Third-dimensional tatting air layer suede fabric

A technology of air layer and three-dimensional effect, which is applied in fabrics, textiles, multi-strand fabrics, etc., can solve the problems of high hardware and software requirements in the production cycle, high technical requirements for dyeing and finishing, high cost of high-shrinkage yarns, etc., to achieve enhanced cashmere Feeling, simple and firm structure, tight cloth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

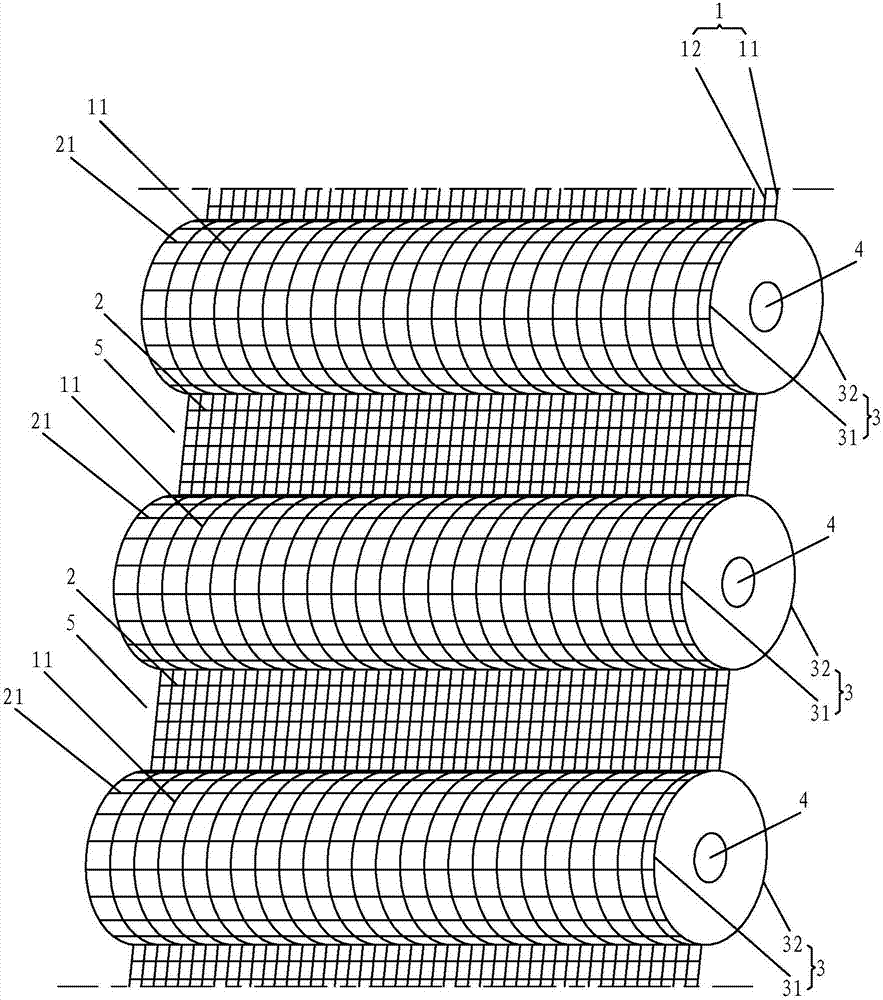

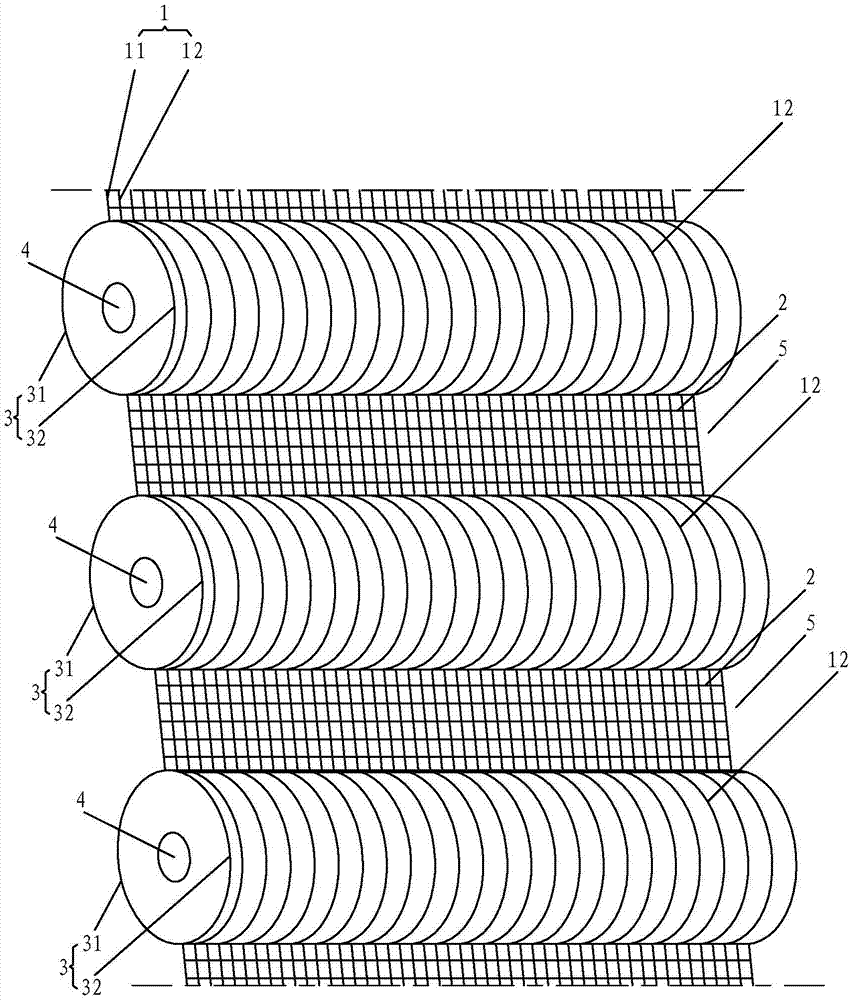

[0042] A kind of three-dimensional feeling woven air layer suede cloth of the present invention, as figure 1 and 2 As shown, warp 1 and weft 2 are included.

[0043] The warp yarn 1 and the weft yarn 2 enclose a plurality of cloth tubes 3 extending along the direction of the warp yarn 1 or the weft yarn 2, and the cloth tubes 3 are filled with cloth fillers 4 . The cloth tube 3 in the front of the present invention highlights the obvious three-dimensional effect, the cloth surface is tight, the back side has a strong velvet feeling, and has a three-dimensional effect, and the hollow cloth tube formed by the front and back sides is filled with beating wefts in the middle, and filled with fillers 4. Form the fabric of the air layer, and the filler 4 plays an important supporting role to ensure the existence of the structure of the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com