Patents

Literature

75results about How to "Consistent clearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

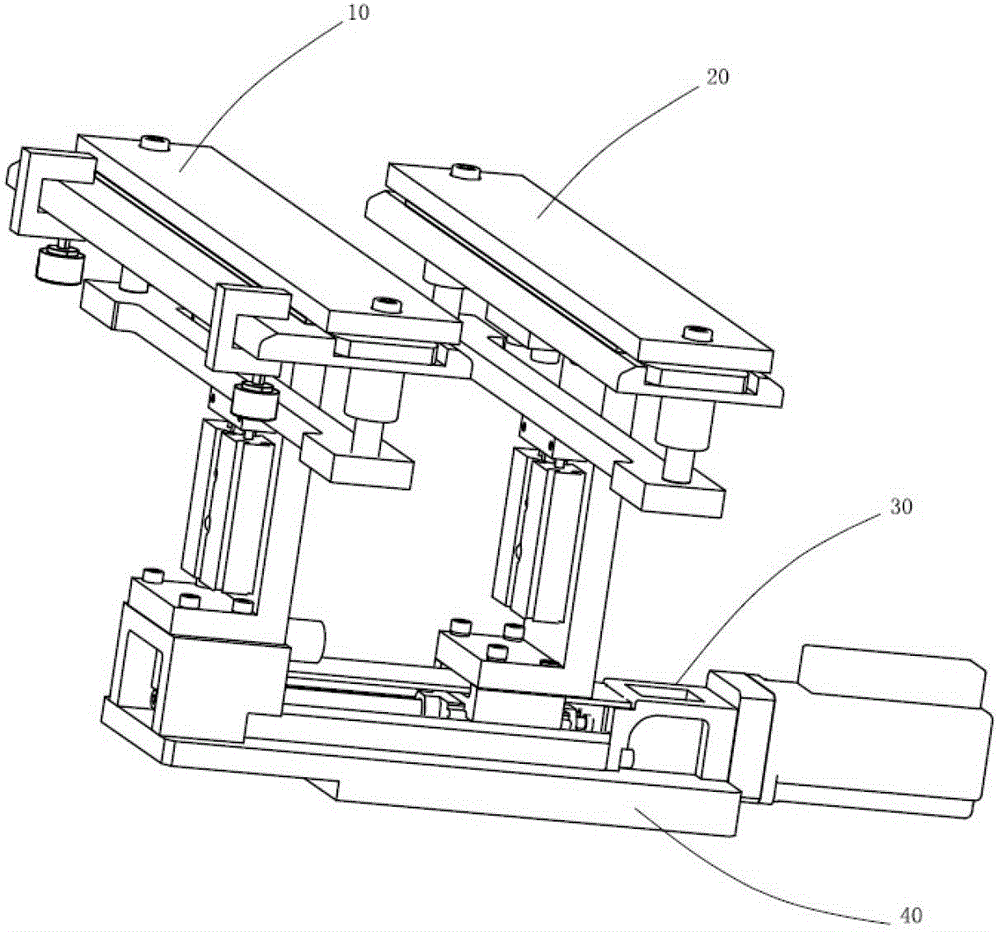

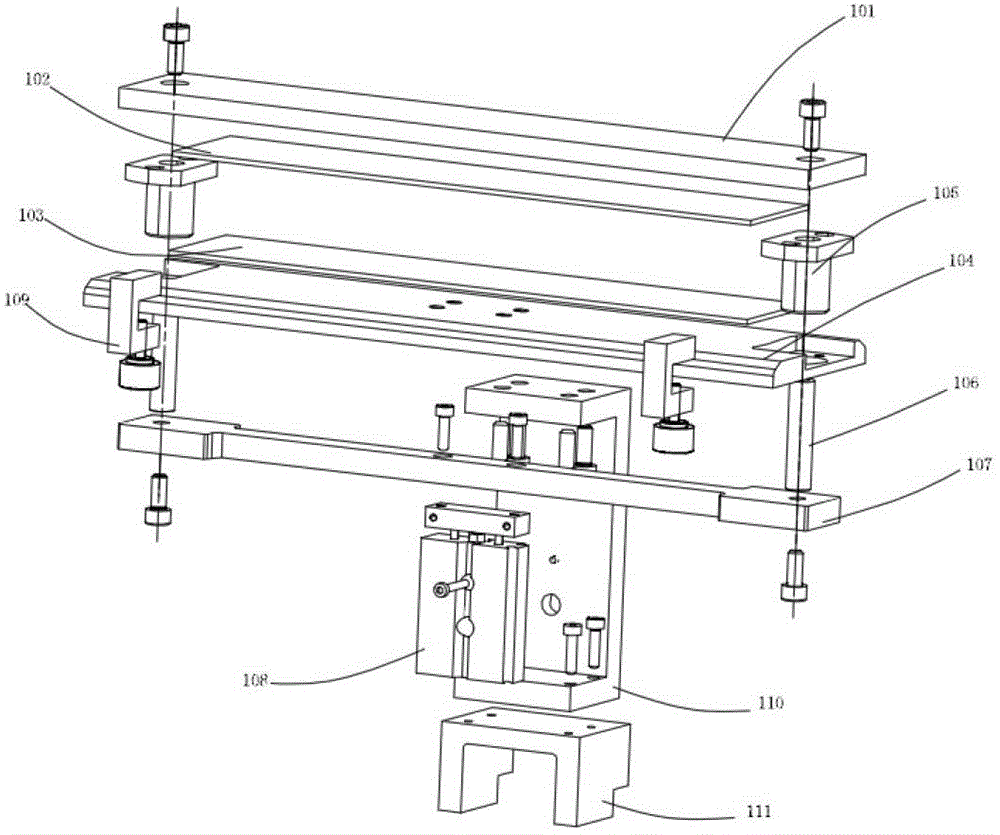

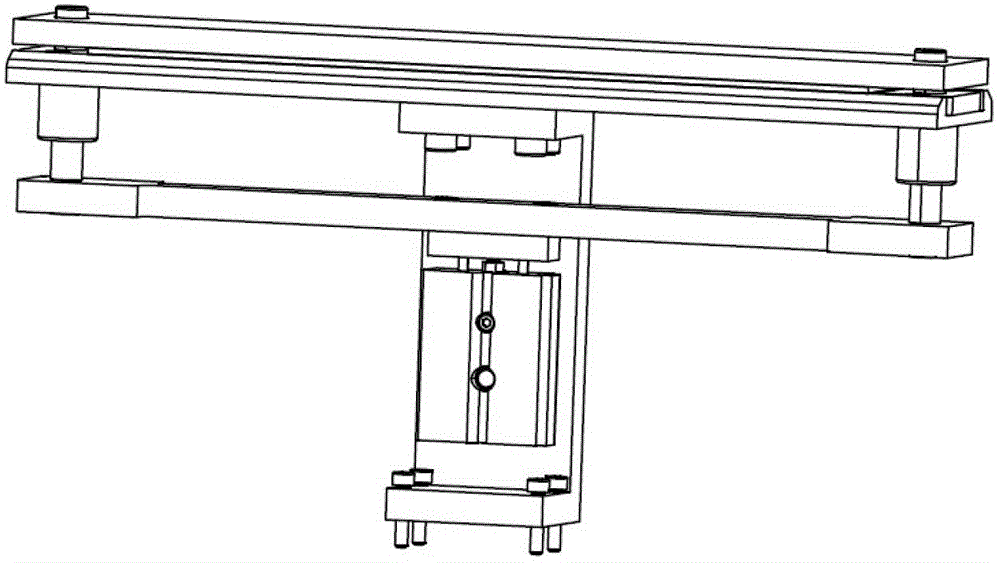

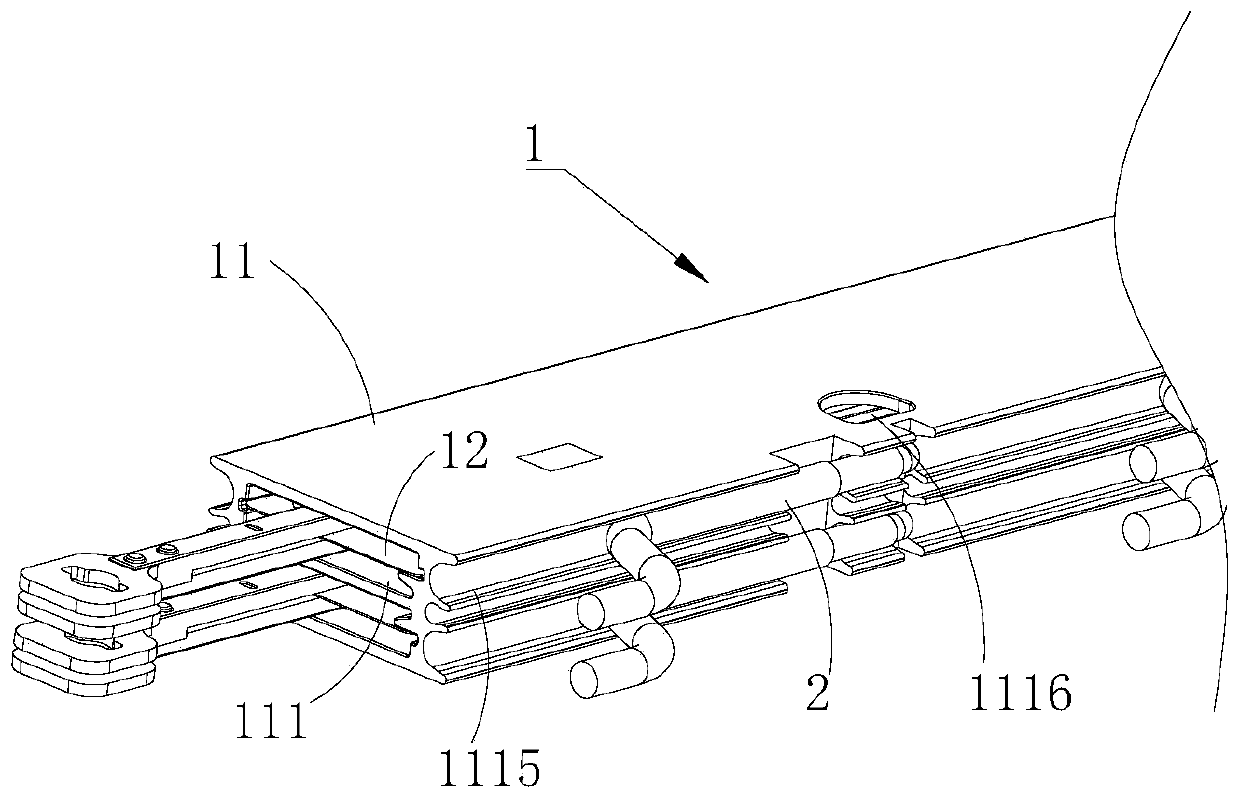

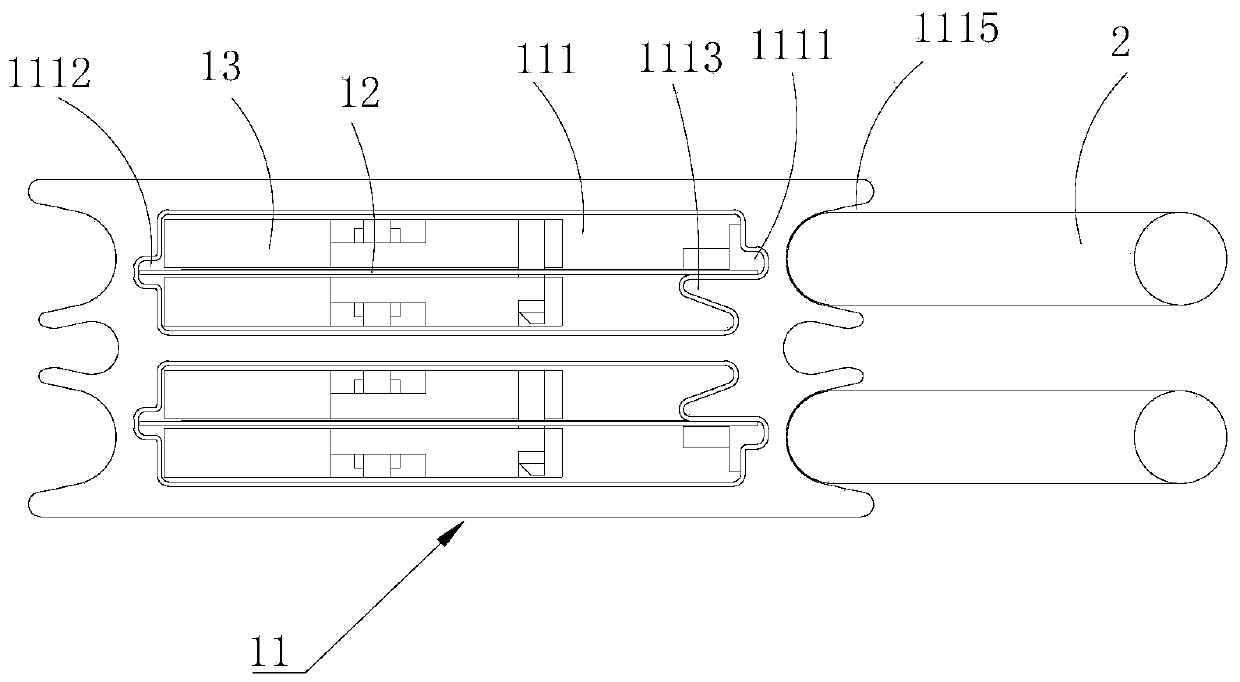

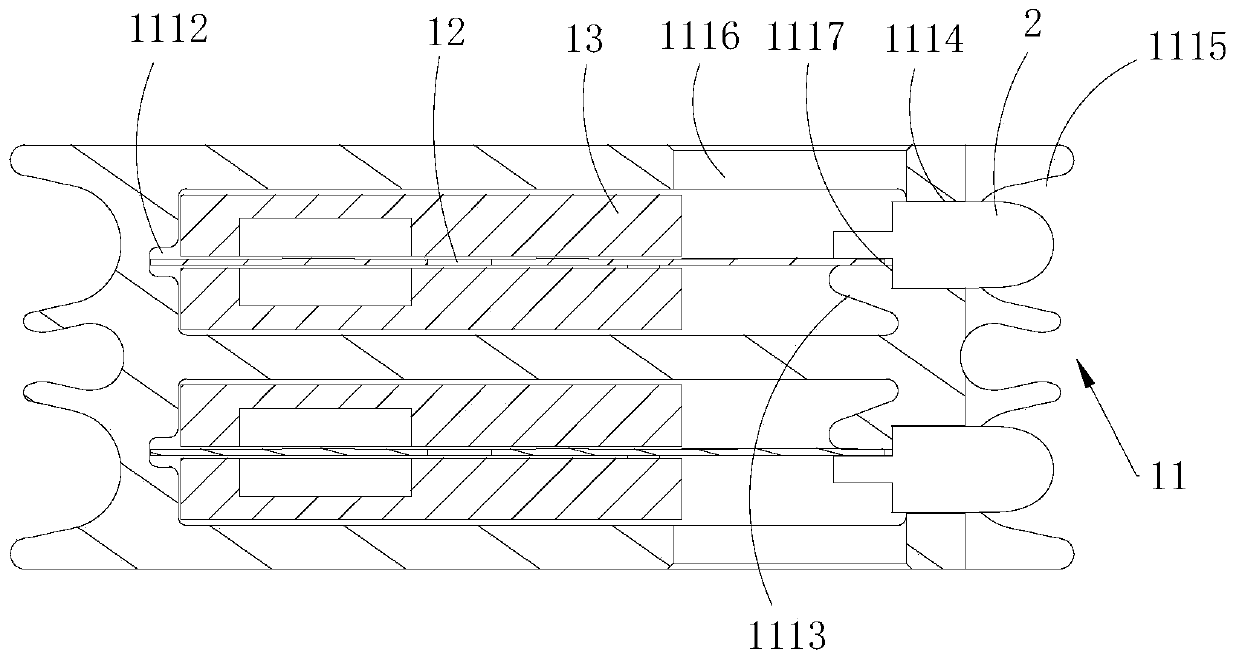

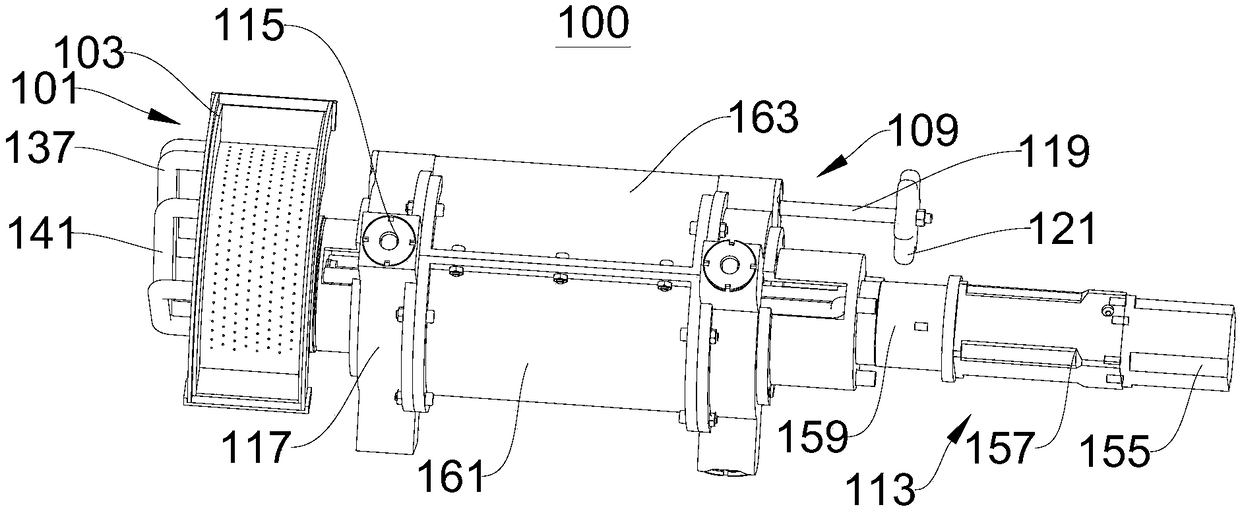

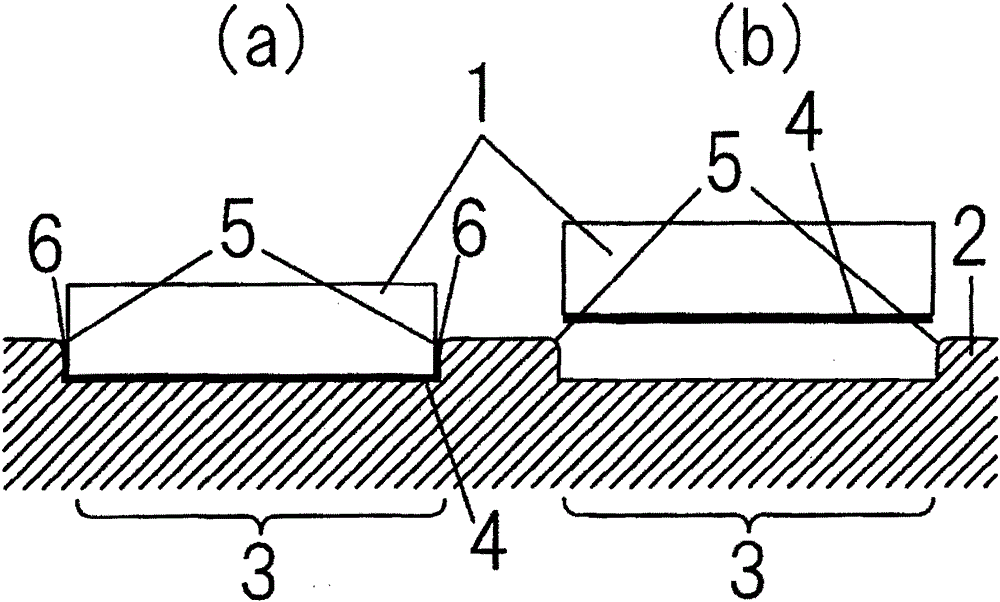

Clamping device for intermittently feeding films

The invention discloses a clamping device for intermittently feeding films. The clamping device comprises a supporting base, a driving component, a fixed clamping piece and a movable clamping piece; the fixed clamping piece is fixedly arranged on the driving component; the movable clamping piece is movably arranged on the driving component; the structure of the fixed clamping piece is similar to that of the movable clamping piece; and each of the fixed clamping piece and the movable clamping piece comprises a base, a single driving cylinder, a horizontal supporting plate, an upper clamping plate, a lower clamping plate and a pair of linear bearings, the single driving cylinder is arranged along a vertical direction, the horizontal supporting plate is fixedly connected with a piston of the driving cylinder, the