Template automatic alignment device of building machine

An automatic alignment and formwork technology, applied in the field of building machines, can solve problems such as low work efficiency, achieve the effect of improving work efficiency and solving positioning errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further described in conjunction with the following examples.

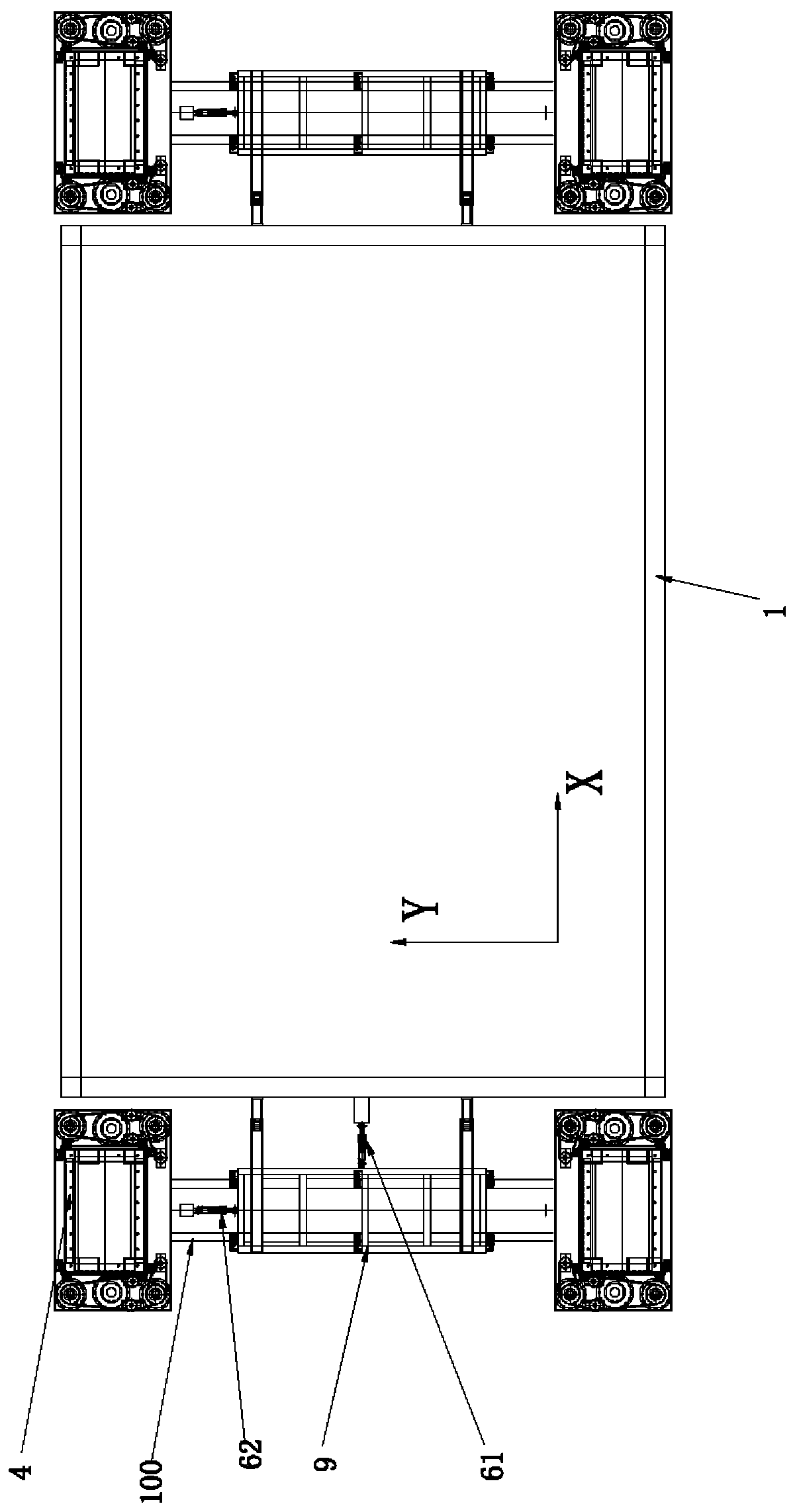

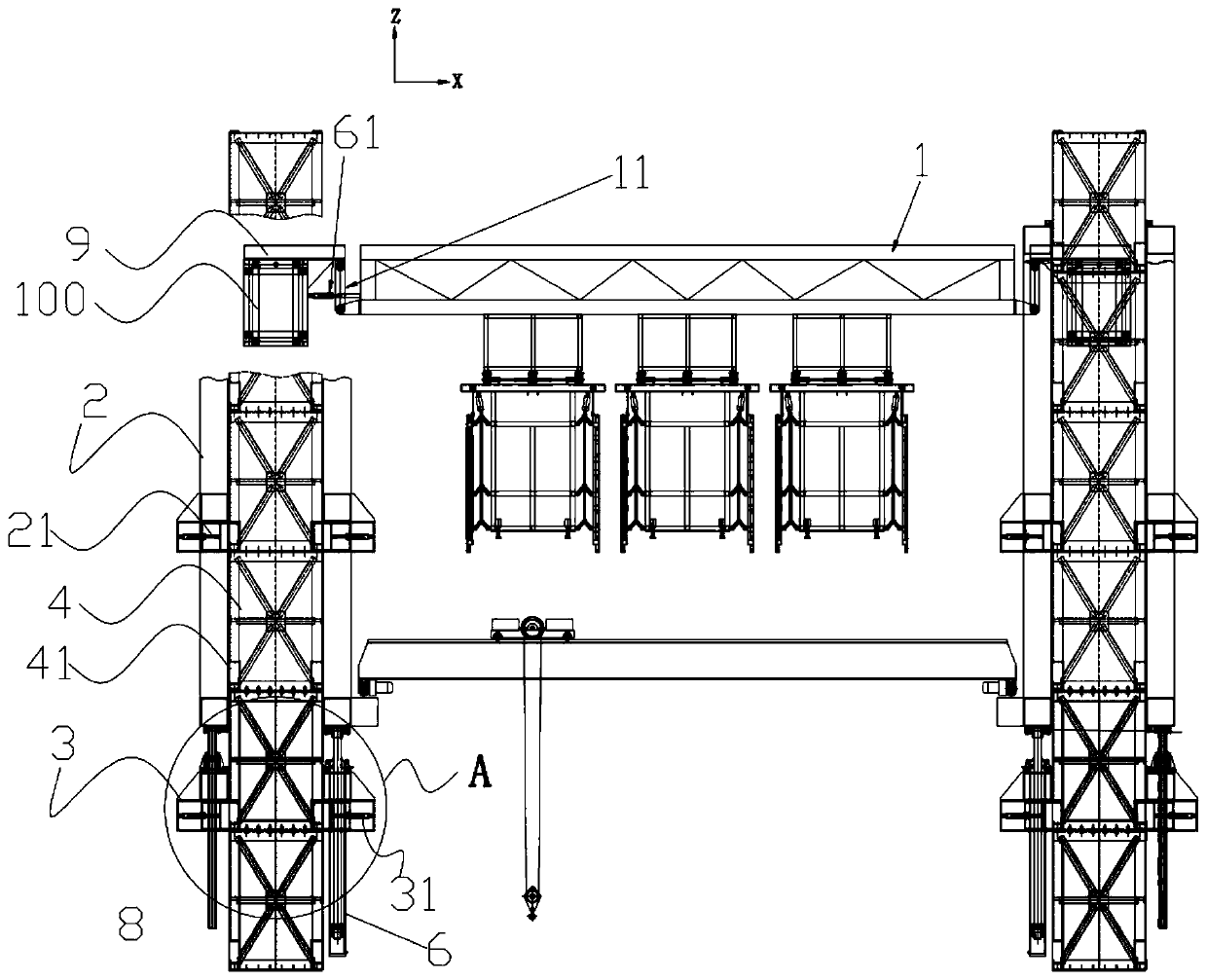

