Patents

Literature

93results about How to "Avoid defective products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

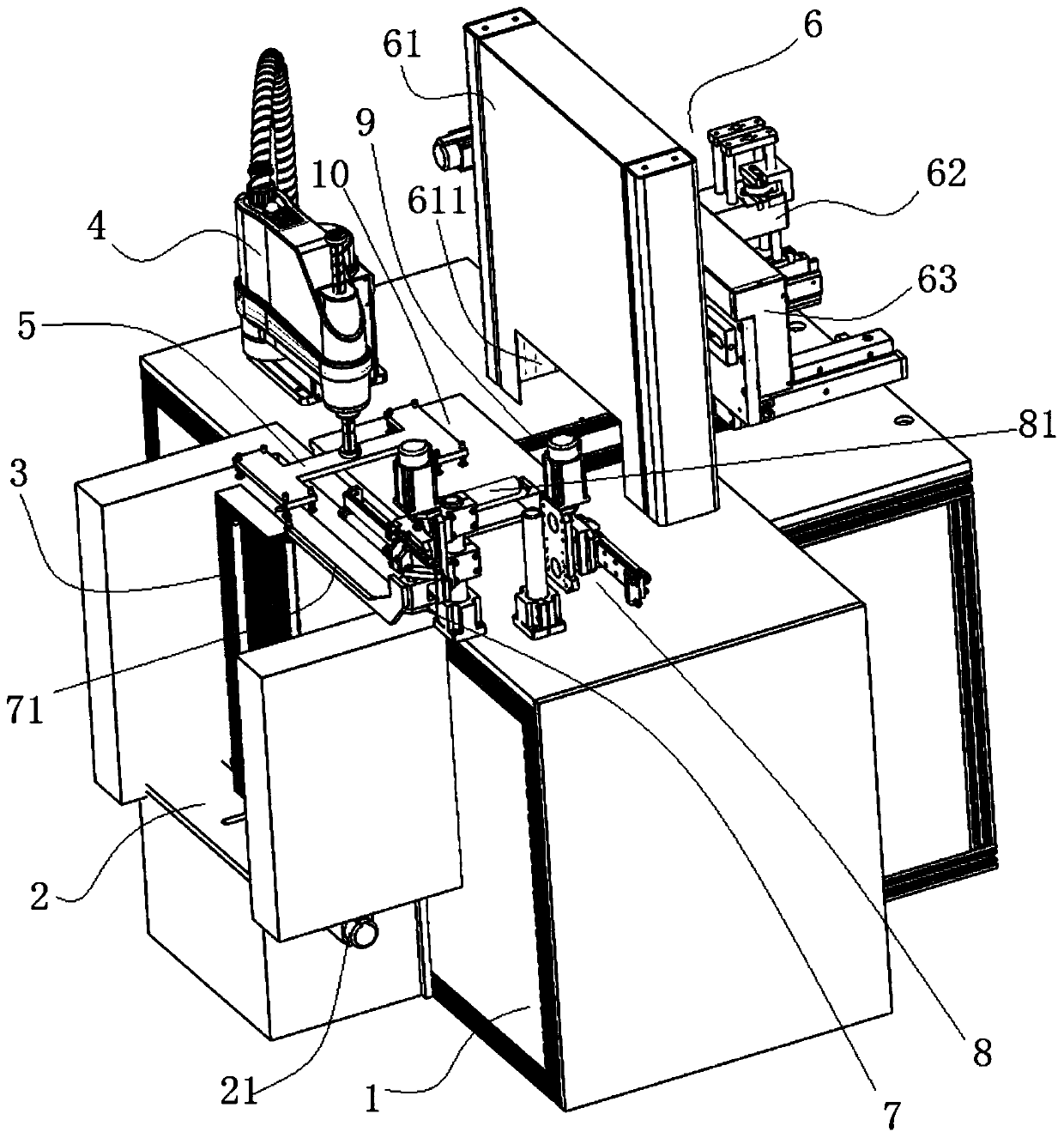

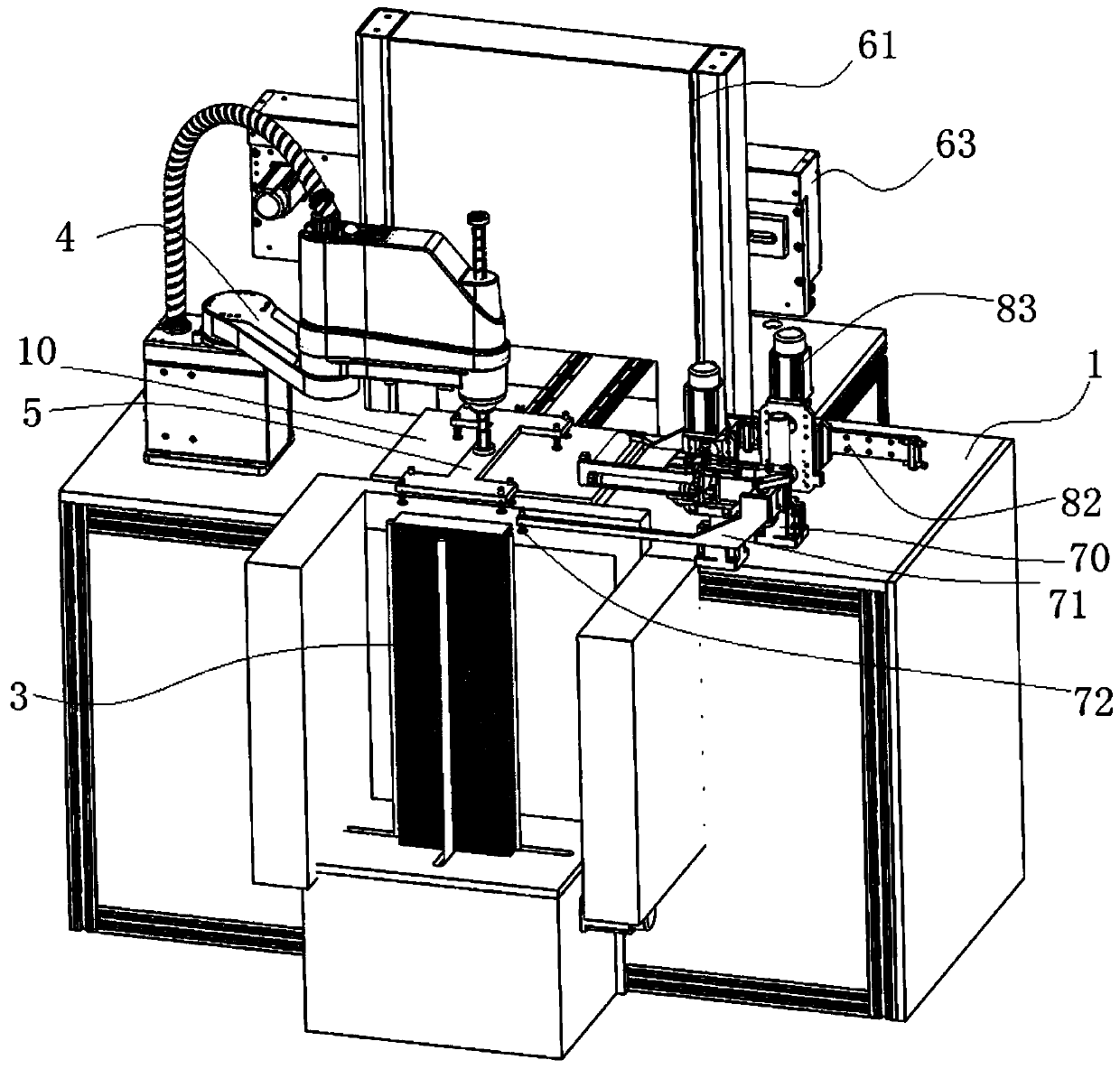

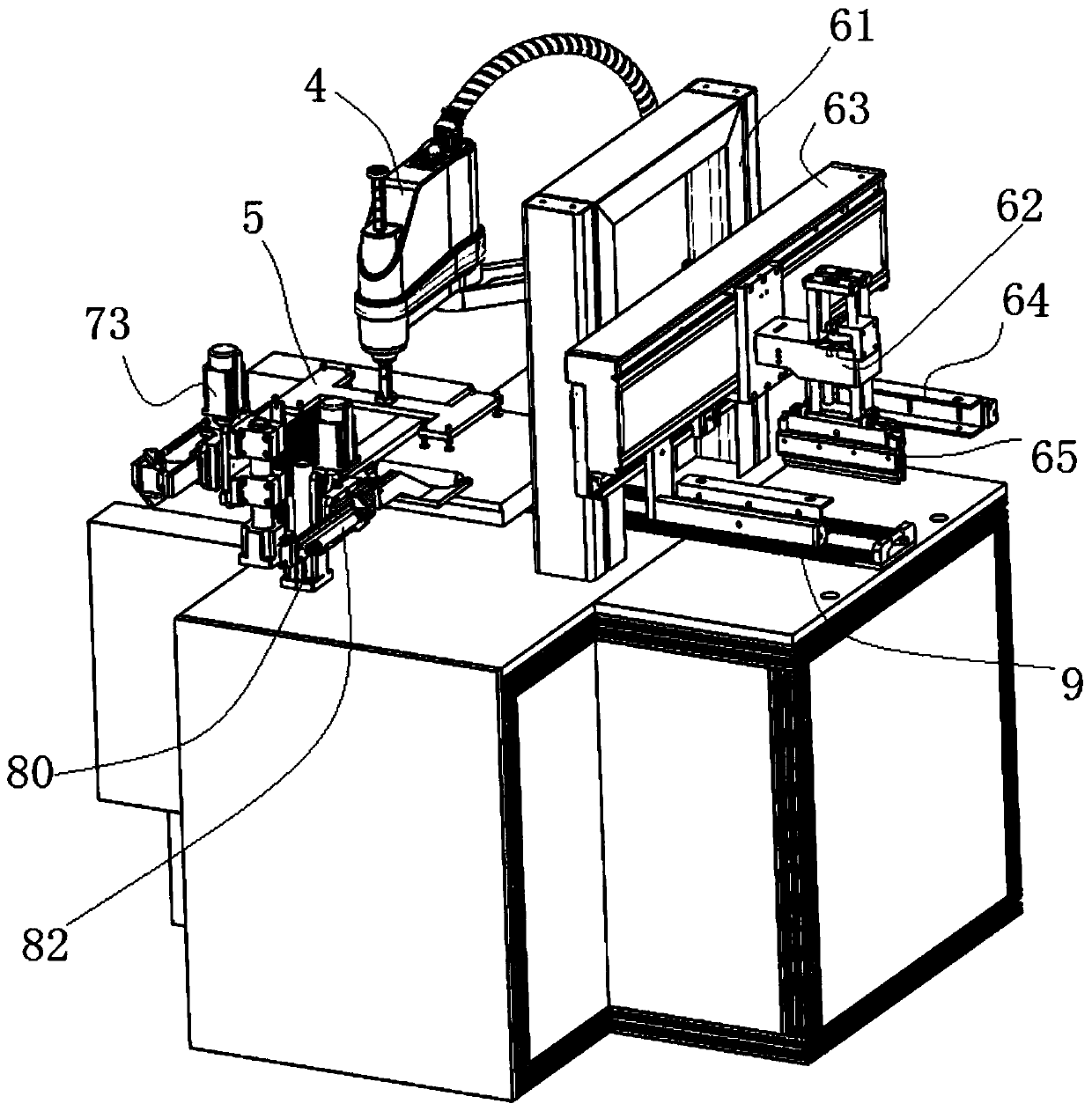

Full-automatic printing machine with touch screen

ActiveCN104441936AReduce manufacturing costAvoid defective productsScreen printersPrinting press partsManipulatorEngineering

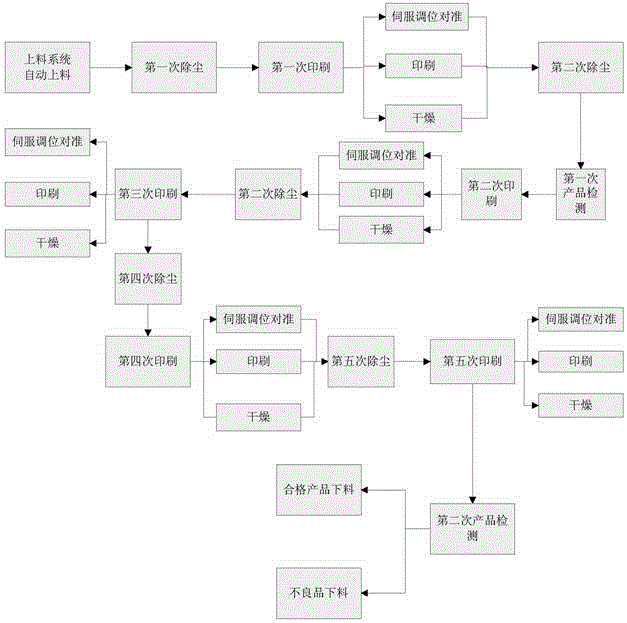

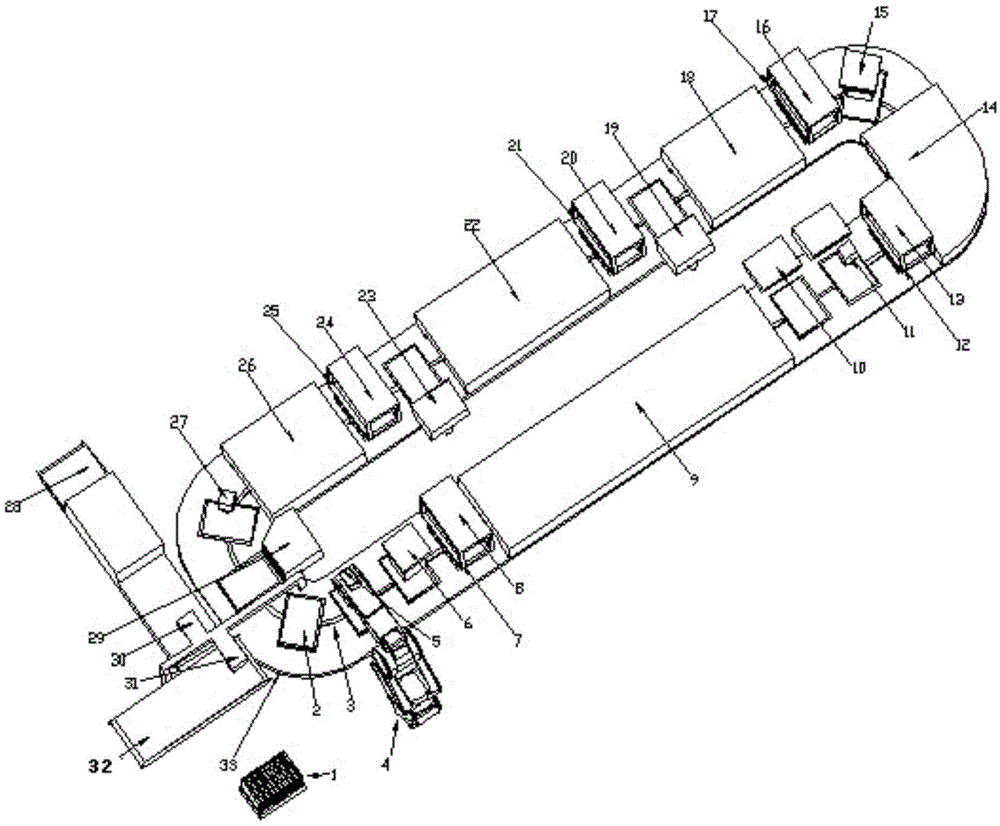

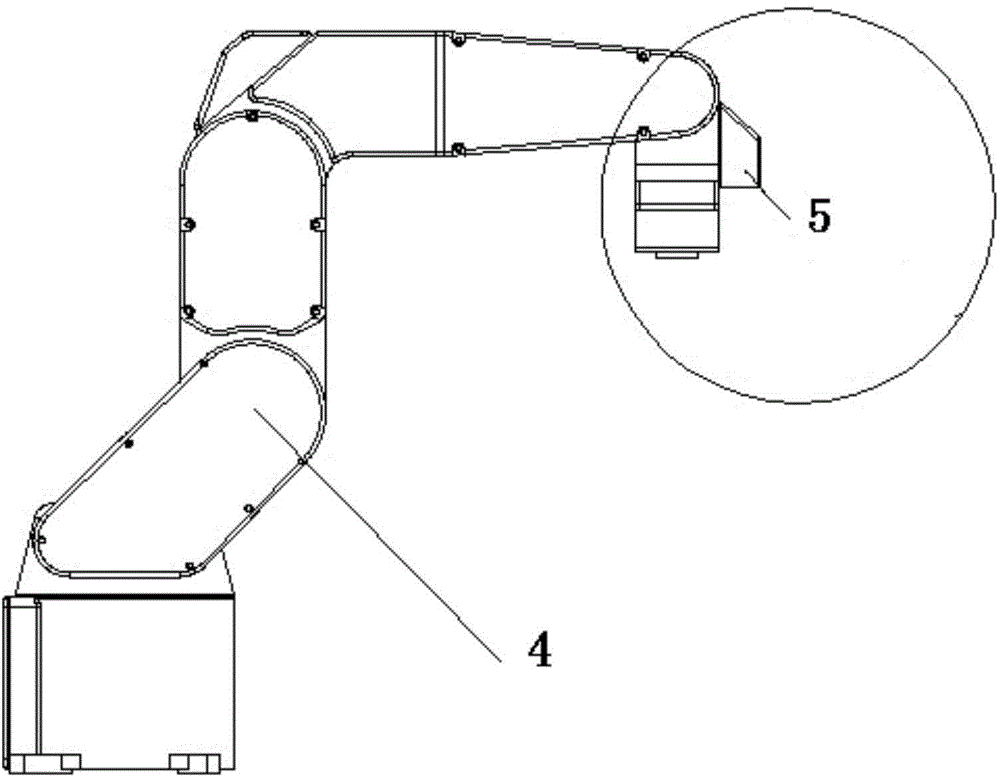

The invention discloses a full-automatic printing machine with a touch screen. According to the technical scheme, the full-automatic printing machine with the touch screen comprises a base, working tables, a feeding device and at least two machining devices; the multiple working tables are installed on the base and are in sliding fit with the base, and the touch screen is accurately driven by a divider to the specified machining procedure; the feeding device comprises a mechanical arm and a CCD detection device installed on the mechanical arm; the at least two machining devices include a silk-screen printing device and a servo position adjustment device; the servo position adjustment device is installed on the silk-screen printing device, the silk-screen printing device is adjusted through the touch screen position fed back by the CCD detection device, and therefore it is guaranteed that the silk-screen printing device directly faces the machining position. The full-automatic printing machine has the advantages that the full-automatic production procedure is achieved; meanwhile, as the multiple silk-screen printing-drying machining devices are arranged, multicolor chromatography can be achieved through one production line, the production efficiency can be greatly improved, and the production cost can be greatly reduced.

Owner:广州泰行智能科技有限公司

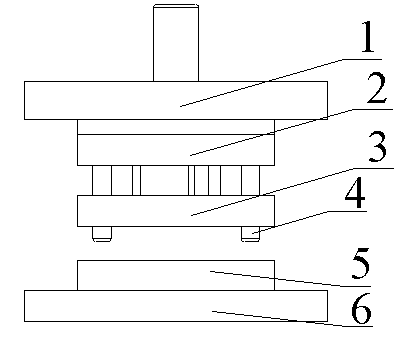

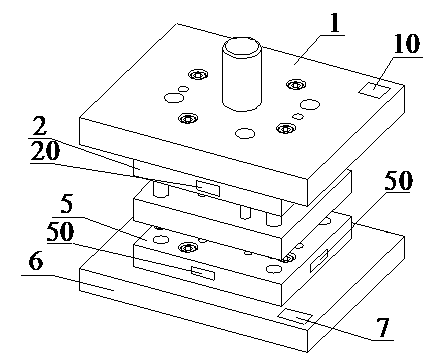

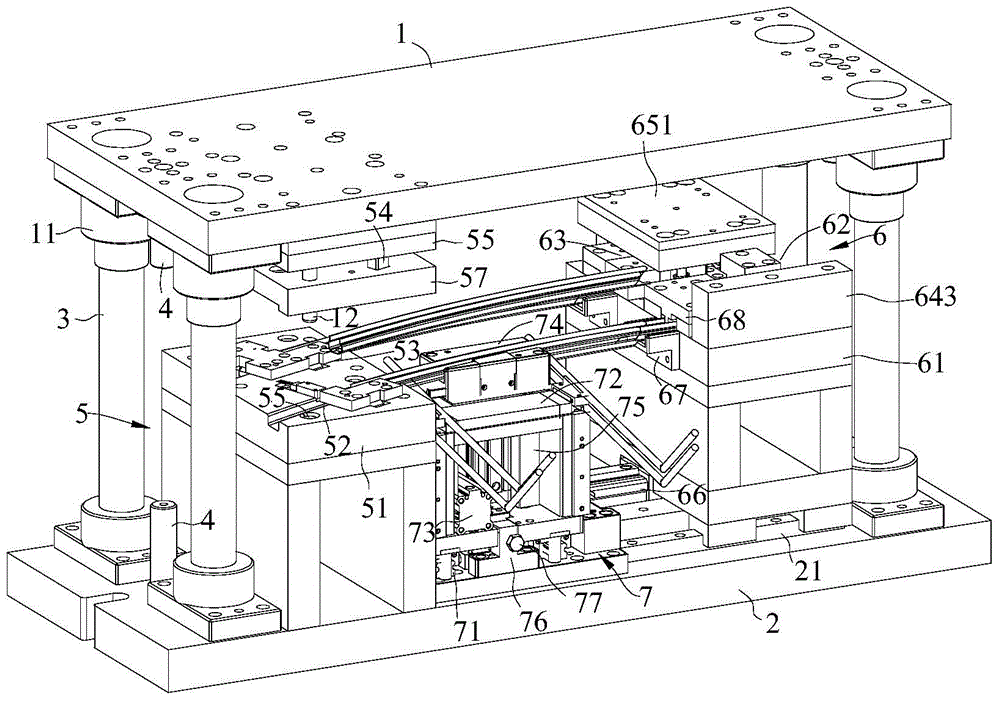

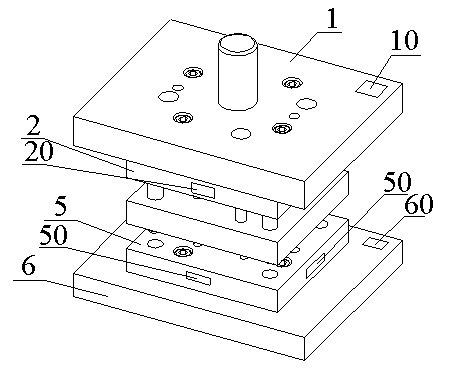

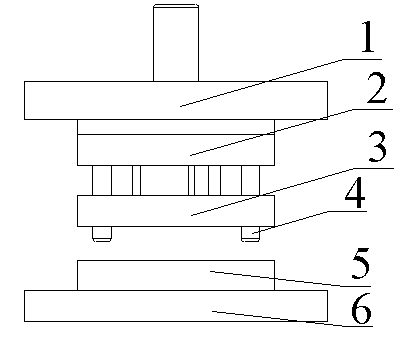

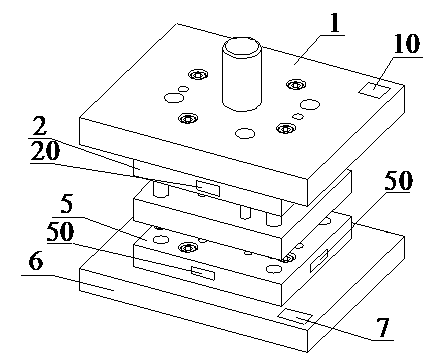

Embedded integrated intelligent die

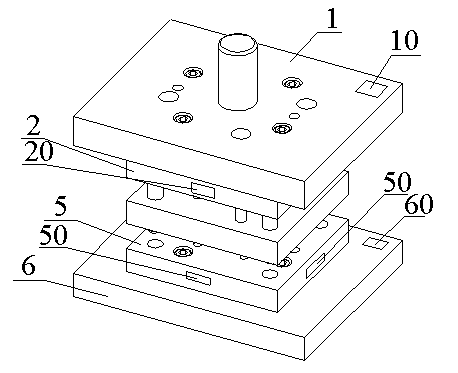

The invention discloses an embedded integrated intelligent die which comprises an upper die set plate, an upper die fixing plate, a guide pillar, a core die, a discharging plate, a lower die set plate and a cavity die. The cavity die is arranged on the lower die set plate; the upper die fixing plate is provided with the core die which is matched with the cavity die; the upper die fixing plate is arranged on the upper die set plate; the core die is arranged on the upper die set plate; the guide pillar which penetrates through the discharging plate to be fixed on the upper die set plate enters into the cavity die to guide and correct under the working state of the embedded integrated intelligent die; an elastic device is arranged between the discharging plate and a core die fixing plate; the discharging plate can move up and down along the guide pillar; and the upper die set plate, the cavity die and the lower die set plate are respectively provided with a sensor. Accordingly, the embedded integrated intelligent die has the advantages of being capable of utilizing the sensors which are embedded in the embedded integrated intelligent die to integratedly obtain various information on the embedded integrated intelligent die to adjust technical parameters when the embedded integrated intelligent die works, guaranteeing that die machining is under real-time monitoring and accurate machining conditions, reducing defective products and reducing the rate of the detective products by 20%, improving the working efficiency and being capable of reducing debugging time of the embedded integrated intelligent die by 50%.

