Heliostat hoisting device

A hoisting device and heliostat technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of assembly hazards, unsuitable for manual on-site assembly work, and unsmooth alignment between the connecting seat and the installation column surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

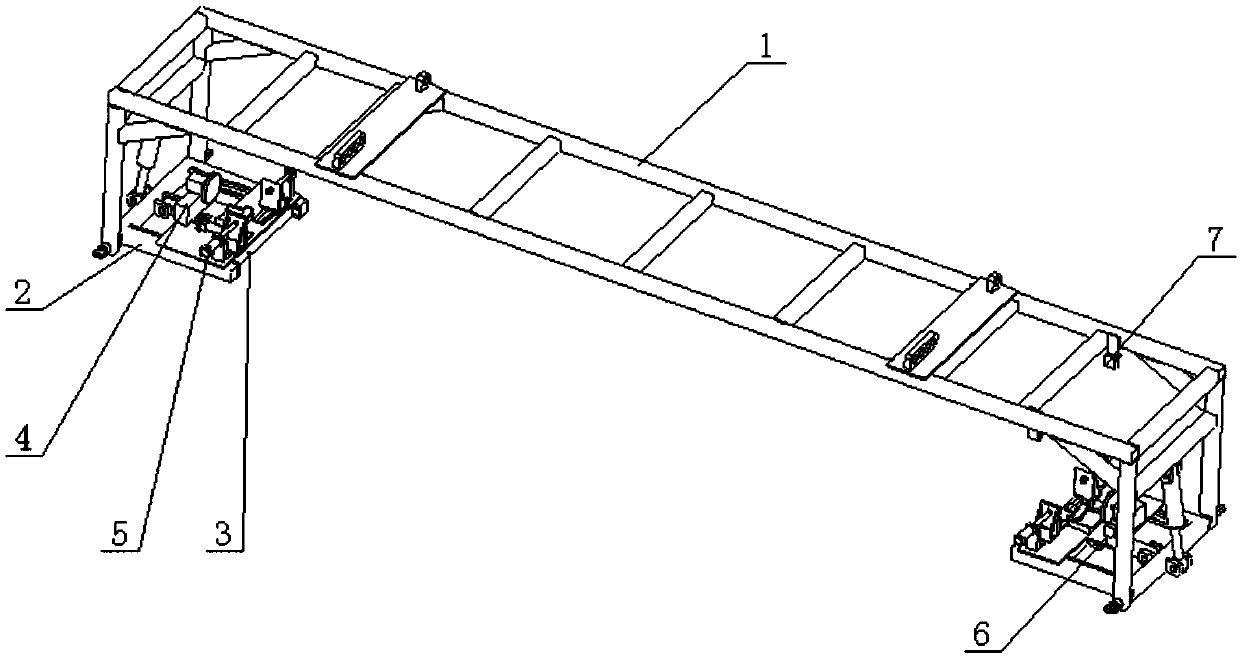

[0073] Such as figure 1 As shown, the heliostat hoisting device provided in this embodiment includes:

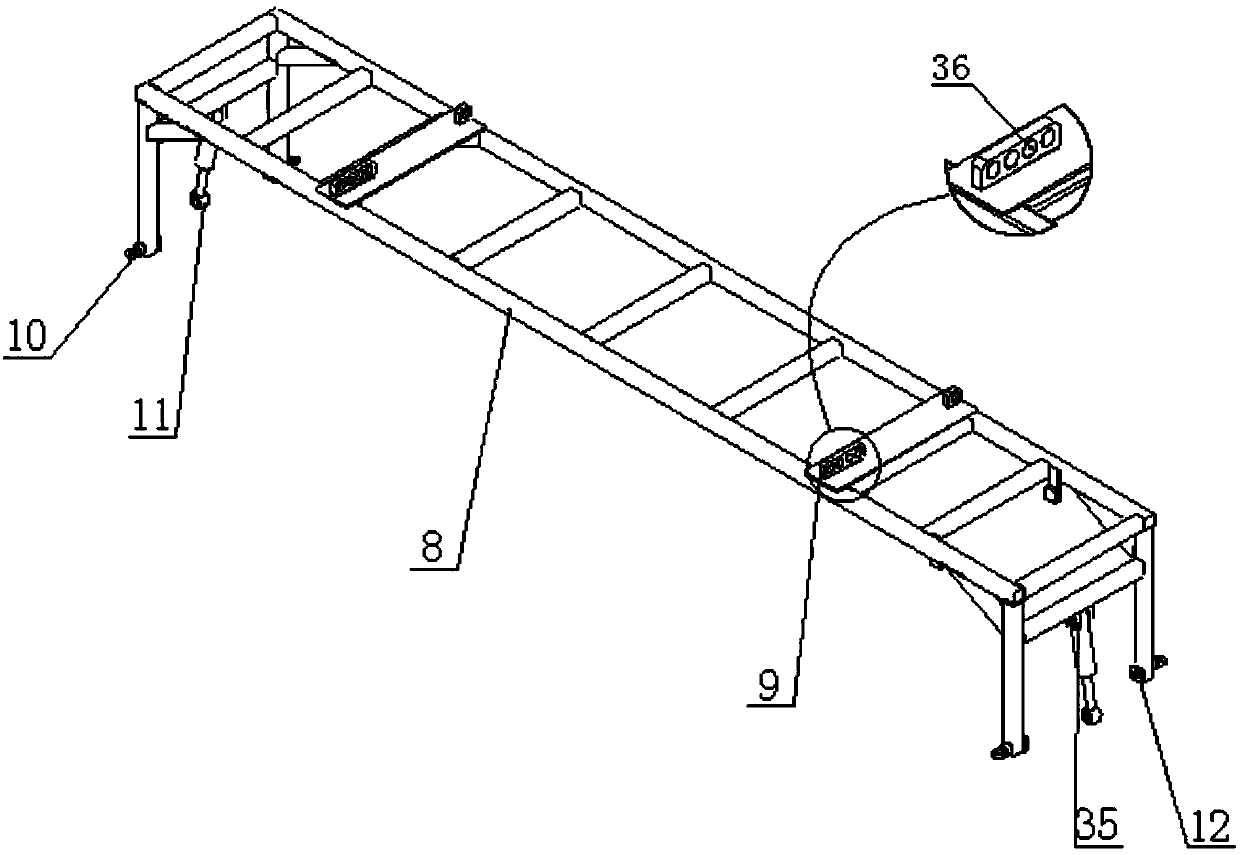

[0074] Lifting frame 1, please go to see figure 2 The lifting frame 1 is mainly composed of a main frame 8, lifting ears 9, side lifting rings 10, turning drive 11, turning support 12, and turning ear seat B 35. Specifically, the main frame 8 is formed by group welding of profiles, and the lifting lugs 9 are respectively symmetrically welded to the left and right 4 positions of the main frame 8. At the same time, the lifting lugs 9 are provided with several groups of lifting holes 36, and the side The hanging rings 10 are respectively hinged on the outer four sides of the root of the main frame 8. The turning drive 11 is hinged to the main frame 8 through the turning pin and the turning lug B 35, and the turning supports 12 are respectively provided In the four positions inside the bottom of the main frame 8; the driving form of the turning drive 11 is not limited to the drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com