Injection molding fine Yangba resin for synthetic leather and preparation method thereof

A technology of synthetic leather and yangbuck, which is applied in the direction of textiles and papermaking, fiber treatment, improved handle fibers, etc., to achieve the effect of strong cashmere feeling, good color development and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Injection molding yambuck resin for synthetic leather is composed of the following raw material components: in parts by mass, it contains 52 parts of injection molding yambuck resin, 14 parts of butanone, 11 parts of toluene, 15 parts of methyl acetate, and 2.5 parts of fine yambuck powder , Phthalate ester plasticizer 1.5 parts.

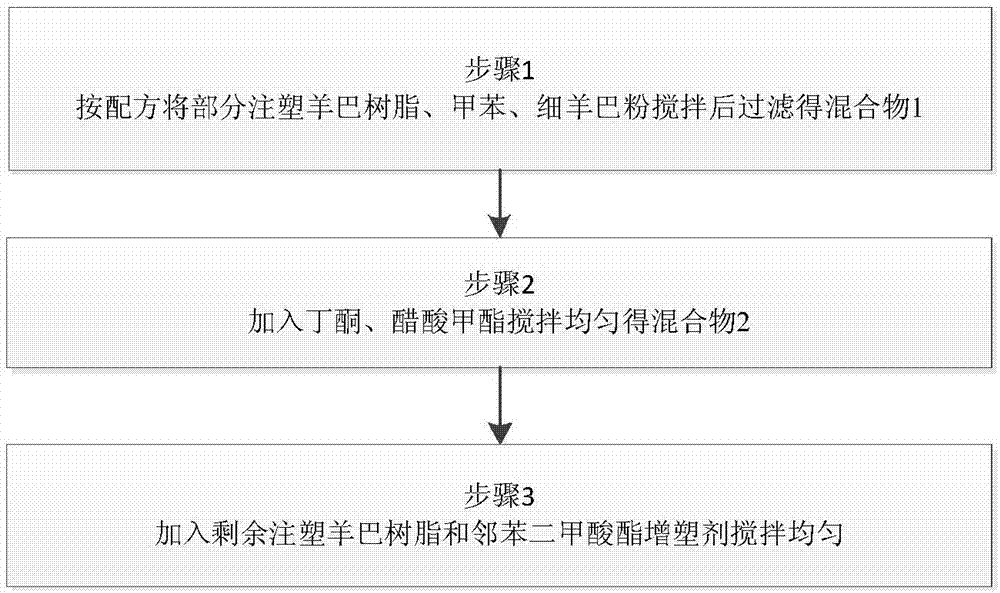

[0025] The production technology of injection molding thin yamba resin of the present invention is as follows:

[0026] Step 1: According to the formula, 42 parts of injection-molded yambuck resin, 11 parts of toluene, and 2.5 parts of fine yambuck powder were stirred and filtered to obtain mixture 1;

[0027] Step 2: Add mixture 1 obtained in step 1 to 14 parts of butanone and 15 parts of methyl acetate and stir to obtain mixture 2;

[0028] Step 3: Add the mixture 2 obtained in step 2 to the remaining 10 parts of injection molding yambuck resin and 1.5 parts of phthalate plasticizer and stir well to obtain injection molding yambuck resin. ...

Embodiment 2

[0030] Injection molding yambuck resin for synthetic leather is composed of the following raw material components: in parts by mass, it contains 50 parts of injection molding yambuck resin, 13 parts of butanone, 10 parts of toluene, 14 parts of methyl acetate, and 2 parts of fine yambuck powder , phthalate plasticizer 1 part.

[0031] The production technology of injection molding thin yamba resin of the present invention is as follows:

[0032] Step 1: According to the formula, 40 parts of injection-molded yangbuck resin, 10 parts of toluene, and 2 parts of fine yangbuck powder were stirred and filtered to obtain mixture 1;

[0033] Step 2: Add 12 parts of butanone and 14 parts of methyl acetate to the mixture 1 obtained in step 1 and stir to obtain mixture 2;

[0034] Step 3: Add the mixture 2 obtained in step 2 to the remaining 10 parts of injection-molded yambuck resin and 1 part of phthalate plasticizer, and stir evenly to obtain injection-molded fine yambuck resin.

Embodiment 3

[0036] Injection molding yambuck resin for synthetic leather is composed of the following raw material components: in parts by mass, it contains 53 parts of injection molding yambuck resin, 15 parts of butanone, 12 parts of toluene, 16 parts of methyl acetate, and 3 parts of fine yambuck powder , phthalate plasticizer 2 parts.

[0037] The production technology of injection molding thin yamba resin of the present invention is as follows:

[0038] Step 1: According to the formula, 43 parts of injection-molded yangbuck resin, 12 parts of toluene, and 3 parts of fine yangbuck powder were stirred and filtered to obtain mixture 1;

[0039] Step 2: Add 15 parts of butanone and 16 parts of methyl acetate to the mixture 1 obtained in step 1 and stir to obtain mixture 2;

[0040] Step 3: Add the mixture 2 obtained in step 2 to the remaining 10 parts of injection molding yambuck resin and 2 parts of phthalate plasticizer and stir well to obtain injection molding yambuck resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com