Owner:SOHBI CRAFT CHANGSHU

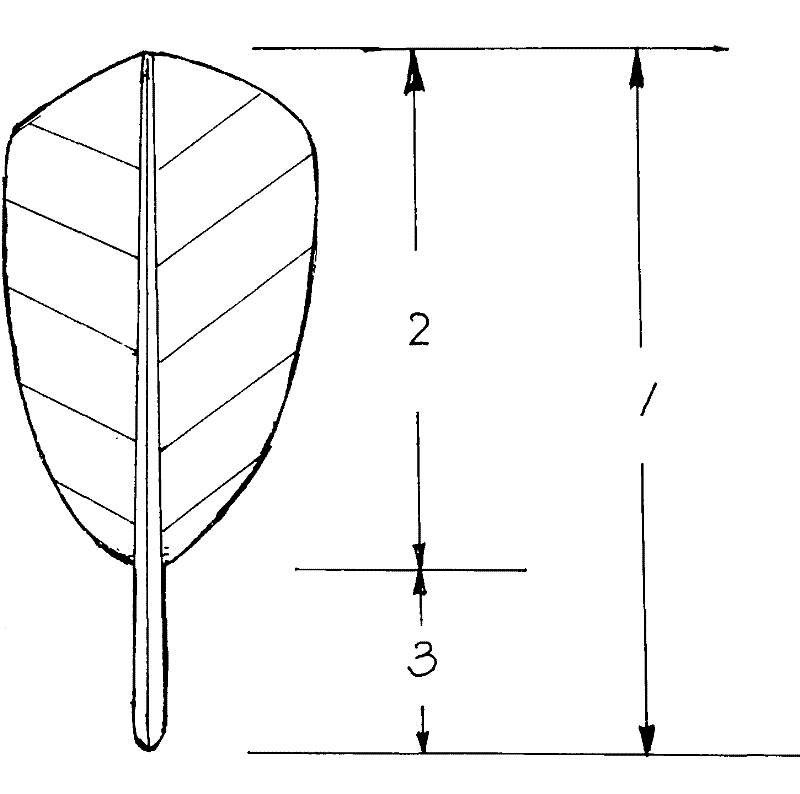

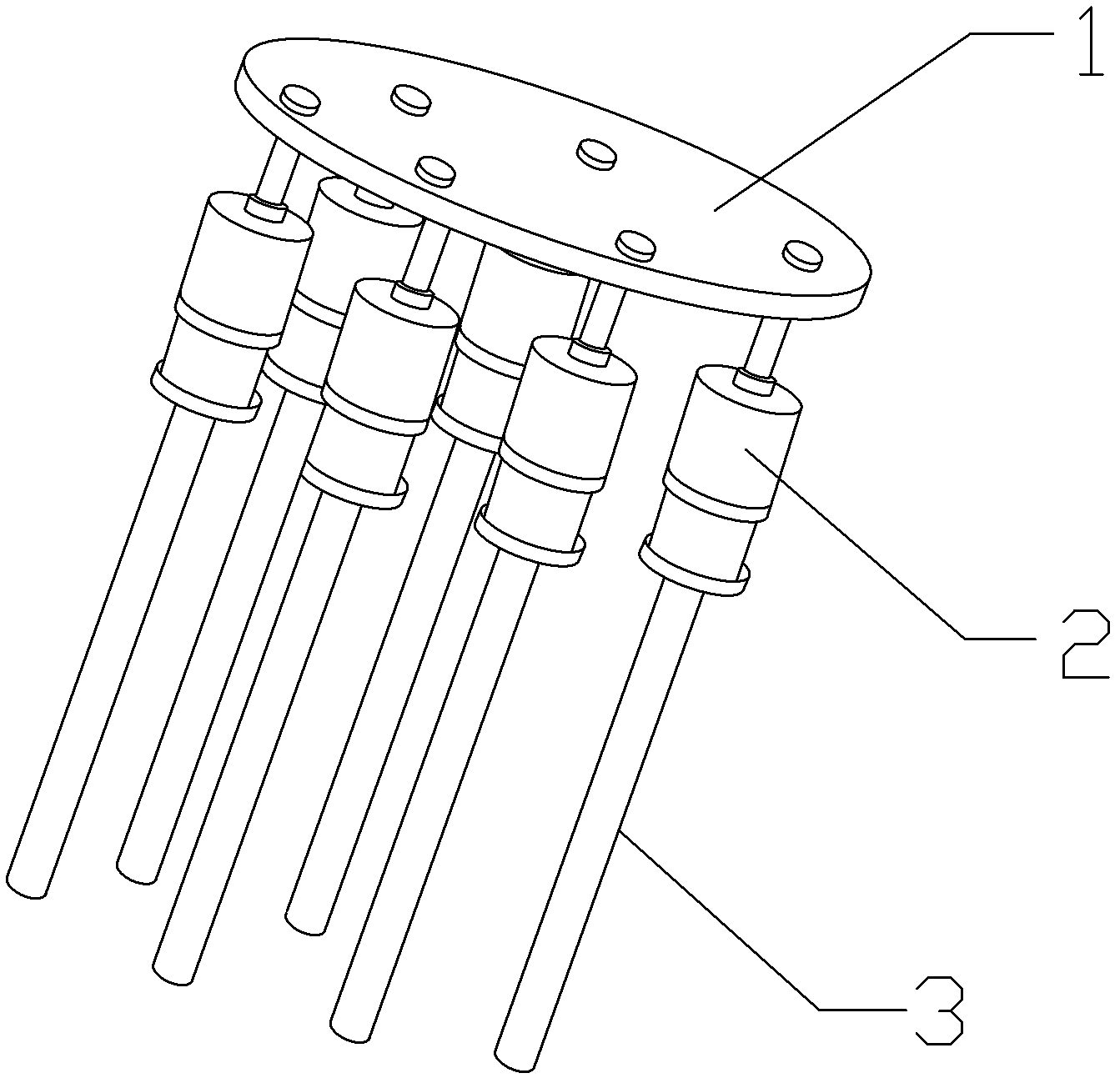

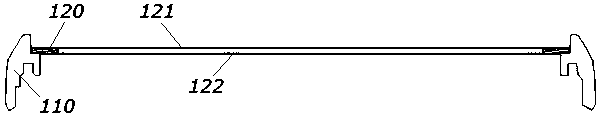

Shuttlecock

InactiveCN102327694AReduce manufacturing costImprove consistencySport apparatusCompression moldingEngineering

The invention discloses a shuttlecock, which consists of a vane, a feather implanting rack and a bulb. A connecting rod positioned on the central axis of a feather implanting bracket is a unique connector of the feather implanting rack and the bulb. The upper end of the vane is a feather wing; the lower end of the vane is a root; and the root of the vane is implanted in a feather implanting pipe, so that the shuttlecock provided by the invention is manufactured. As a plurality of working procedures of manufacturing a conventional shuttlecock are replaced with the feather implanting bracket which is subjected to compression molding, the time and the labor are saved; the manufacturing cost is decreased; the connecting rod of the feather implanting bracket and the bulb is positioned on the central axis; the flying stability of the shuttlecock is improved profitably; the feather implanting bracket and the bulb are connected only by one connecting rod; and the weight of the shuttlecock is decreased profitably.

Owner:戴见霖

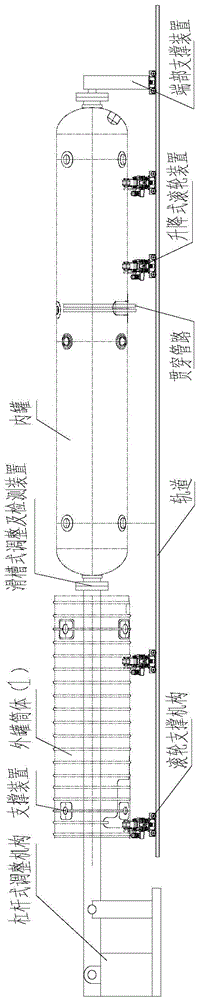

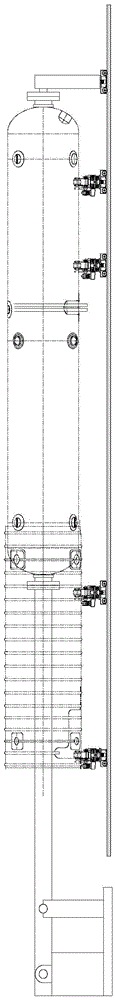

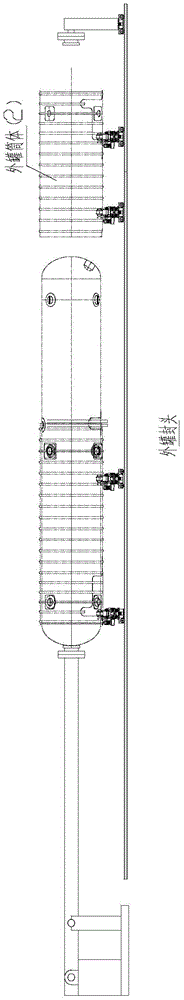

Tank sleeving technological method of railway tank car of double-layer structure

ActiveCN105458609AReduce quality riskAvoid defective productsWelding/cutting auxillary devicesAuxillary welding devicesManufacturing efficiencyProcess control

The invention relates to a tank sleeving technological method of a railway tank car of a double-layer structure. The technological method includes the steps that firstly, one side of an inner tank body and one side of an outer-tank barrel matched with the inner tank body are assembled, wherein one side of the inner tank body and one side of an outer tank body are adjusted by supporting and positioning one side of the outer-tank barrel, and the sleeved outer-tank barrel and the inner tank body are supported and fixed; secondly, the other side of the inner tank body and the other side of the outer-tank barrel matched with the inner tank body are assembled, wherein the other side of the outer-tank barrel and the other side of the inner tank body are adjusted to move relatively, and the sleeved outer-tank barrel and the inner tank body are supported and fixed; thirdly, the two sides of the completely-sleeved outer-tank barrel are overall adjusted, and a circular seam at a combined portion is welded; and finally, end sockets on the two sides are assembled and welded. According to the tank sleeving technological method, quality risks are reduced, all the technical indexes can be more easily guaranteed, and defective products are avoided; the influences of human factors on the quality are eliminated to the maximum degree, and process control is more easily controlled; and the influence of auxiliary time on the production takt is reduced, and the product manufacturing efficiency is improved.

Owner:CRRC YANGTZE CO LTD

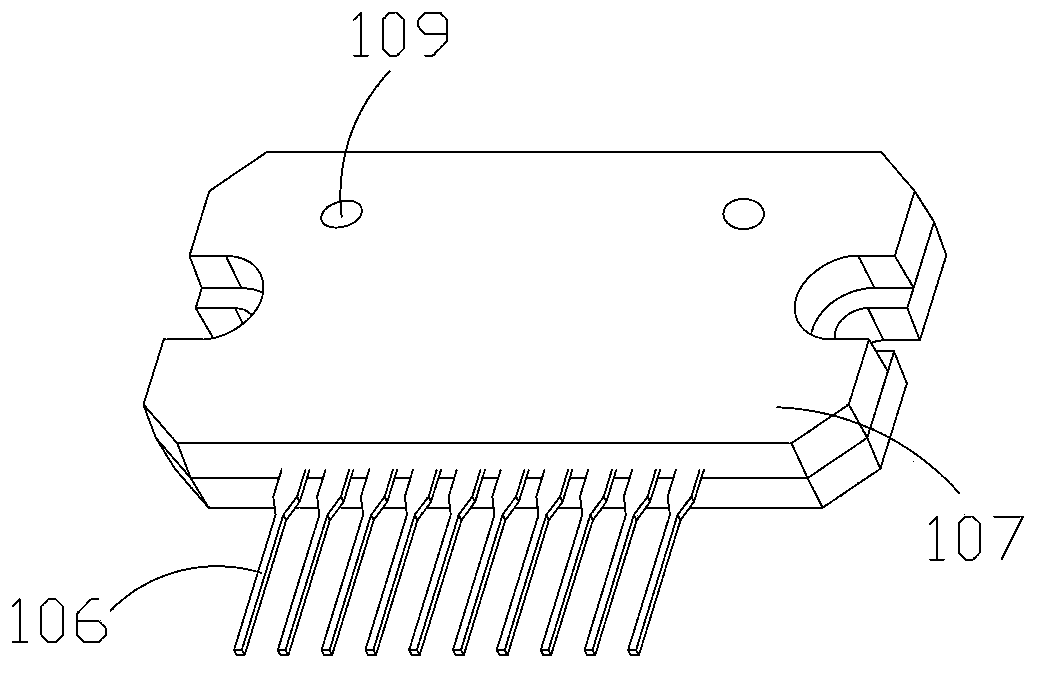

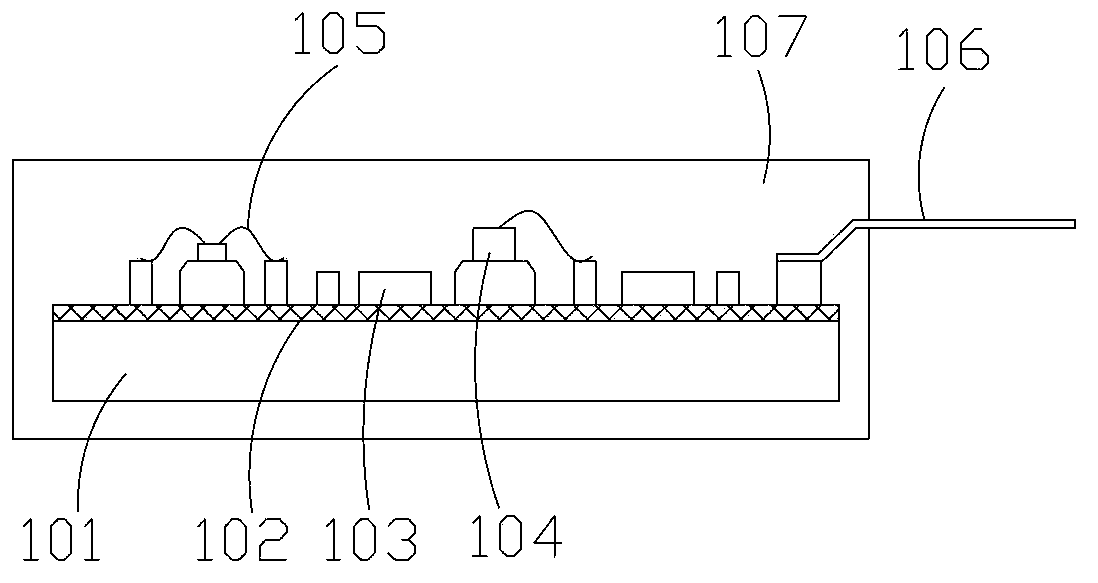

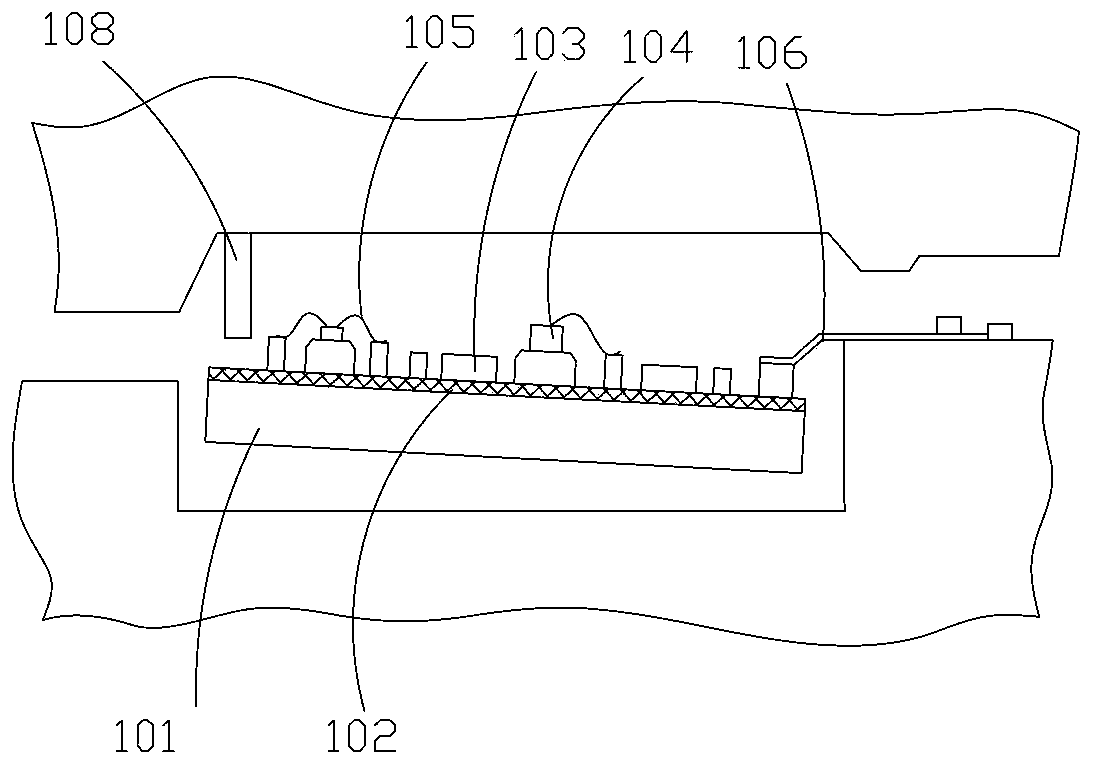

Manufacturing method for intelligent power module

ActiveCN104112678AImprove reliabilityAvoid defective productsSolid-state devicesSemiconductor/solid-state device manufacturingElectricityComputer module

The invention provides a manufacturing method for an intelligent power module. The method comprises the steps that: S1) a semi-finished intelligent power module is provided; S2) a lead-wire framework structure is provided; S3) all fixed pins are welded and the fixed pins and electric pins are enabled to be respectively arranged on the two opposite sides of a substrate; S4) the semi-finished intelligent power module is arranged in a mould cavity of a mould, and the tail ends of the fixed pins and the tail ends of the electric pins are clamped by utilizing the mould; S5) a liquid packaging body is injected into the mould cavity of the mould and molded; S6) the mould is opened and the semi-finished intelligent power module after being packaged is taken out; and S7) the tail ends, which are connected together, of the electric pins are cut and the part, which stretches out of the packaging body, of the fixed pins is cut. The substrate is fixed via the electric pins and the fixed pins which are arranged on the two opposite sides so that defective products caused by unbalanced injection molding force can be completely avoided and packaging yield rate can be enhanced. Meanwhile, generation of packaging holes is eliminated, and reliable performance of the intelligent power module is enhanced.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

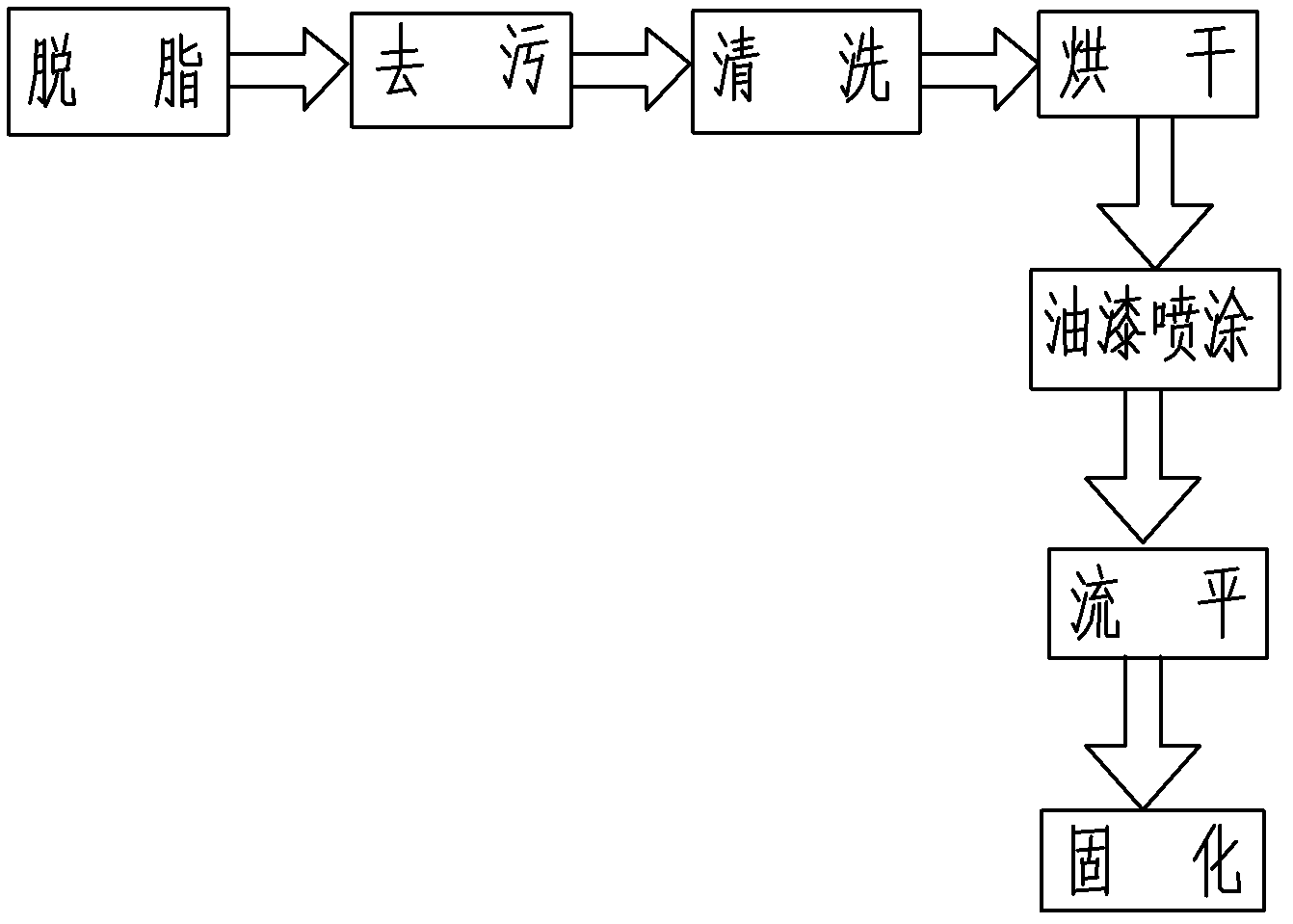

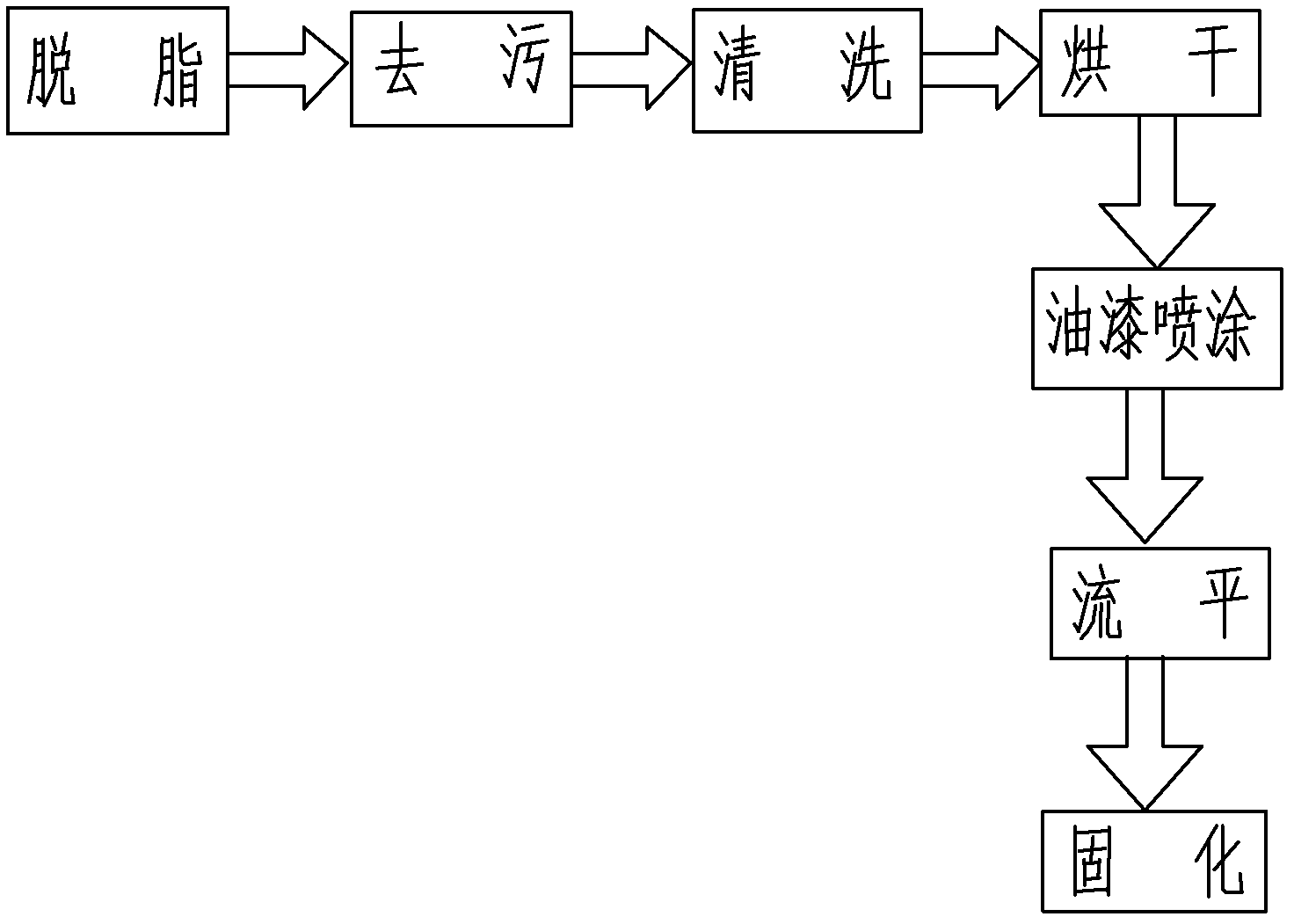

Coating process of carbon fiber fishing rod

InactiveCN102527596AUniform adsorptionReduce pollutionPretreated surfacesCoatingsFiberNumerical control

The invention provides a coating process of a carbon fiber fishing rod. The coating process of the carbon fiber fishing rod sequentially comprises the steps of: degreasing, decontaminating, cleaning and drying a fishing rod, sealing and plugging the mouth of the fishing rod by using a silicone head; vertically hanging the fishing rod on a hanger and spraying paint up and down by a numerical controlled DISK electrostatic spraying device, then entering a leveling region for leveling within 10-15 minutes, irradiating 8-15 minutes by far infrared rays to solidify the fishing rod. By adopting the method provided by the invention, the surface of the sprayed fishing rod is smooth and full, the painting rate of dead angles is high, the whole fishing rod is painted evenly, the brightness is high, the adhesive force is good, the stable product quality is ensured, bad phenomena such as color distortion and bubbling are avoided, the paint film is 50% thinner than the conventional paint and the whole fishing rod has less paint; besides, the painting way is lighter than the traditional way and is independent of skilled labors with high spraying seed and high efficiency.

