Environmentally friendly anti-siphon afterfinishing method for suede microfiber synthetic leather

A microfiber and anti-siphon technology, which is applied in fiber processing, textiles and papermaking, etc., can solve the problems of increased surface tension of microfiber leather, decreased anti-siphon effect, and poor suede creases, etc., to increase softness The effect of high degree, improved grade, good crease and velvet feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

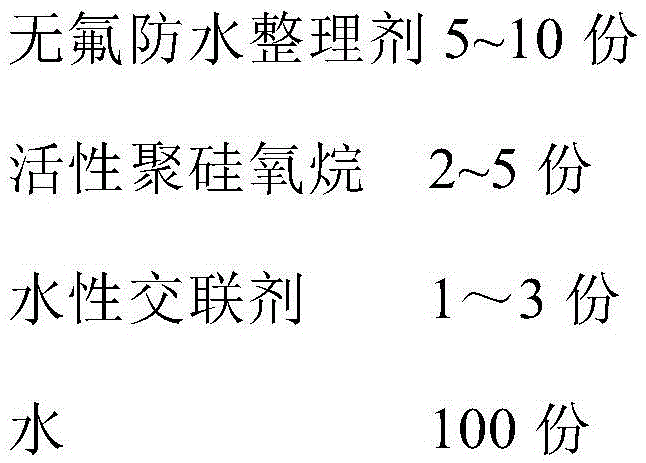

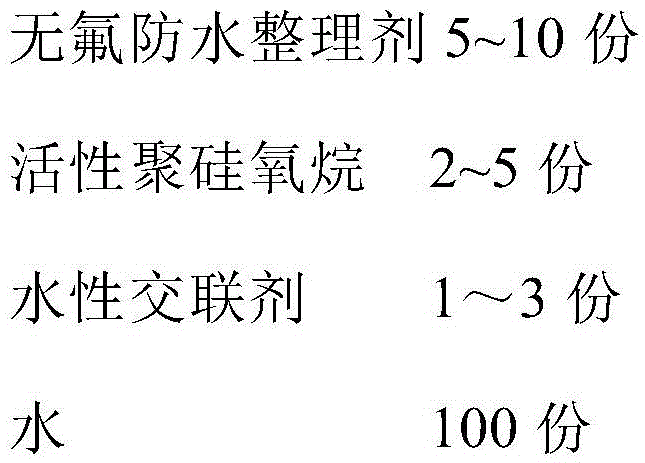

[0022] (1) In parts by weight, add 5 parts of fluorine-free waterproof finishing agent ECOplus, 5 parts of active polysiloxane NFR-A, 3 parts of water-based crosslinking agent FU and 100 parts of deionized water into the mixing tank and stir Evenly, mixed solution A is obtained, and the pH of mixed solution A is adjusted to 5 with acetic acid to obtain anti-siphon treatment solution B;

[0023] (2) Using ultrasonic technology, immerse the superfine fiber synthetic leather in the anti-siphon treatment solution B, at 100kHz, control the vehicle speed to 8m / min. After 1 dipping and 1 rolling treatment, the liquid carrying rate of microfiber leather is controlled to 65%;

[0024] (3) High-temperature cross-linking treatment, drying at 130°C for 10 minutes, and anti-siphon treatment after cooling, winding, kneading and other processes.

Embodiment 2

[0026] (1) In parts by weight, add 10 parts of fluorine-free waterproof finishing agent LZ-XR88, 2 parts of active polysiloxane NFR-A, 1 part of water-based crosslinking agent FU and 100 parts of deionized water into the mixing tank Stir evenly in the middle to obtain the mixed solution A, then use acetic acid to adjust the pH of the mixed solution A to be 4, and obtain the anti-siphon treatment solution B;

[0027] (2) Using ultrasonic technology, immerse the superfine fiber synthetic leather in the anti-siphon treatment solution B, at 50kHz, control the vehicle speed to 2m / min. After 1 dipping and 1 rolling treatment, the liquid-carrying rate of microfiber leather is controlled to 70%;

[0028] (3) High-temperature cross-linking treatment, drying treatment at 160°C for 5 minutes, and anti-siphon treatment after cooling, winding, kneading and other processes.

Embodiment 3

[0030] (1) In parts by weight, add 6 parts of fluorine-free waterproof finishing agent LZ-XR88, 3 parts of active polysiloxane NFR-A, 3 parts of water-based crosslinking agent 628 and 100 parts of deionized water into the mixing tank Stir evenly to obtain mixed solution A, then use acetic acid to adjust the pH of mixed solution A to 5.5 to obtain anti-siphon treatment solution B;

[0031] (2) Using ultrasonic technology, immerse the superfine fiber synthetic leather in the anti-siphon treatment solution B, at 80kHz, control the vehicle speed to 5m / min. After 1 dipping and 1 rolling treatment, the liquid carrying rate of microfiber leather is controlled to 55%;

[0032] (3) High-temperature cross-linking treatment, drying treatment at 140°C for 7 minutes, and anti-siphon treatment after cooling, winding, kneading and other processes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com