Wear-resistant scratch-resistant extraordinarily thick Yangba resin for synthetic leather and preparation method thereof

A technology of yangbuck resin and synthetic leather, which is applied in the directions of abrasion-resistant fibers, improved hand-feel fibers, textiles and papermaking, etc., to achieve the effects of bright color development, increased production cost, and good velvet feel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

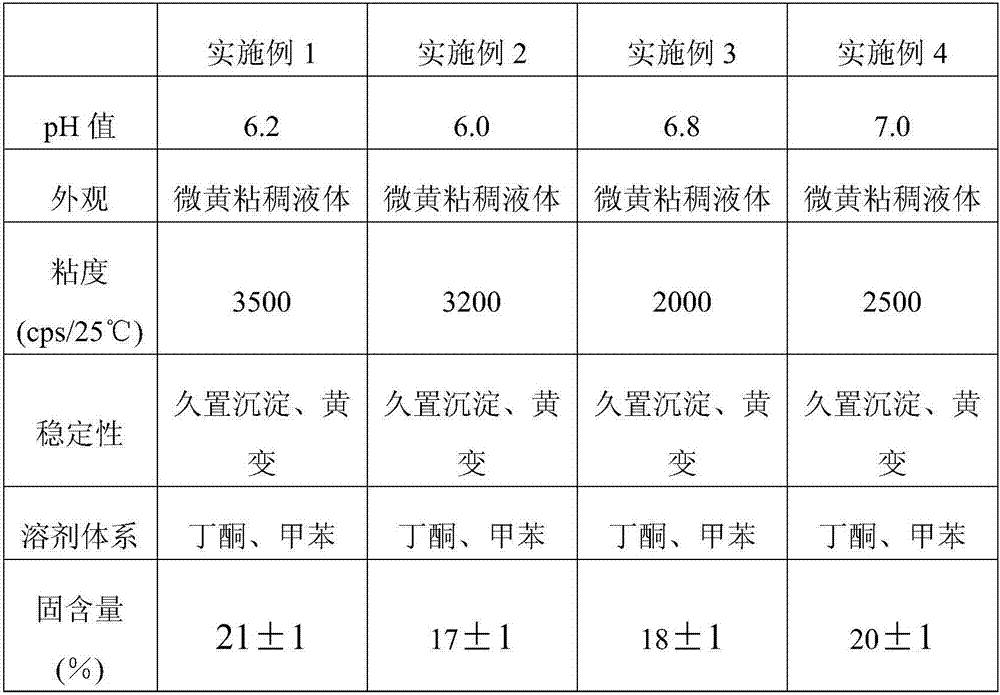

Embodiment 1

[0028] The wear-resistant and scratch-resistant ultra-coarse Yangbuck resin for synthetic leather is composed of the following components: 54 parts by weight of high-film Yangbuck resin, 23 parts by weight of butanone, 18 parts by weight of toluene, and 4 parts by weight of extra-coarse Yangbuck powder. 1 part by weight of phenylmethyl silicone oil.

[0029] The preparation method of the above-mentioned wear-resistant and scratch-resistant ultra-coarse yambuck resin for synthetic leather is: mix 42 parts by weight of high-film yambuck resin, 18 parts by weight of toluene and 4 parts by weight of extra-coarse yambuck powder, and stir until the mixture is mixed. Filter after uniformity; then, add 23 parts by weight of butanone and 1 part by weight of benzyl silicone oil to the obtained solid mixture, and stir until the mixture is evenly mixed; finally, add the remaining 12 parts by weight of After the high-film Yangbuck resin is stirred until the mixture is evenly mixed, the wea...

Embodiment 2

[0032] The wear-resistant and scratch-resistant ultra-coarse yangbuck resin for synthetic leather consists of the following components: 53 parts by weight of high-film yangbuck resin, 21 parts by weight of methyl ethyl ketone, 16 parts by weight of toluene, and 2 parts by weight of extra-coarse yangbuck powder.

[0033] The preparation method of the wear-resistant and scratch-resistant ultra-coarse yambuck resin for synthetic leather is: mix 44 parts by weight of high-film yambuck resin, 16 parts by weight of toluene and 2 parts by weight of extra-coarse yambuck powder, and stir until the mixture is mixed. Filter evenly; Then, add 21 parts by weight of methyl ethyl ketone to the obtained solid mixture, stir until the mixture is evenly mixed; finally, add the remaining 9 parts by weight of high-film yangbuck resin to the above-mentioned mixture obtained, and stir until the mixture After mixing evenly, the wear-resistant and scratch-resistant ultra-coarse Yangbuck resin for synth...

Embodiment 3

[0036] The wear-resistant and scratch-resistant ultra-coarse Yangbuck resin for synthetic leather is composed of the following components: 52 parts by weight of high-film Yangbuck resin, 24 parts by weight of butanone, 17 parts by weight of toluene, and 3 parts by weight of extra-coarse Yangbuck powder. 0.5 parts by weight of phenylmethyl silicone oil.

[0037] The preparation method of the wear-resistant and scratch-resistant ultra-coarse yambuck resin for synthetic leather is: mix 46 parts by weight of high-film yambuck resin, 17 parts by weight of toluene and 3 parts by weight of extra-coarse yambuck powder, and stir until the mixture is mixed. Filter after uniformity; then, add 24 parts by weight of butanone and 0.5 parts by weight of benzyl silicone oil to the obtained solid mixture, stir until the mixture is evenly mixed; finally, add the remaining 6 parts by weight of After the high-film Yangbuck resin is stirred until the mixture is evenly mixed, the wear-resistant and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com