upper clamping plate is connected with the supporting plate through a pair of vertical guide shafts, the upper clamping plate and the supporting plate jointly form a frame structure, the lower clamping plate is positioned between the upper clamping plate and the supporting plate, and the linear bearings are respectively used for accommodating and installing the vertical guide shafts and are fixed at two ends of the lower clamping plate. By the clamping device for intermittently feeding films, the phenomenon of jamming or uneven pressure caused by double-cylinder drive can be avoided, damage of elements such as the cylinders is avoided by the linear bearings and corresponding structures, feeding accuracy and clamping stability are improved, and accordingly the films can be ensured to be accurately clamped and conveyed.

Owner:HUAZHONG UNIV OF SCI & TECH

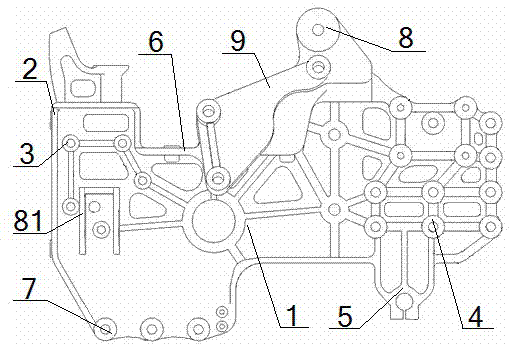

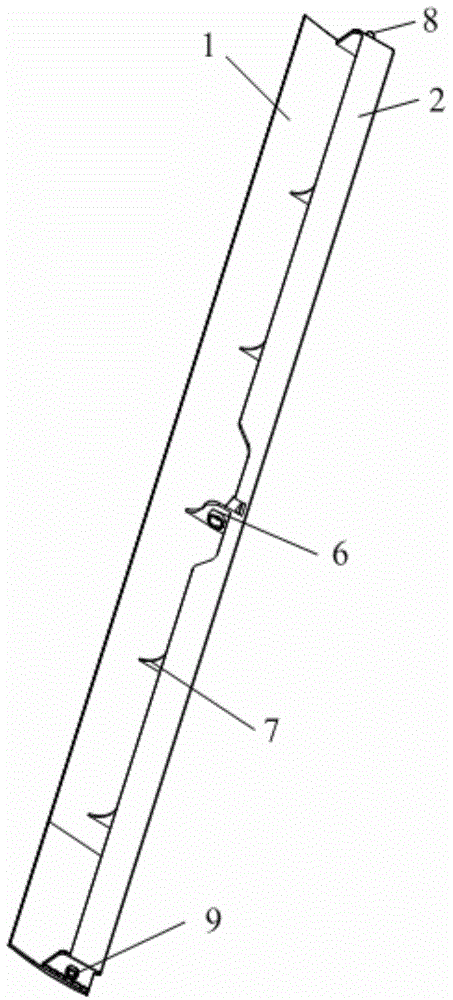

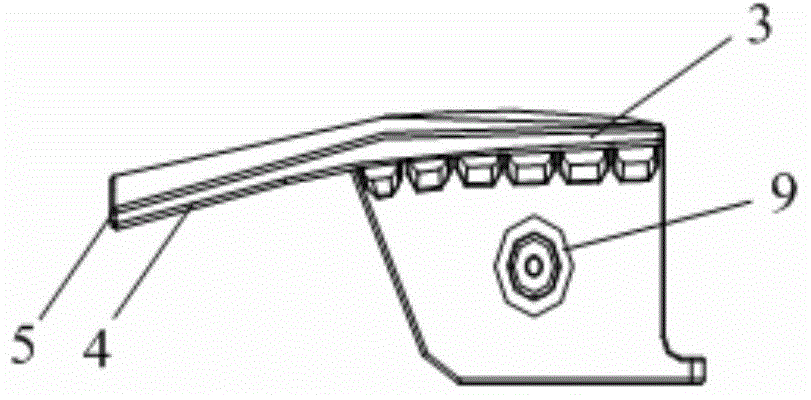

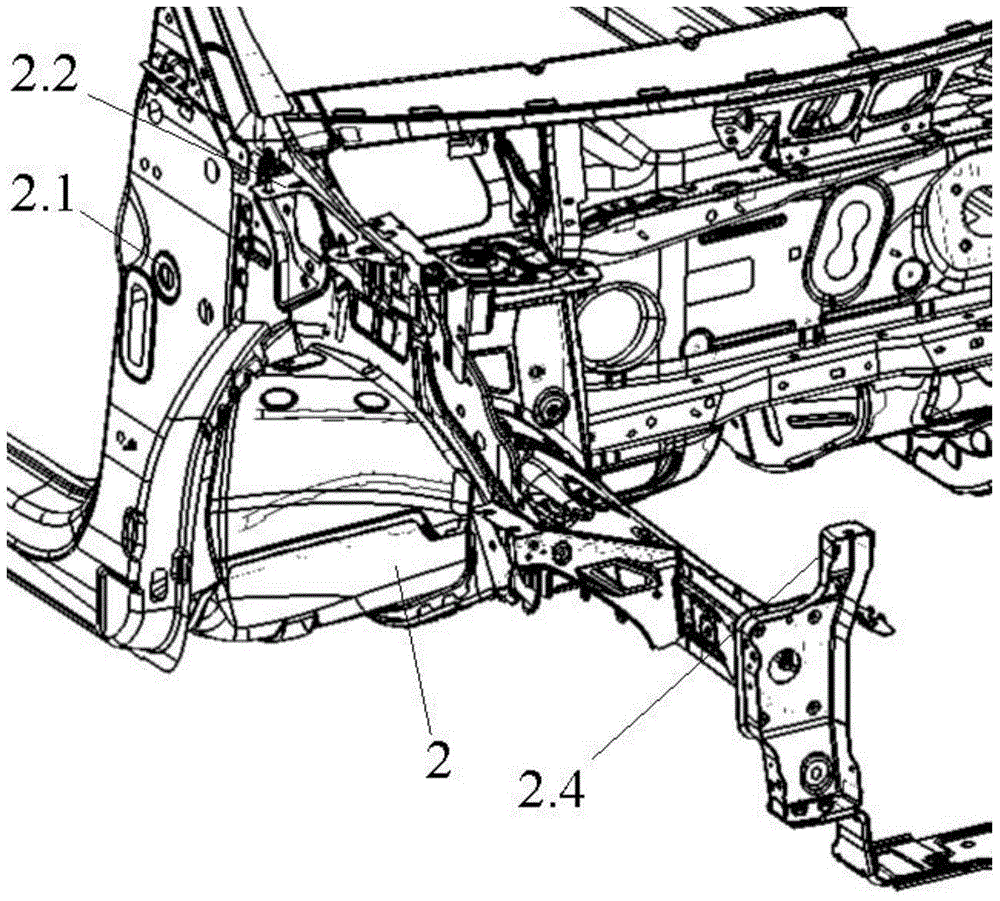

Integrated frame longitudinal beam connecting support

ActiveCN103921842AHigh mechanical strengthReduce in quantityUnderstructuresLoading-carrying vehicle superstructuresVehicle frameEngineering

An integrated frame longitudinal beam connecting support comprises a base and a bumper mounting portion, a beam assembly mounting portion, a frame fixing portion and a plate spring mounting portion which are arranged on the base. The back of the bumper mounting portion is fixedly connected to the front end of the frame fixing portion through the beam assembly mounting portion, the bottom of the frame fixing portion is fixedly connected to the plate spring mounting portion, a sunken water tank mounting portion and a cab front suspension turning arm mounting portion are arranged between the beam assembly mounting portion and the frame fixing portion, a front-lower protective supporting base fixing portion is fixedly connected to the lower portion of the beam assembly mounting portion, and a front suspension vibration absorber mounting support is fixedly connected to the side of the beam assembly mounting portion; the base is integrated with the bumper mounting portion, the beam assembly mounting portion, the frame fixing portion, the plate spring mounting portion, the sunken water tank mounting portion, the front-lower protective supporting base fixing portion, the cab front suspension turning arm mounting portion and the front suspension vibration absorber mounting support. The support is in high integrated level, is reasonable in structure and has high mechanical strengthen.