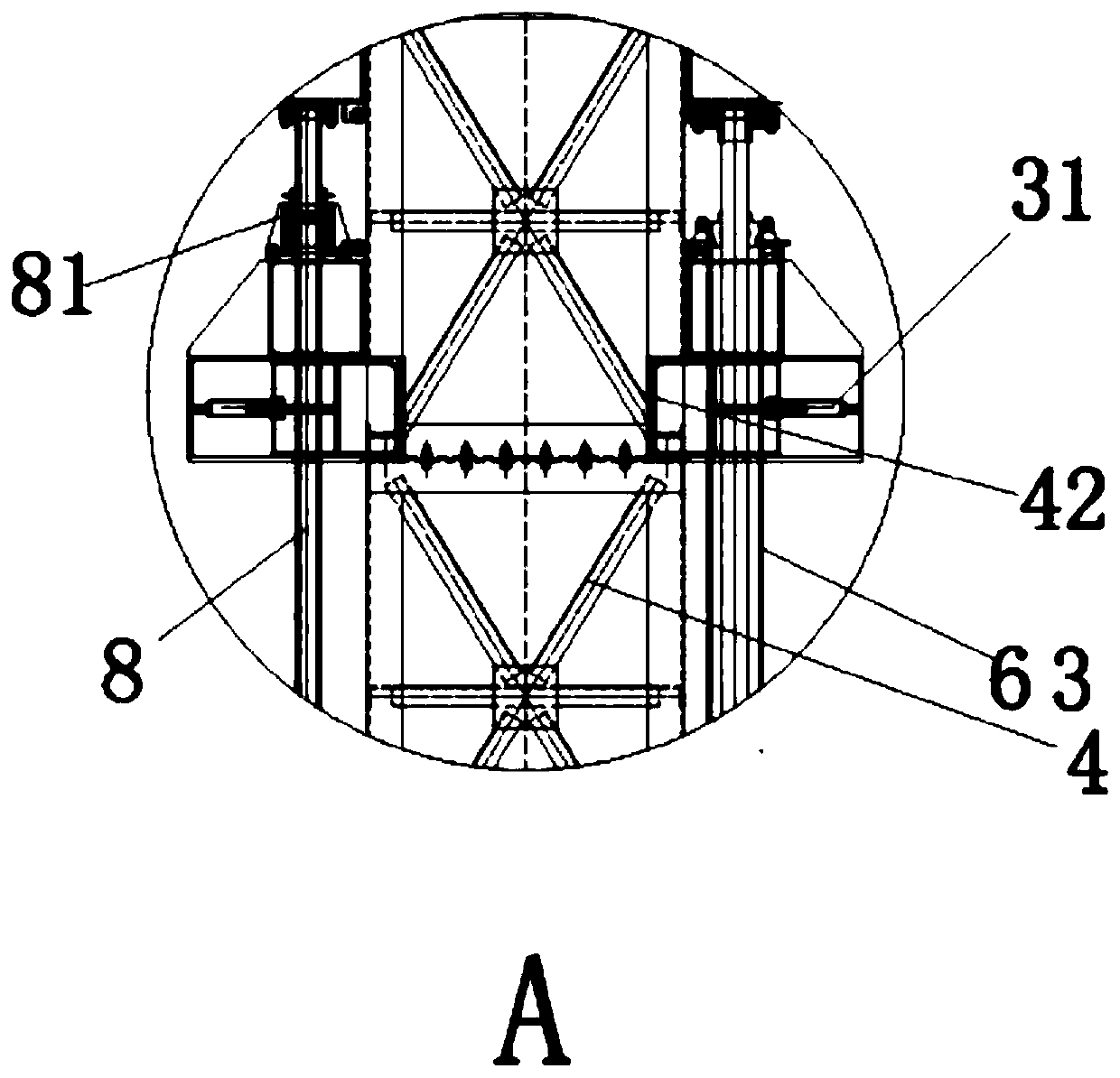

[0024] The specific embodiment of the template automatic alignment device of the building machine of the present invention is as follows: figure 1 As shown, it includes four standard section groups, a jacking mechanism and two truss profiles 100 . Each standard section group is composed of multiple standard sections 4 connected end to end. The two ends of the truss profile 100 are sleeved on two standard joint groups located on the same side, the jacking mechanism is installed on the standard joint set, and the working end of the jacking mechanism is fixedly connected to the end of the truss profile 100 to drive The truss profile 100 moves in the vertical direction, and the alignment device includes an alignment trolley 9 that is sleeved on the truss profile 100 and can slide along the truss profile 100. The alignment trolley 9 is connected to the formwork frame 1 through a connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com