Firefighting uniform fabric

A technology for fire-fighting clothing and fabrics, applied in clothing, clothing, protective clothing, etc., can solve the problems of heavy weight, fire-fighting work obstacles, poor ventilation performance, etc., and achieve the effects of light weight, uniform pore size distribution, and anti-ultraviolet wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

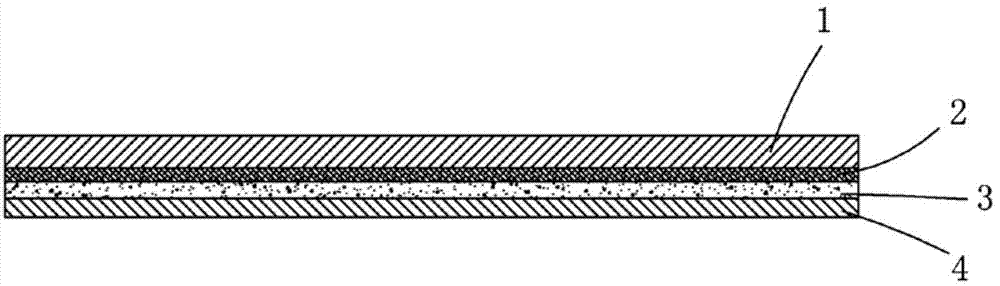

[0014] Examples, see attached figure 1 , a kind of fire-fighting clothing fabric, which includes a flame-retardant layer 1 on the surface from the outside to the inside, and a polytetrafluoroethylene microporous film layer 2 that has been processed by mixing, billeting, extrusion, calendering, stretching and sintering. water PU layer 3 and inner mesh layer 4; the flame retardant layer is composed of far-infrared ceramic composite fiber, aramid fiber and carbon fiber; The film layers are hot-pressed and fused together; the polytetrafluoroethylene microporous film layer and the hydrophilic PU layer are bonded together by a release paper transfer method; the hydrophilic PU layer and the inner mesh layer are glued and bonded on the Together.

[0015] The thickness of the polytetrafluoroethylene microporous film layer is 2.5um, and the polytetrafluoroethylene microporous film is evenly provided with micropores, and the micropore aperture is 0.8um. When the polytetrafluoroethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com