Owner:DONGFENG COMML VEHICLE CO LTD

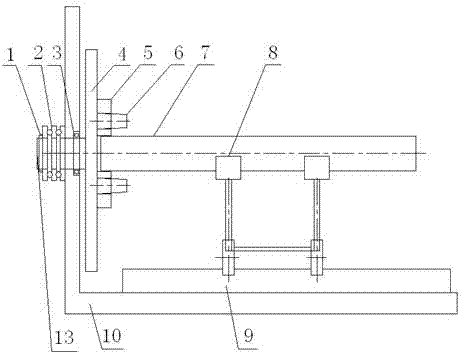

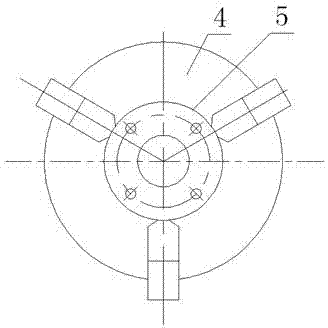

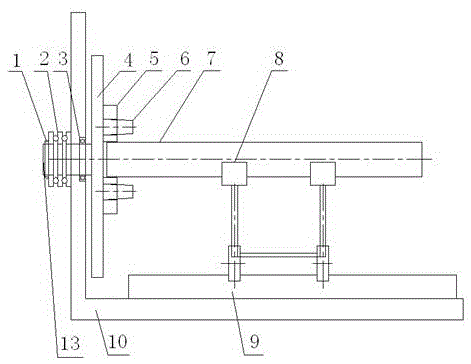

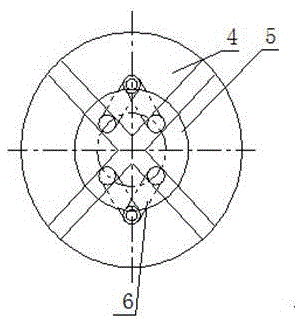

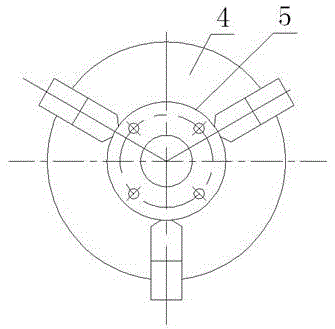

Connecting pipe and flange assembling device

ActiveCN103921043AGuaranteed verticality requirementsGuaranteed parallelismWelding/cutting auxillary devicesAuxillary welding devicesBall bearingButt joint

The invention discloses a connecting pipe and flange assembling device, belongs to the technical field of oil and gas field connecting pipe assembling, and aims to solve the problems that manual connecting pipe flange assembling efficiency is low through a skid mounted unit and assembling quality is difficult to guarantee. The assembling device comprises an L-shaped operating platform, a fixing support member, a rail, a flange fixing member, a flange, a rotary shaft, a locking nut, a planar pushing ball bearing, a deep groove ball bearing and the like. According to the device, by controlling the coaxiality during connecting pipe and flange assembling, high accuracy of connecting pipe and flange assembling is guaranteed, and consistence requirements of assembling gaps and unfitness of butt joint in the same batch can be improved; in addition, by adjusting the device once, rapid assembly of connecting pipes and flanges in batches can be implemented, labor force is saved, and assembling efficiency is improved.