Owner:湖北钓鱼王渔具有限公司

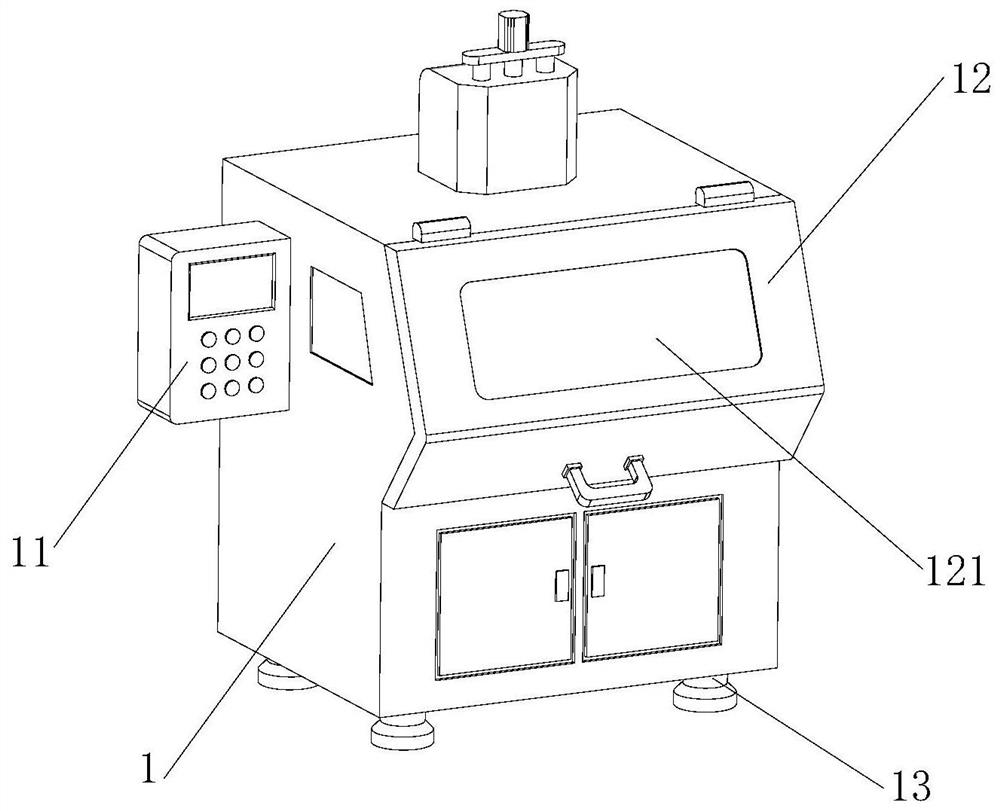

Painting device for surface of computer case

ActiveCN112774918AExtended service lifeIncrease air pressurePretreated surfacesCleaning using toolsPhysicsComputer case

The invention discloses a painting device for the surface of a computer case. The painting device for the surface of the computer case comprises a paint spraying machine body, wherein a control panel is fixedly installed on the side wall of the paint spraying machine body, a plurality of supporting legs are fixedly installed at the bottom of the paint spraying machine body, a baffle is rotationally arranged on the paint spraying machine body, and photoscopes are arranged on the side wall of the paint spraying machine body and the baffle separately; and a spraying mechanism is fixedly arranged in the paint spraying machine body, and comprises a bottom plate, the bottom plate is fixedly installed in the paint spraying machine body, vertical supporting rods are symmetrically connected to the bottom plate, and threaded rods are rotationally arranged on the vertical supporting rods. According to the invention, dotted or granular foreign matters such as dust on the surface of the case can be removed through an arc-shaped scraping plate along with movement of a moving seat, so that defective products are avoided; elastic bristles on the surface of a dust removal block can brush away the dust on the surface of a case housing when the moving seat returns; and meanwhile, a third air bag can blow air, so that an auxiliary dust removal effect is achieved, and drying for a paint can be accelerated.

Owner:浙江台州求精真空泵有限公司

Air tightness detection system and workpiece clamping abnormity early warning method

InactiveCN106197889AAvoid defective productsAvoid causingMeasurement of fluid loss/gain ratePneumatic pressureEngineering

The invention relates to the product crack detection field and especially relates to an air tightness detection system and a workpiece clamping abnormity early warning method. The system and the method of the invention aim at solving a technical problem of accurately determining whether a surface of a clamp, which is tightly contacted with the workpiece, is really blown cleanly. When operating personnel does not blow cleanly the surface of a clamp, which is tightly contacted with the workpiece, a machine can not be started. When the surface is blown cleanly, the machine can be started. The air tightness detection system comprises an air inlet, an air pipe, an air pressure detector, an air pressure change signal output line, a CNC machine, an air pipe joint, the clamp, a contact surface of the clamp and the workpiece, a vent hole and a workpiece to be processed. In the invention, inferior-quality product generation caused by a manual operation fault can be well avoided.

Owner:惠州市华阳精机有限公司

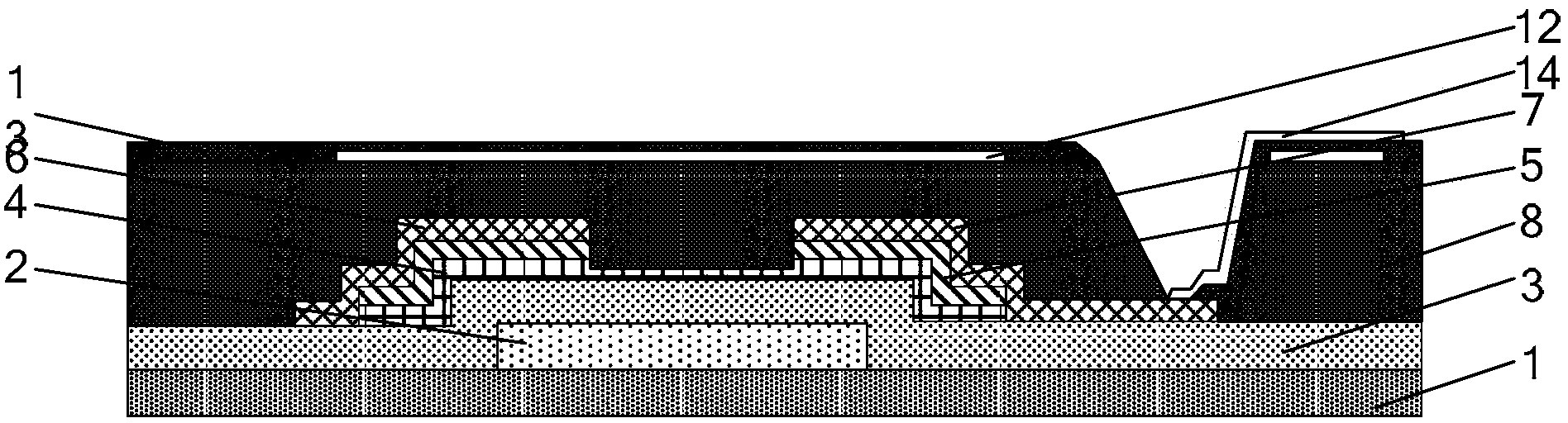

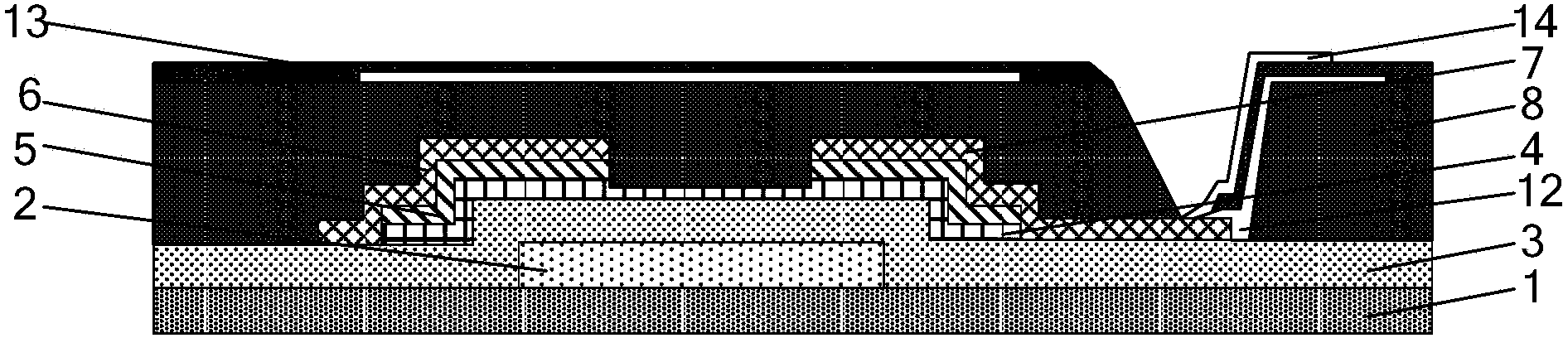

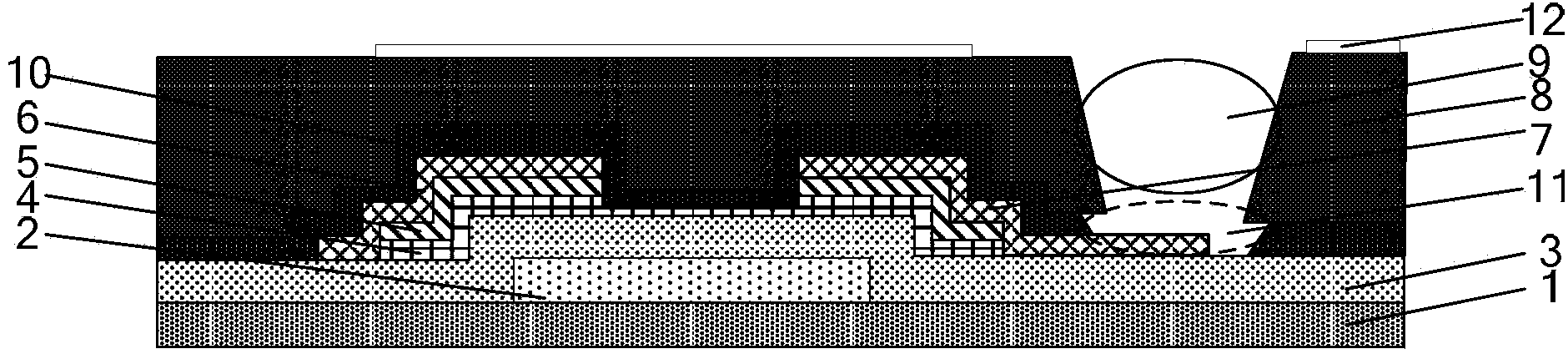

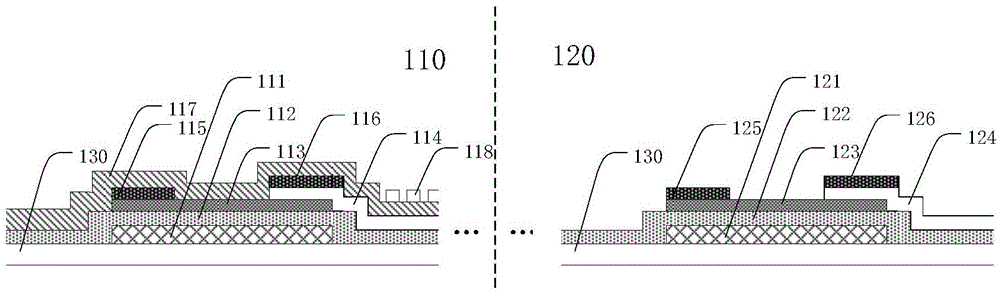

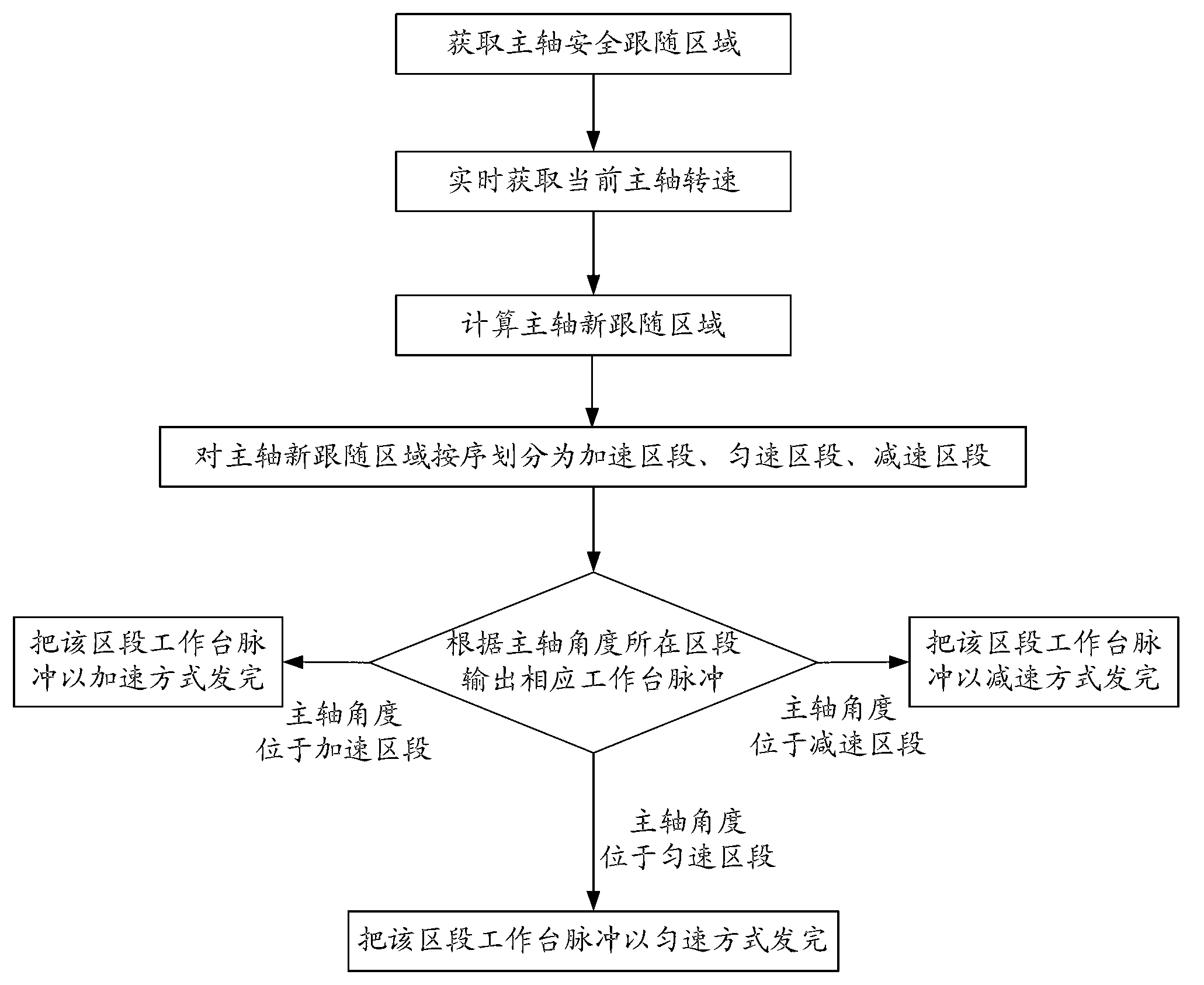

Array substrate, manufacturing method thereof and display device

ActiveCN104241296AGuaranteed qualityAvoid defective productsSolid-state devicesSemiconductor/solid-state device manufacturingDark spotLiquid-crystal display

The invention provides an array substrate, a manufacturing method of the array substrate and a display device and relates to the technical field of liquid crystal display panel manufacture. The problems that a drain electrode and a common electrode layer of an existing high-definition display device are communicated, so that the common electrode layer and a pixel electrode layer are communicated, the sub-pixel function can not be achieved normally, and dark spots are generated are solved. Product quality is guaranteed, the waste of production materials is reduced, and production cost is reduced. The array substrate comprises a substrate body, a source electrode, a drain electrode, an organic resin layer and a common electrode layer formed on the organic resin layer. A first passing hole is formed in the organic resin layer, an isolation layer is arranged on the source electrode and the drain electrode and covers the substrate body, and the isolation layer is completely covered with the organic resin layer. A second passing hole communicated with the first passing hole to expose part of the drain electrode is formed in the isolation layer, wherein the size of the firs passing hole is larger than that of the first passing hole. The array substrate, the manufacturing method of the array substrate and the display device are applied to the technical field of display panel manufacture.

Owner:BOE TECH GRP CO LTD +1

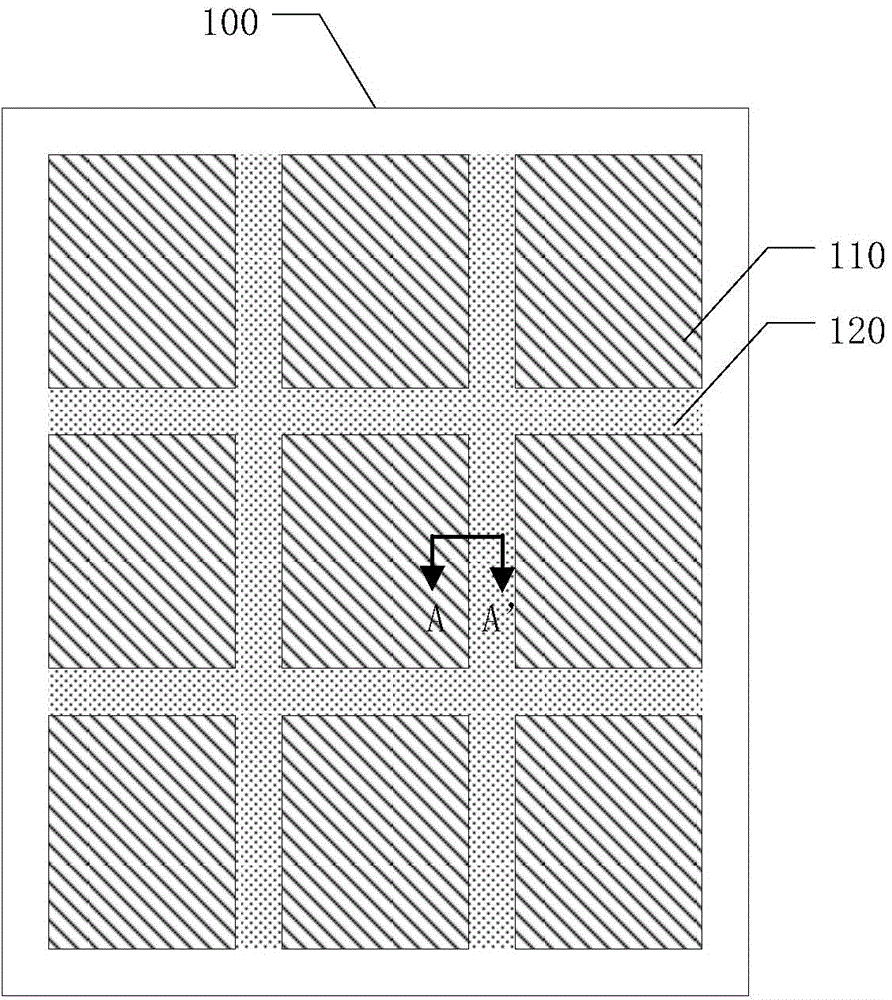

Array substrate mother plate and manufacture method thereof

InactiveCN104898342ATimely detection of badPromote research and developmentSemiconductor/solid-state device testing/measurementSolid-state devicesOptoelectronicsTransistor

Owner:BOE TECH GRP CO LTD +1

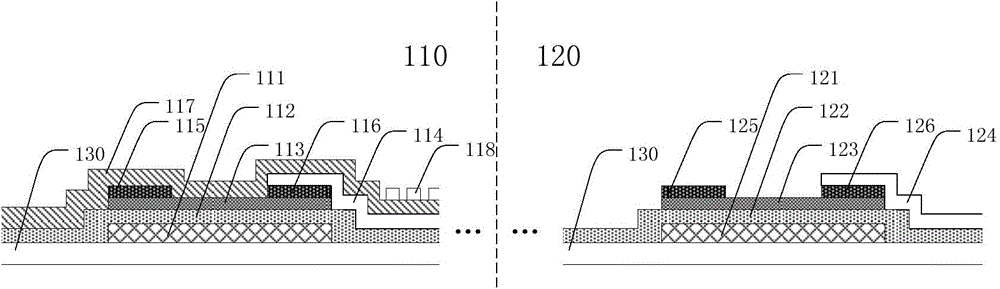

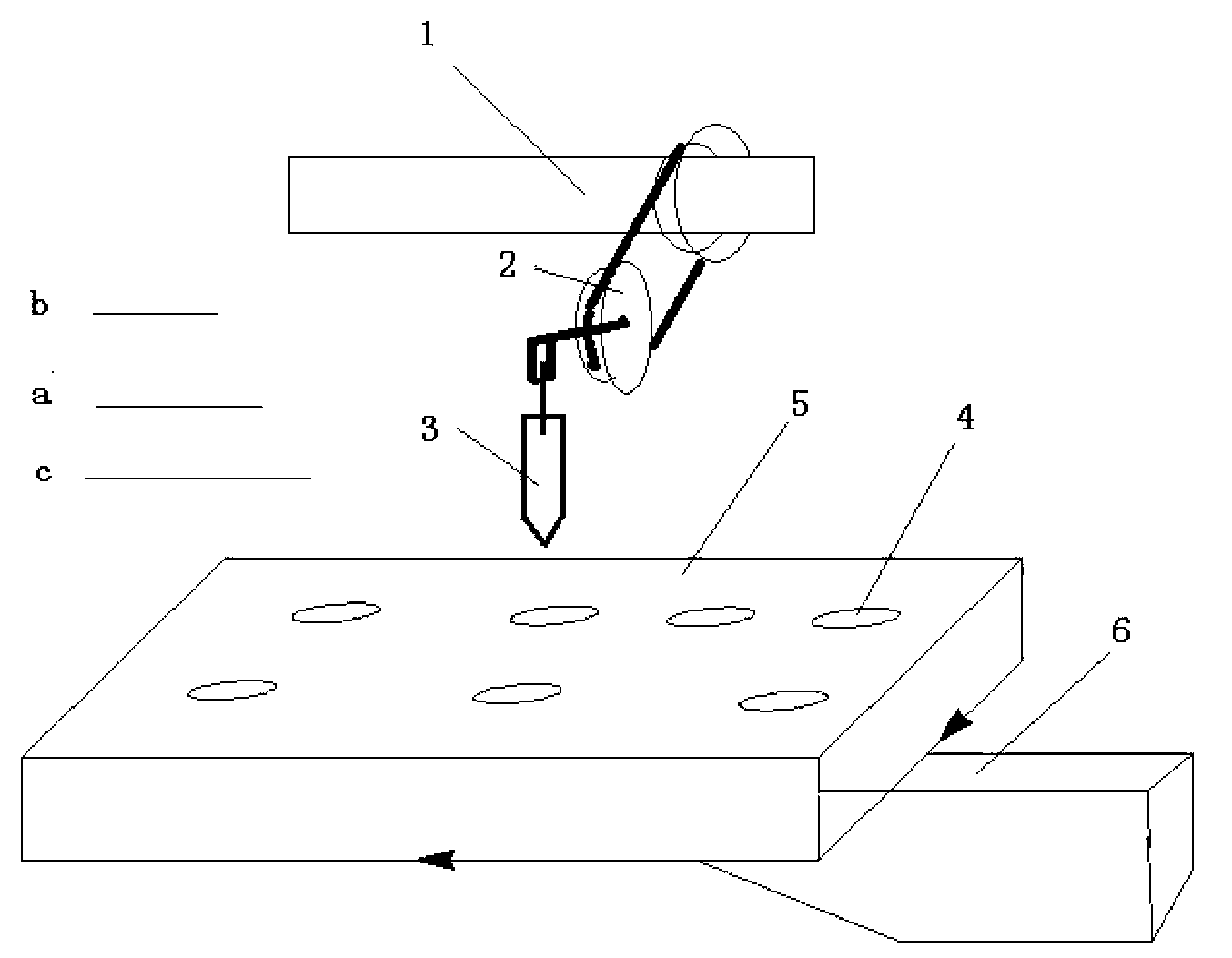

Machine tool table movement control method

InactiveCN103240613AAvoid damageReduce scrap rateLarge fixed membersImpulse frequencyInterference factor

A machine tool table movement control method includes the steps: acquiring a spindle safety following area; acquiring the current spindle speed in real time; calculating the offset angle of a spindle according to response lag time of a table servo driver and the spindle speed to obtain a new spindle following area for controlling a table; and dividing the new spindle following area into an accelerating section, a constant-speed section and a decelerating section in sequence, correspondingly changing the impulsing frequency of the table servo driver by a controller when the angle of the spindle is respectively positioned in the accelerating section, the constant-speed section and the decelerating section, and controlling the table to respectively run in accelerating, constant-speed and decelerating modes. By the aid of characteristics of the spindle following area, the rotating angle of the spindle serves as a triggering condition of the controller without depending on an upper sensor and a lower sensor, external interference factors are decreased, so that control is more accurate, damage and the scrap rate of workpieces are reduced, and the moving area is divided into three sections which are respectively controlled so that more stable movement of the table is ensured.

