A kind of high-shrinkage and high-efficiency dust-free dust-free cloth and its production method

A production method and high-shrinkage technology, applied in fiber types, dry-cleaning fiber products, textiles and papermaking, etc., can solve the problems of inability to meet strict dust-free environment requirements, fiber opening degree, and insufficient dust and pollution removal capabilities, and achieve improved dust removal Pollution removal ability, good fiber opening effect, and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

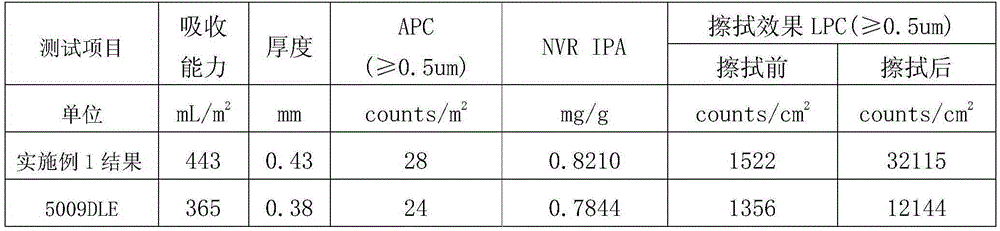

Embodiment 1

[0036] It is the preparation example of dust-free cloth.

[0037] A high-shrinkage and high-efficiency dust-free dust-free cloth is prepared according to the following steps:

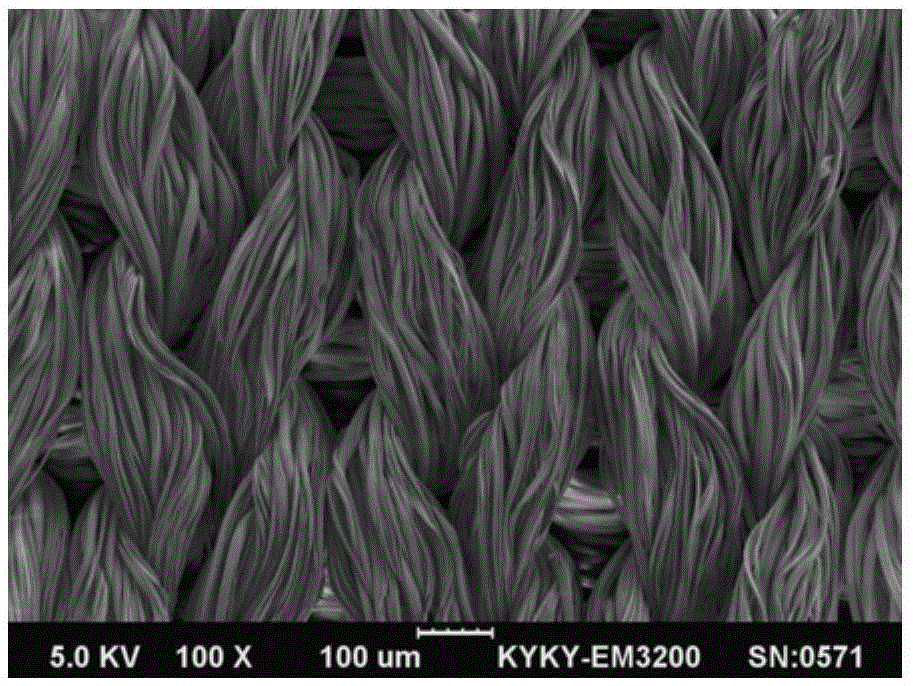

[0038] 1) Knit polyester and nylon superfine fiber yarn 75D / 35F into gray cloth with a 40-needle circular knitting machine, and the grammage of the prepared gray cloth is 135g / m 2 ;

[0039] 2) Add RO water (about 2400L) into the dyeing vat, and put the gray cloth prepared in step 1) into the dyeing vat according to the bath ratio of 1:6;

[0040] 3) Add penetrating agent JFC1g / L, sodium hydroxide 10g / L, chelating agent EDTA-4Na1g / L, degreasing agent LZ3054g / L into the dyeing vat, heat the solution in the dyeing vat to 125°C, and keep warm for 35 minutes;

[0041] 4) Clean the gray cloth in the dyeing vat by washing while discharging (i.e. discharge the solution in the dyeing vat while cleaning), cool down to 50°C, and keep warm for 3 minutes;

[0042] 5) Add acetic acid 0.4g / L to the dye vat;

[00...