Owner:XIAN CHANGQING TECH ENG

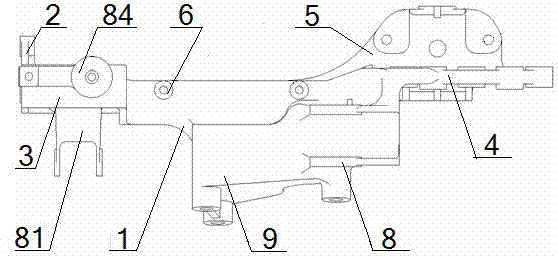

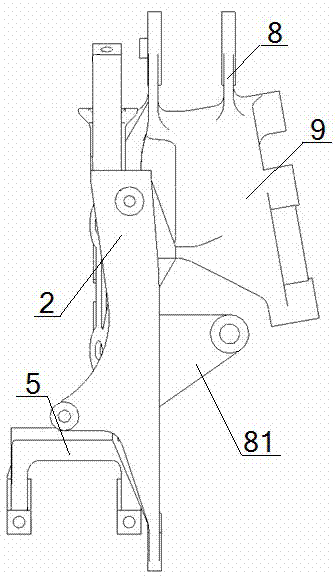

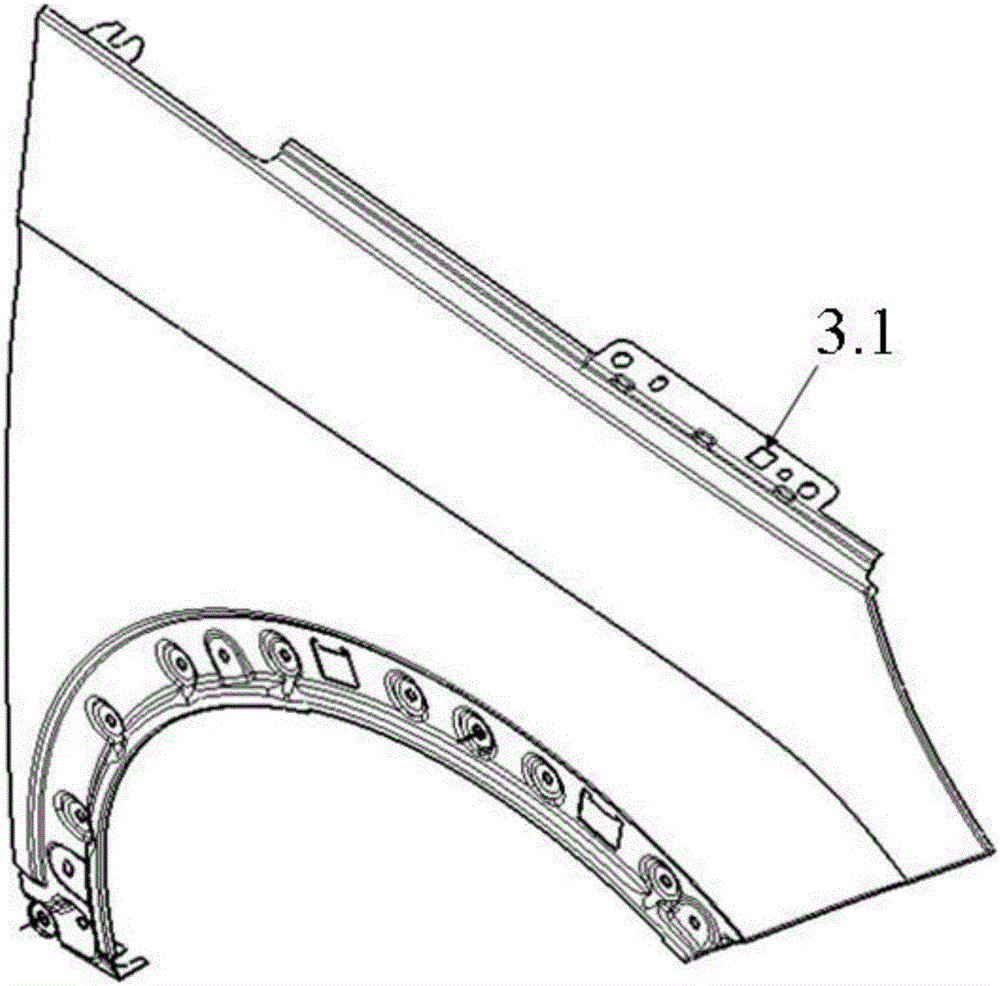

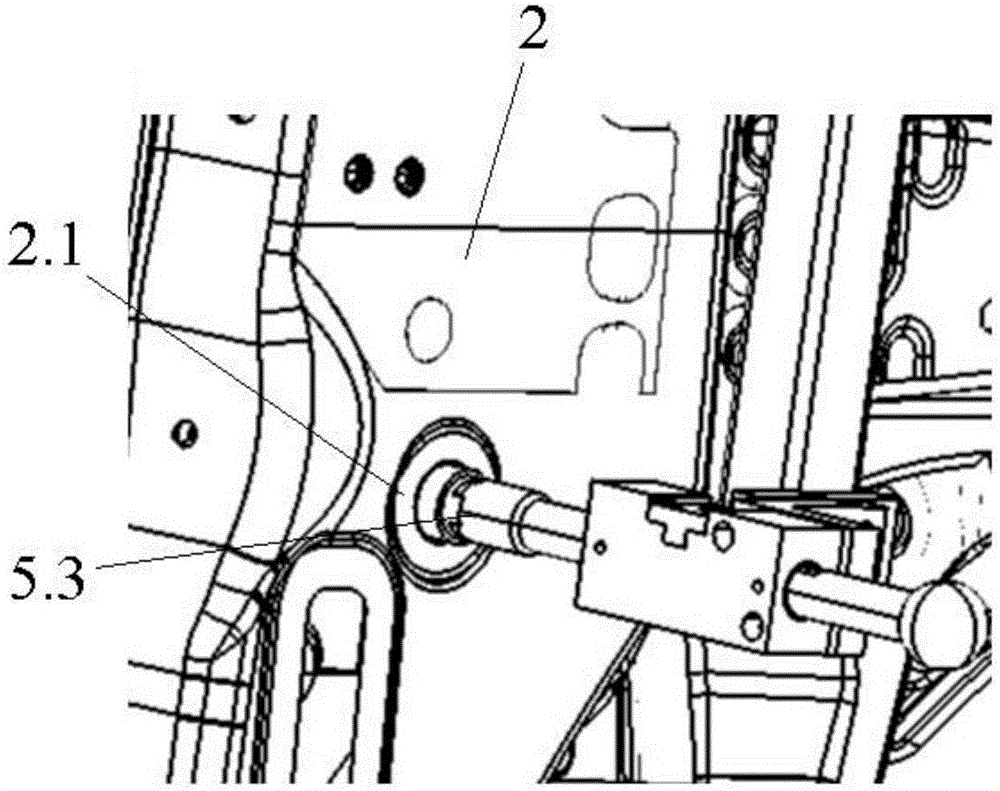

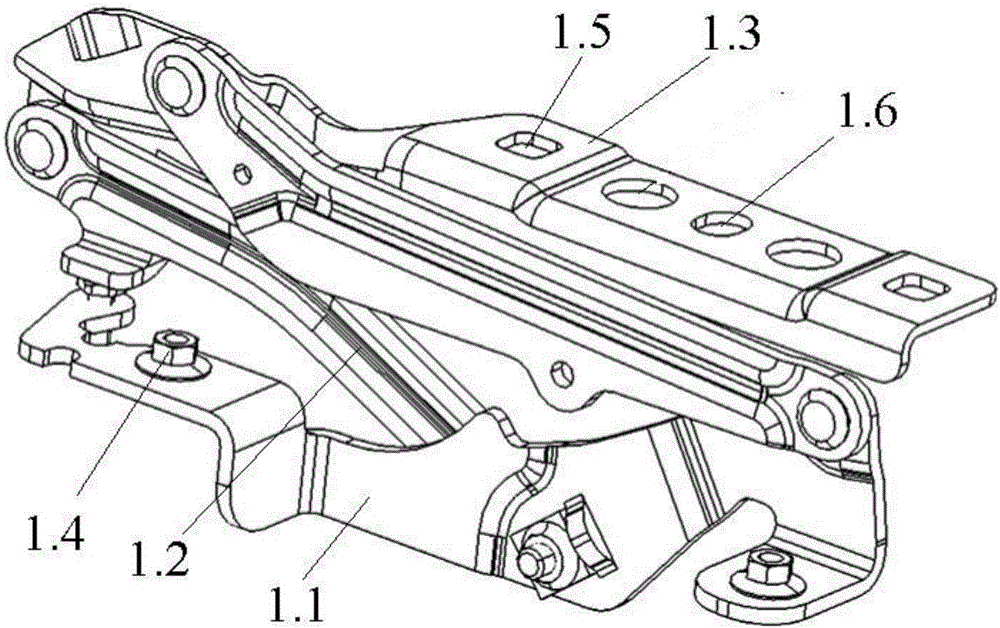

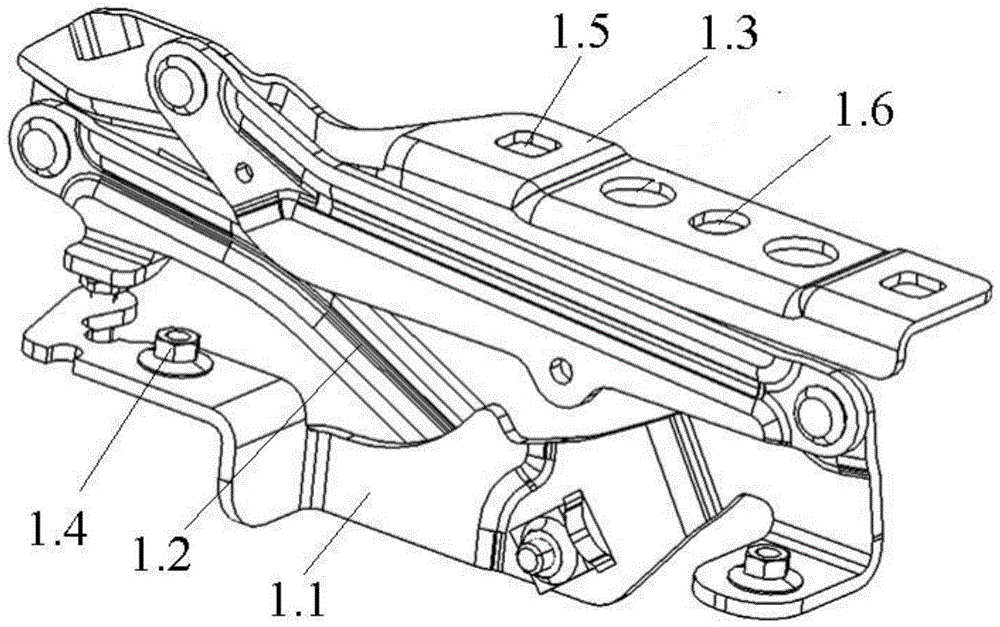

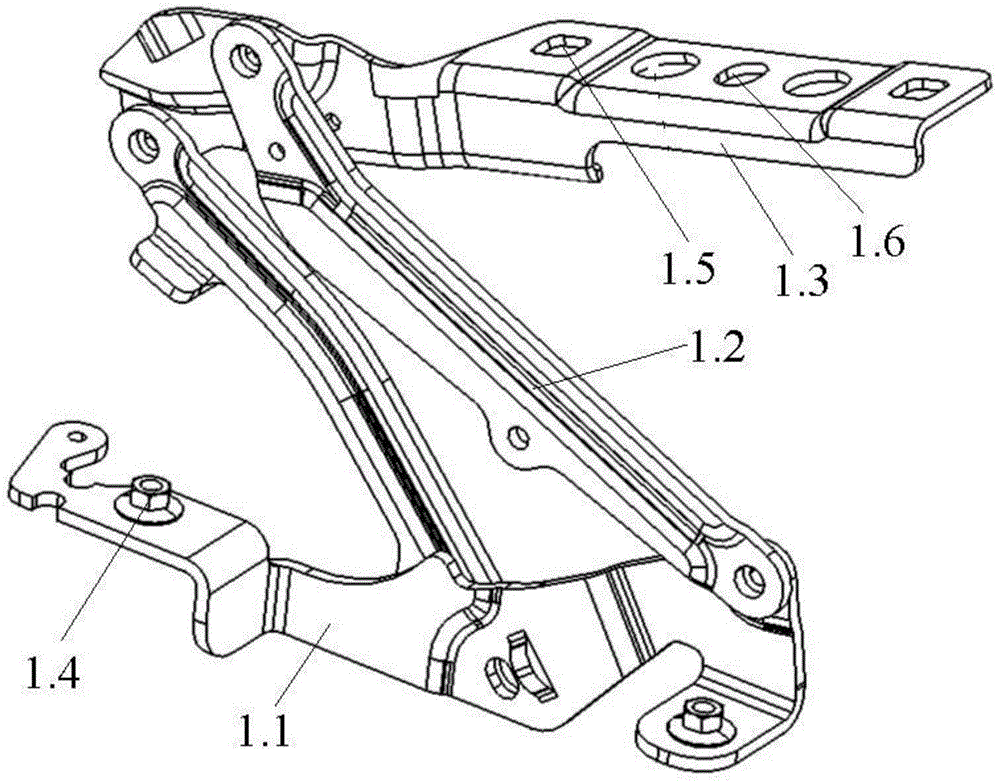

Assembly positioning tool and assembly method for four-bar linkage hood hinge

ActiveCN104985559ASolve the problem that the gap is difficult to keep in the proper rangeSolve the unstable positioningMetal-working hand toolsStructural engineeringMechanical engineering

The invention relates to the field of automobile part assembly tools, in particular to an assembly positioning tool and an assembly method for a four-bar linkage hood hinge. The assembly positioning tool comprises a first sample frame and a second sample frame. The first sample frame is used for positioning and installing a fixed leaf on the hinge. The second sample frame is used for positioning and installing a movable leaf on the hinge. The two sample frames are matched to assemble the four-bar linkage hinge. The first sample frame is used for positioning and installing the fixed leaf, and the distance between the fixed leaf and an automobile body column A is accurately positioned; the second sample frame is used for installing a hood, the distance between the movable leaf and the hood is accurately positioned, and the problem that assembly accuracy between the hood and the column A is not certain when the hood is opened and closed due to clearances between screw bolts and bolts is solved. In addition, the assembly efficiency is improved, the hinge installing difficulty is lowered, the structure is simple, use is convenient, and great promotional value is achieved.

Owner:DONGFENG PEUGEOT CITROEN AUTOMOBILE

Nuclear power push-pull airtight door

ActiveCN102146765AReduce the pressing strokeConsistent clearanceFrame fasteningWindow/door framesPush and pullLocking mechanism

The invention relates to a nuclear power push-pull airtight door belonging to the technical field of nuclear power special facilities. The airtight door comprises a door frame fixed on a building door opening, wherein a horizontal guide rail with a hanging pulley wheel is fixedly arranged on the door frame; a door sash is hung below the hanging pulley wheel through a short connecting rod; the outer side of a door plate of the door sash is provided with a side frame with a profile being larger than the inner profile of the door frame; the inner side of the door plate is provided with a door body which protrudes towards the door frame and has a profile being smaller than the inner profile of the door frame; sealing strips are fixed around the door body; a group of positioning screw rods with compression hand wheels extending towards the door sash is fixed at one side of the door frame; a group of nuts is fixed at the other side of the door frame; one side of the door sash is provided with a group of horizontal guide grooves corresponding to the positions of the screw rods respectively; and the other side of the door sash is provided with a group of locking hand wheels with screw rods, which correspond to the positions of the nuts respectively. By adopting the airtight door, the door sash can be opened and closed by freely pushing and pulling and can be moved towards the door frame within a certain range, so that compressing force can be applied by using a locking mechanism, the sealing strips are utilized effectively, and reliable sealing is realized.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

