett...

PUM

| Property | Measurement | Unit |

|---|---|---|

| twist factor | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com