Color fixed island composite short fiber and preparation method thereof

A short fiber and island-setting technology, which is applied in the field of color-fixed-island composite nylon staple fiber and its production field, can solve the problems of difficult removal of dust, poor fluffing effect, and insufficiently bright colors, and achieves high color fastness and wear resistance. Good, colorful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

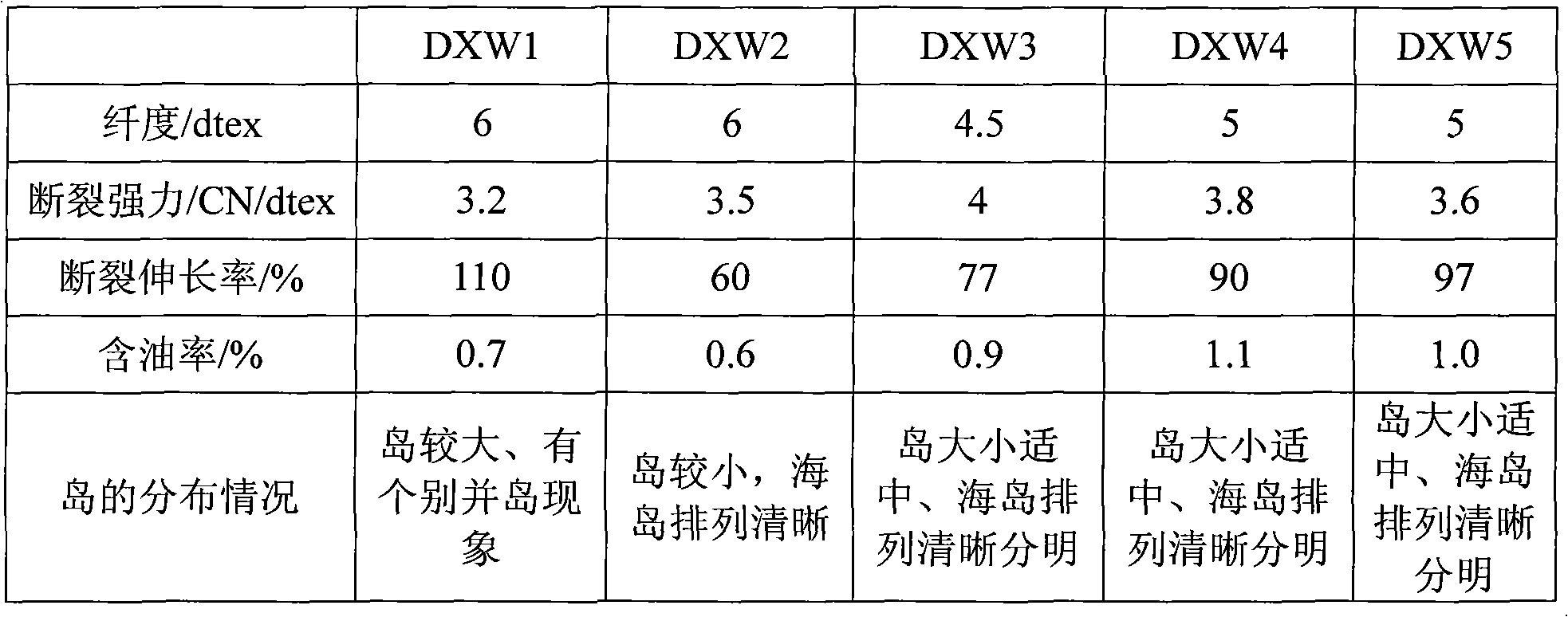

Embodiment 1

[0037] Nylon 6 chips, nylon-based coloring masterbatch (brown masterbatch, pigment weight content 30%) and polyethylene grafted acrylic acid (PE-g-AA, Shenyang Kingsway Rubber Technology Co., Ltd.) are 70 by weight: After 4:1 mixing, add to the island component silo, and add low-density polyethylene chips to the sea component silo.

[0038] Add the material in the silo to the respective screw extruders to heat, extrude, and melt to become a spinnable melt, and spin after being measured respectively according to the weight ratio of the island component and the sea component at 75:25 (sea group The temperature of the spinning box of the component is 150°C, the temperature of the spinning box of the island component is 295°C, and the spinning speed is 700m / min). Cooling and forming, the cooled tow is oiled by a pair of oiling rollers, then clustered and dropped into the barrel (the falling speed is 700m / min), and stored in the silk barrel. The oil used is: the weight concentratio...

Embodiment 2

[0042]Nylon 6 slices, nylon-based coloring masterbatch (blue masterbatch, pigment weight content 45%) and polypropylene grafted maleic anhydride (PP-g-MAH, Qinhuangdao Keruida Polymer Material Co., Ltd.) by weight 39.2:0.3:0.5 is mixed evenly and then added to the island component silo, and low-density polyethylene is added to the sea component silo. Add the material in the silo to the respective screw extruders to heat, extrude, and melt to become a spinnable melt, and spin after being measured respectively according to the weight ratio of the island component and the sea component at 40:60 (sea group The temperature of the spinning box of the component is 170°C, the temperature of the spinning box of the island component is 285°C, and the spinning speed is 500m / min), and the fine flow of the melt ejected from the spinneret hole is passed through the ring blowing to form the filaments. Cooling and forming, the cooled tow is oiled by a pair of oiling rollers, then clustered, d...

Embodiment 3

[0046] Nylon 6 slices, nylon-based coloring masterbatch (black masterbatch, pigment weight content 15%) and polyethylene grafted maleic anhydride (PE-g-MAH, Hebei Tianqi Plastic Co., Ltd.) in a weight ratio of 30:25 : 2 Add the island component silo after mixing evenly, and add the low-density polyethylene into the sea component silo. Add the material in the silo to the respective screw extruders to heat, extrude, and melt to become a spinnable melt, and spin after being measured respectively according to the weight ratio of the island component and the sea component at 55:43 (sea group The temperature of the spinning box of the component is 120°C, the temperature of the spinning box of the island component is 295°C, and the spinning speed is 1200m / min), and the fine flow of the melt ejected from the spinneret hole is passed through the ring blowing to form the filaments. Cooling and forming, the cooled tow is oiled by a pair of oiling rollers, then clustered, dropped into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com