Owner:NANJING UNIV OF TECH +3

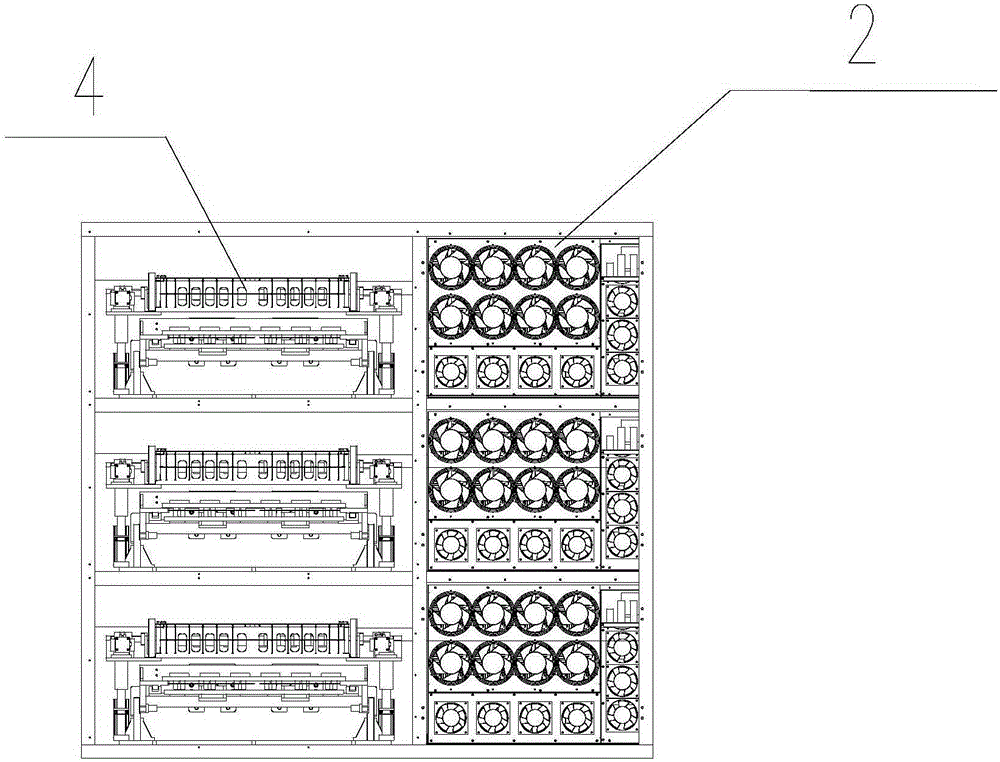

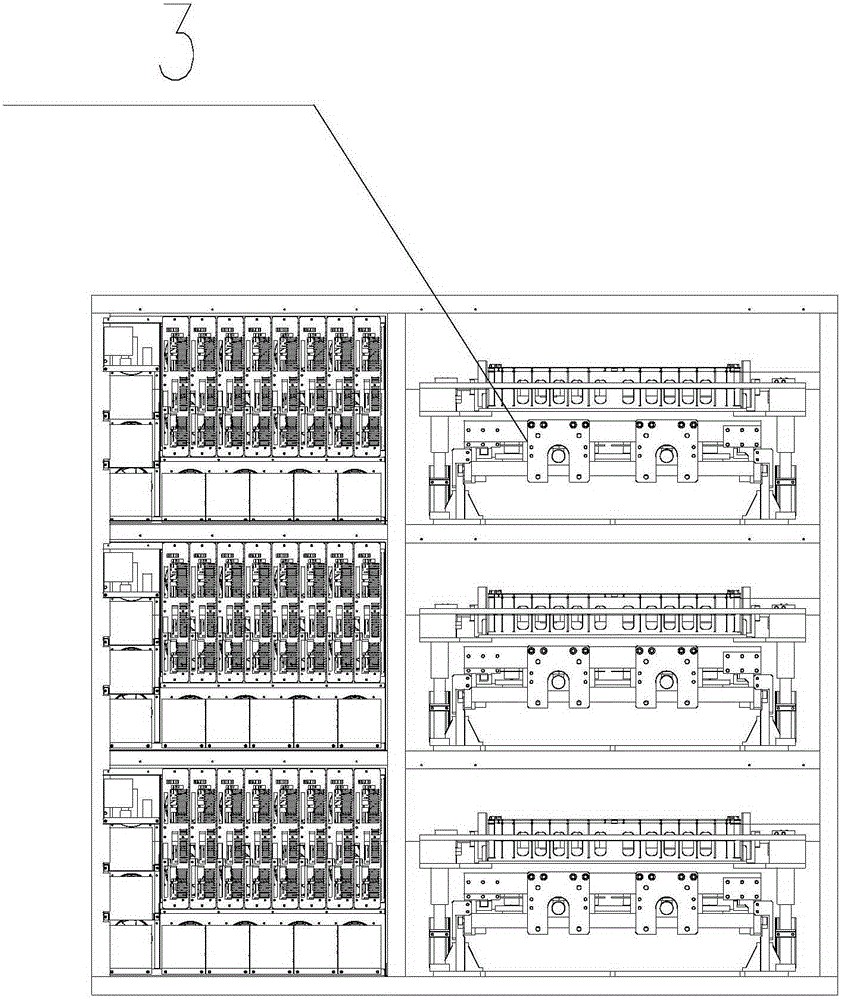

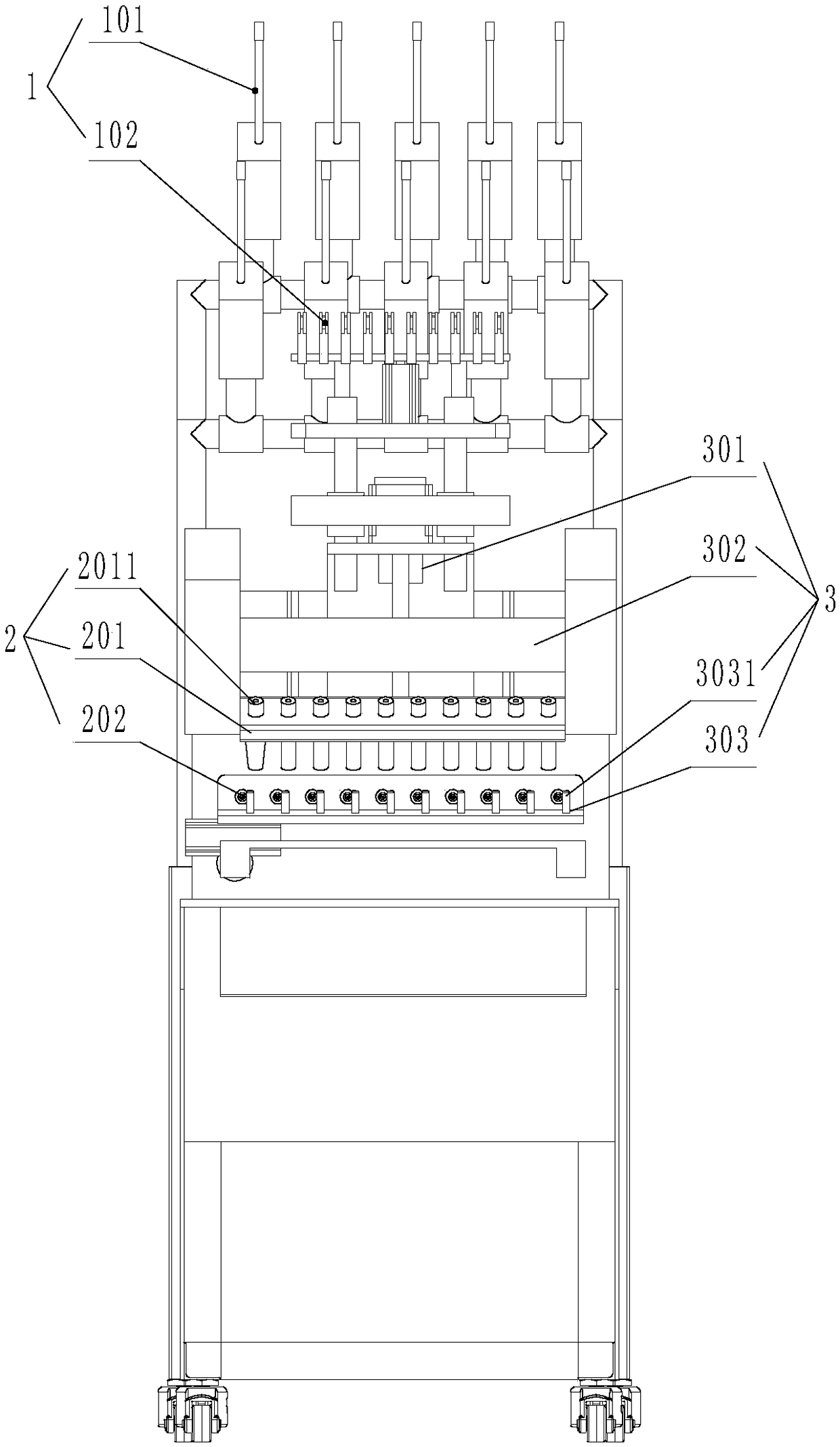

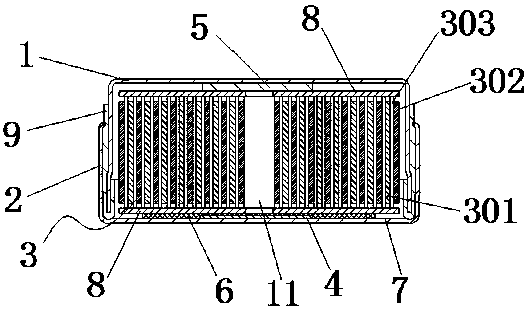

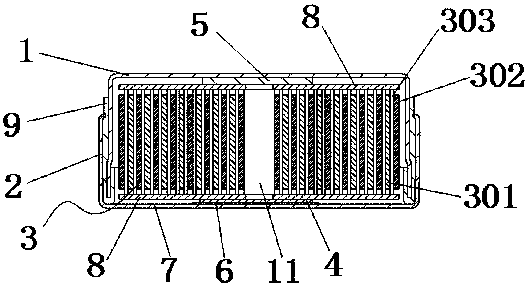

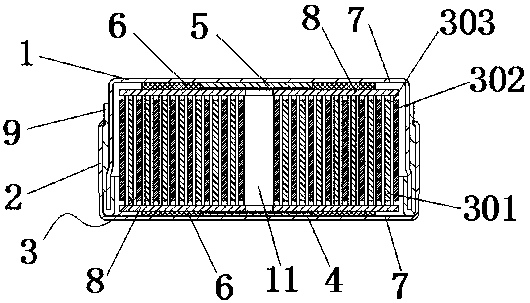

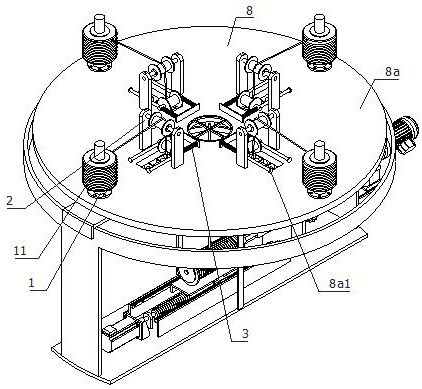

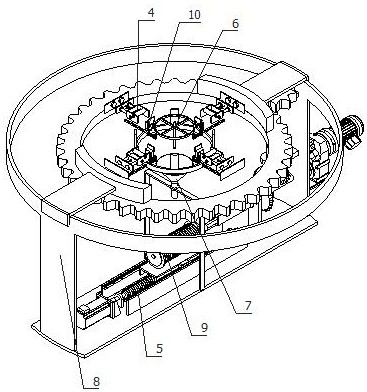

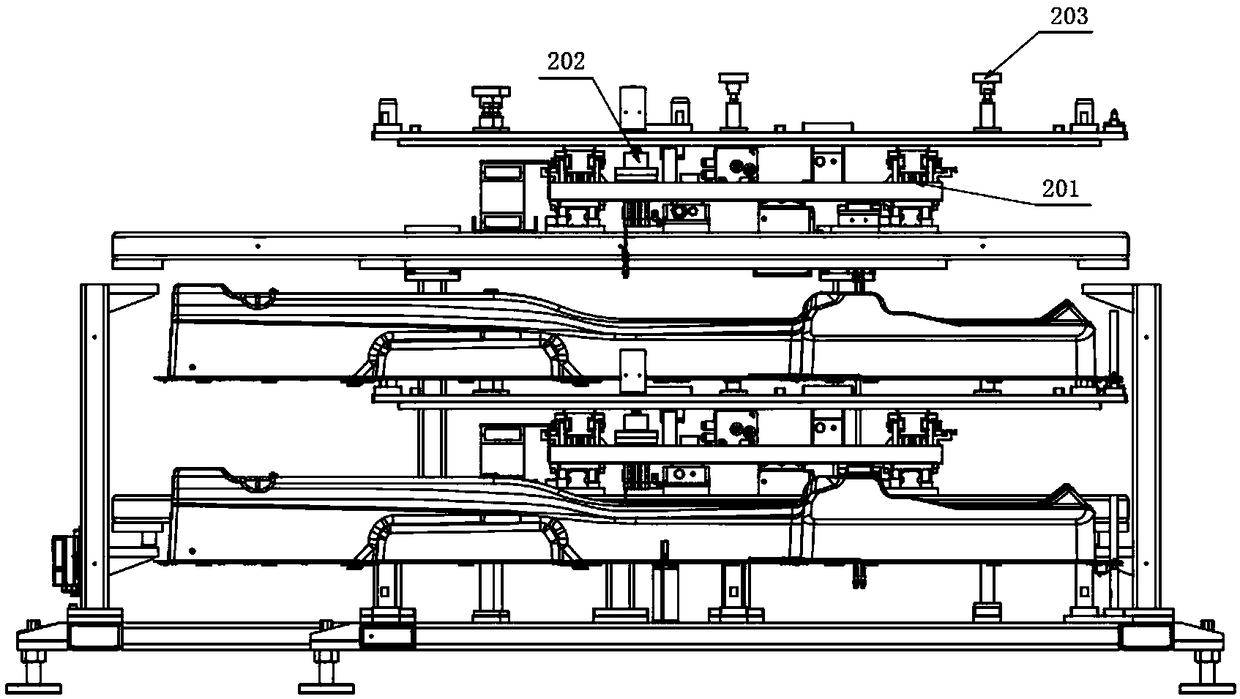

Cylindrical lithium-ion battery forming and capacity-grading equipment

InactiveCN105186041ASo as not to damageHigh profileFinal product manufactureElectrolyte accumulators manufactureElectrical batteryPersonal computer

The invention discloses cylindrical lithium-ion battery forming and capacity-grading equipment, which comprises a rack, a charge-discharge power box, a battery clamping movement mechanism, a battery tray and a control mechanism, wherein the charge-discharge power box with a variable condition is arranged on the rack; the battery clamping movement mechanism is used for clamping positive and negative electrode tabs of a cylindrical lithium-ion battery; the battery tray is arranged in the battery clamping movement mechanism; the control mechanism is arranged in a personal computer (PC) outside a rack; the charge-discharge power box with the variable condition is electrically connected with the battery clamping movement mechanism; and the charge-discharge power box and the battery clamping movement mechanism are in control connection with the control mechanism respectively. According to the cylindrical lithium-ion battery forming and capacity-grading equipment, two procedures of forming and capacity-grading of the cylindrical lithium-ion battery can be finished; the equipment variety is simplified; and the production efficiency is improved, so that high quality, high efficiency and traceability of the cylindrical lithium-ion battery in the manufacturing process are achieved.

Owner:ZHEJIANG HANGKE TECH

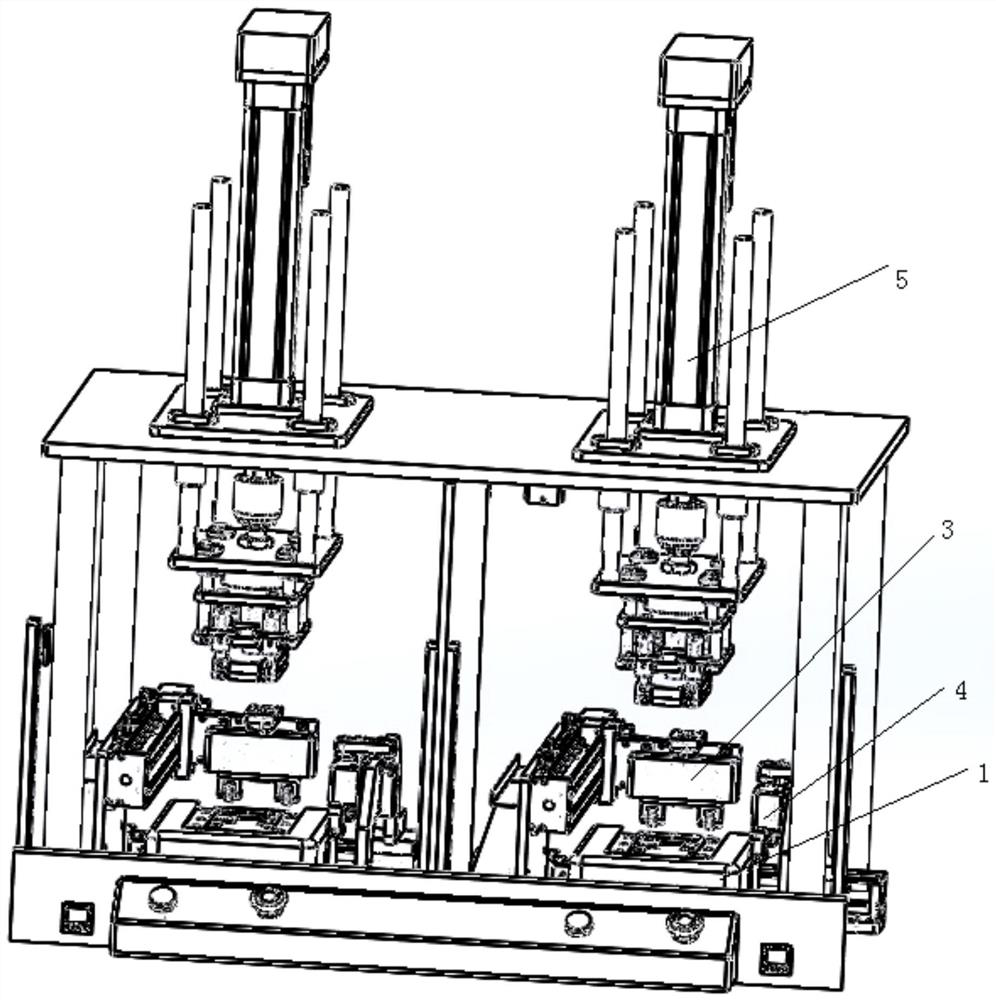

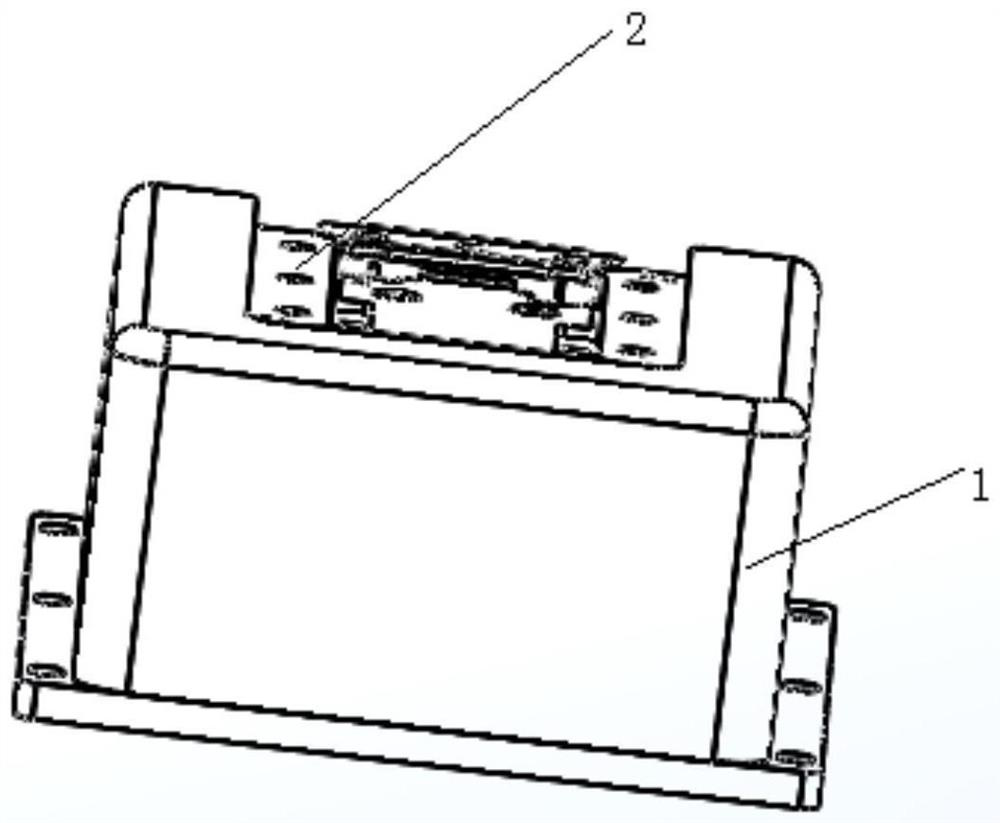

Equipment for processing musical instrument bags

InactiveCN108237580ASolve the problem of difficult processing and low efficiencyEasy to punchMetal working apparatusEngineeringCantilever

The invention provides equipment for processing musical instrument bags. The equipment comprises a base and two drilling and trimming mechanisms arranged on the base in a mirror symmetry mode. A clamping mechanism is arranged between the two drilling and trimming mechanisms. Each drilling and trimming mechanism comprises a support, and the support arranged on each drilling and trimming mechanism is slidably connected with the base through a first sliding mechanism. A first rotation mechanism is further arranged between each first sliding mechanism and the corresponding support. Cantilevers arerotationally connected with the side walls of the supports through second rotation mechanisms. Drilling and trimming assemblies are slidably connected with the cantilevers through second sliding mechanisms. The minimum distance between the edges of the cantilevers and the clamping mechanism is greater than or equal to 10 mm. According to the equipment for processing the musical instrument bags, the irregular bags are drilled and trimmed through the special clamping mechanism and the drilling and trimming mechanisms, drilling of curved side walls is rapid and convenient, the assembling efficiency can be improved through the clamping mechanism when the bags are assembled, and the problem that the musical instrument bags are difficult to process and low in efficiency is solved.

