Weather-resistant island-and-island fiber base fabric and preparation method and application thereof

A weather resistance, base fabric technology, applied in fiber processing, fiber type, non-woven fabrics, etc., can solve problems such as high cost and environmental pollution, and achieve the effect of improving weather resistance, excellent fleece feeling, and avoiding water waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

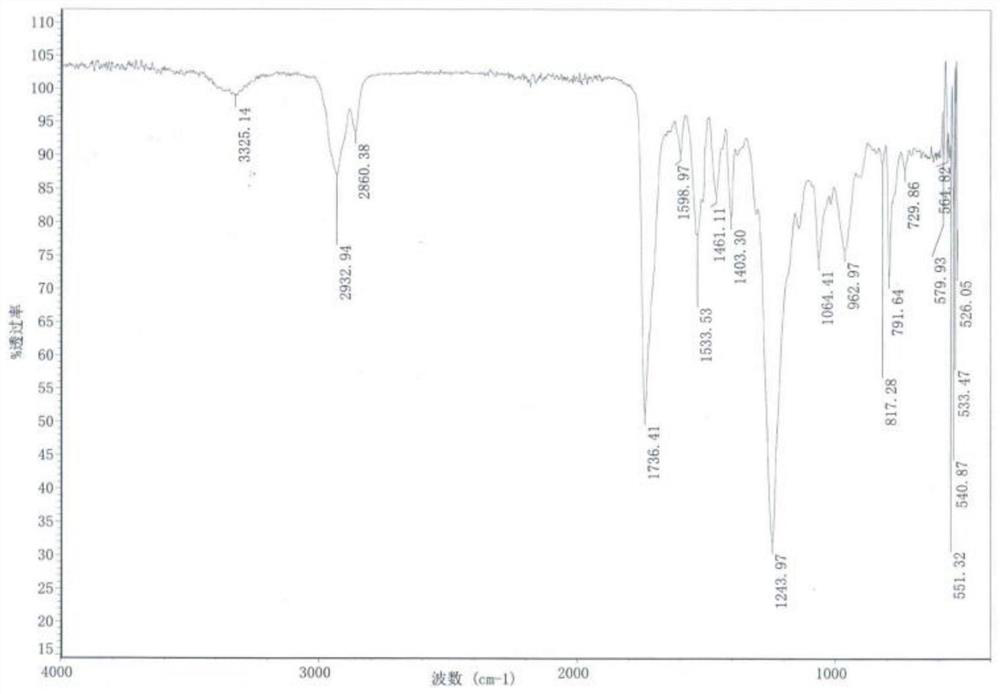

Embodiment 1

[0068] (1) Put poly-3-methylpentanediol adipate diol (0.03 mol), polycarbonate diol (0.1 mol), and solvent N,N-dimethylformamide (100 ml) into the reaction flask , mix evenly, put in hexamethylene diisocyanate (0.12mol), the catalyst bismuth neodecanoate (0.01g) react at 95 ℃, until the isocyanate group content is constant;

[0069] (2) After the prepolymerization is completed, add ethylene glycol (0.277mol), N,N-dimethylformamide (80ml), add MDI (0.4mol), react at 75°C for 1 hour, add N,N-dimethylformamide Formamide (200ml), cool down to below 50°C, add 4,4'-diaminodiphenylmethane (0.11mol) dropwise, stop adding when the viscosity rises to 200Pa·s (25°C);

[0070] Then add DMF (92ml) to dilute to the viscosity of the reactant to 160Pa·s (25℃), add 0.003mol methanol terminator to react for 30min, cool down to 50℃ and discharge the material to obtain the weather-resistant polyurethane resin, solid resin The mass fraction is 30%.

[0071] The obtained product has a number-aver...

