Velvet finishing agent for synthetic leather and preparation method thereof

A treatment agent, synthetic leather technology, applied in fiber processing, textiles and papermaking, etc., can solve problems such as high cost and difficult control of yambar process, and achieve low cost of raw materials, improved gloss and smooth feel, and stable state. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

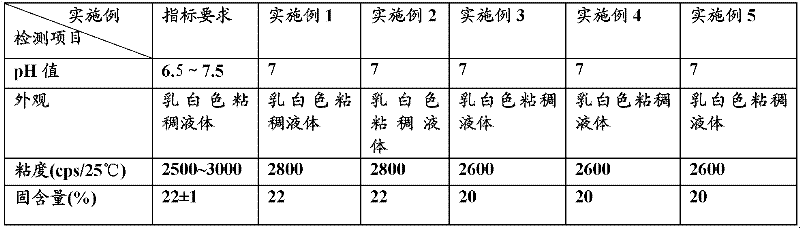

Embodiment 1

[0019] According to the cashmere treatment agent for synthetic leather of the present embodiment, it is directly mixed by the following components by weight: 100 parts of anti-yellowing high-brightness polyurethane resin; 7 parts of dry sliding wax powder; 4 parts of silica matting powder 10 parts of glass microspheres with a particle size of 30-50 μm; 3 parts of epoxy soybean oil; 3 parts of benzyl silicone oil; 2 parts of plasticizer (tributyl citrate); 40 parts of dimethylformamide; 40 parts of ester; 30 parts of methylal; 30 parts of xylene. See Table 1 for the technical specifications of the cashmere treatment agent, which meet the application requirements.

Embodiment 2

[0021] According to the cashmere treatment agent for synthetic leather of this embodiment, its formula is the same as that of Example 1, but it is prepared by the following preparation method: 40 parts of dimethylformamide and 40 parts of butyl acetate are added to 100 parts of bright polyurethane resin. 30 parts of methylal, 30 parts of xylene, 3 parts of benzyl silicone oil, 3 parts of epoxidized soybean oil, 2 parts of plasticizer tributyl citrate), stir at high speed until evenly dispersed, and then add 4 parts of silicon dioxide matting powder, 7 parts of dry sliding wax powder and 10 parts of glass microspheres are uniformly dispersed, ground by a grinder and filtered to obtain the cashmere treatment agent for synthetic leather. See Table 1 for the technical specifications of the cashmere treatment agent, which meet the application requirements.

Embodiment 3

[0023] According to the cashmere treatment agent for synthetic leather of the present embodiment, it is directly mixed by the following components by weight: 105 parts of anti-yellowing bright polyurethane resin; 8 parts of dry wax powder; 5 parts of silica matting powder ; 8 parts of glass microspheres with a particle size of 30-50 μm; 4 parts of epoxidized soybean oil; 2 parts of benzyl silicone oil; 1 part of plasticizer (tributyl citrate); 45 parts of dimethylformamide; 45 parts of ester; 35 parts of methylal; 35 parts of xylene. See Table 1 for the technical specifications of the cashmere treatment agent, which meet the application requirements. See Table 1 for the technical specifications of the cashmere treatment agent, which meet the application requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com