Owner:TIANJIN JINAOLIN LUGGAGE CO LTD

Device capable of automatically adjusting distance between front and back lifting tables of AGV

PendingCN107235300AGuarantee product qualityAvoid defective productsMechanical conveyorsAutomotive engineeringPotential risk

Owner:SAIC GENERAL MOTORS +1

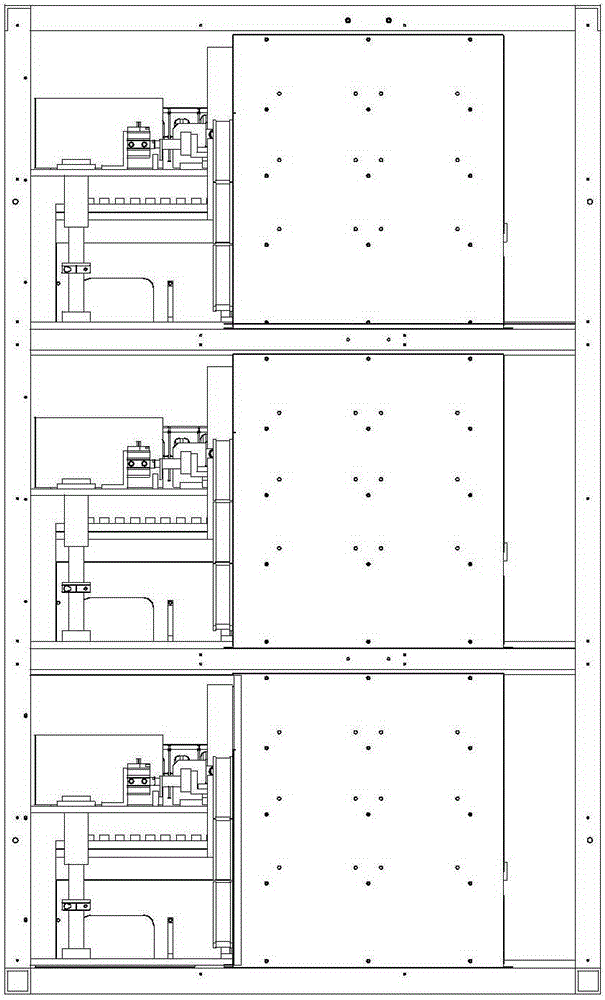

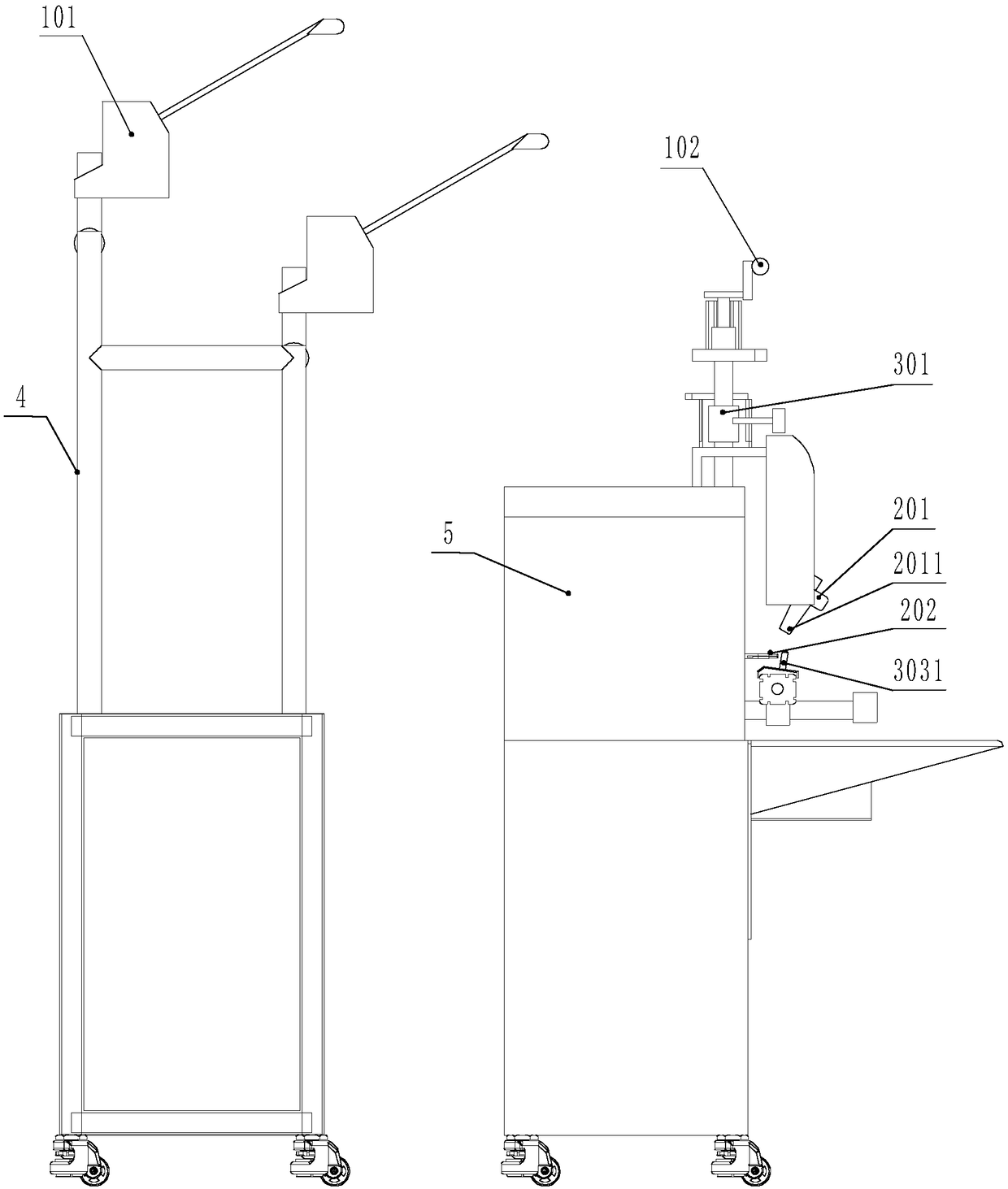

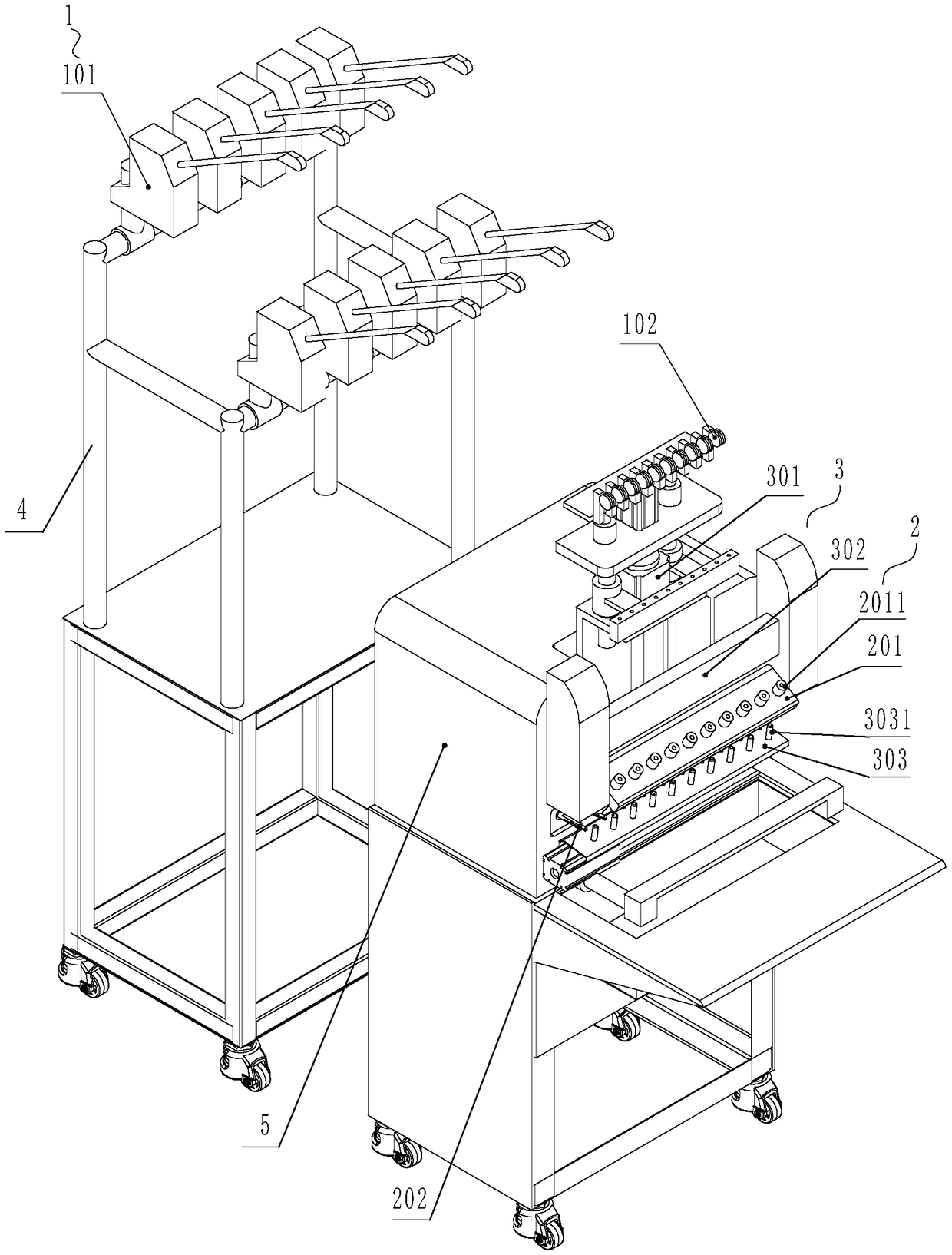

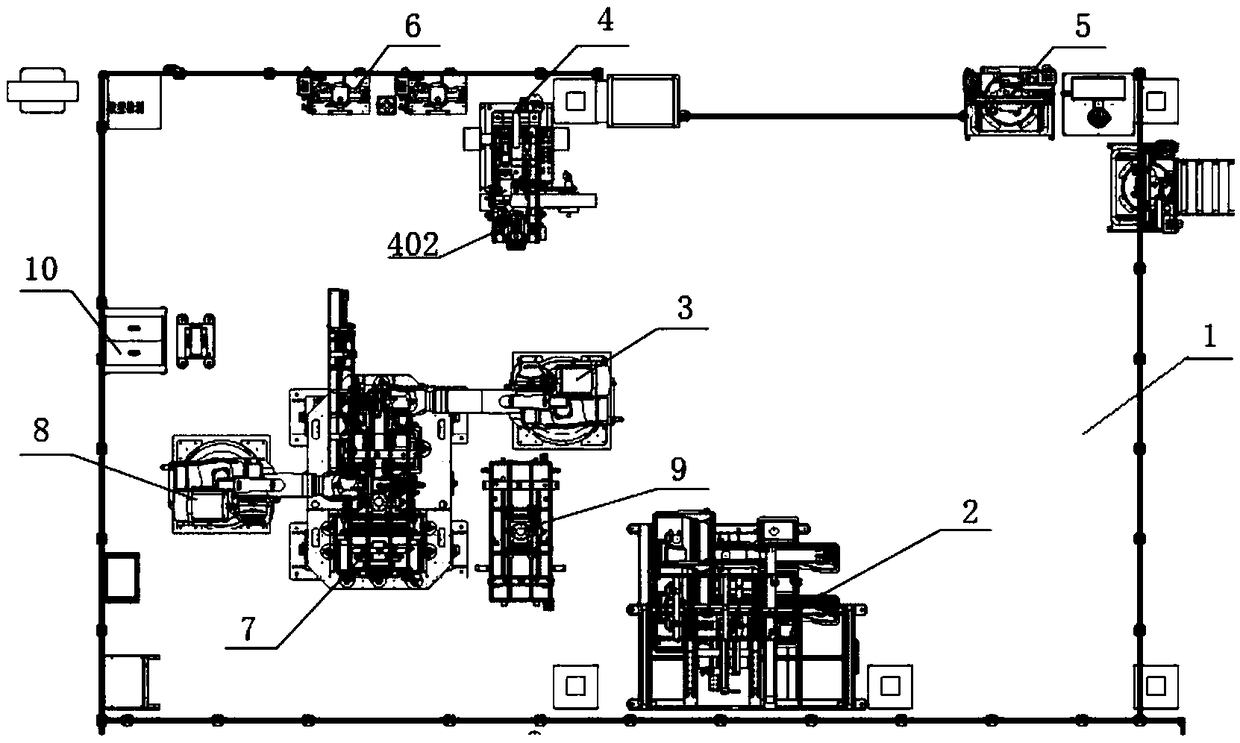

Full-automatic sheet screen printing machine

PendingCN109823033AFlexible control of the feeding positionShorten the timeScreen printersArticle feedersScreen printingTime efficient

The invention relates to a full-automatic sheet screen printing machine comprising a rack and an automatic loading device for stacking sheet products. The rack is provided with a loading and unloadingrobot and a movable printed material platform, the output tail end of the loading and unloading robot is provided with a sucking disc, the lower side of the sucking disc is provided with a first suction nozzle group and a second suction nozzle group, one of the first suction nozzle group and the second suction nozzle group is used for grasping a to-be-printed sheet of the automatic loading device, and the other one of the first suction nozzle group and the second suction nozzle group is used for grasping a printed sheet on the printed material platform; and the printed material platform is slidably assembled on a guide rail on the rack, and the printed material platform slides back and forth between a loading station and a printing station. The screen printing machine can save time and improve efficiency. In addition, the loading and unloading robot can flexibly control the placing position of the printed sheet, and the condition that non-performing products are generated by product stacking caused by too low drying speed of a drying furnace is avoided.