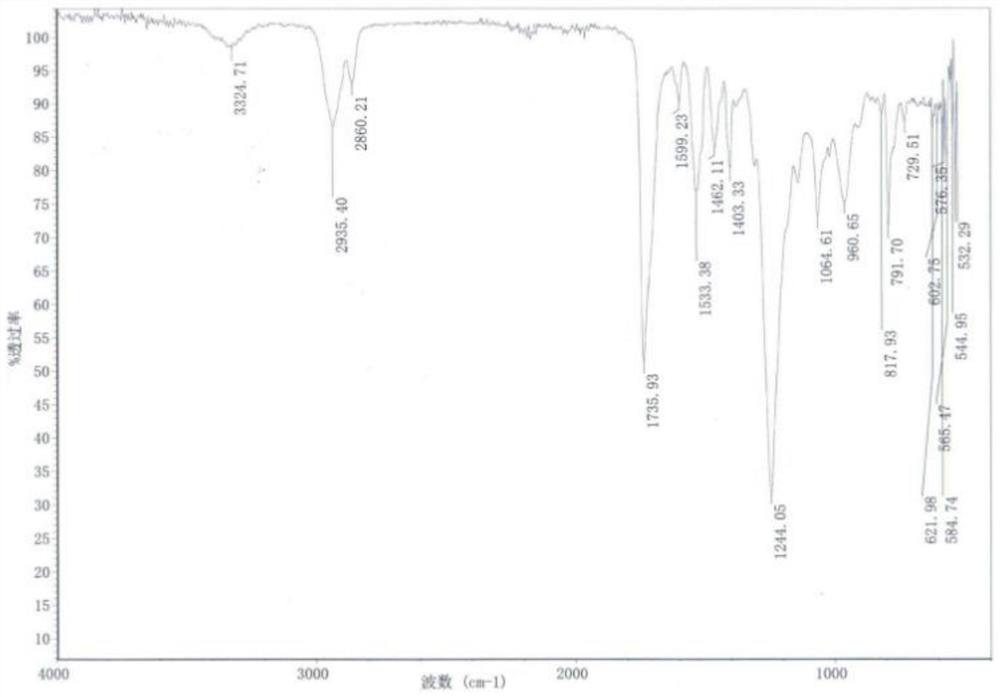

Embodiment 2

[0083] (1) Put poly-3-methylpentanediol adipate diol (0.044mol), polycarbonate diol (0.086mol), solvent N,N-dimethylformamide (100ml) into the reaction flask , mix evenly, put in hexamethylene diisocyanate (0.11mol), and react with bismuth neodecanoate (0.01g) as a catalyst at 95°C until the isocyanate group content is constant;

[0084] (2) After the prepolymerization is completed, add ethylene glycol EG (0.139mol), DMF (96ml), add MDI (0.278mol), react at 75°C for 1.5 hours, add N,N-dimethylformamide (150ml), Cool down to below 50°C, add 4,4'-diaminodicyclohexylmethane (0.139mol) dropwise, and stop adding when the viscosity rises to 200Pa·s (25°C);

[0085] Then add DMF (80ml) to dilute to the viscosity of the reactant to 160Pa·s (25℃), add methanol 0.003mol terminator to react for 30min, cool down to 50℃ and discharge the material to obtain the weather-resistant polyurethane resin, solid resin The mass fraction is 30%.

[0086] The obtained product has a number-average mo...

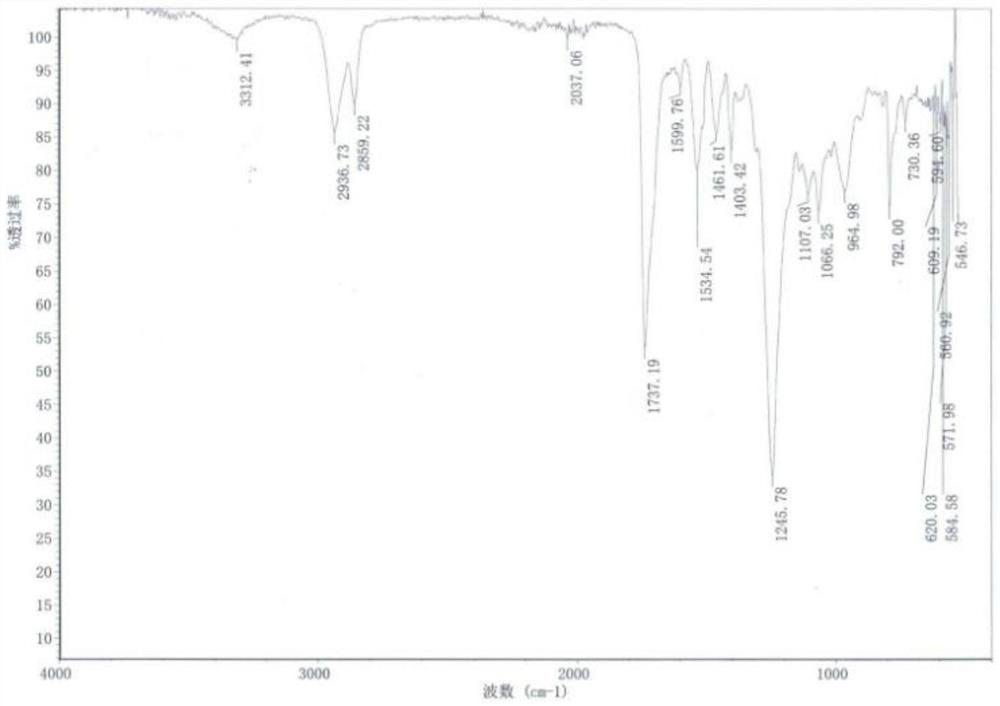

Embodiment 3

[0097] (1) Polytetrahydrofuran ether diol (0.017mol), poly-3-methylpentanediol adipate diol (0.02mol), polycarbonate diol (0.093mol), solvent N,N-diol Methylformamide (100ml) was put into the reaction flask, mixed evenly, put into hexamethylene diisocyanate (0.1mol), and the catalyst bismuth neodecanoate (0.01g) was reacted at 95°C until the isocyanate group content was constant;

[0098] (2) After the prepolymerization is completed, add ethylene glycol EG (0.322mol), DMF (100ml), add MDI (0.35mol), react at 75°C for 1.5 hours, add N,N-dimethylformamide (170ml), Cool down to below 50°C, add 4,4'-diaminodicyclohexylmethane (0.143mol) dropwise, and stop adding when the viscosity rises to 200Pa·s (25°C);

[0099] Then add DMF (80ml) to dilute to the viscosity of the reactant to 160Pa·s (25℃), add methanol 0.003mol terminator to react for 30min, cool down to 50℃ and discharge the material to obtain the weather-resistant polyurethane resin, solid resin The mass fraction is 30%.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com