Embodiment 2

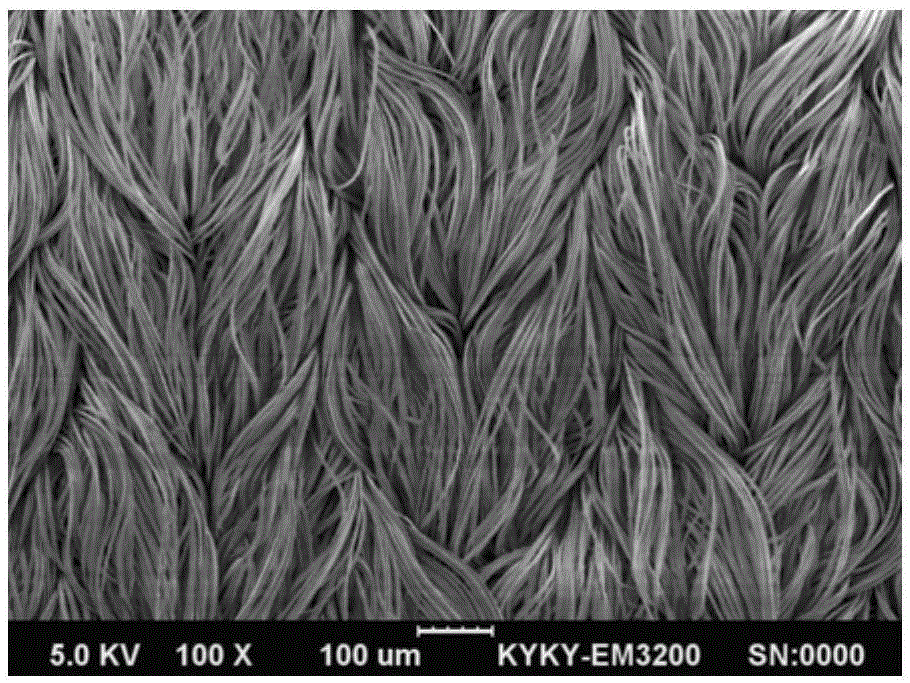

[0055] It is the preparation example of dust-free cloth.

[0056] A high-shrinkage and high-efficiency dust-free dust-free cloth is prepared according to the following steps:

[0057] 1) Knit polyester and nylon superfine fiber yarn 75D / 35F into gray cloth with a 42-needle circular knitting machine, and the grammage of the prepared gray cloth is 150g / m 2 ;

[0058] 2) Add RO water (about 2400L) into the dye vat, and put the gray cloth prepared in step 1) into the dye vat according to the soaking bath ratio of 1:5;

[0059] 3) Add 1.5g / L penetrant JFC, 12g / L sodium hydroxide, 1.5g / L chelating agent EDTA-4Na, 5g / L degreaser to the dye vat, raise the temperature of the solution in the dye vat to 125°C, and keep warm 35 minutes;

[0060] 4) Clean the gray cloth in the dyeing vat by washing while discharging (i.e. discharge the solution in the dyeing vat while cleaning), cool down to 50°C, and keep warm for 5 minutes;

[0061] 5) Add acetic acid 0.5g / L to the dye vat;

[0062] 6...

Embodiment 3

[0074] It is the preparation example of dust-free cloth.

[0075] A high-shrinkage and high-efficiency dust-free dust-free cloth is prepared according to the following steps:

[0076] 1) Weave polyester and nylon superfine fiber yarn 75D / 35F into gray cloth with a 40-needle circular knitting machine, and the grammage of the prepared gray cloth is 140g / m 2 ;

[0077] 2) Add RO water (about 2400L) into the dyeing vat, and put the gray cloth prepared in step 1) into the dyeing vat according to the bath ratio of 1:6;

[0078] 3) Add 1g / L of penetrant JFC, 10g / L of sodium hydroxide, 1g / L of chelating agent EDTA-4Na, 4g / L of degreasing agent to the dyeing vat, raise the temperature of the solution in the dyeing vat to 120°C, and keep it running for 30 minutes;

[0079] 4) Clean the gray cloth in the dyeing vat by washing while discharging (i.e. discharge the solution in the dyeing vat while cleaning), cool down to 50°C, and keep warm for 3 minutes;

[0080] 5) Add acetic acid 0.3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com