Owner:郑州丝珂瑞科技有限公司

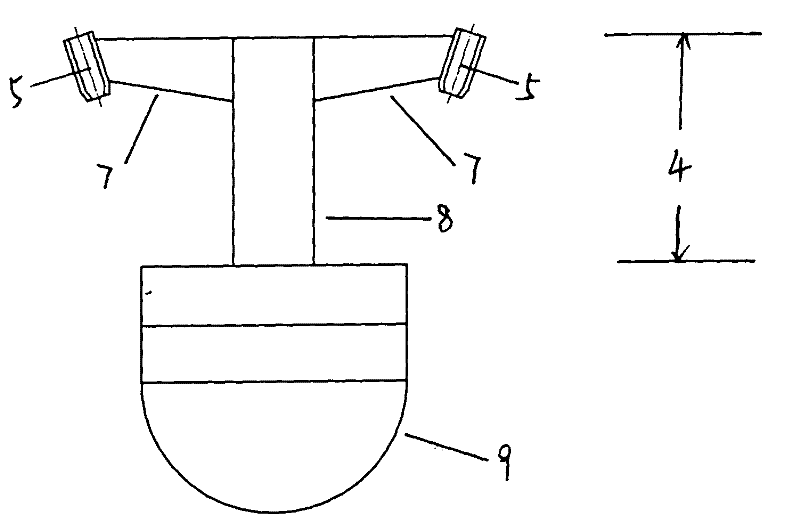

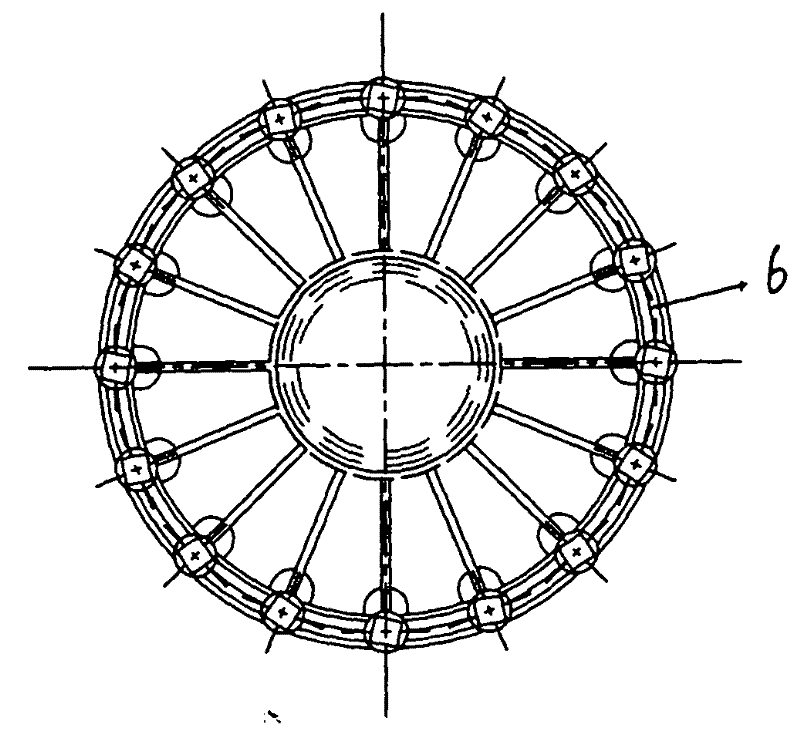

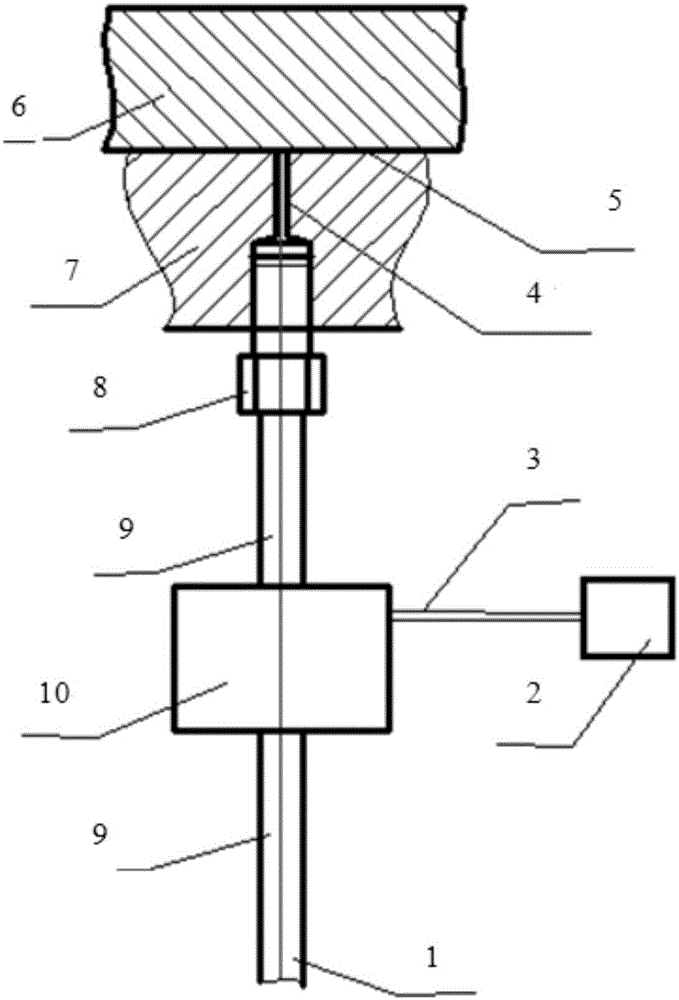

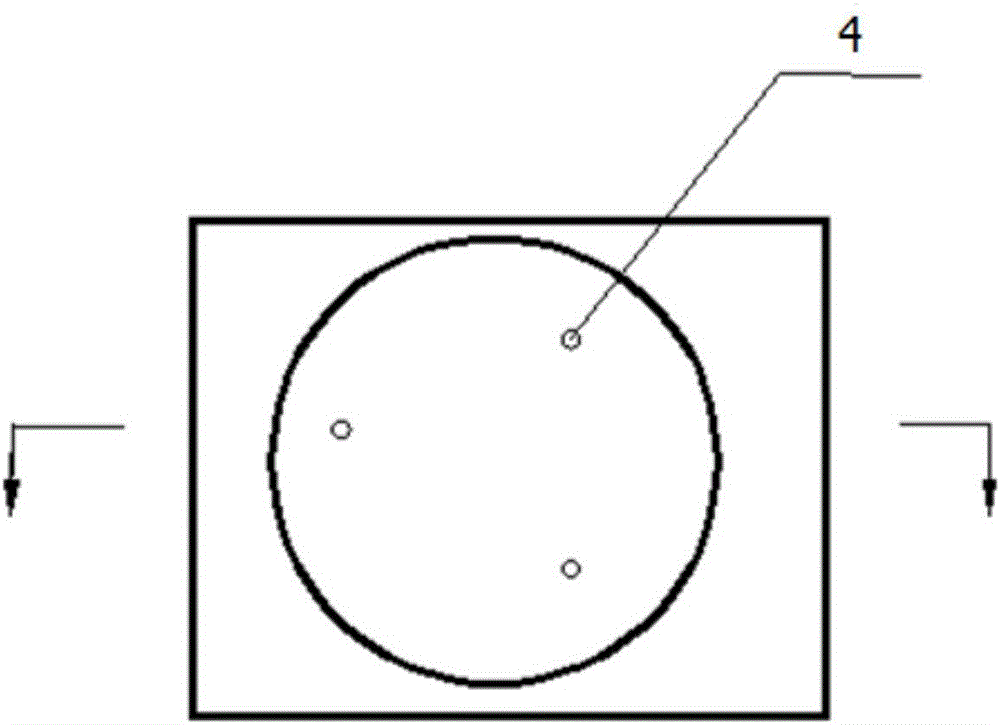

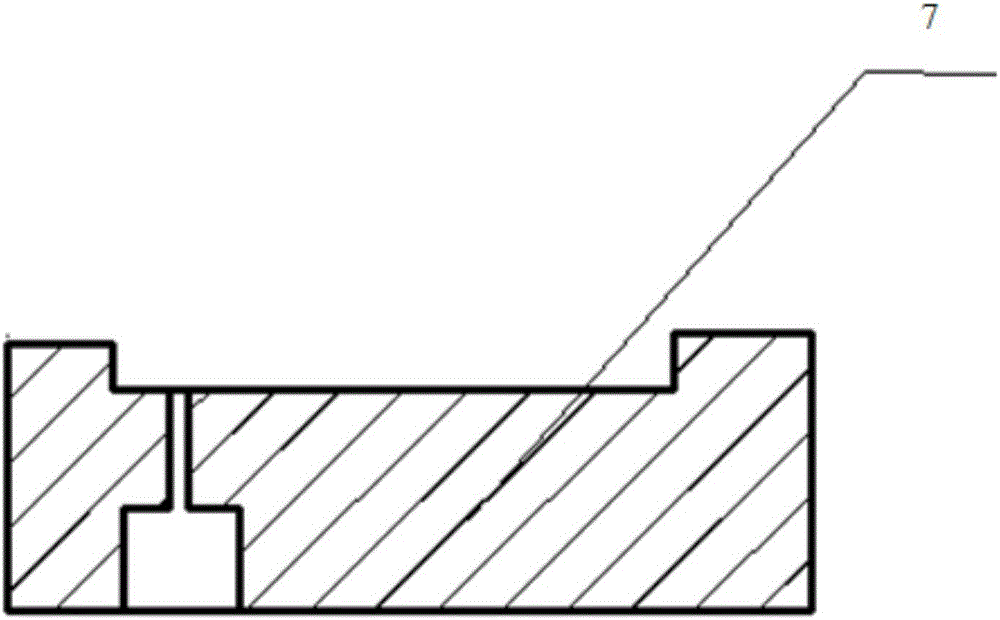

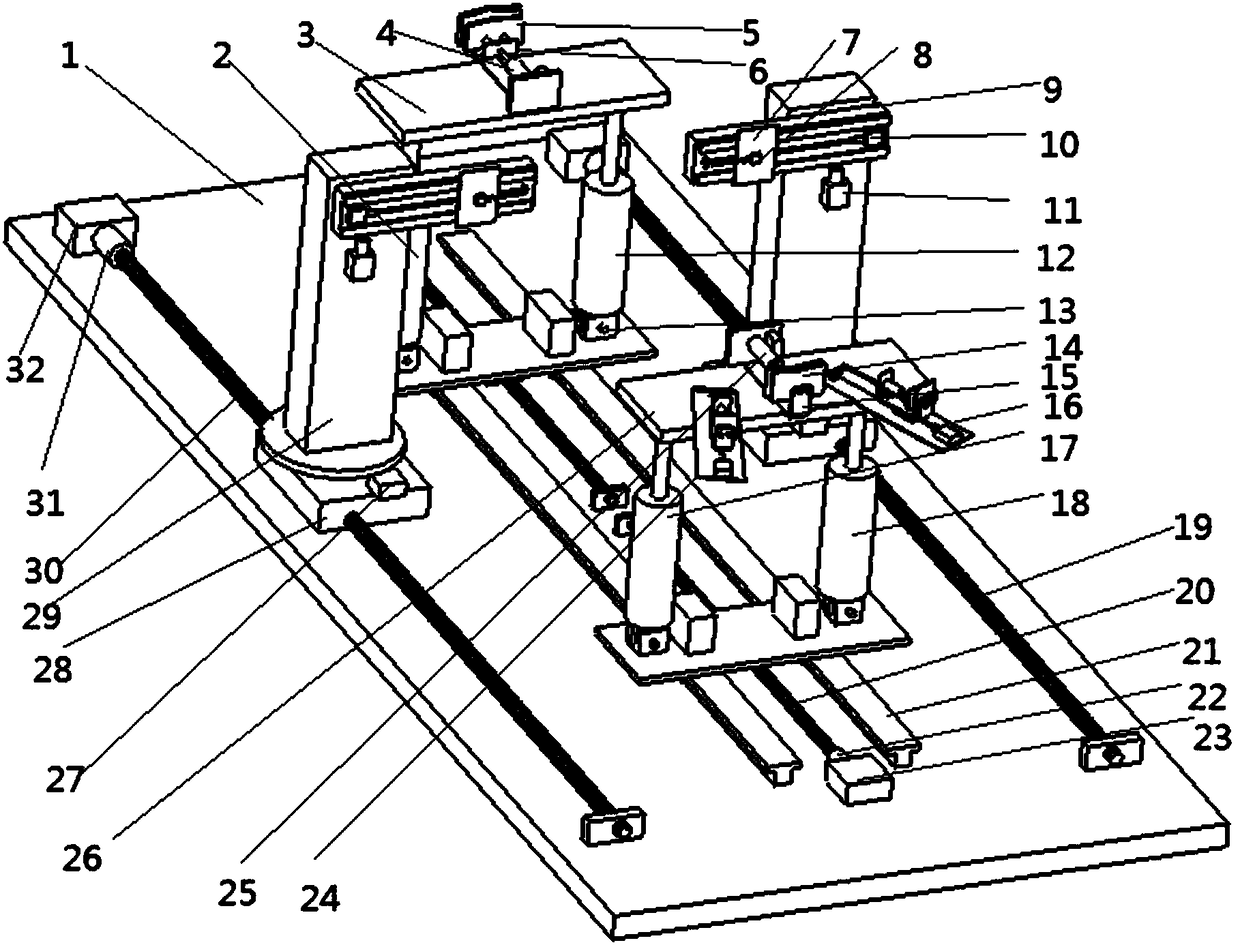

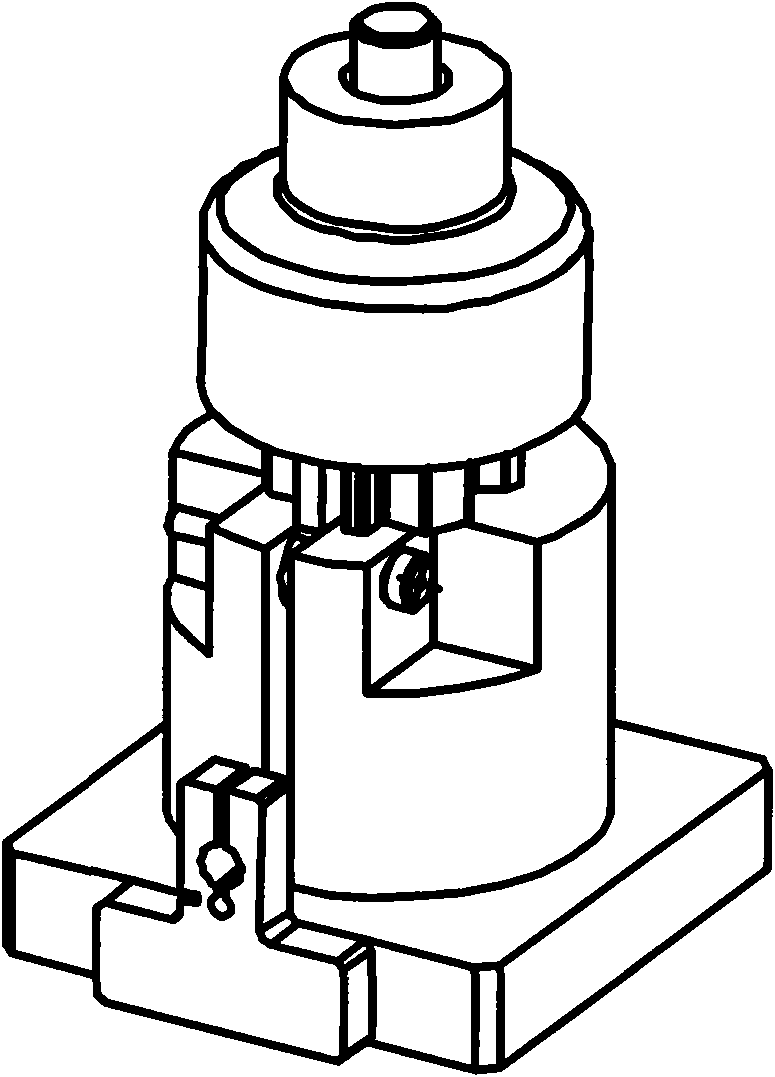

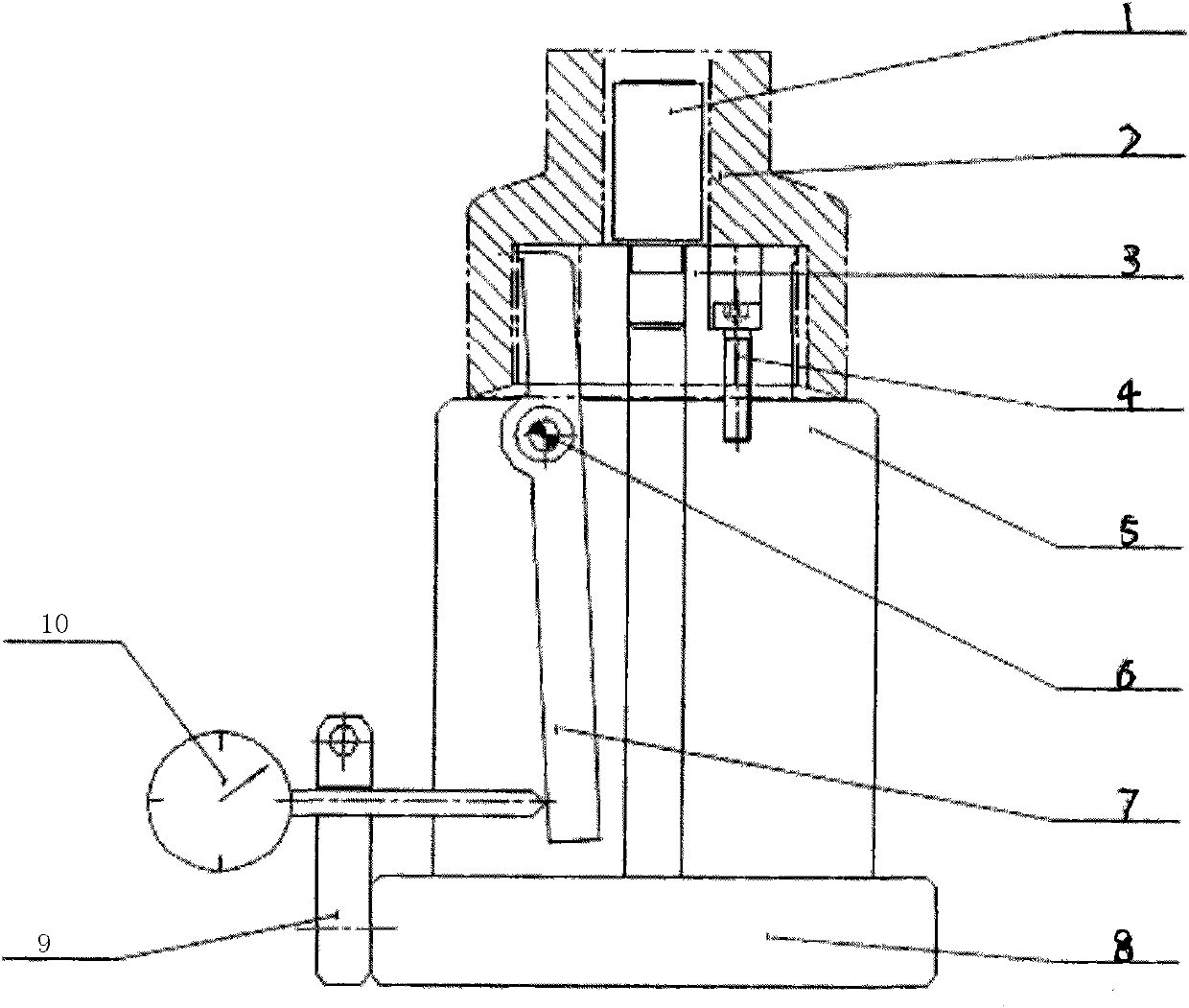

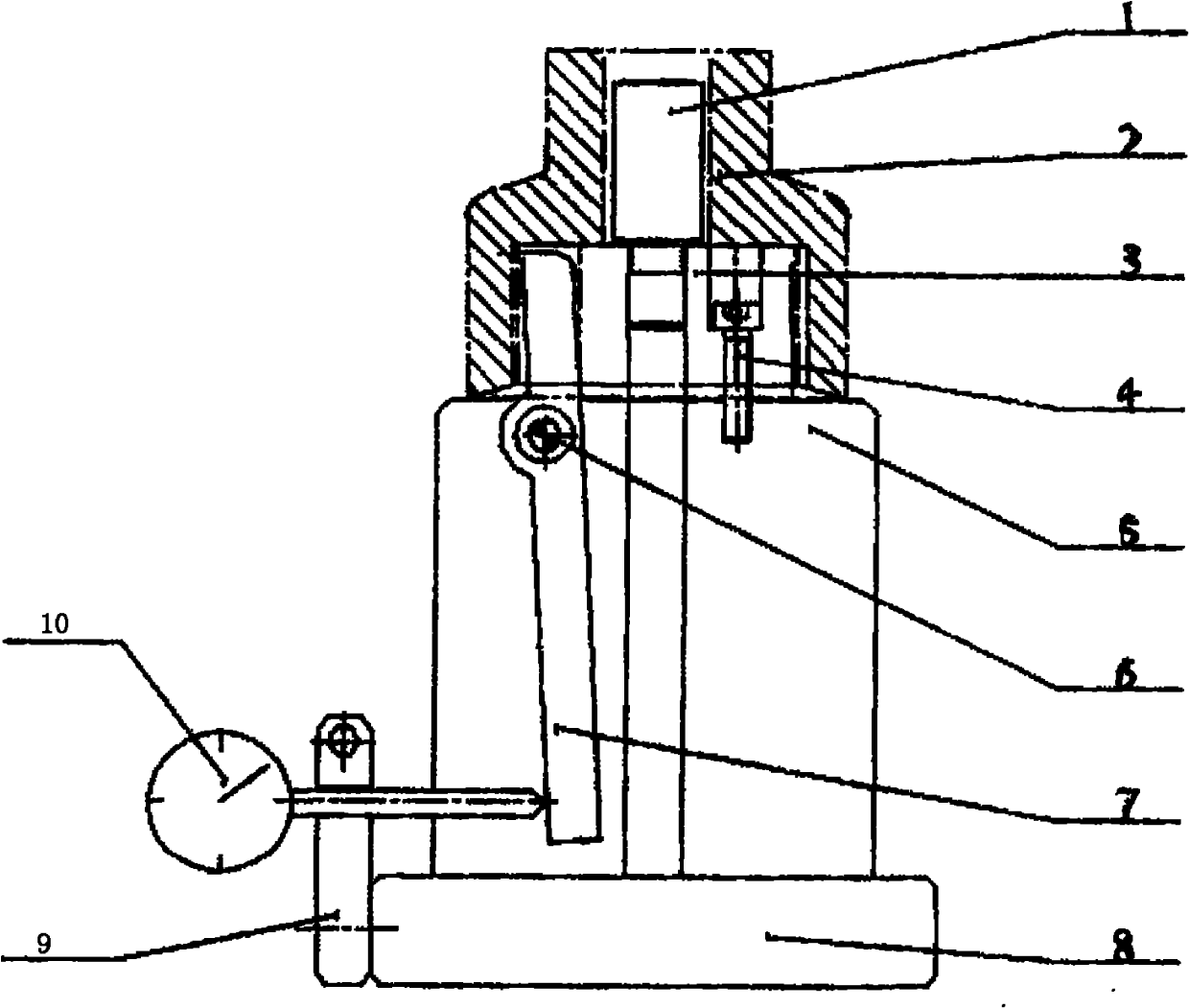

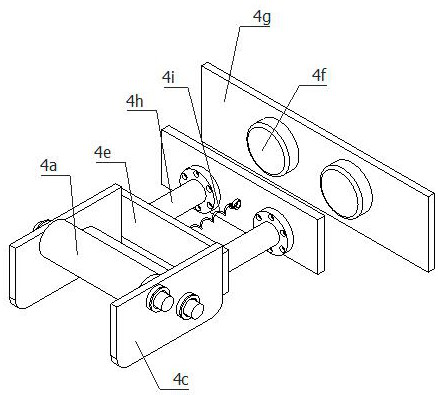

Measuring method and apparatus for size of raceway of one-way sleeve

InactiveCN102564254ASolve the unmeasurableEasy to measureAngles/taper measurementsSize measurementEngineering

