Differential shrinkage composite fiber

A composite fiber and different shrinkage technology, which is applied in textiles and papermaking, can solve the problems of fabric velvet, poor softness, lack of ultra-fine fibers, and affect the functional use of different shrinkage composite fibers, etc., to achieve a velvet feel Excellent, soft-touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

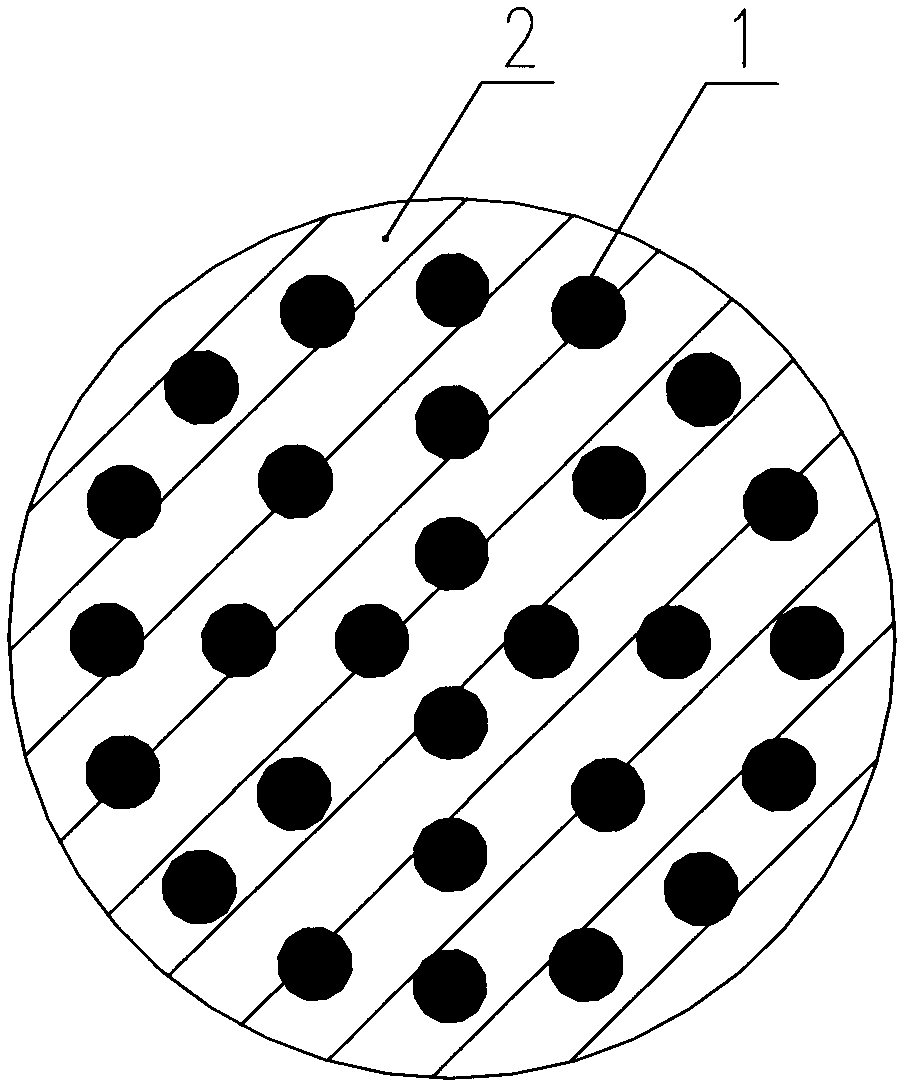

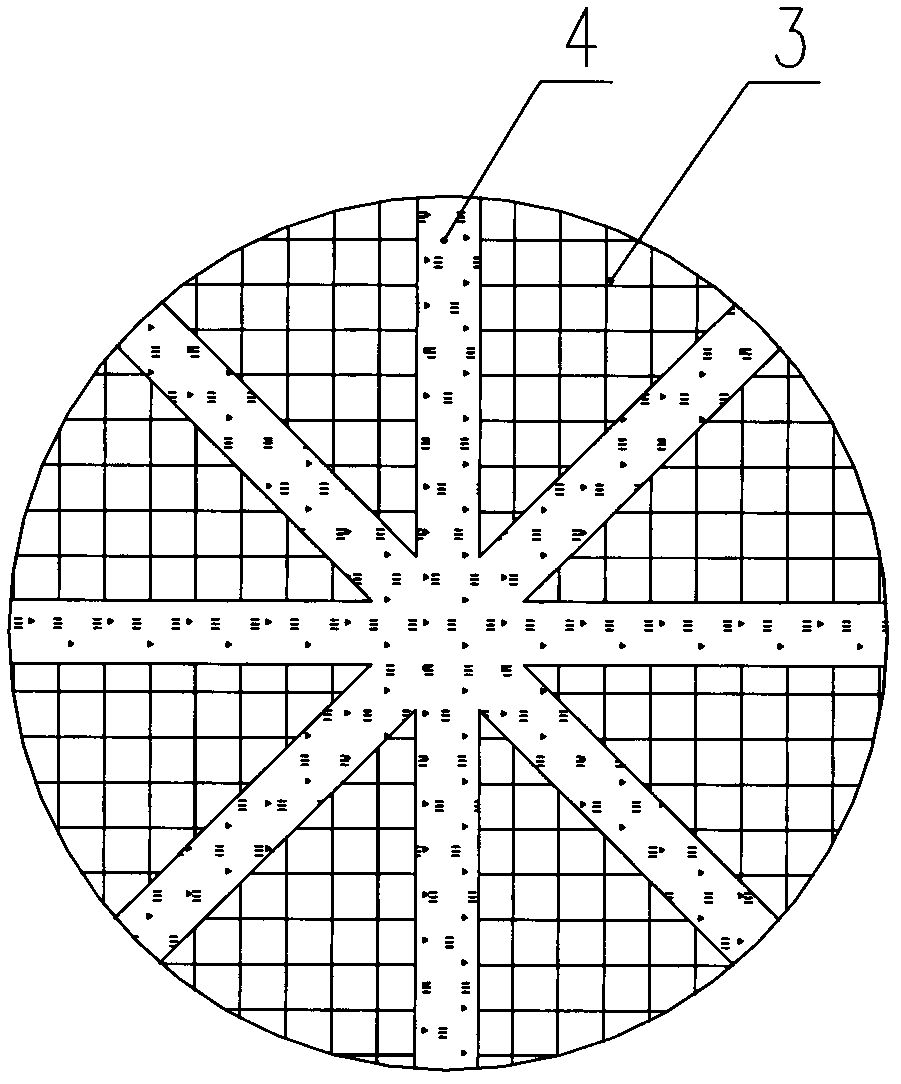

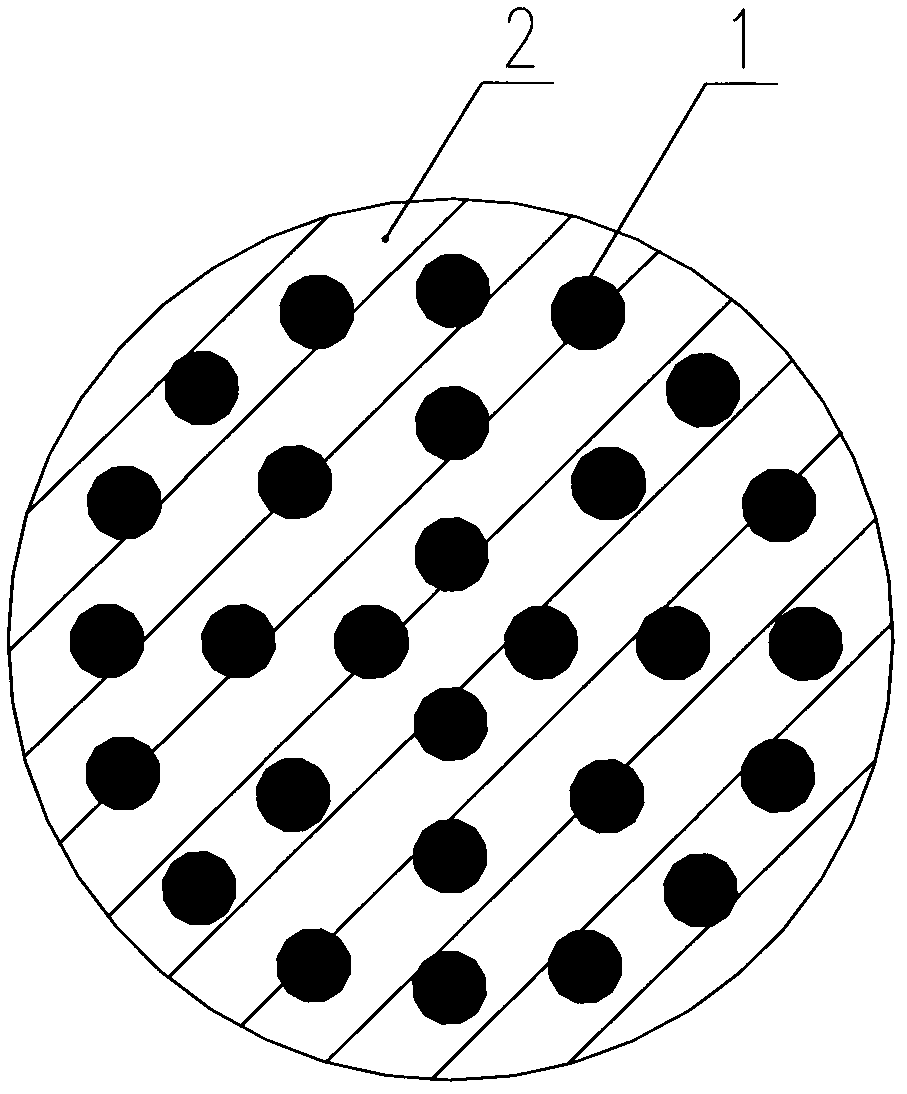

[0010] Such as figure 1 , figure 2 As shown, the different shrinkage composite fiber of the present invention is composed of FDY fiber filaments and POY fiber filaments through network plying, and its characteristics are: the cross section of the FDY fiber filaments is an island-in-the-sea type; the POY fiber filaments The cross-section is an orange segment with a "rice" structure. And: the cross-section of the FDY fiber is an island-in-the-sea type in which the island component 1 is polyester—PET for short, and the sea component 2 is water-soluble polyester—COPET for short; the cross section of the POY fiber It is an orange petal shape with a "rice" structure, in which component 4 of the "rice" character is water-soluble polyester - COPET for short, and component 3 embedded in the "rice" structure is polyester - PET for short .

[0011] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com