Bright ITY fiber production device and production method

A production method and fiber technology, applied in the field of bright ITY fiber production equipment, can solve the problems of large equipment investment and low production efficiency, and achieve the effects of improving competitiveness, profitability, and excellent drapability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

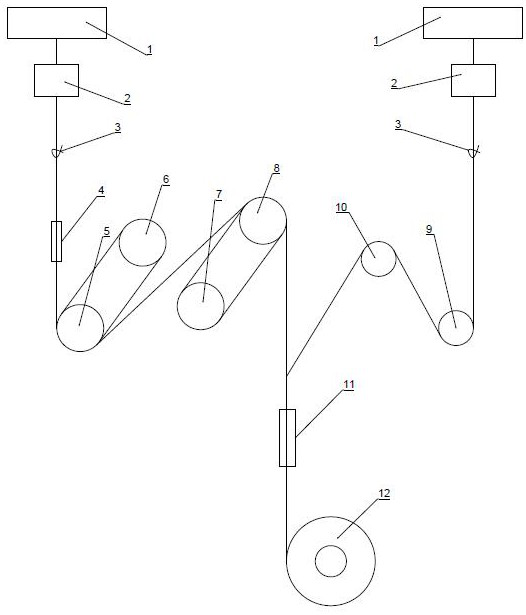

[0022] Such as figure 1 As shown, a bright ITY fiber production device described in this embodiment includes a spinning assembly 1, a cooling device 2, and an oiling device 3, wherein part of the spinning assembly 1 is used to produce FDY fibers, and the remaining spinning assembly 1 For the production of POY fibers, a pre-internet device 4 is provided under the spinning assembly 1 for producing FDY fibers, and a first heat roll 5, a second heat roll 6, a third heat roll 8, and a fourth heat roll are arranged below the pre-net device 4. Heat roll 7, the first godet 9 and the second godet 10 are arranged below the spinning assembly 1 producing POY fibers, and the main network is arranged below the second godet 10 and the fourth heat roll 7 Device 11 and winding mechanism 12.

Embodiment 2

[0024] A method for producing bright ITY fibers using the device described in Example 1 described in this embodiment specifically includes the following steps:

[0025] S1. Spinning assembly 1 spins FDY as-spun fibers. FDY as-spun fibers enter the oiling device 3 after being cooled by the cooling device 2, then pass through the pre-netting device 4, and then bypass the first hot roller 5 and the second hot roller 6, and enter The third hot roller 8 and the fourth hot roller 7;

[0026] S2. The spinning assembly 1 spins POY primary fibers, and the POY primary fibers enter the oiling device 3 after being cooled by the cooling device 2, and then pass through the first godet 9 and the second godet 10 in sequence;

[0027] S3, the FDY fibers output from the third heat roll 8 and the fourth heat roll 7 are plied with the POY fibers output from the second godet 10, enter the main network device 11, and finally enter the winding mechanism 12 for winding forming, Get Glossy ITY Fiber ...

Embodiment 3

[0034] A method for producing bright ITY fibers using the device described in Example 1 described in this embodiment specifically includes the following steps:

[0035] S1. Spinning assembly 1 spins FDY as-spun fibers. FDY as-spun fibers enter the oiling device 3 after being cooled by the cooling device 2, then pass through the pre-netting device 4, and then bypass the first hot roller 5 and the second hot roller 6, and enter The third hot roller 8 and the fourth hot roller 7;

[0036] S2. The spinning assembly 1 spins POY primary fibers, and the POY primary fibers enter the oiling device 3 after being cooled by the cooling device 2, and then pass through the first godet 9 and the second godet 10 in sequence;

[0037] S3, the FDY fibers output from the third heat roll 8 and the fourth heat roll 7 are plied with the POY fibers output from the second godet 10, enter the main network device 11, and finally enter the winding mechanism 12 for winding forming, Get Glossy ITY Fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com