A mechanical opening machine for producing polyester and nylon superfine fiber dust-free cloth

A technology of polyester and nylon microfibers and microfibers, which is applied in the processing of textile materials, the treatment of textile material carriers, the liquid/gas/steam jet propulsion of fabrics, etc., which can solve the problems of uncontrollable fiber opening rate, inconvenient operation, Fabric breakage and other problems, to achieve precise temperature control, avoid secondary pollution, and low weight loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

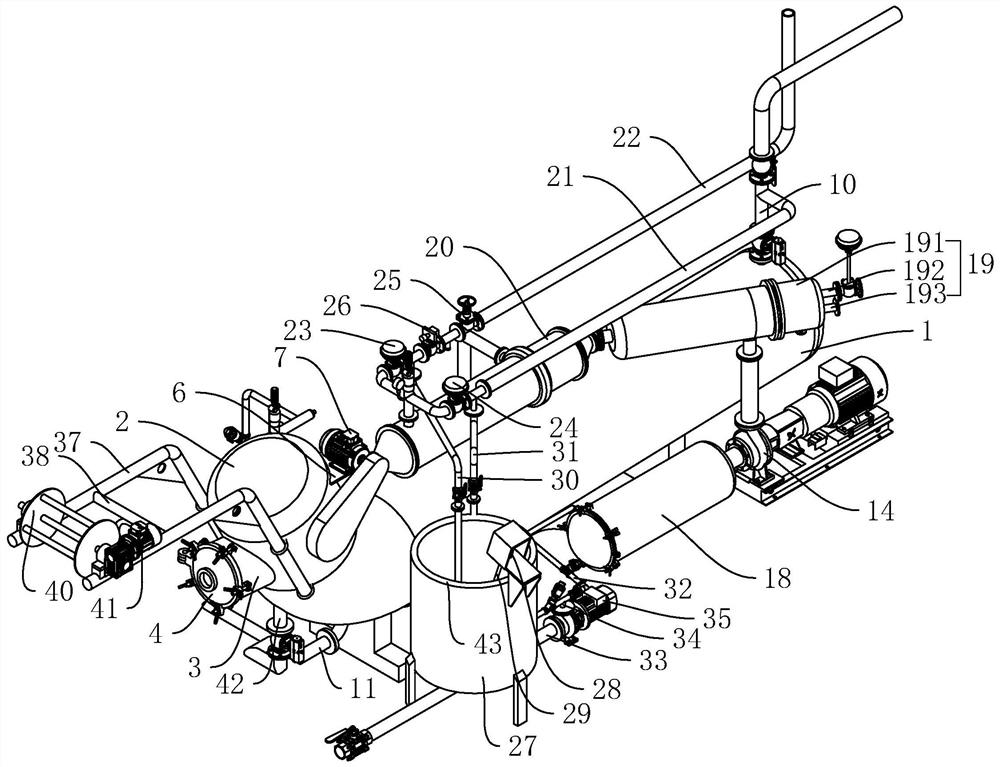

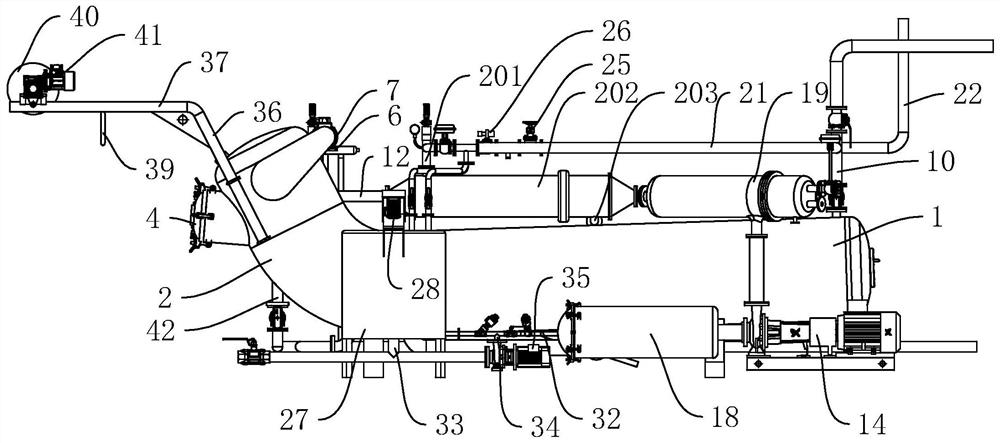

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

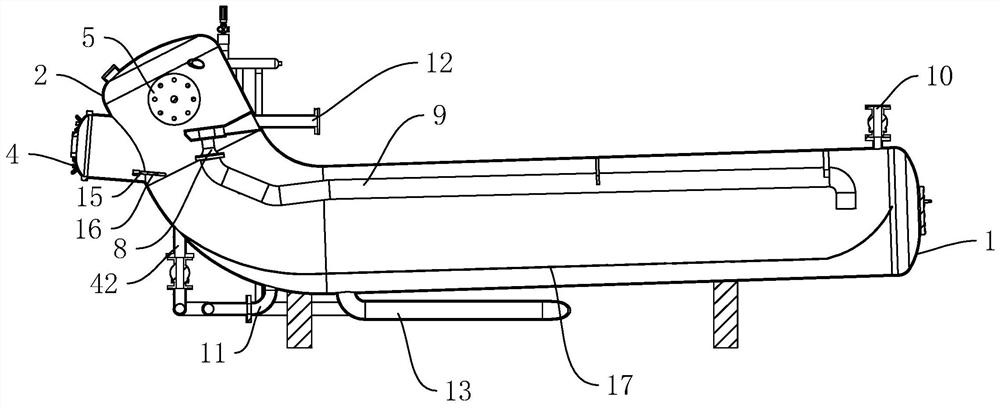

[0044] Such as figure 1 and figure 2 As shown, a mechanical opening machine for producing polyester-nylon ultrafine fiber dust-free cloths includes a cylinder 1 arranged obliquely, and the lower end of the cylinder 1 is integrally formed with an upwardly bent elbow 2. The cloth feeding pipe 3 connected with it is welded on the peripheral side. The cloth feeding pipe 3 is located on the side of the elbow 2 away from the cylinder body 1. The axis of the cloth feeding pipe 3 is parallel to the horizontal plane. The opening of the cloth feeding pipe 3 is provided with a sealing cover 4.

[0045] Such as figure 2 and image 3 As shown, the inside of the elbow 2 is horizontally and rotatably provided with a cloth lifting roller 5, the axis of the cloth lifting roller 5 is perpendicular to the axis of the cylinder 1, and the outer wall of the elbow 2 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com