Combined fabric for uniforms

A fabric and tooling technology, applied in the field of composite tooling fabrics, can solve problems such as lack of heat preservation, workers' lack of moisture permeability, poor moisture permeability and warmth retention, etc., and achieve the effect of reducing resource waste and maintaining temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

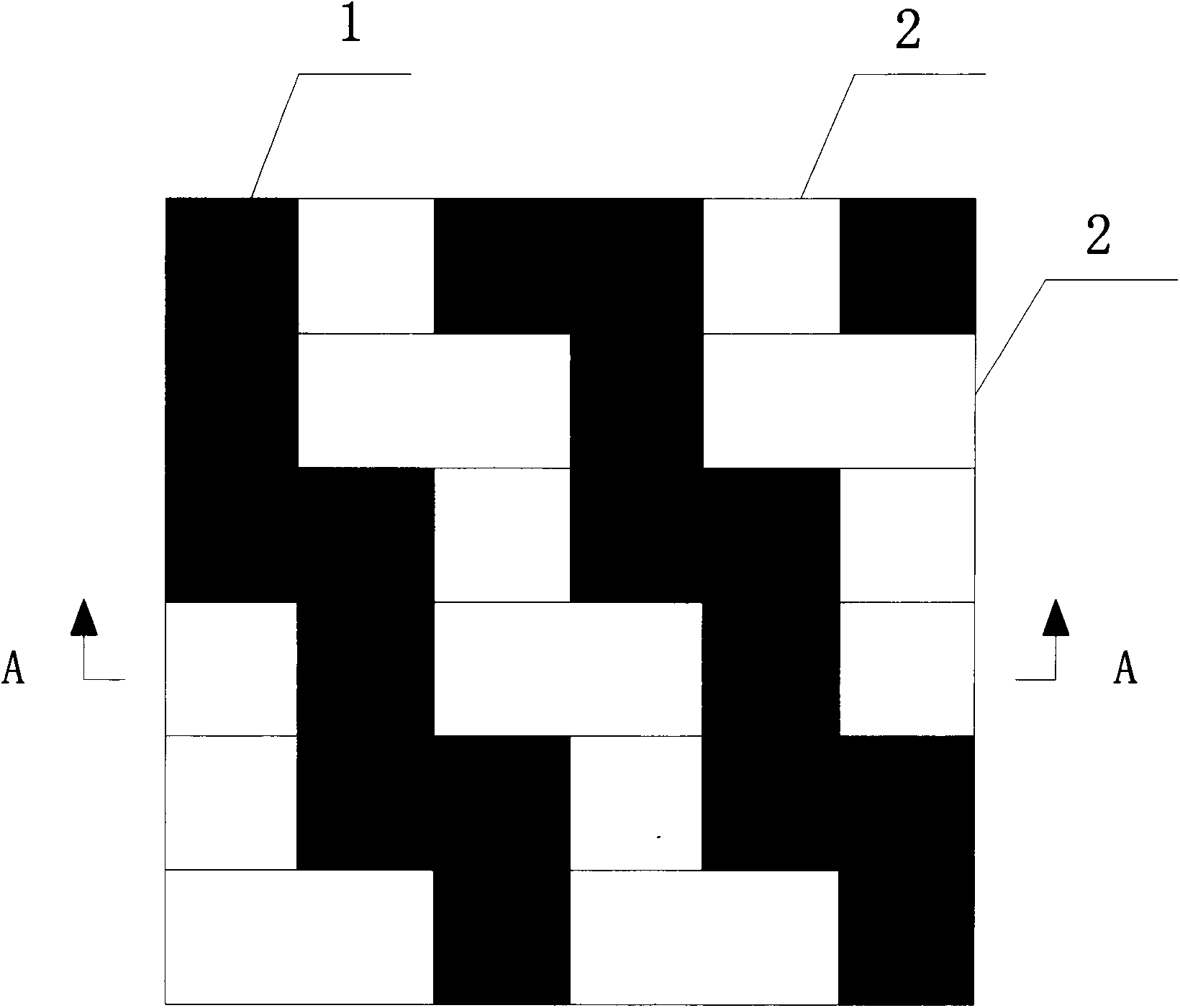

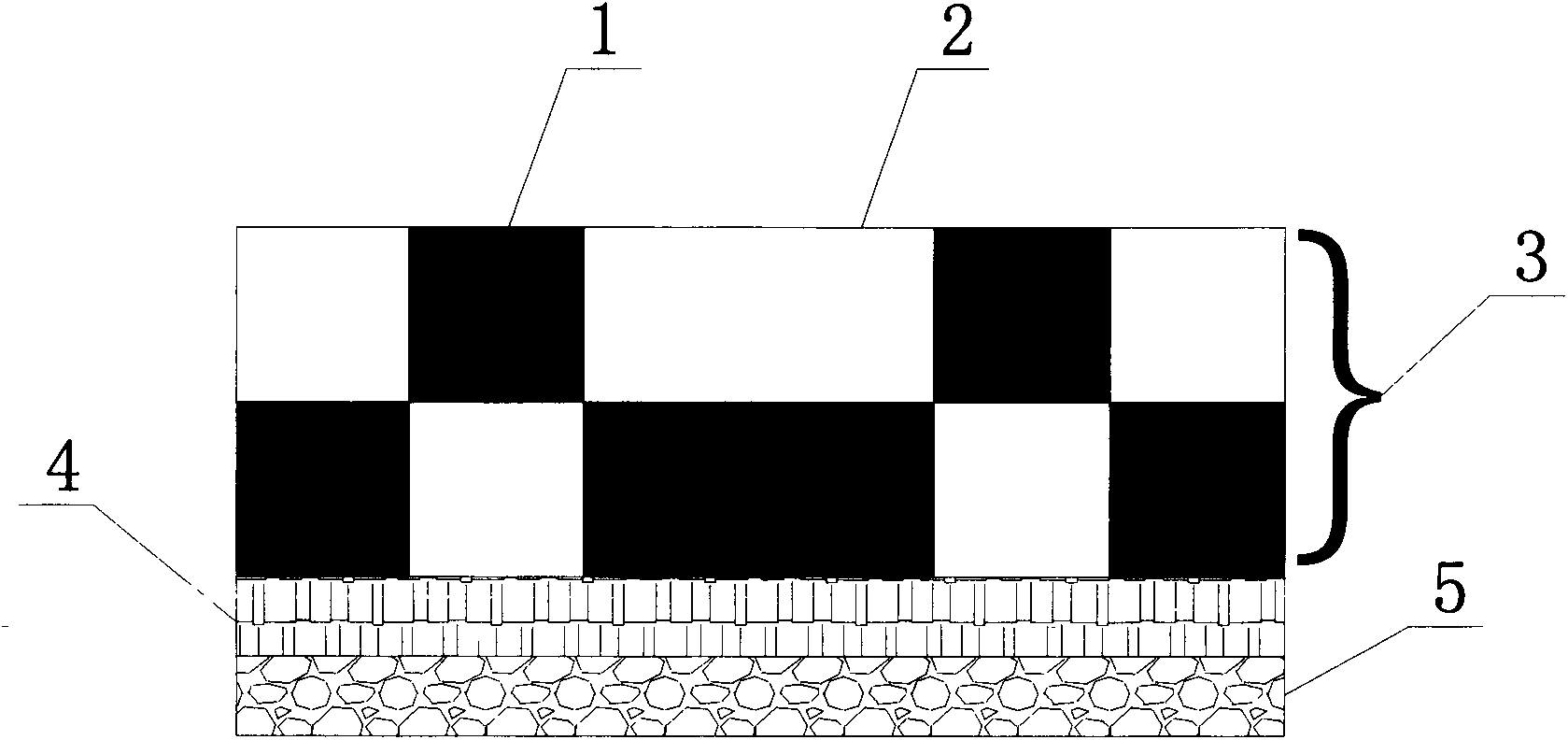

[0010] The present invention is described in further detail now in conjunction with accompanying drawing. The accompanying drawings are simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so that they only show the components relevant to the present invention.

[0011] see figure 1 , a composite tooling fabric, the fabric is composed of a base fabric layer 3, a TPU film layer 4 and a polyester Tricot fabric layer 5, the warp yarn 1 of the base fabric layer 3 is 250D polyester low elastic yarn, and the base fabric layer The weft yarn 2 of layer 3 is 10S TC polyester-cotton regenerated yarn, and the mass ratio of polyester and recycled cotton in the base fabric layer 3 is 8:2, wherein polyester includes polyester low elastic yarn and polyester-cotton recycled yarn, recycled cotton It refers to the regenerated cotton in the polyester-cotton regenerated yarn.

[0012] The invention relates to a composite toolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com