An anti-siphon method for generator stator cooling water system

A technology for generator stators and cooling water systems, applied in cooling/ventilation devices, electromechanical devices, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

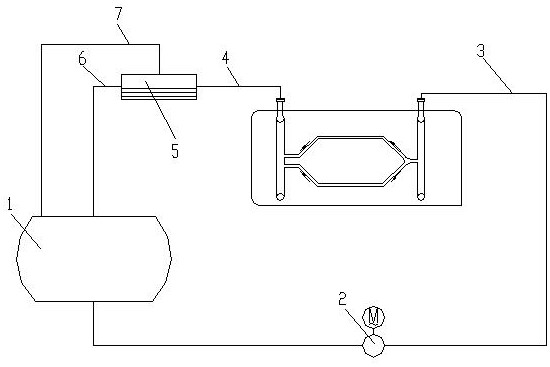

Embodiment 1

[0042] An anti-siphon method for a generator stator cooling water system, comprising the following steps:

[0043] a. Connect the water inlet pipe 3 of the anti-siphon device to the inlet of the generator stator coil, and connect the water outlet pipe 4 of the anti-siphon device to the outlet of the generator stator coil;

[0044] b. Place the expander 5 of the anti-siphon device in a spatial position higher than the outlet of the generator stator coil, and the expander 5 is connected between the outlet of the generator stator coil and the water tank 1 through pipelines to form a generator stator coil a cooling water flow channel from the outlet to the inlet of the water tank 1;

[0045] c. Use the air pipe 7 to connect the expansion vessel 5 with the upper part of the water tank 1 to form an air flow passage from the upper part of the water tank 1 to the expansion vessel 5, and guide the air in the upper part of the water tank 1 into the expansion vessel 5 through the air flo...

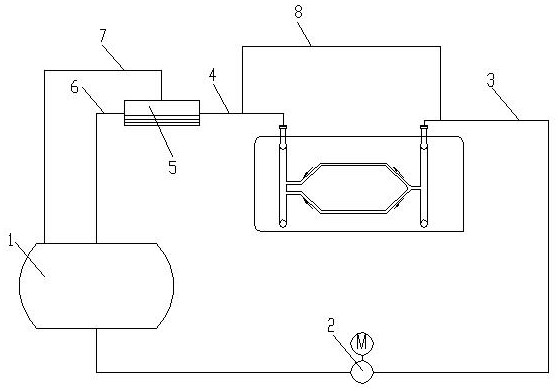

Embodiment 2

[0048] An anti-siphon method for a generator stator cooling water system, comprising the following steps:

[0049] a. Connect the water inlet pipe 3 of the anti-siphon device to the inlet of the generator stator coil, and connect the water outlet pipe 4 of the anti-siphon device to the outlet of the generator stator coil;

[0050] b. Place the expander 5 of the anti-siphon device in a spatial position higher than the outlet of the generator stator coil, and the expander 5 is connected between the outlet of the generator stator coil and the water tank 1 through pipelines to form a generator stator coil a cooling water flow channel from the outlet to the inlet of the water tank 1;

[0051] c. Use the air pipe 7 to connect the expansion vessel 5 with the upper part of the water tank 1 to form an air flow passage from the upper part of the water tank 1 to the expansion vessel 5, and guide the air in the upper part of the water tank 1 into the expansion vessel 5 through the air flo...

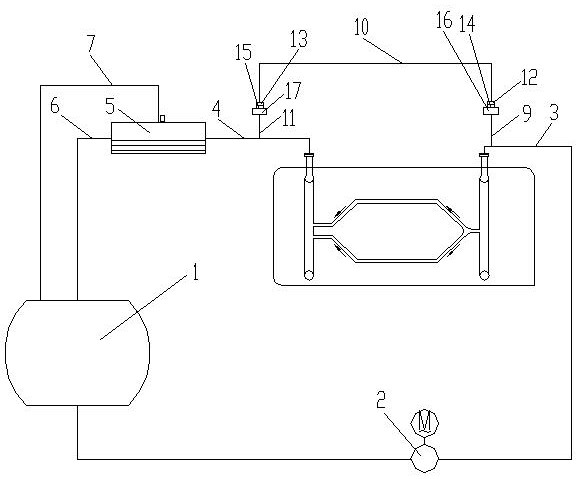

Embodiment 3

[0055] An anti-siphon method for a generator stator cooling water system, comprising the following steps:

[0056] a. Connect the water inlet pipe 3 of the anti-siphon device to the inlet of the generator stator coil, and connect the water outlet pipe 4 of the anti-siphon device to the outlet of the generator stator coil;

[0057] b. Place the expander 5 of the anti-siphon device in a spatial position higher than the outlet of the generator stator coil, and the expander 5 is connected between the outlet of the generator stator coil and the water tank 1 through pipelines to form a generator stator coil a cooling water flow channel from the outlet to the inlet of the water tank 1;

[0058] c. Use the air pipe 7 to connect the expansion vessel 5 with the upper part of the water tank 1 to form an air flow passage from the upper part of the water tank 1 to the expansion vessel 5, and guide the air in the upper part of the water tank 1 into the expansion vessel 5 through the air flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com