Clamp for machining of resin dome cover flanged edge and with one-time clamping formation function and machining method for resin dome cover flanged edges

A technology of flange edge and ball cover, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of secondary positioning error, improve processing efficiency, solve positioning error and bruise pollution, and solve Difficult to pick and place effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following embodiments can make those skilled in the art better understand the present invention, and it is possible to modify, add and replace the following embodiments without departing from the protection scope of the present invention.

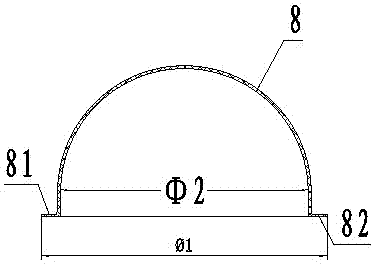

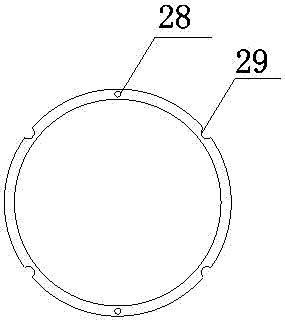

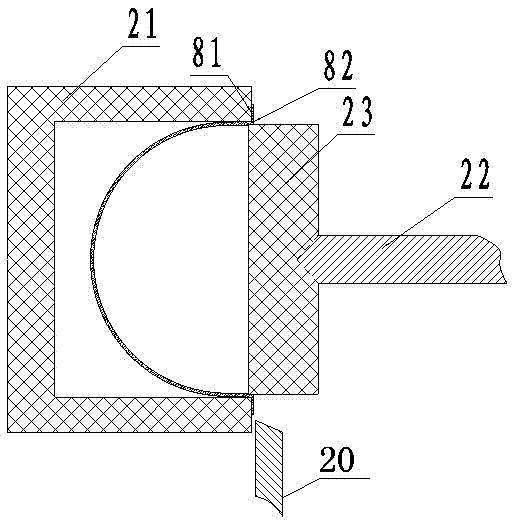

[0032] like Figure 5-9 As shown in the figure, a fixture for one-time clamping and forming of the flange edge of a resin optical dome cover, which includes a bottom plate 1, a supporting cylinder 2, a movable plate 5, a vacuum fixing seat 6, a guide post 7, a top plate 9, and a dome cover positioning ring 10 , Normally open one-way solenoid valve 11, normally closed one-way negative pressure solenoid valve 12, vacuum generating device 13, cylinder solenoid valve 14, vacuum fixing seat 6 is made of nylon or other engineering plastics, ball cover positioning ring 10 is made of aluminum alloy or Made of other metals.

[0033] The inner cavity of the vacuum fixing seat 6 matches the outer surface of the ball cover. There are two st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com