A kind of pure cotton soft mat fabric and preparation method thereof

A technology of soft mats and pure cotton, applied in fabric surface trimming, textile material treatment, textile material continuous treatment, etc., can solve the problems of high weaving tightness, low twist, rough fabric surface, etc., and achieve good hygroscopicity And softness, smooth touch, fine surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

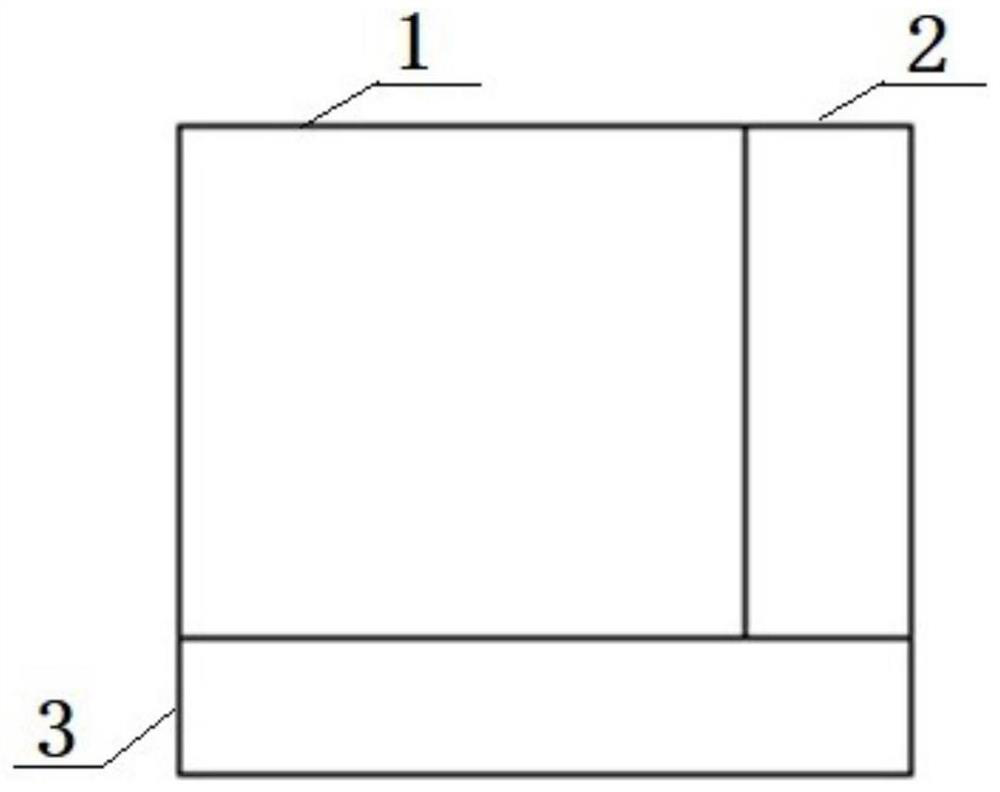

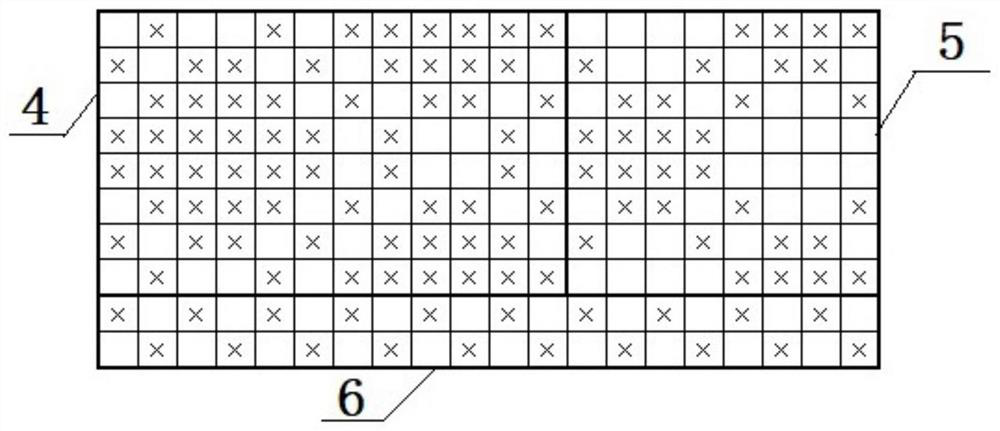

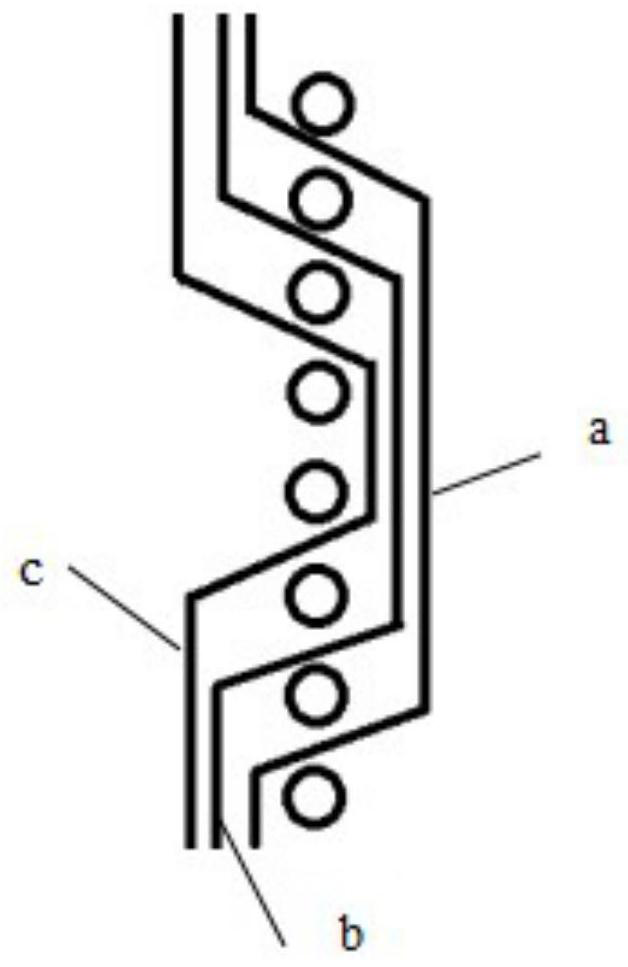

[0028] Such as figure 1 Shown, wherein, 1, the first area, 2, the second area, 3, the third area. The pure cotton mat fabric of the present invention is composed of basic units arranged circularly. The basic unit includes a first area 1 and a second area 2 paralleled in the horizontal direction, and a third area 3 arranged vertically with the first area 1 and the second area 2 . The area of the basic unit of the present embodiment is 0.78cm 2 , the area ratio of the first region 1 is 68.6%, the area ratio of the second region is 11.4%, and the area ratio of the third region is 20%. The area ratio of the first region 1 may be 65%-75%, the area ratio of the second region 2 may be 10%-20%, and the area ratio of the third region 3 may be 10%-20%. The first area 1 is the main composition surface, showing a dense and elevated structure, using heavy warp weaving, this embodiment is triple weaving, and can also be double weaving; the second area 2 is distributed in parallel with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com