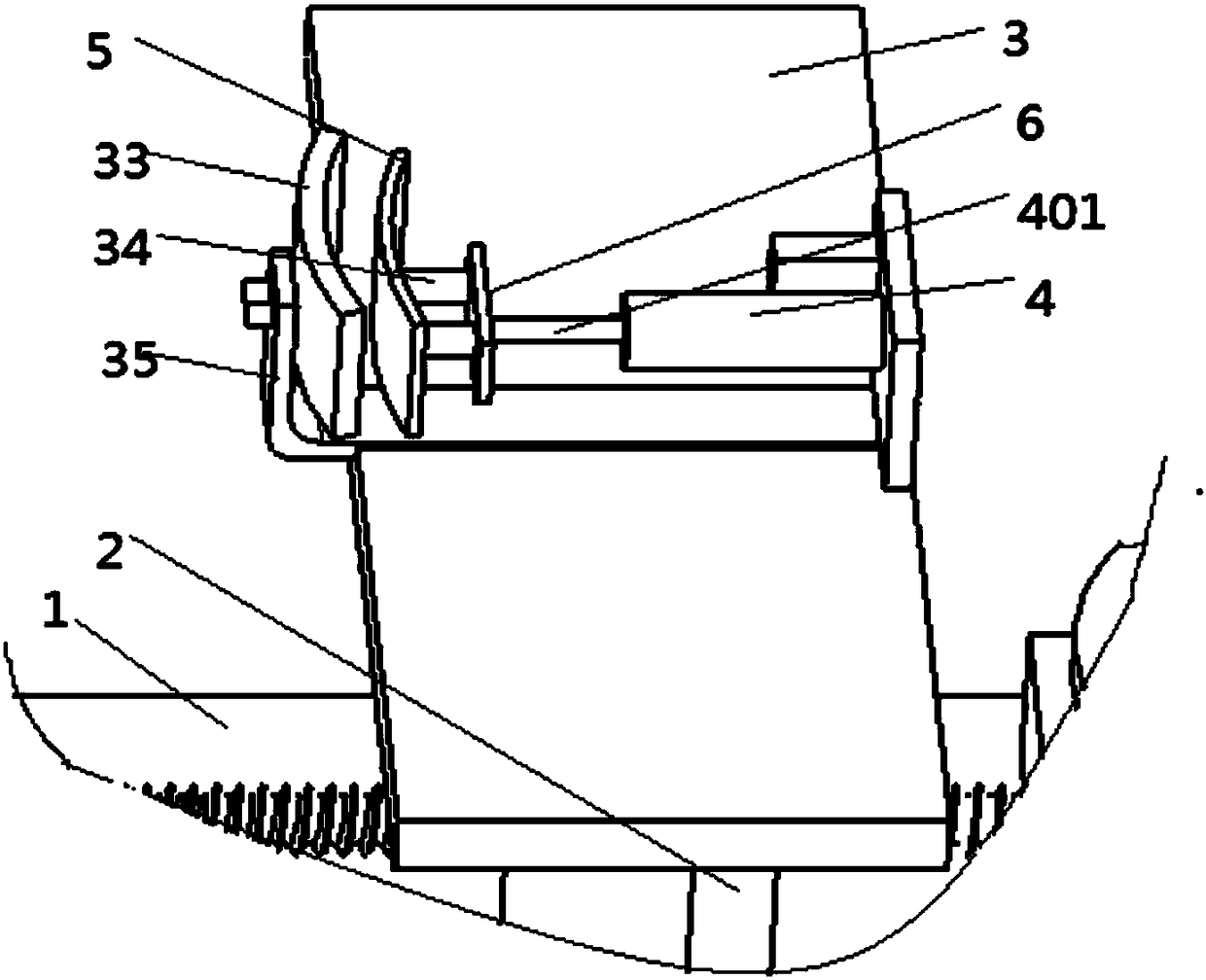

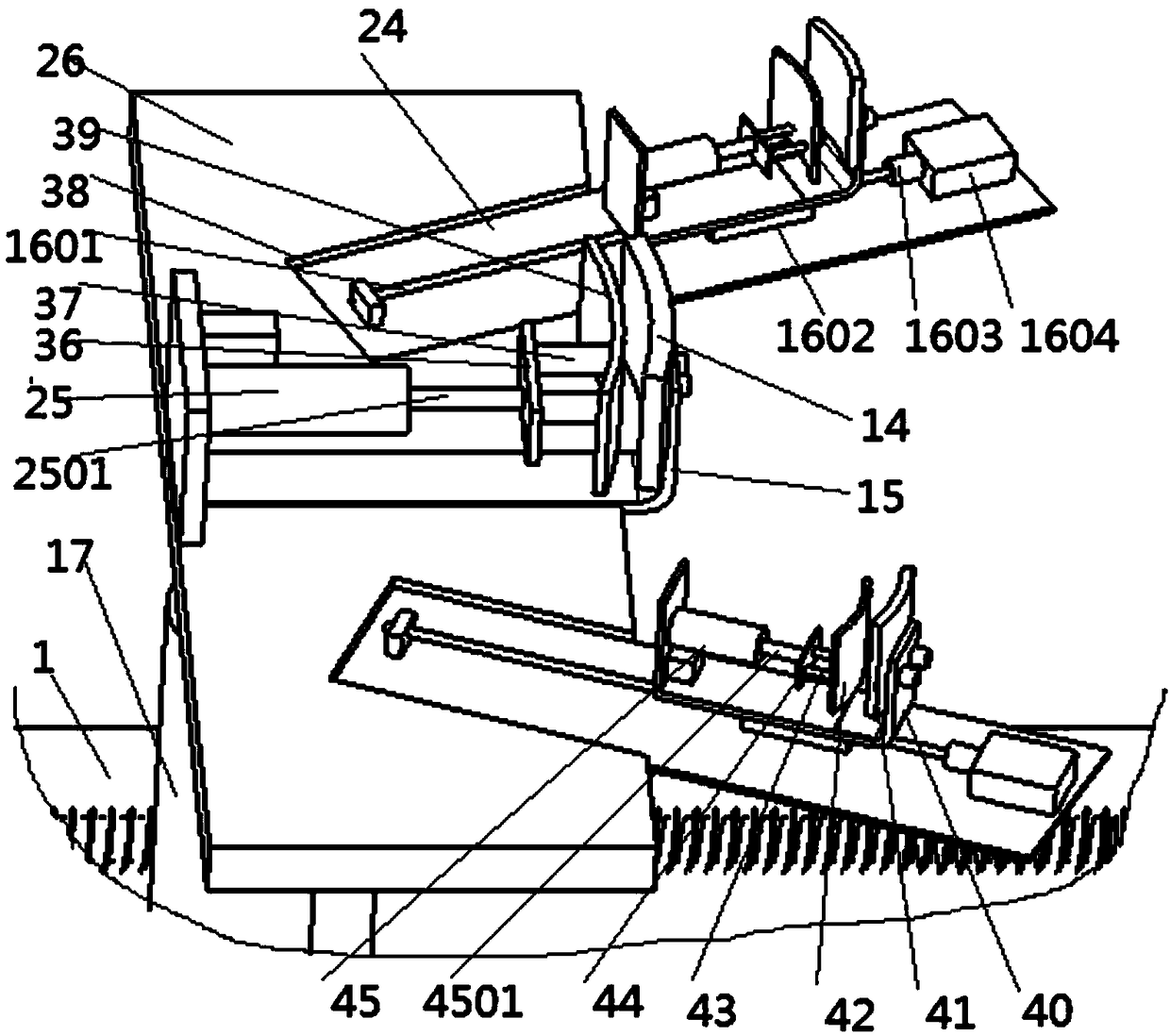

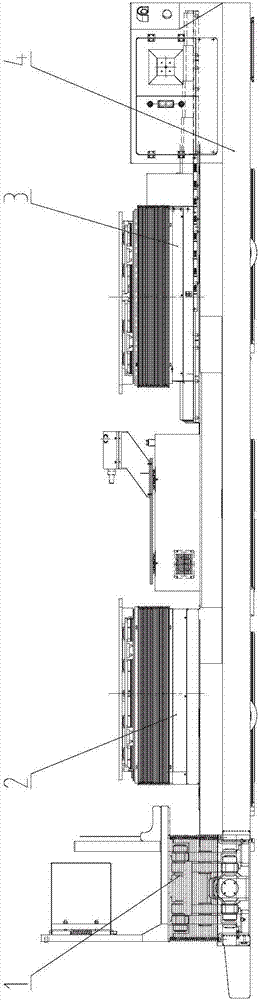

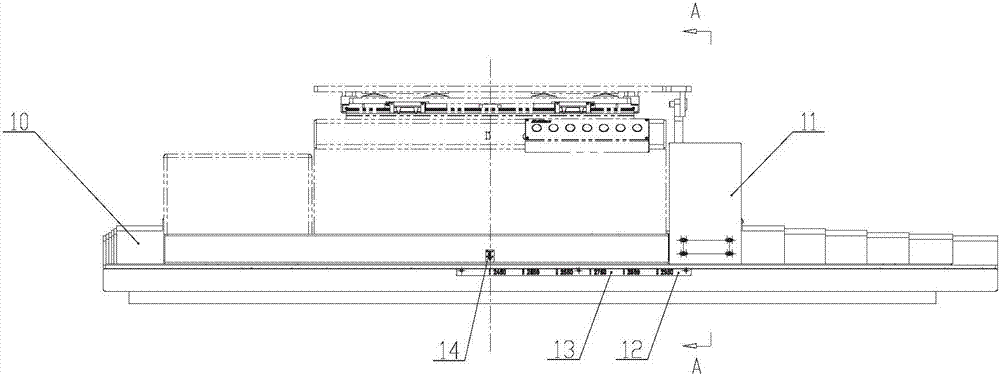

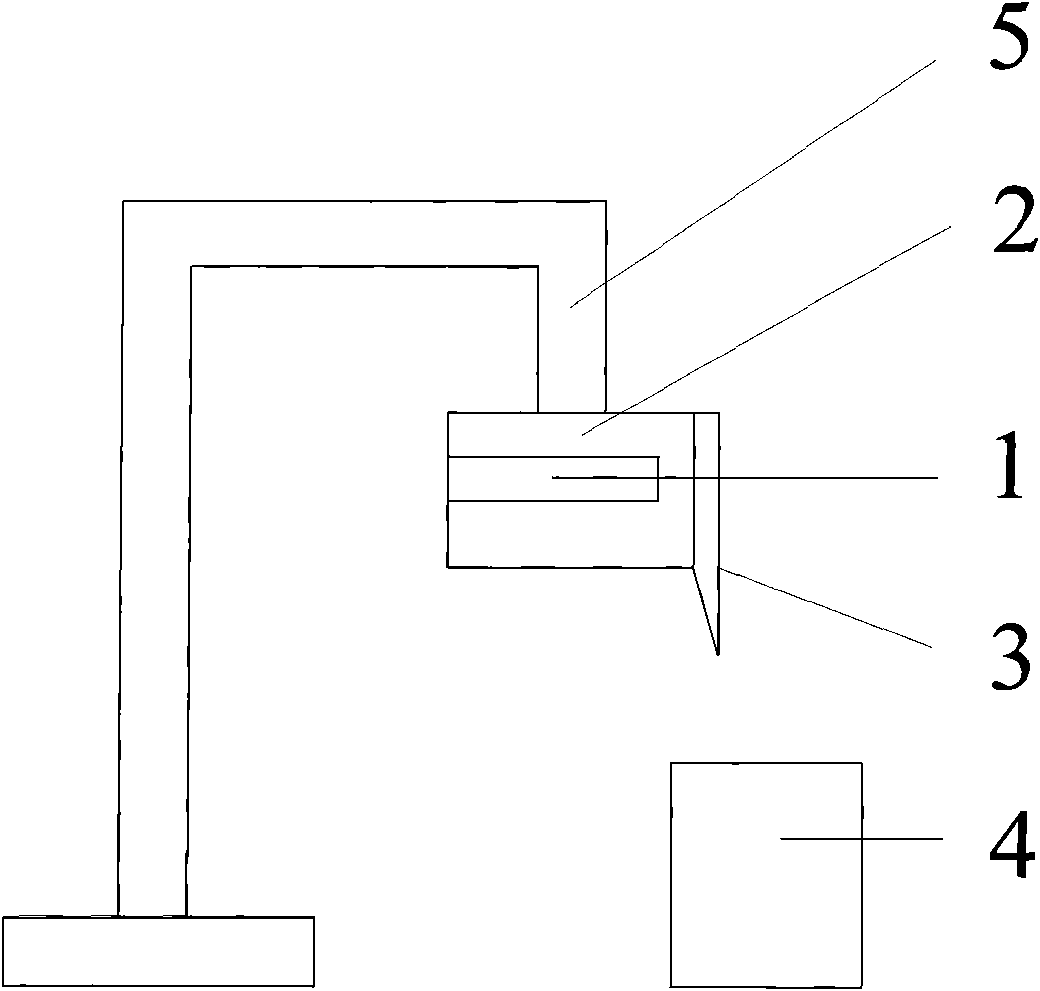

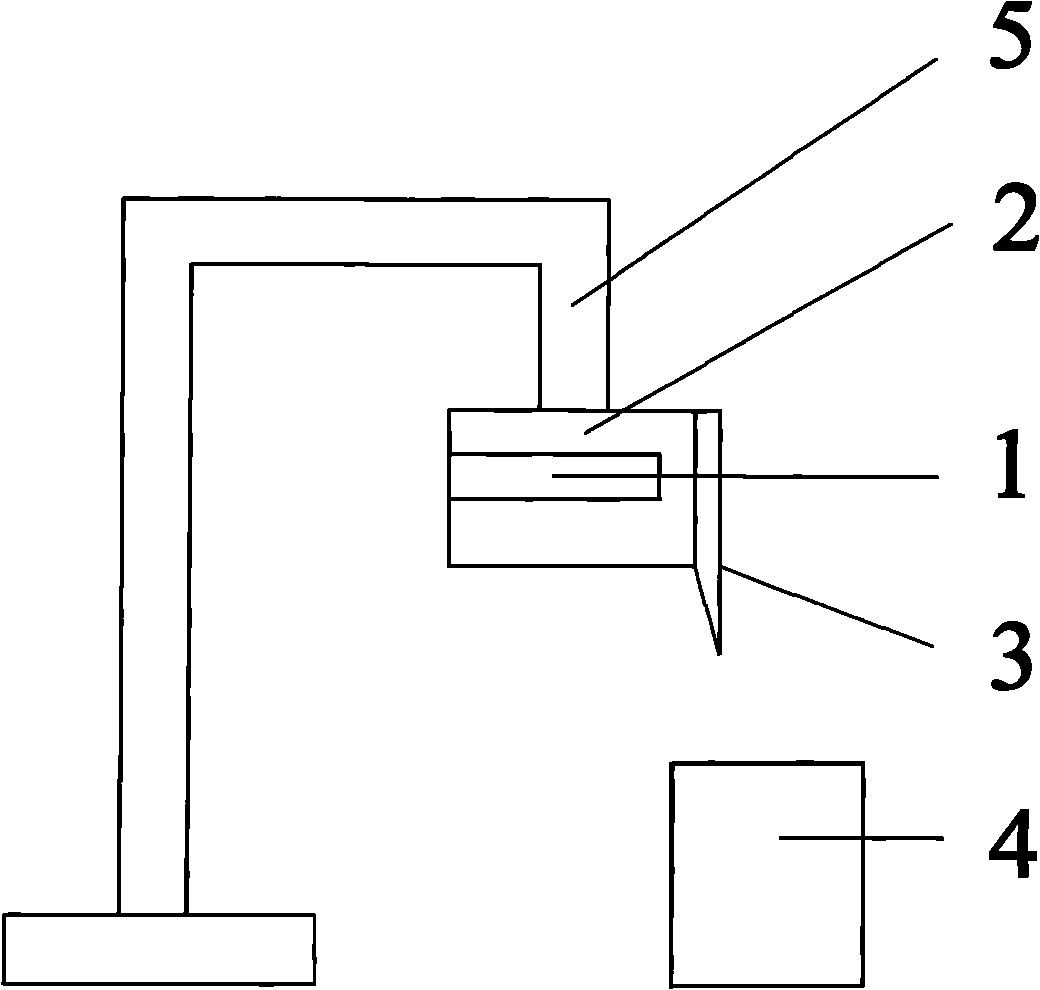

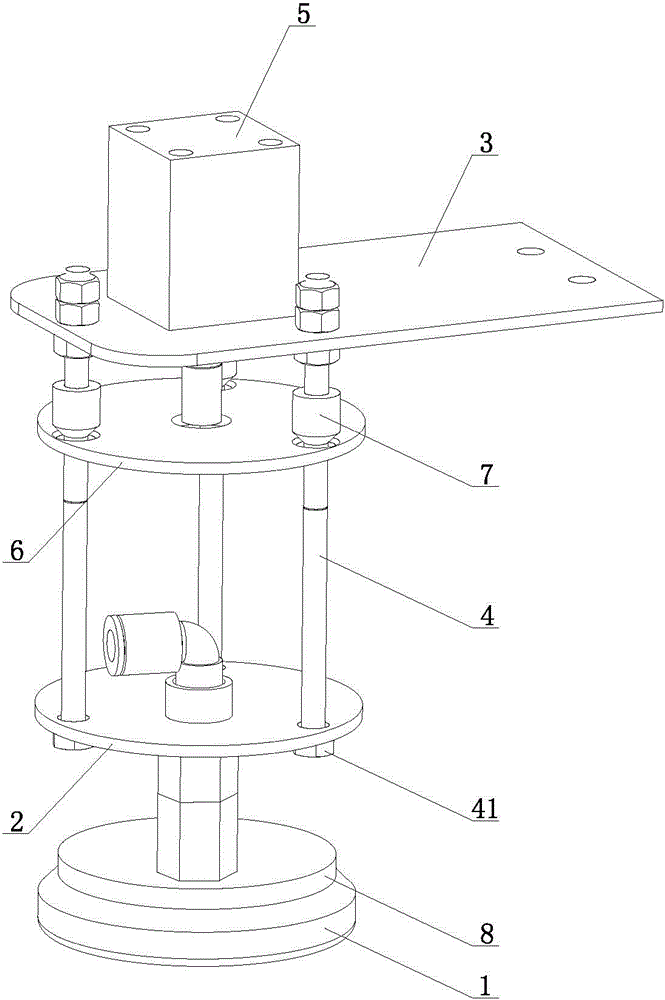

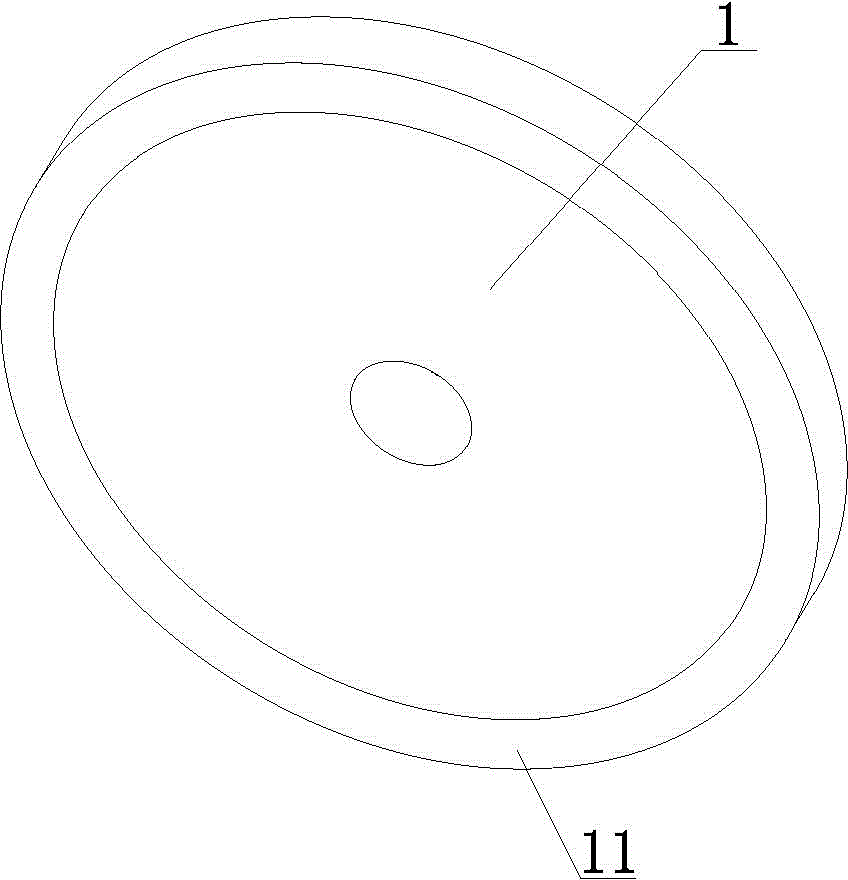

The invention discloses a measuring method and apparatus for the size of a raceway of a one-way sleeve in a one-way clutch of an automobile starting engine and provides a simple, convenient and rapid method for measuring the size of the raceway of the one-way sleeve, which can be used for directly measuring on a production field, stopping unqualified products and increasing the production efficiency. The measuring apparatus provided by the invention comprises a locating core 1, an irregularly-shaped locating ring 3, a joint screw 4, a support 5, a long pin 6, a measurement oscillating bar and a bottom plate 8, wherein the support 5 is arranged on the bottom plate 8, the irregularly-shaped locating ring 3is jointed onto the support 5 by using the joint screw 4, the locating core 1 is inserted to the irregularly-shaped locating ring 3, the measurement oscillating bar 7 is fixed on the support 5 by using the long pin 6, and a meter frame and a dial indicator are well assembled together and fixed on the bottom plate 8. The measuring apparatus can be used for measuring the sizes of different raceways of one-way sleeves. The measuring method and apparatus are applied to a production field, are remarkable in effect and are used for solving the problem that an irregularly-shaped raceway of the one-way sleeve cannot be measured.

Owner:JIANGSU SUNWAY GROUP

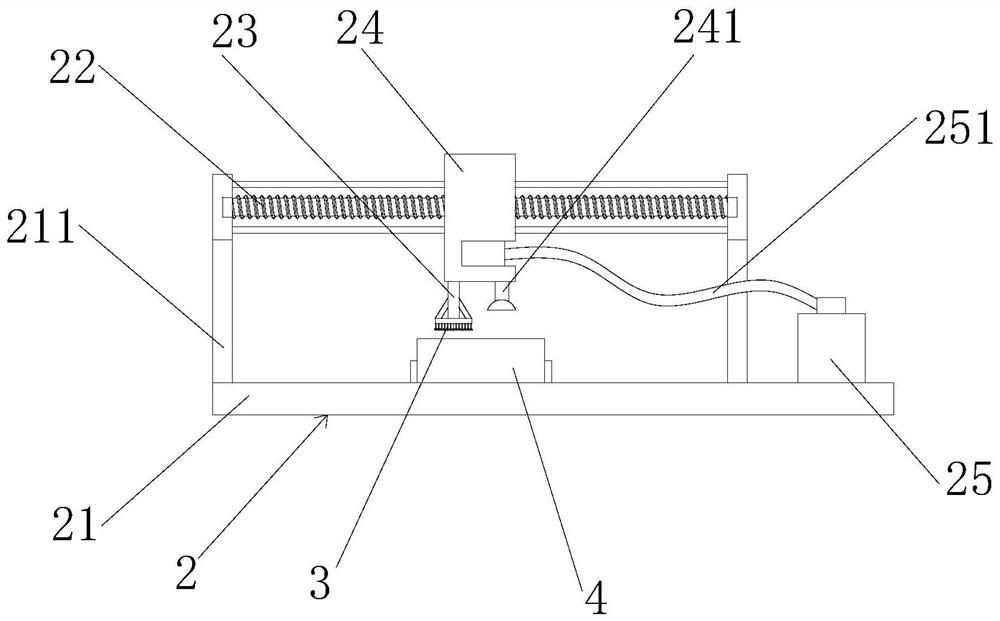

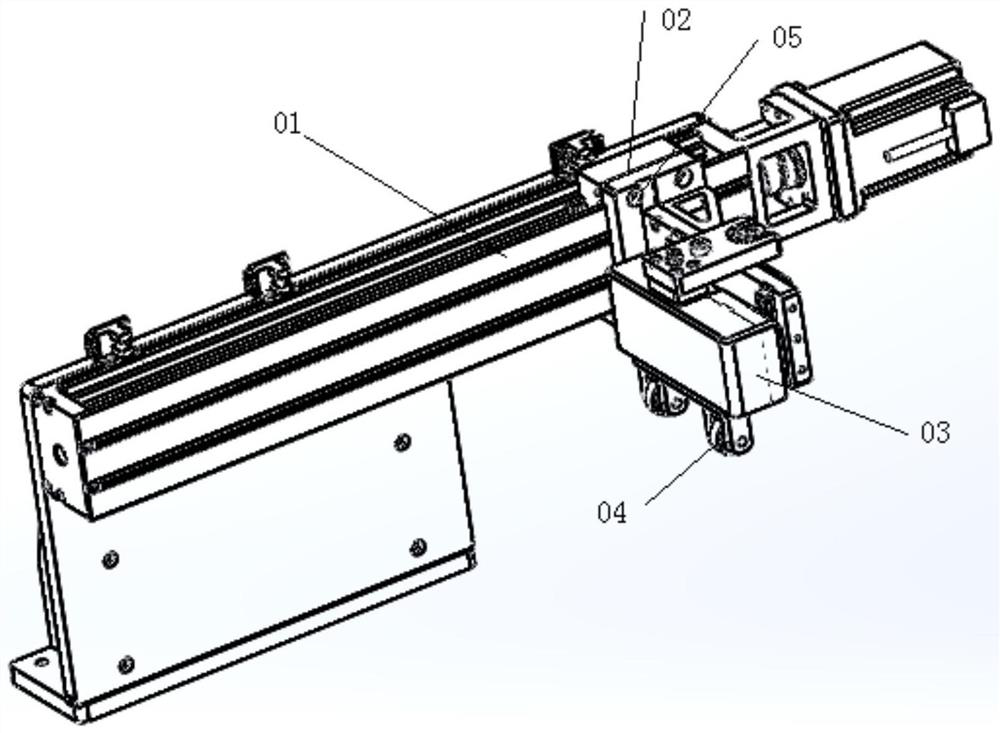

Fuel-injector high-precision automatic wire winding device and method thereof

PendingCN109166723APrecise speed controlPrecise position controlCoils manufactureControl systemMiddle line

A high-precision automatic wire winding device for fuel injector and its method relate to an automatic wire winding device and its method. The device comprises a tension control mechanism, a main wirewinding mechanism, a coil tap winding mechanism and a control system. The control system is respectively connected with a tension control mechanism, a main winding mechanism and a coil tap winding mechanism. The method comprises the following steps: step S1. Waiting starts, step S2. Winding the first tap of the coil, step S3. Winding the coil, step S4. Winding the second tap of the coil, step S5.Breaking the coil, and step S6. Removing the coil. As that tension control mechanism, main winding mechanism, Cooperation between that coil tap win mechanism and the control system, The invention canaccurately control the speed and winding position of the coil in the winding process, so that the winding wire is evenly distributed, the consistency is good, the wire tightness in the winding process can be ensured to be suitable, the requirements of the high-precision metering fuel injector for the winding wire are met, and the coil has the characteristics of good precision, high efficiency andhigh qualified rate, and is easy to be popularized and used.

Owner:LIUZHOU YUANCHUANG EFI TECH

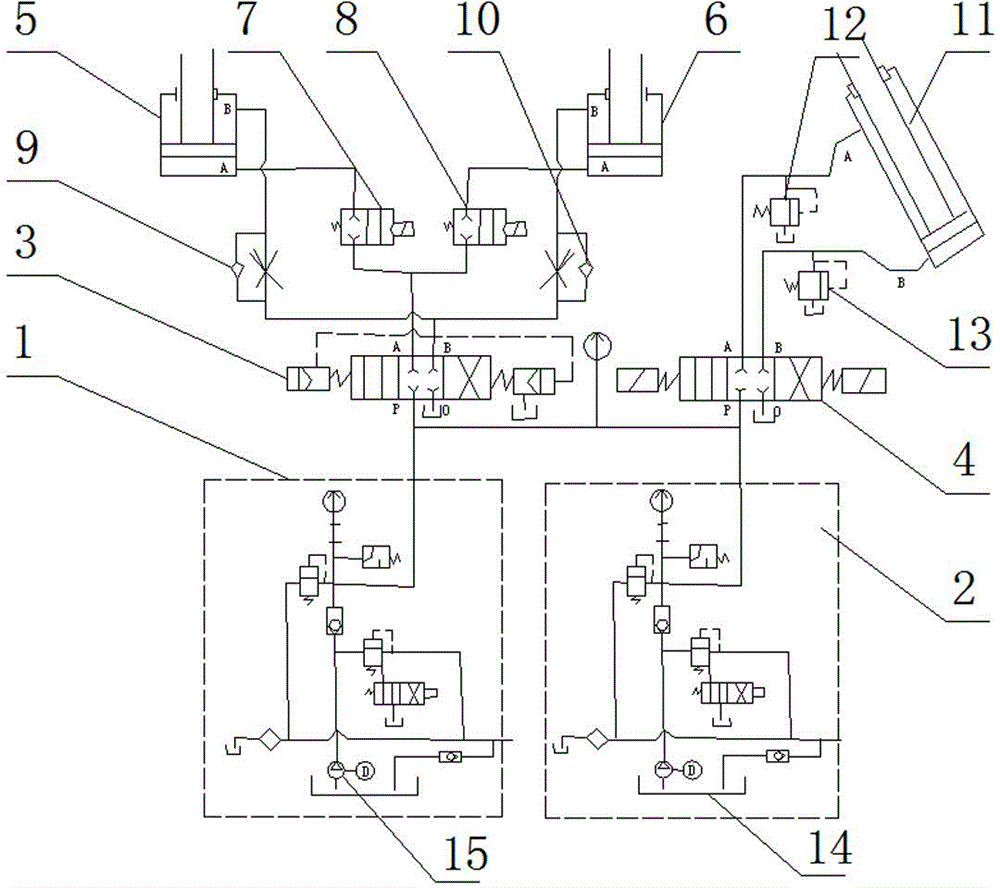

Hydraulic system for driving middle lower roller of four-roller plate bending machine

InactiveCN104832478AConsistent clearanceAvoid defective productsServomotor componentsServomotorsElectro hydraulicEngineering

The invention discloses a hydraulic system for driving middle lower roller of a four-roller plate bending machine. The hydraulic system comprises a first hydraulic station and a second hydraulic station, wherein an oil outlet pipe of the first hydraulic station is connected onto a port P of an electro-hydraulic reversing valve; a port A of the electro-hydraulic reversing valve is connected with two branches, one branch is connected with a reversing valve VII and a lower cavity of a first oil cylinder, and the other branch is connected with a reversing valve VIII and a lower cavity of a second oil cylinder; a port B of the electro-hydraulic reversing valve is connected with two branches, one branch is connected with a throttling valve I and an upper cavity opening of the first oil cylinder, and the other branch is connected with a throttling valve II and an upper cavity of the second oil cylinder; an oil outlet pipe of the second hydraulic station is connected onto a port P of a electromagnet reversing valve, and a port A of the electromagnet reversing valve is connected with an overflow valve I and an upper cavity of a third oil cylinder; the port B of the electromagnet reversing valve is connected with an overflow valve II and a lower cavity of the third oil cylinder. The hydraulic system has the advantages that the gap between the middle lower roller and an upper roller is uniform during processing, so the production of defective products is avoided, and the working efficiency is greatly improved; the functions of reversing and resetting a overturn device are realized, and the operation is automatic.

Owner:江苏亚星波纹管有限公司

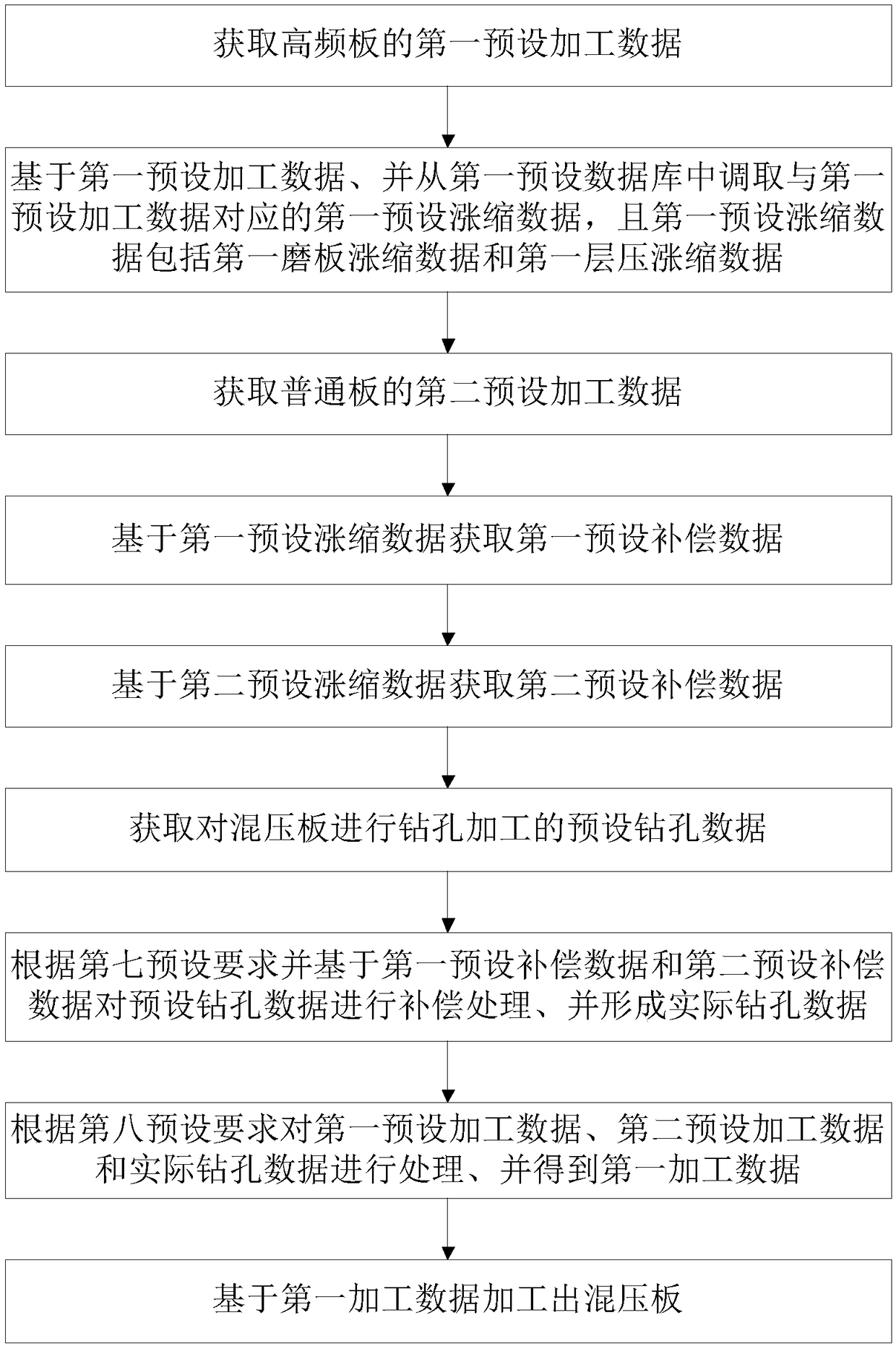

Mixed pressing plate machining method and system, computer storage medium and equipment

ActiveCN108668470AAvoid defective productsAvoid scrappingMultilayer circuit manufactureMachining systemSoftware

The invention relates to a mixed pressing plate machining method and system, a computer storage medium and equipment. The machining method comprises the following steps of obtaining first preset machining data; obtaining first preset collapsible data; obtaining second preset machining data; obtaining second preset collapsible data; according to a first preset requirement, processing the data, andobtaining first machining data; on the basis of the first machining data, machining a mixed pressing plate. According to the machining system, the computer storage medium and the equipment, the hardware or software basis is provided for the machining method. The first preset collapsible data of a high frequency plate and the second preset collapsible data of a common plate are obtained, processingis performed on the basis of the first preset requirement, the first preset machining data and the second preset machining data, and therefore the first machining data is obtained; then, the mixed pressing plate is machined and obtained on the basis of the first machining data, the problem that different layer plates are defective or scrapped due to inconsistent collapsing is avoided, and the production cost is lowered.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

Gate cutting device

InactiveCN102009455APrecise cut sizeImprove work efficiencyMetal working apparatusPunch pressHeat conducting

The invention relates to a gate cutting device, which comprises a heater, a heat conducting part, a cutting blade, a product fixing seat and a punch. The heater is connected to the heat conducting part, the cutting blade is arranged at one end of the heat conducting part, the product fixing seat is arranged below the heat conducting part and the punch is connected to the upper part of the heat conducting part. Compared with the prior art, the invention has the advantages of accurate positioning, capability of controlling cutting size, greater batch cutting speed, nearly no scratching risk in use, high work efficiency, reduced defective products and wide scope of application.

Owner:SHANGHAI FUJITECH PLASTIC

Form design system for personalized implants

InactiveCN102915393AFully meet the needsMeet needsSpecial data processing applicationsPersonalizationData acquisition

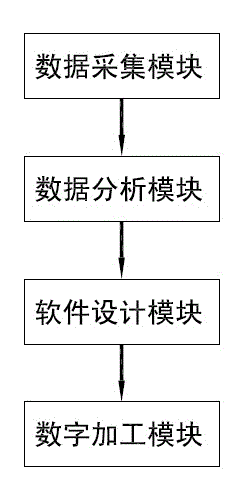

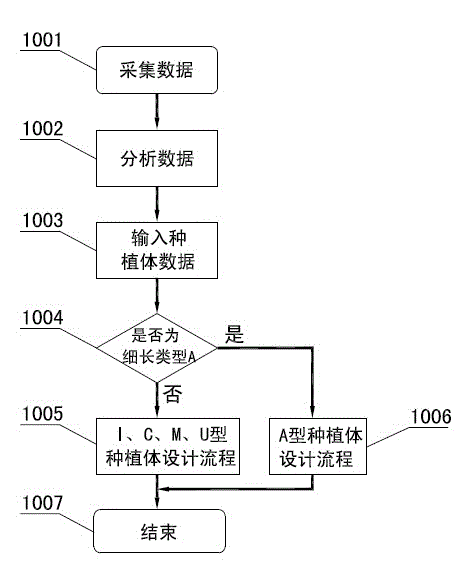

The invention relates to a form design system for personalized implants and belongs to the field of biomedical engineering. The form design system for personalized implants comprises a data acquisition module, a data analysis module, a software design module and a digital processing module. The data acquisition module is used for acquiring various preoperative clinical data of a patient, acquired by clinical examination and CBCT (cone beam computed tomography) image examination. The data analysis module is used for determining the type of an implant to be designed by analyzing the data acquired by the data acquisition module. The software design module is used for designing the form of the implant according to the data acquired by the data acquisition module and the analysis results from the data analysis module. The digital processing module is used for finish processing of the implant. The design system and method allow for targeted design according to individual differences of patients, are higher in fitness, fully satisfy the personalized requirements of the patients and greatly save medical resources.

Owner:淄博昌国口腔种植技术研究院

Internal connection structure of button cell and manufacturing method of internal connection structure

InactiveCN111048730AFirmly connectedImprove assembly efficiencyFinal product manufacturePrimary cellsButton batteryElectrical battery

The invention provides an internal connection structure of a button cell and a manufacturing method of the internal connection structure. The internal connection structure of the button cell is characterized in that the internal connection structure comprises an upper shell and a lower shell which are arranged in a covering manner; a winding body is arranged between the lower shell and the upper shell; the winding body comprises a positive electrode plate, a negative electrode plate and an isolation body which is positioned between the positive electrode plate and the negative electrode plateand is used for isolating the positive electrode plate from the negative electrode plate; the winding body is provided with a positive electrode tab and a negative electrode tab which respectively extend towards the upper part and lower part of the winding body; the positive electrode tab is connected with the positive electrode plate; the negative electrode tab is connected with the negative electrode plate; and at least one of the positive electrode tab and the negative electrode tab is electrically connected with the inner surface of the upper shell and the lower shell through a liquid metal layer or a low-temperature alloy layer, wherein the inner surface of the upper shell and the lower shell is opposite to the upper end surface and lower end surface of the winding body. With the above structure adopted, the connection between the tabs of the button battery and the battery shells is facilitated, and assembly efficiency is improved; welding equipment is decreased, so that manufacturing cost is saved; and defective products caused by solder skips and incomplete welding can be avoided.

