A kind of three-dimensional block corduroy fabric and its manufacturing method

A manufacturing method, the technology of corduroy, applied in the field of clothing fabrics, can solve the problems of straight strips with no new ideas, simple tones, poor color and light effects, etc., to meet the diverse needs of individuals, soft to the touch, and novel in performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

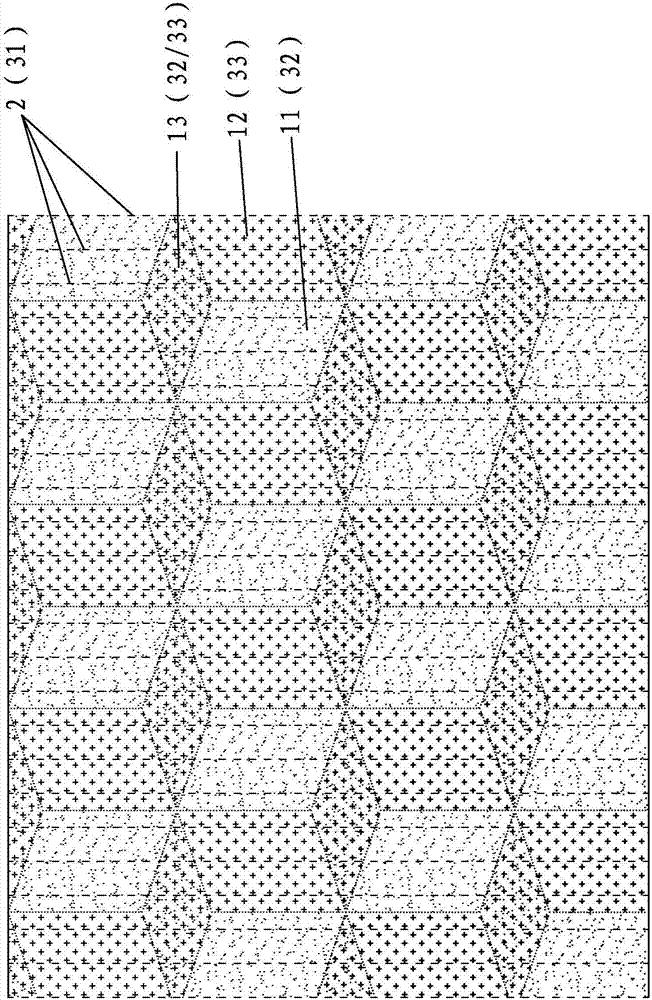

[0033] This case involves a three-dimensional cube corduroy fabric, such as figure 1 As shown, one group of warp yarns 2 and three groups of weft yarns are included, the three groups of weft yarns are respectively ground weft 31, the first pile weft 32 and the second pile weft 33; the first pile weft 32 and the second pile weft 33 are in different colors . The ground weft 31 is interwoven with the warp yarn 2 to form a ground texture of the fabric; specifically, the ground texture adopts a plain weave, and the binding method adopts a W-shaped joint.

[0034] The first suede weft 32 and the second suede weft 33 interweave with the warp yarn 2 to form regular floating wefts for forming fluff. The fabric is designed with a three-dimensional block pattern, which is composed of a plurality of small three-dimensional blocks regularly arranged,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com