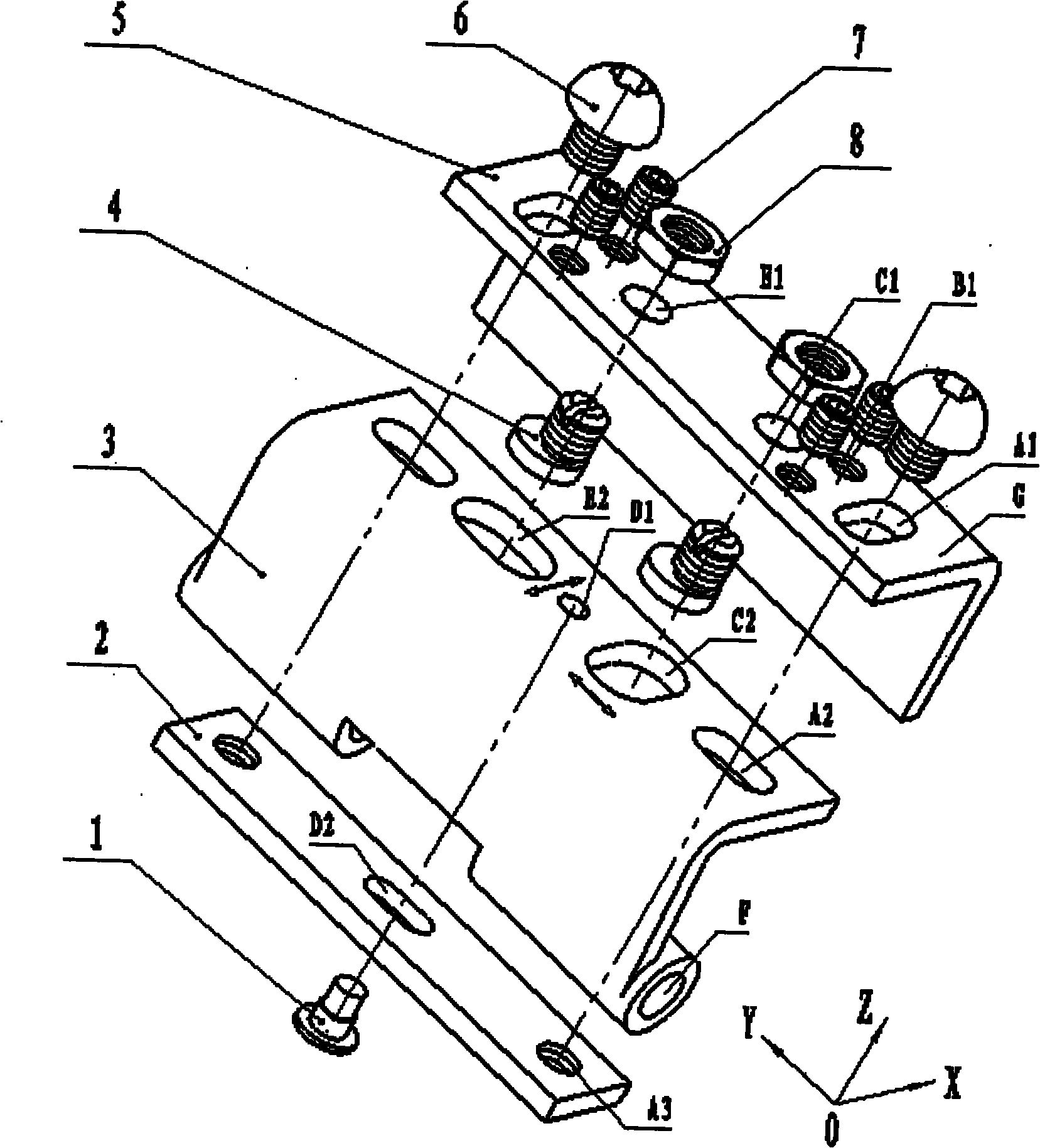

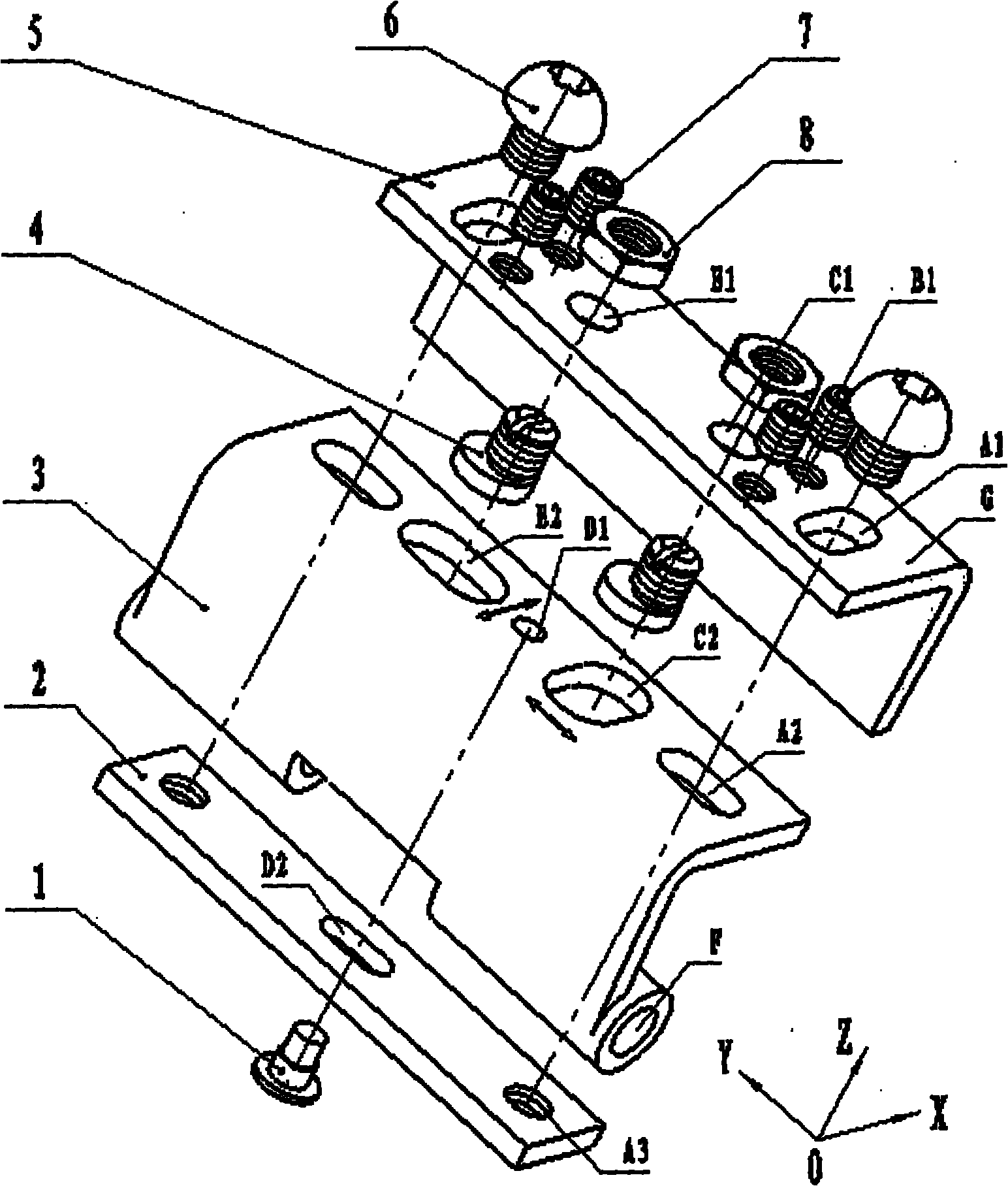

Three-way adjustable blind hinge

The invention provides a three-way adjustable blind hinge, comprising a hinge, a hinge connecting block, a fixed pin, an adjusting block, eccentric pins, tightening screws, adjusting screws and nuts. Two eccentric pins rotate to carry out eccentric motion around a circular hole C1 and a circular hole C2; the flat head parts of the two eccentric pins respectively rotate in a strip-shaped hole C2 and a strip-shaped hole E2 of the hinge so that the hinge and the hinge connecting block generate relative motion in an X direction and a Y direction, thus realizing adjustment in the X direction and the Y direction; and meanwhile the adjusting screws are screwed in or out to adjust the distance between the hinge and the hinge connecting block, thus realizing distance adjustment between the hinge and the hinge connecting block in a Z direction. The hinge can realize free adjustment on clearance of a door leaf in three directions, and ensure the clearance consistency of assembly of the door leafand a doorframe in three directions.