Owner:ZHANGZHOU WANBAO ENERGY TECH CO LTD

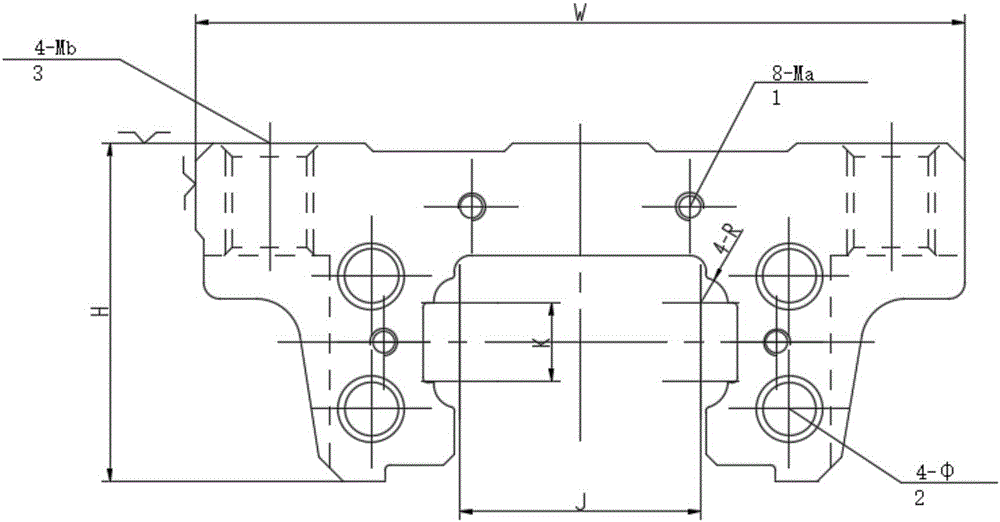

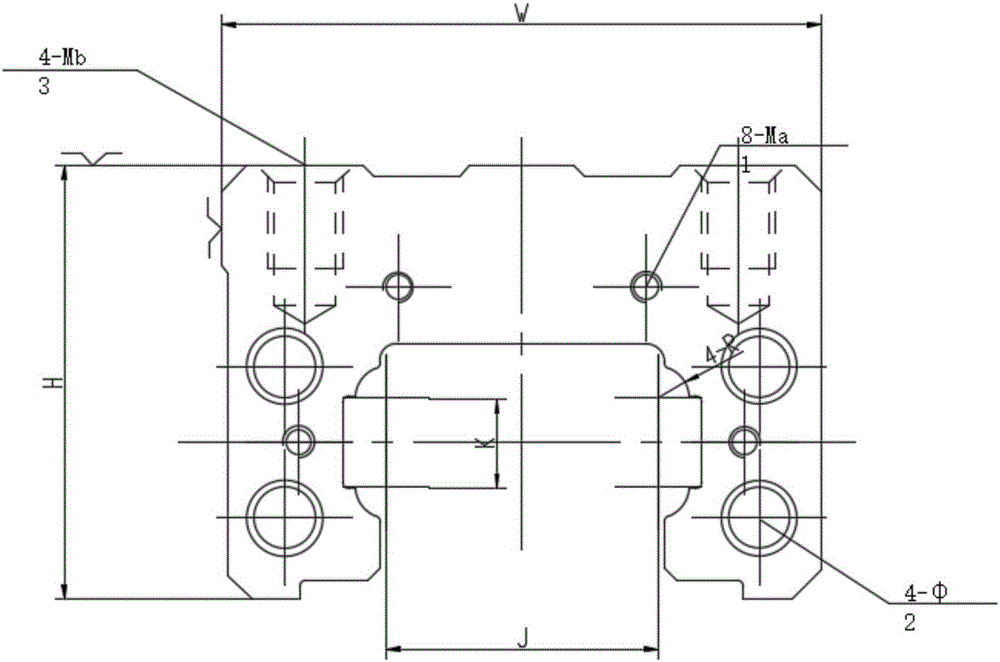

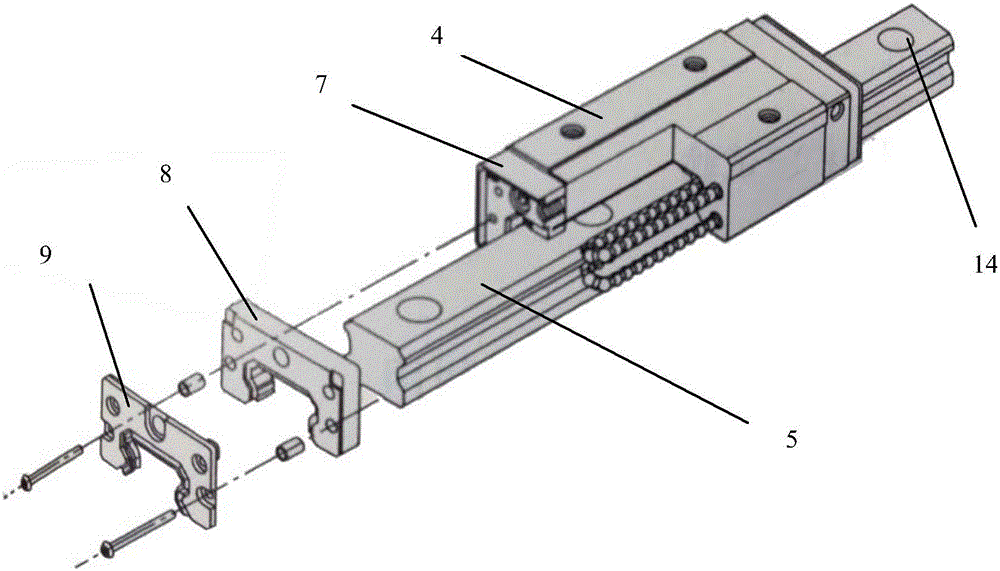

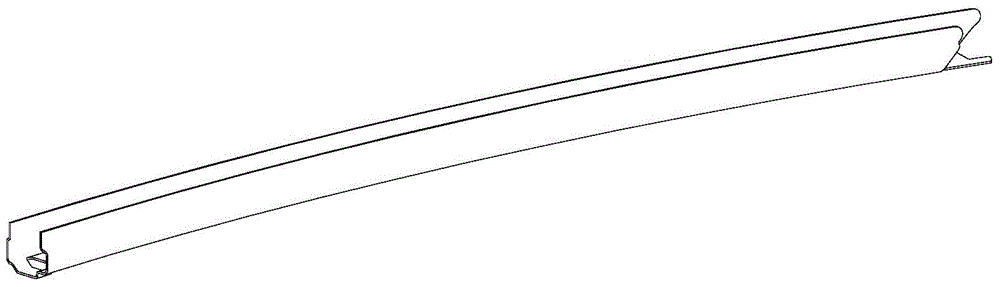

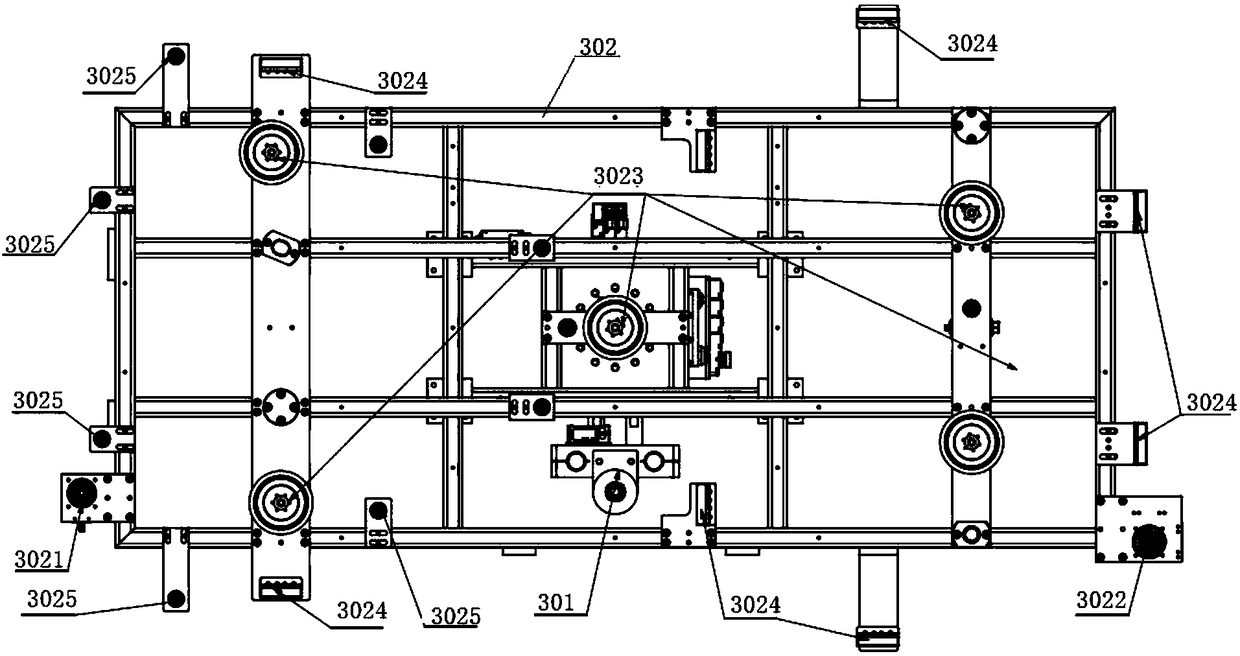

Machining method of sliding block cavity formed through precision cold drawing and guiding rail pair

ActiveCN106346201AShorten the processing and manufacturing cycleIncrease profitQuenching agentsEngineeringSurface grinding

The invention discloses a machining method of a sliding block cavity formed through precision cold drawing and a sliding block produced by adopting the method. The method comprises the steps that a sliding block is prepared, a precision cold drawing section bar is sawed into the sliding block with the length slightly greater than L by using a band sawing machine; two end faces are roughly milled, the front end face and the rear end face of a raw material block are milled by a horizontal milling machine to make the length of the sliding block basically equal to L; six surfaces are roughly grinded, namely the six surfaces of the sliding block are grinded by using a surface grinding machine, so that the width of the sliding block is equal to W, the height of the sliding block is equal to H, and the length of the sliding block is equal to L; return device holes and rolling ball through holes are drilled, namely the return device installing holes 8-Ma are dilled in the front and rear end faces of the sliding block and rolling ball through holes (shown in the description) are drilled in the front and rear end faces of the sliding block by adopting a machining center, user installing holes are drilled, namely the user installing holes 4-Mb are drilled in the upper end face of the sliding block by adopting the machining center; heat treatment is performed, namely the sliding block is quenched and oxidized; accurate grinding is conducted on a reference surface; the reference surface is accurately grinded to reach the sizes W and H by using the surface grinding machine; rollaway forming grinding is performed, namely forming and accurate grinding of a rollaway 4-R are performed by using a grinding machine special for the sliding block.

Owner:JIAXING HAILINGDA PRECISION TRANSMISSION TECH CO LTD

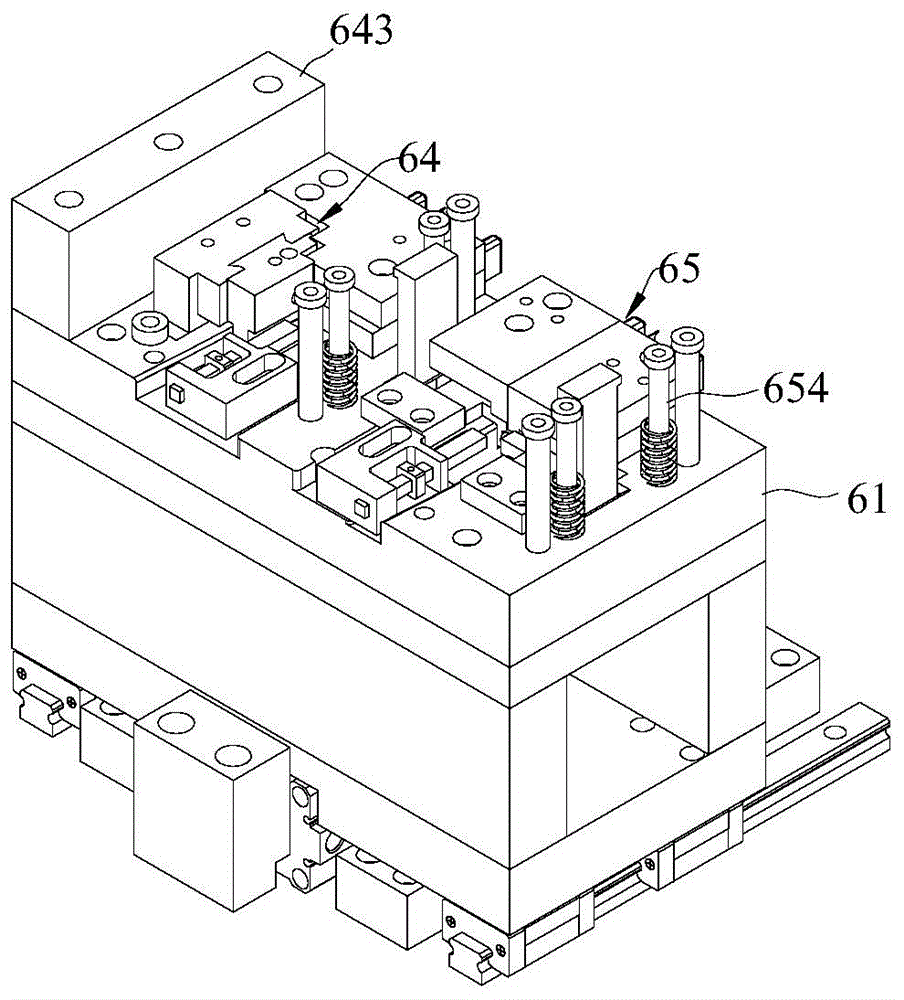

Punching die for door and window glass guide groove

The invention discloses a punching die for a door and window glass guide groove. The punching die comprises an upper die plate, a lower die plate, guide posts, a left side punching mechanism, a right side punching mechanism and a movable clamping claw; the left side punching mechanism comprises a left side punching base with a left side first punching position and a left side second punching position, a plunger chip is installed on the upper die plate, and the right side punching mechanism comprises a right side punching base with a right side first punching position, a right side second punching position, a right side first plunger chip mechanism and a right side second plunger chip mechanism; the left side first punching position and the right side first punching position form a first station, and the left side second punching position and the right side second punching position form a second station. Punching of the two stations is achieved on one die, the two stations share one oil press, the space occupancy rate is small, the punching die is convenient and fast to operate, manual operation time is shortened, the product quality is promoted, the tatk is accelerated, the product qualification precision is met, and defective products are eradicated.

Owner:GUANGZHOU MINTH AUTOMOBILE PARTS CO LTD

Preparation device of aluminum alloy cable

ActiveCN111768927AReduce wasteSave time at workCable/conductor manufactureElectric machineEngineering

The invention relates to the field of aluminum alloy cable processing and relates to a preparation device of an aluminum alloy cable. The device comprises a left-right adjusting mechanism, a hot melting mechanism, a wire winding frame, a rotating base, a winder, four rotating bases, a wire guide frame, a tension adjusting mechanism, a wire breaking induction mechanism, an annular proximity switchand an aluminum alloy wire coil. According to the preparation device of the aluminum alloy cable of the invention, the equipment can sense the fracture of an aluminum alloy wire, a manual observationmethod is replaced; a method of manually connecting the broken aluminum alloy wire is replaced, full-automatic wiring is realized, a large amount of working time of workers is saved; when a driving motor rotates reversely, the aluminum alloy wire is unreeled and unreeled, the auxiliary effect on the hot melting of the aluminum alloy wire is achieved, the situation that the workers pull the aluminum alloy wire manually is avoided, the palms of the workers are prevented from being hurt, and the danger of the work of the workers is reduced.

Owner:南昌新华电缆有限公司

Method for assembling touch screen foam of smart phone

ActiveCN103595831AAvoid defective productsReduce defective rateTelephone set constructionsTouchscreenSmart phone

The invention discloses a method for assembling touch screen foam of a smart phone. The method comprises the steps that firstly, the frame-shaped touch screen foam is attached to a front shell of the smart phone, and then a touch screen of the smart phone is assembled on the front shell. The technical means that the touch screen and the touch screen foam are assembled separately is adopted, so that rejects caused by the touch screen foam being pasted on the touch screen in the supplying process of the touch screen is avoided, the reject ratio of supplied materials of the touch screen is reduced, meanwhile, assembling efficiency can be improved, and production cost can be reduced.

Owner:威海神舟信息技术研究院有限公司

Embedded integrated intelligent die

ActiveCN103230977BAchieve production optimizationEasy to debugShaping toolsPressesEngineeringMachining

The invention discloses an embedded integrated intelligent die which comprises an upper die set plate, an upper die fixing plate, a guide pillar, a core die, a discharging plate, a lower die set plate and a cavity die. The cavity die is arranged on the lower die set plate; the upper die fixing plate is provided with the core die which is matched with the cavity die; the upper die fixing plate is arranged on the upper die set plate; the core die is arranged on the upper die set plate; the guide pillar which penetrates through the discharging plate to be fixed on the upper die set plate enters into the cavity die to guide and correct under the working state of the embedded integrated intelligent die; an elastic device is arranged between the discharging plate and a core die fixing plate; the discharging plate can move up and down along the guide pillar; and the upper die set plate, the cavity die and the lower die set plate are respectively provided with a sensor. Accordingly, the embedded integrated intelligent die has the advantages of being capable of utilizing the sensors which are embedded in the embedded integrated intelligent die to integratedly obtain various information on the embedded integrated intelligent die to adjust technical parameters when the embedded integrated intelligent die works, guaranteeing that die machining is under real-time monitoring and accurate machining conditions, reducing defective products and reducing the rate of the detective products by 20%, improving the working efficiency and being capable of reducing debugging time of the embedded integrated intelligent die by 50%.

Owner:SOHBI CRAFT CHANGSHU

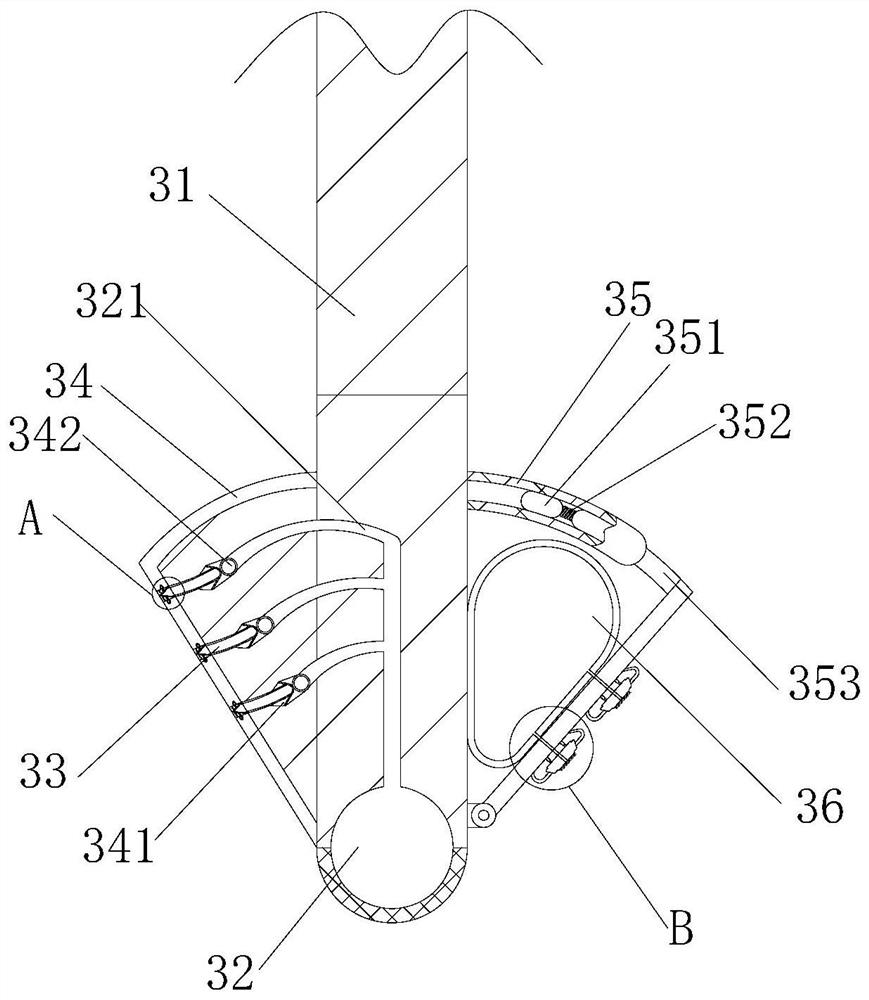

High-temperature moving spherical rearview mirror glass suction device

InactiveCN104803189AAvoid contusionAvoid defective productsCharge manipulationManual conveyance devicesRear-view mirrorMarine engineering

The invention relates to the technical field of glass suction device, in particular to a high-temperature moving spherical rearview mirror glass suction device. The high-temperature moving spherical rearview mirror glass suction device comprises a floating control device and a metal vacuum cup, wherein the floating control device comprises a lower floating plate, an upper floating plate and a floating connection rod. The lower floating plate is provided with a lower floating hole with the hole diameter greater than the rod diameter of the floating connection rod, a circular table is arranged at the bottom end of the floating connection rod, the top end of the floating connection rod penetrates through the lower floating hole to be connected with an upper fixing plate, the lower floating plate is in butting connection with the circular table, and the metal vacuum cup is located under the lower floating plate and is connected with the lower floating plate. When the high-temperature moving spherical rearview mirror glass suction device conducts suction on high-temperature spherical glass in a moving state, it can be ensured that the surface of the spherical glass is not damaged and scratched, defective products can be avoided, dropping and glass surface impressions caused by shake in the suction process of the spherical glass can be avoided, and suction quality and stability can be ensured.

Owner:DONGGUAN XINTENG ROBOT TECH

Mounting equipment used for mobile phone screen

PendingCN111843438AAvoid defective productsPrecise control of output powerMetal working apparatusElectric machineryStress sensors

The invention discloses mounting equipment used for a mobile phone screen. The mounting equipment comprises a jig, heating blocks arranged on the four sides of the jig, a first rolling mechanism moving in the X-axis direction of the jig, a second rolling mechanism moving in the Y-axis direction of the jig, a pressure maintaining mechanism right facing the position over the jig and a control unit.The control unit comprises a microcontrol processor and a pressure sensor unit connected with the first rolling mechanism, the second rolling mechanism and the pressure maintaining mechanism, the first rolling mechanism, the second rolling mechanism and the pressure maintaining mechanism receive signals of the microcontrol processor successively, downward pressure is applied to the heating blocksto execute corresponding actions, and the output power of the first rolling mechanism, the second rolling mechanism and the pressure maintaining mechanism is controlled according to weather received pressure signals transmitted by the pressure sensor unit reach the set threshold value or not. According to the equipment, the output power of relevant motors in the equipment is actively and preciselycontrolled in the automatic work process, and generated defective products are reduced.

Owner:昆山铭世特精密机械有限公司

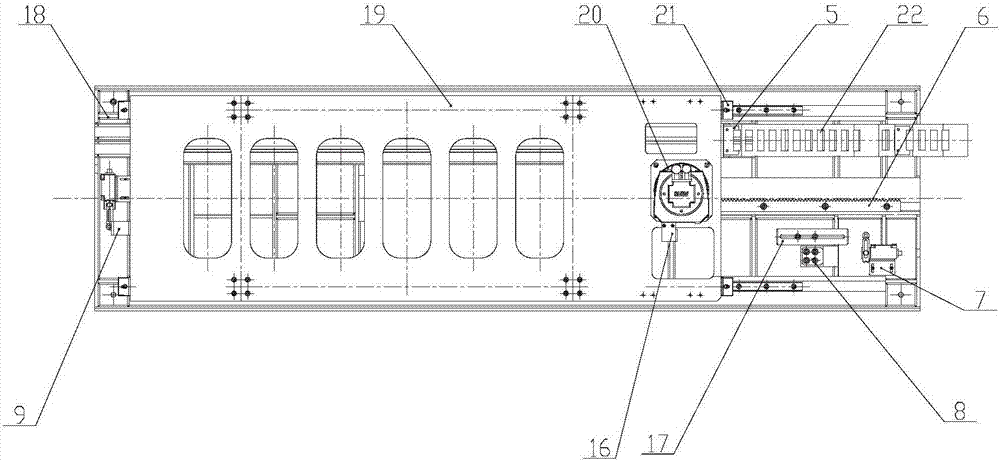

Battery pack upper cover full automatic glue coating installing system

The invention discloses a battery pack upper cover full automatic glue coating installing system, which comprises a work table, a static material frame, a glue coating robot, a glue coating tower, a glue supply assembly A, a glue supply assembly B, a scaffold car tray positioning assembly and a tightening robot, wherein the work table is used for bearing each component; the tightening robot is used for performing screw bolt screwing on a battery pack upper cover to be subjected to glue coating, tightly pressed by the scaffold car tray positioning assembly. The system provided by the inventionhas the advantages that the automatic degree is high; the occurrence of the condition of upper cover collision can be directly avoided; the collision of the coated glue can be avoided; the generationof unqualified products is prevented; the automatic screw bolt feeding and the automatic tightening are realized, so that the occurrence of errors is reduced. The glue coating is uniform; the consistency is high; the glue type is smooth. The labor can be effectively reduced; the cost is reduced; meanwhile, the capacity can be improved. The stability is reliable, so that the management is convenient; the non-qualified rate is reduced.

Owner:SHANGHAI SK SPECIAL MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com