Variable raised warp knitted fabric and knitting method

A technology of knitted fabric and pile warp, which is applied in the field of variable pile warp knitted fabric and weaving, which can solve the problems of poor temperature control of spandex core-spun yarn, single mesh structure, easy shrinkage and deformation, etc., and achieve strong wear resistance , The structure is changeable and stable, and the effect is soft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example example 1

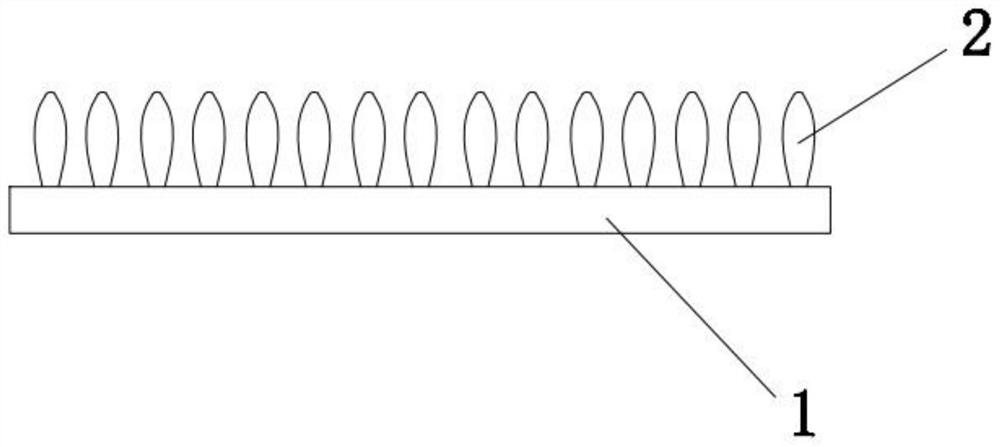

[0033] refer to figure 1 , a variable pile warp knitted fabric, comprising a pile knitted fabric body integrally woven by a double-needle bed warp knitting jacquard machine, the pile knitted fabric body comprising an integrally knitted surface layer 1 and a pile layer 2. The pile layer 2 is located on the upper surface of the surface layer 1, the surface layer 1 is integrally woven from three surface layer yarns, and the pile layer 2 is integrally woven from two pile layer yarns .

[0034] One of the surface layer yarns walks side chain weaves, and the organization structure is 0-0 / 0-1 / 1-1 / 1-0 / / ; the other two described surface layer yarns walk through flat weaves, Organization structure is respectively 1-1 / 1-2 / 1-1 / 1-0 / / and 1-1 / 2-1 / 1-1 / 0-1 / / ; Walking through the flat organization, the organization structure is 1-1 / 1-0 / 1-1 / 1-2 / / and 1-1 / 1-0 / 1-1 / 1-2 / / .

[0035] The pile layer 2 includes several pile loops with the same height.

[0036] The fleece layer 2 is a whole piece an...

Embodiment 2

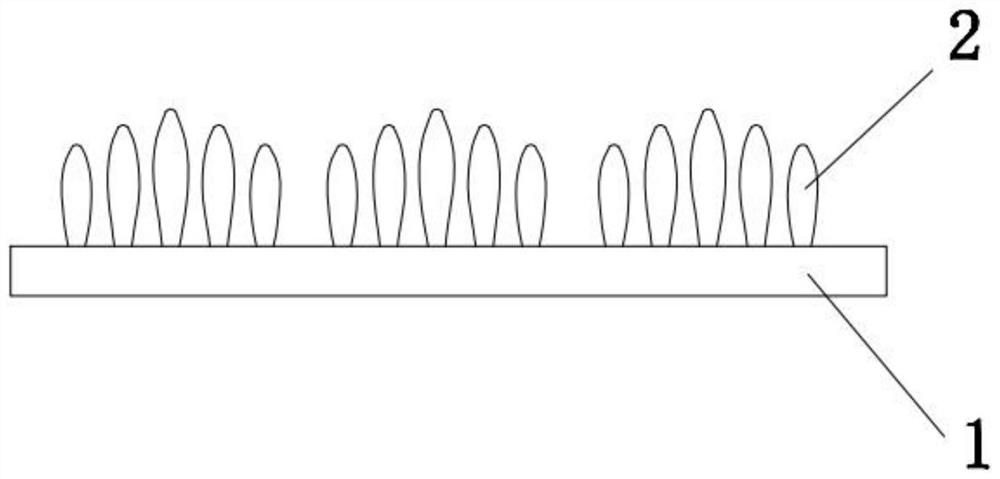

[0039] refer to figure 2 , The difference between this embodiment and Embodiment 1 is that: the pile layer 2 includes several pile loops with different heights.

