Penioillin acylase preparation and immobilization method

A penicillin acylase and preparation technology, applied in the field of materials, can solve the problems of low recovery rate and loss of enzyme activity of immobilized enzymes, and achieve the effects of easy recycling, high loading rate, and easy availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

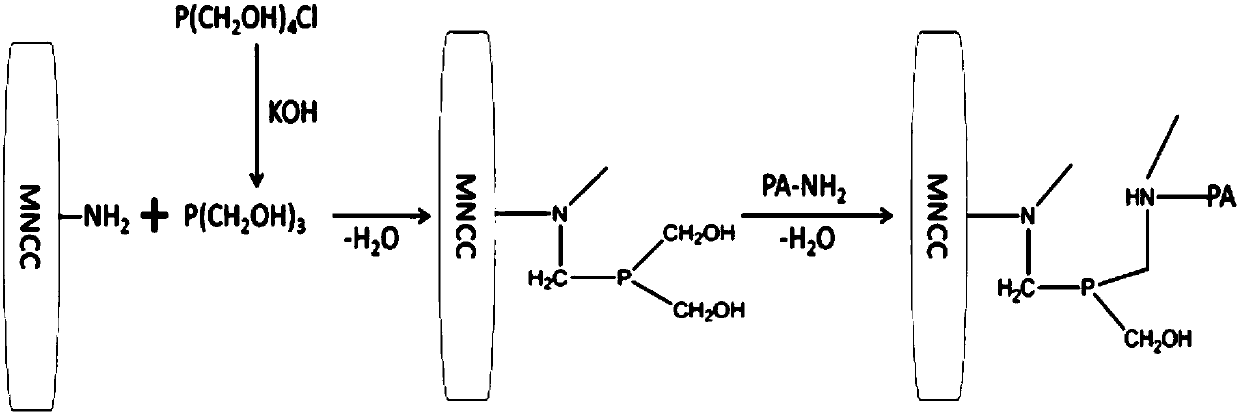

Method used

Image

Examples

Embodiment 1

[0037] (1) getting quality is that 2.00g tetrakis hydroxymethyl phosphorus chloride is added in 90ml water, obtains tetrakis hydroxymethyl phosphorus chloride aqueous solution; Getting quality is that 0.56g potassium hydroxide is added in 10ml water, obtains potassium hydroxide aqueous solution ;

[0038] (2) At room temperature, slowly drop an aqueous potassium hydroxide solution into an aqueous tetrakishydroxymethyl phosphorus chloride solution to obtain a mixed solution A;

[0039] (3) Add 2.00 g of magnetic cellulose nanocrystals to the mixed solution A, stir at room temperature (the stirring speed is 150 rpm) for 8 minutes, centrifuge, and wash with deionized water to obtain the treated magnetic cellulose nanocrystals;

[0040] (4) 200.00 mg of penicillin acylase was dissolved in 50 ml of phosphate buffer with a pH of 7.5 to obtain an enzyme solution;

[0041] (5) Mix the processed magnetic cellulose nanocrystals obtained in step (3) with the enzyme solution configured in ...

Embodiment 2

[0044] (1) Get a quality of 7.00g of tetrakis hydroxymethyl phosphorus chloride and join it in 90ml water to obtain a tetrakis hydroxymethyl phosphorus chloride aqueous solution; get a quality of 1.96g of potassium hydroxide and join it in 10ml water to obtain an aqueous solution of potassium hydroxide ;

[0045] (2) At room temperature, slowly drop an aqueous potassium hydroxide solution into an aqueous tetrakishydroxymethyl phosphorus chloride solution to obtain a mixed solution A;

[0046] (3) Add 2.00 g of magnetic cellulose nanocrystals to the mixed solution A, stir at room temperature (the stirring speed is 150 rpm) for 8 minutes, centrifuge, and wash with deionized water to obtain the treated magnetic cellulose nanocrystals;

[0047] (4) 200.00 mg of penicillin acylase was dissolved in 50 ml of phosphate buffer with a pH of 7.5 to obtain an enzyme solution;

[0048] (5) Mix the processed magnetic cellulose nanocrystals obtained in step (3) with the enzyme solution conf...

Embodiment 3

[0050] (1) getting quality is that 2.00g tetrakis hydroxymethyl phosphorus chloride is added in 90ml water, obtains tetrakis hydroxymethyl phosphorus chloride aqueous solution; Getting quality is that 0.56g potassium hydroxide is added in 10ml water, obtains potassium hydroxide aqueous solution ;

[0051] (2) At room temperature, an aqueous potassium hydroxide solution is slowly added dropwise to an aqueous tetrakishydroxymethyl phosphorus chloride solution to obtain a mixed solution A;

[0052] (3) Add 2.00 g of magnetic cellulose nanocrystals to mixed solution A, stir at room temperature (150 rpm) for 8 min, centrifuge, and wash with deionized water to obtain treated magnetic cellulose nanocrystals;

[0053] (4) 600.00 mg of penicillin acylase was dissolved in 50 ml of phosphate buffer solution with a pH of 7.5 to obtain an enzyme solution;

[0054] (5) Mix the processed magnetic cellulose nanocrystals obtained in step (3) with the enzyme solution configured in step (4), st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com