Laundry soap powder and preparation method thereof

A soap powder and non-ionic surface technology, applied in the field of daily washing, can solve the problems of broken covalent bond between reactive dyes and fabrics, poor solubility of soap powder, weak decontamination ability, etc. , the effect of enhancing the decontamination ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

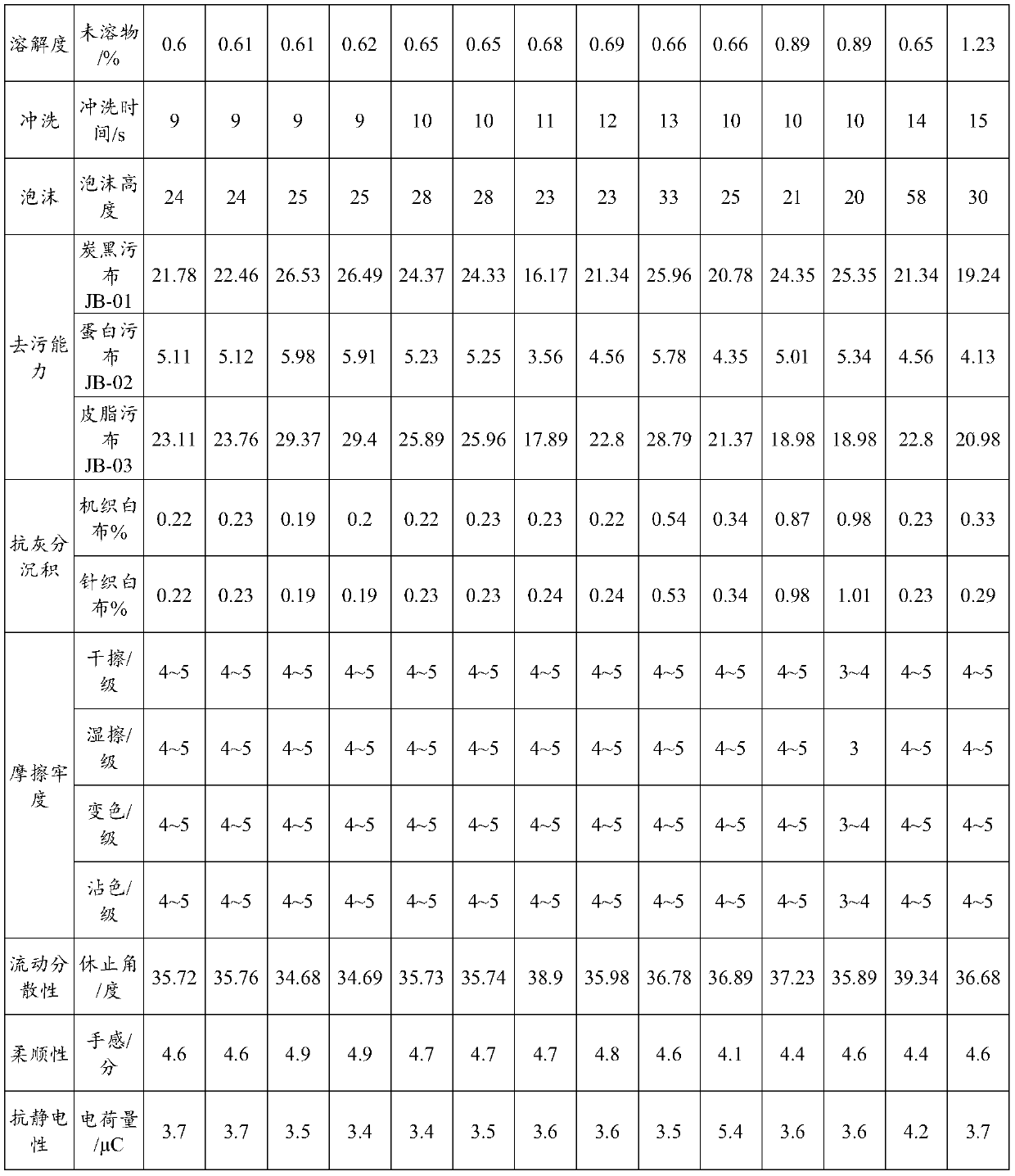

Examples

Embodiment 1

[0029] The preparation of embodiment 1 rose extract, lotus extract

[0030] 1. The preparation of rose extracts, the steps are: crush 1kg of rose petals, add in 7.5L of 75% ethanol aqueous solution, ultrasonic treatment, ultrasonic frequency is 5 ~ 10KHz, ultrasonic time is 3 ~ 5min, then soak for 6 ~ 10h , filtered, and the filtrate was distilled under reduced pressure and dried to obtain rose flower extract.

[0031]2. Preparation of peppermint extract, the steps are: crush 1kg of mint leaves, add to 5L of 50% ethanol aqueous solution, ultrasonically treat, ultrasonic frequency is 5-10KHz, ultrasonic time is 3-5min, then soak for 4-6h, filter , the filtrate was distilled under reduced pressure and dried to obtain mint extract.

Embodiment 2

[0033] A laundry soap powder, which is composed of the following raw materials in proportion by weight: 33 parts of vegetable oil fatty acid sodium salt, 11 parts of α-sulfo fatty acid methyl ester sodium salt, 15 parts of coconut oil fatty acid diethylamide, fatty alcohol polyvinyl ester ether -97 parts, 5 parts of fatty acid methyl ester ethoxylate, 3 parts of tea saponin, 1 part of polyoxyethylene fatty acid ester, 0.35 parts of sodium iminodisuccinate, 0.22 parts of sodium citrate, 0.3 parts of bamboo vinegar, rose 0.05 part of flower extract, 0.05 part of peppermint extract, 0.02 part of high carbon alcohol fatty acid ester compound.

[0034] Preparation:

[0035] (1) First, add vegetable oil fatty acid sodium salt and α-sulfo fatty acid methyl ester sodium salt into a grinder for grinding until the particle size is 200-300 mesh, and the ground vegetable oil fatty acid sodium salt and α-sulfo fatty acid methyl ester Sodium salt and 50 parts of deionized water were added ...

Embodiment 3

[0042] A laundry soap powder, which is composed of the following raw materials in proportion by weight: 33 parts of vegetable oil fatty acid sodium salt, 11 parts of α-sulfo fatty acid methyl ester sodium salt, 15 parts of coconut oil fatty acid diethylamide, fatty alcohol polyvinyl ester ether -97 parts, 5 parts of fatty acid methyl ester ethoxylate, 3 parts of tea saponin, 1 part of polyoxyethylene fatty acid ester, 0.35 parts of sodium iminodisuccinate, 0.22 parts of sodium citrate, 0.5 parts of bamboo vinegar, rose 0.05 part of flower extract, 0.05 part of peppermint extract, 0.04 part of high carbon alcohol fatty acid ester compound.

[0043] The preparation method refers to Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com