Owner:重庆五州门业开发有限公司

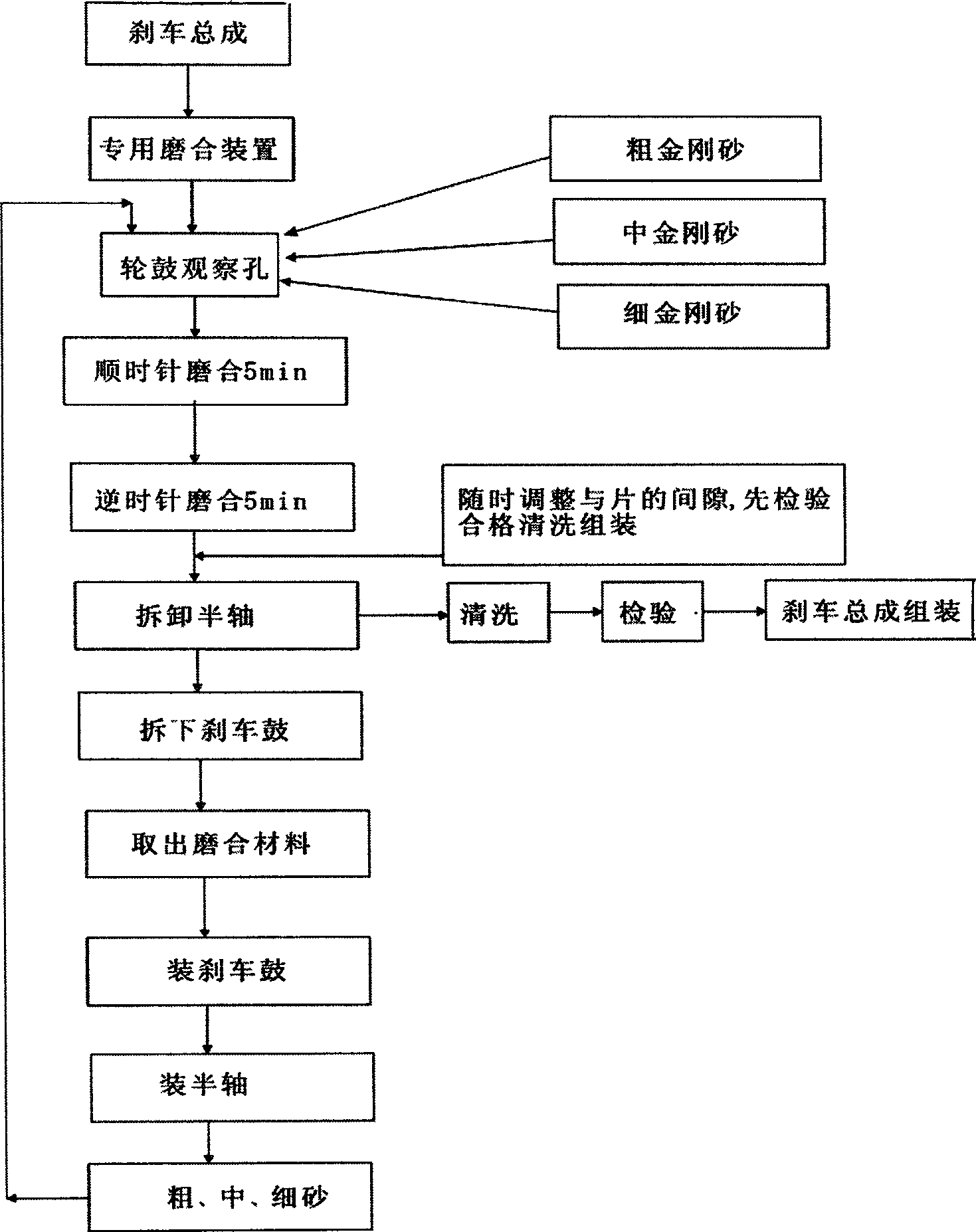

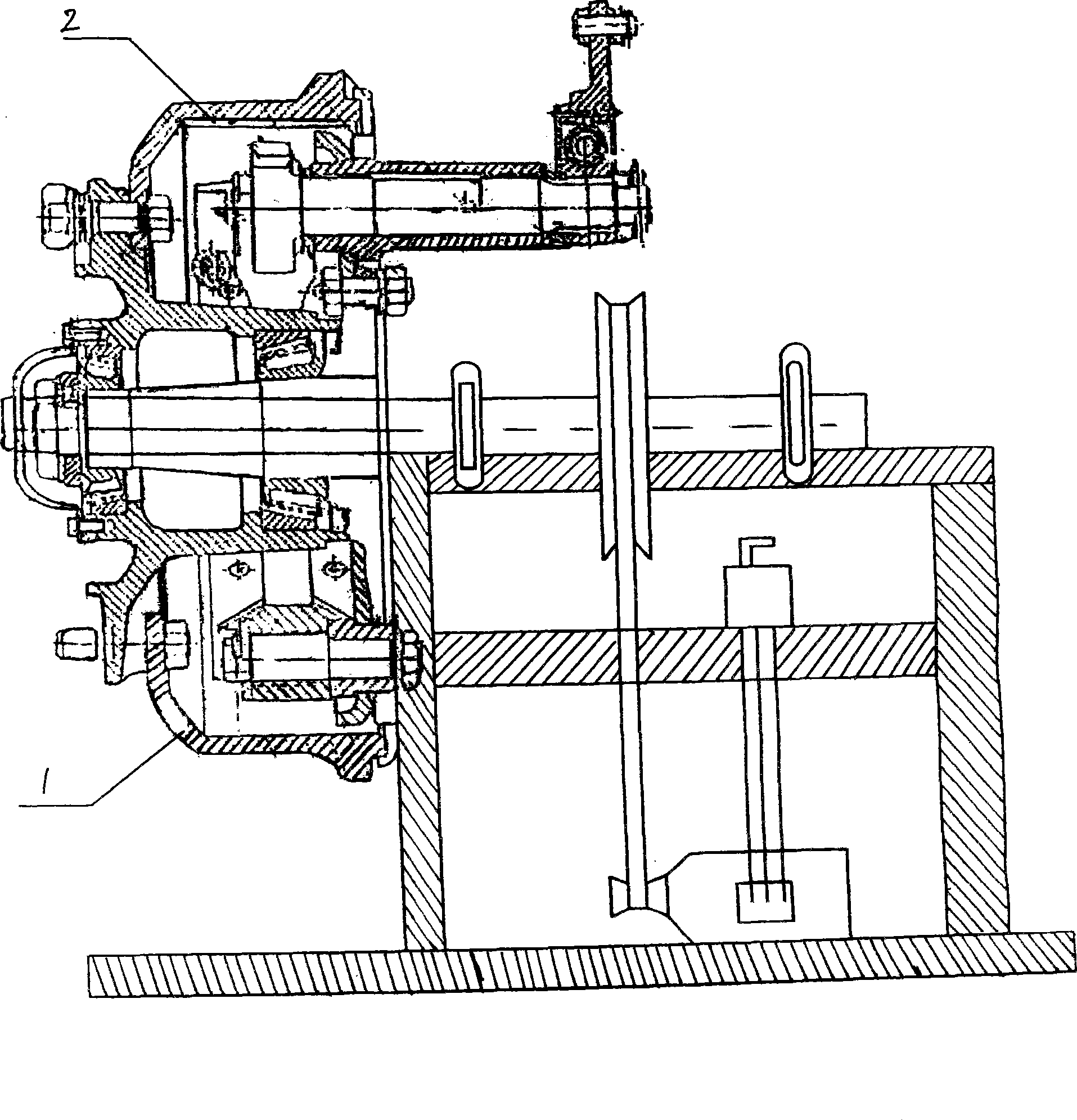

Automotive drum type braking device grinding and renovating method

The invention discloses a grinding and repairing method for a drum-type brake device of an automobile, the grinding and repairing method includes the steps as follows: A. the drum expanding and rough grinding working procedures; B. the drum expansion with the contents of milling and shaving; and C. the brake drum through the circle expanding working procedure, wherein, both the center thereof and the center formed by a friction brake sheet are concentric circles. The grinding and repairing method has the characteristics: A. the positive inversion grinding with three 46<#>, 36<#> and 30<#> carborundums is performed for 5 minutes respectively; B. the positive inversion grinding with fine river sand is performed for 5 minutes similarly again; and C. the brake assembly is assembled or can be utilized. In the entire three rough, moderate and fine grinding working procedures, the adjustment of the clamp of the tool device is particularly utilized, thereby ensuring the consistency between the center of the brake drum and the concentric circle formed by the friction brake sheet. In addition, the consistency of the clearance between the brake drum and the brake lining is particularly ensured so that the contact area of the binding face thereof reaches 90% to 95%.