Embodiment 3

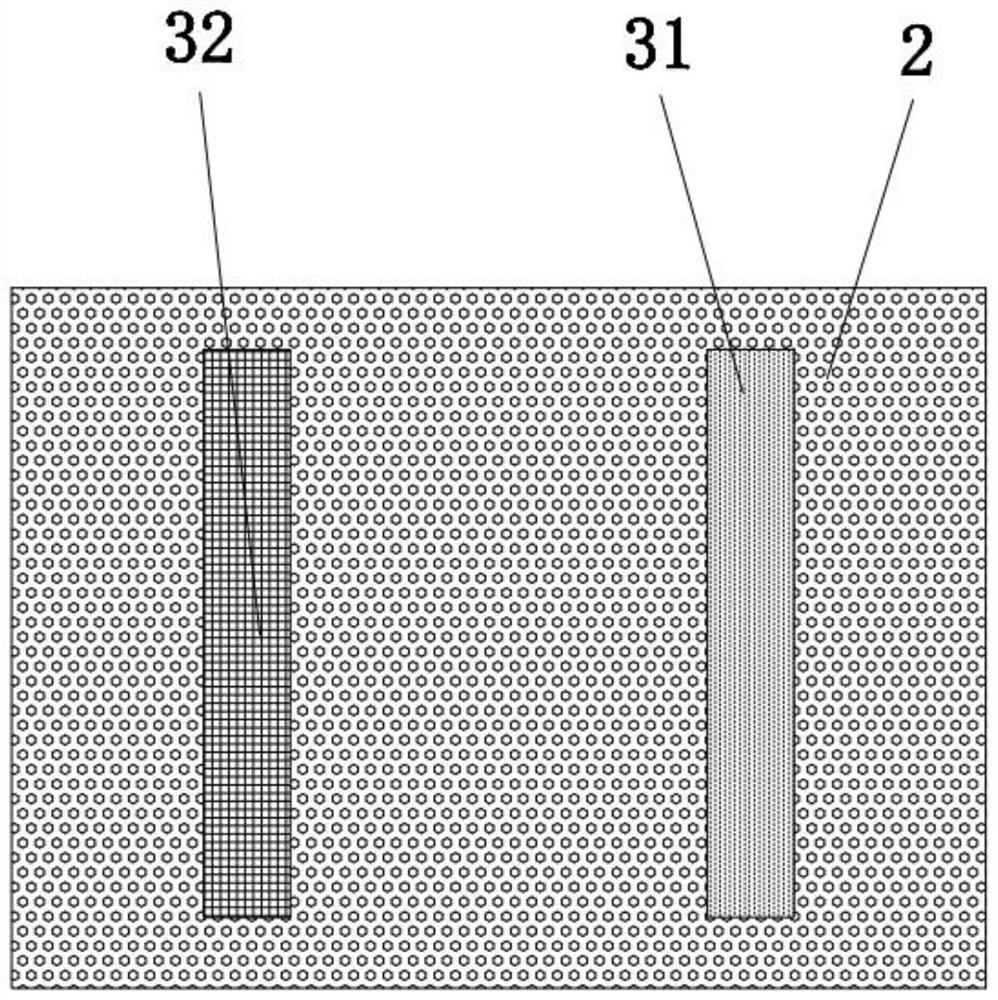

[0041] refer to Figure 3-4 The difference between this embodiment and embodiment 2 is that: the surface layer 1 is also integrally woven with at least one thick and thin layer for increasing the thickness of the surface layer. The thick and thin layers are in contact with the fleece layer 2 in the horizontal direction, and of course they can also be arranged at intervals. The thick and thin layers are the fleece layer 31 and / or the flat layer 32 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com