Durable flame resistance, electric conduction and ash black dyeing one-step processing method of cotton fabric

A processing method and cotton fabric technology, applied in the field of dyeing and finishing, can solve the problems of long process time, low efficiency, high cost, etc., and achieve the effect of broad application prospects and simple and feasible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

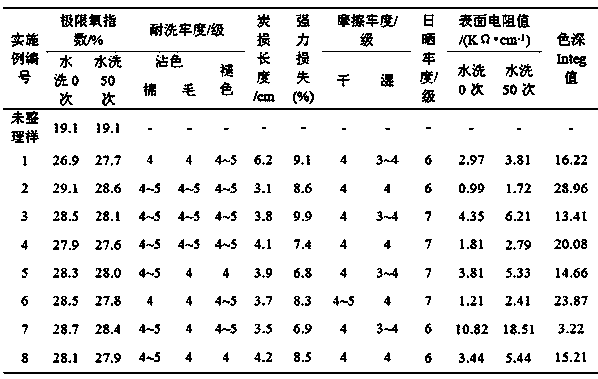

Examples

Embodiment 1

[0024] A one-step processing method for durable flame-retardant, conductive and gray-black dyeing of cotton fabrics, the steps are as follows:

[0025] (1) Preparation of flame retardant, conductive and dyeing one-step processing aids: Dissolve 30g of flame retardant tetrakishydroxymethylphosphorus chloride (THPC) in 500ml of water and fully mix and dissolve to obtain reaction solution A, and 5g of graphene oxide (GO) Disperse in 500ml of water under low-temperature ultrasonic conditions to obtain reaction solution B. Slowly add reaction solution A to reaction solution B under constant stirring, then adjust the pH of the reaction system to 2, and raise the temperature of the reaction system to 180°C for 1 hour. After the reaction, the system is concentrated to a solid content of 70% to obtain THPC-RGO, a one-step processing aid for flame retardant and dyeing;

[0026] (2) Prepare flame retardant, conductive and dyeing one-step finishing solution: make a 200g / L solution of the ...

Embodiment 2

[0029] A one-step processing method for durable flame-retardant, conductive and gray-black dyeing of cotton fabrics, the steps are as follows:

[0030] (1) Preparation of flame retardant, conductive and dyeing one-step processing aids: Dissolve 300g of flame retardant tetrakishydroxymethylphosphine hydroxide (THPOH) in 500ml of water, mix and dissolve fully to obtain reaction solution A, and 10g of graphene oxide (GO) Disperse in 500ml of water under low-temperature ultrasonic conditions to obtain reaction solution B. Slowly add reaction solution A to reaction solution B under constant stirring, then adjust the pH of the reaction system to 5, and raise the temperature of the reaction system to 150°C for 3 hours. After the reaction, the system was concentrated to a solid content of 70% to obtain THPOH-RGO, a one-step processing aid for flame retardant and dyeing;

[0031] (2) Preparation of flame retardant, conductive and dyeing one-step finishing solution: make a 350g / L soluti...

Embodiment 3

[0034] A one-step processing method for durable flame-retardant, conductive and gray-black dyeing of cotton fabrics, the steps are as follows:

[0035] (1) Preparation of flame retardant, conductive and dyeing one-step processing aids: Dissolve 100g of flame retardant tetrakishydroxymethylphosphorus chloride (THPC) in 500ml of water, mix and dissolve fully to obtain reaction solution A, and dissolve 5g of graphene oxide (GO) Disperse in 500ml of water under low-temperature ultrasonic conditions to obtain reaction solution B. Slowly add reaction solution A to reaction solution B under constant stirring, then adjust the pH of the reaction system to 3, and raise the temperature of the reaction system to 120°C for 5 hours. After the reaction, the system is concentrated to a solid content of 70% to obtain THPC-RGO, a one-step processing aid for flame retardant and dyeing;

[0036] (2) Prepare flame retardant, conductive and dyeing one-step finishing solution: make a 300g / L solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com