Owner:冷安福

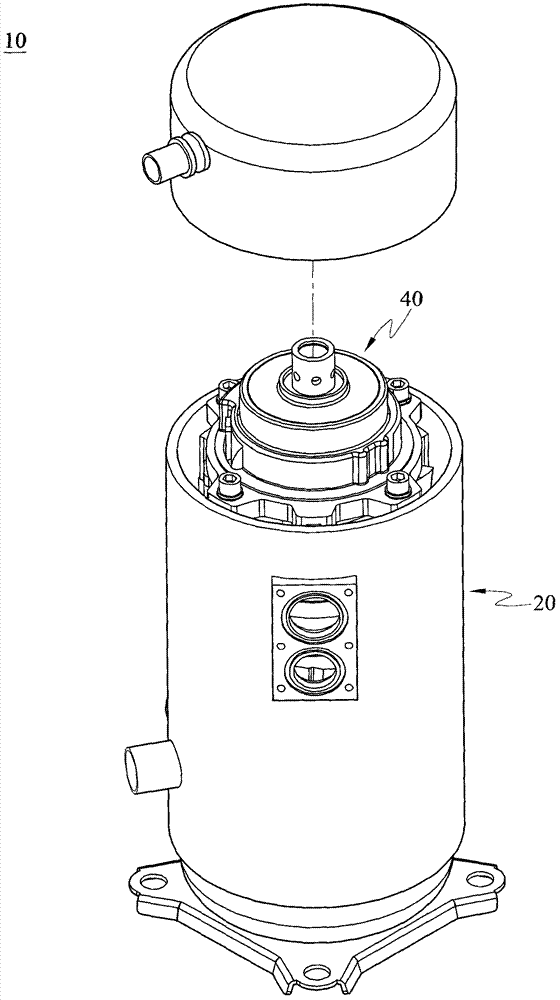

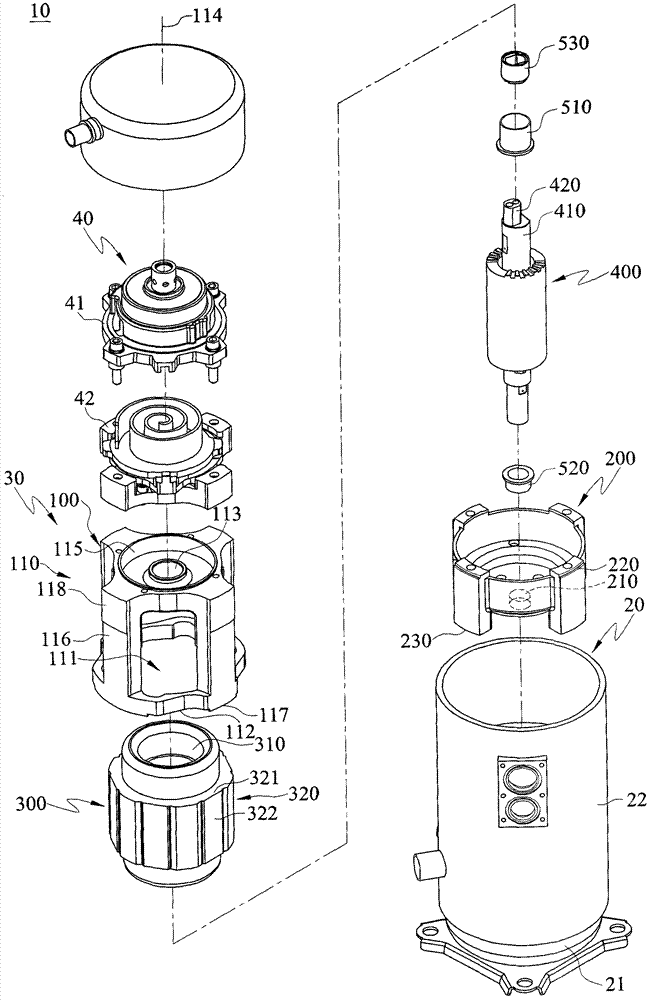

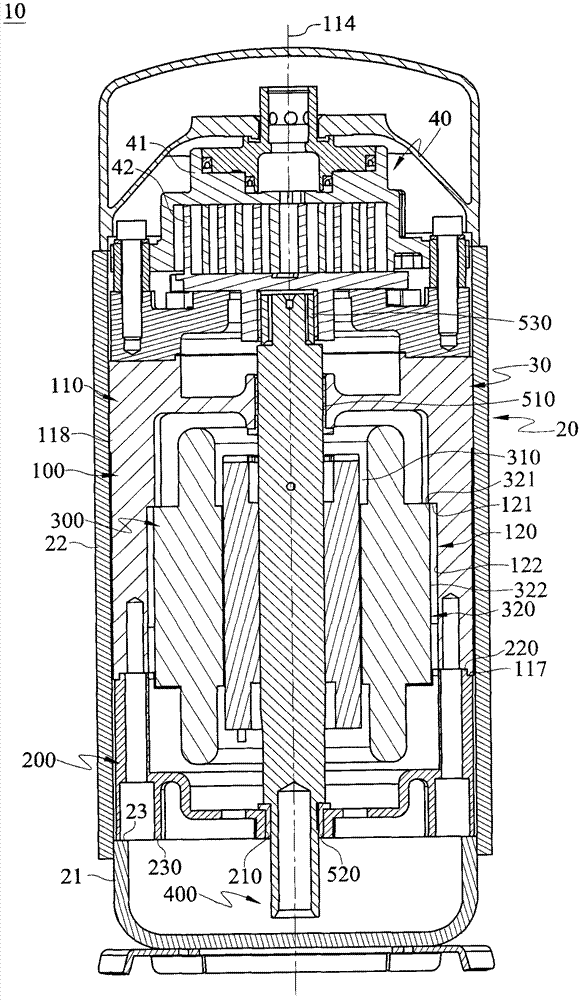

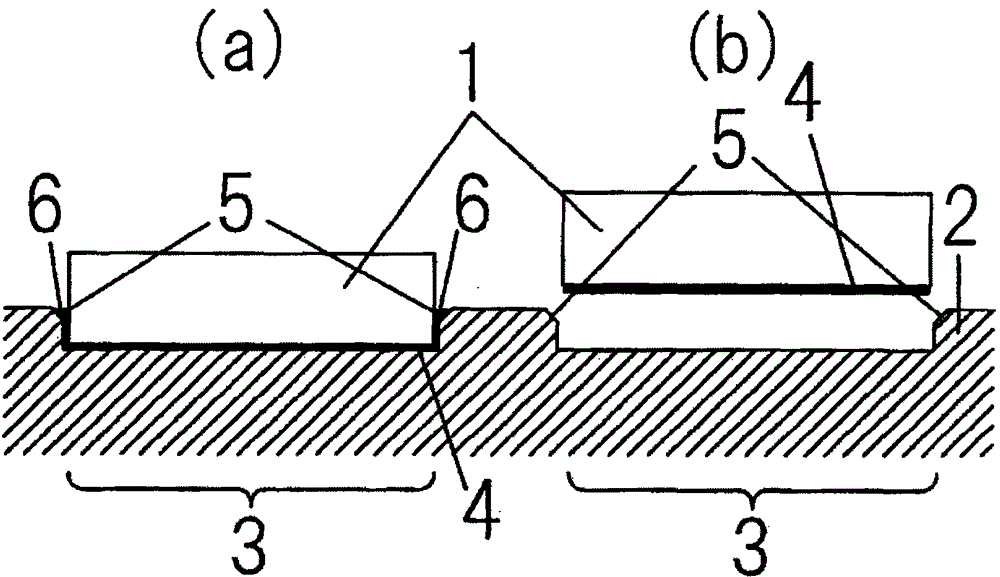

Compressor and motor device thereof

ActiveCN103114995AConsistent clearanceRotary/oscillating piston combinations for elastic fluidsMagnetic circuitMechanical engineeringStator

A motor device includes a main body, an assembling body, a stator and a rotor. The main body includes a first bearing hole and a plurality of first connectors, and all distances between each of the first connectors and an axle of the first bearing hole are the same. The assembling body has a second bearing hole. The stator includes a passage and a plurality of second connectors, the second connectors are coupled to the first connectors respectively to have the stator assembled in the main body, and the passage and the first bearing hole are coaxial. The rotor is disposed inside the passage and two ends of the rotor are installed in the first bearing hole and the second bearing hole respectively. By having both the stator and the rotor positioned by the main body, a gap between the rotor and the stator can be maintained consistently.

Owner:IND TECH RES INST

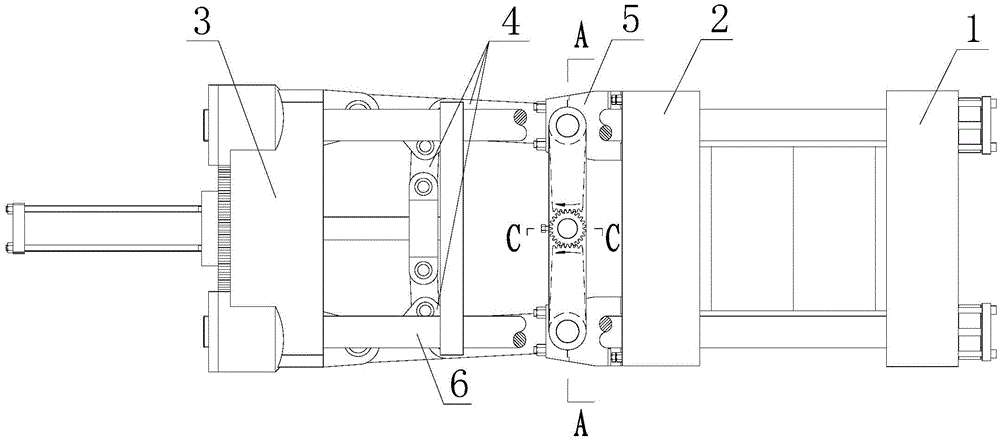

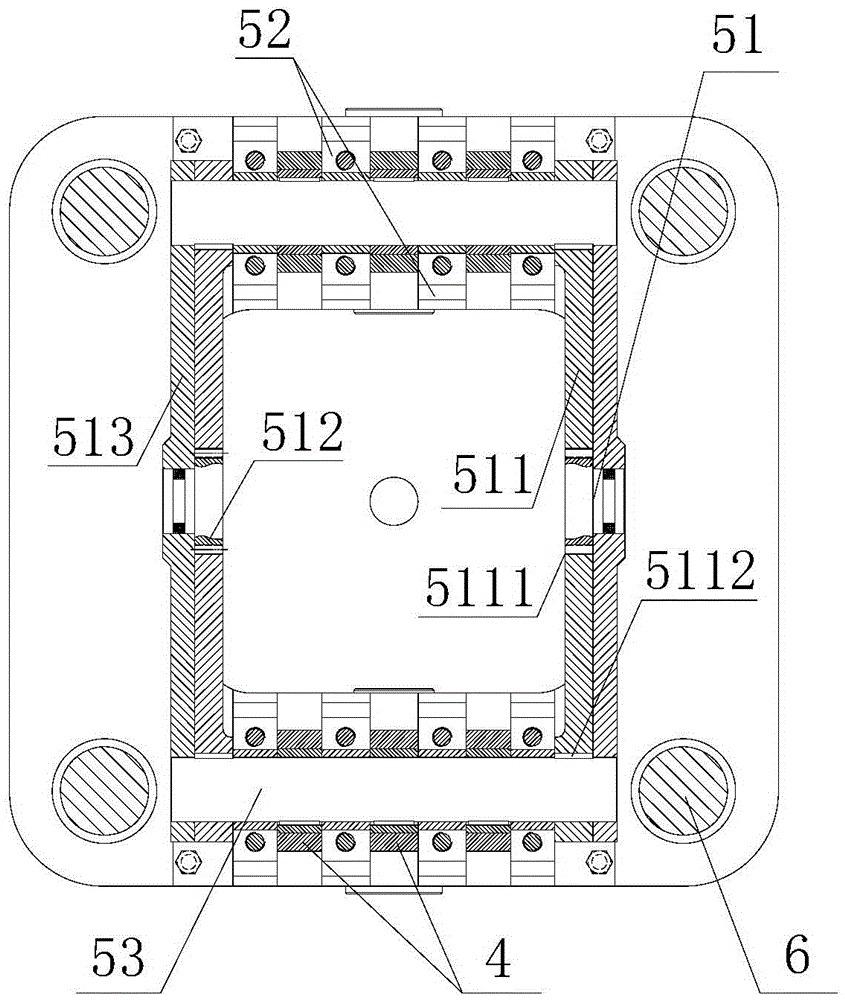

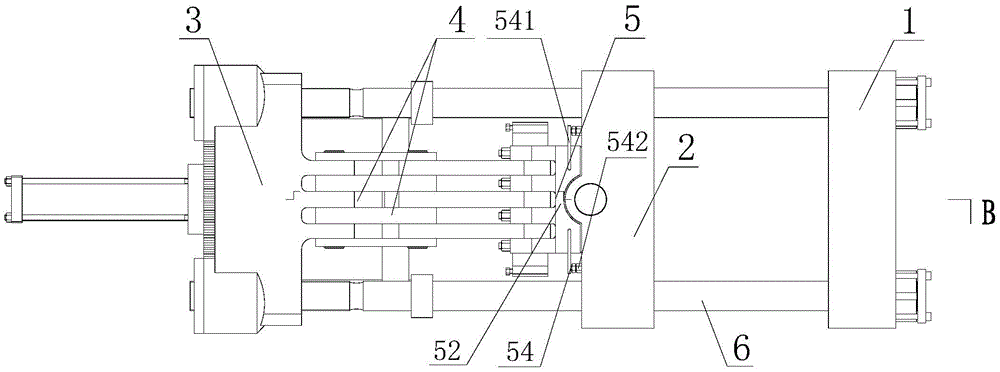

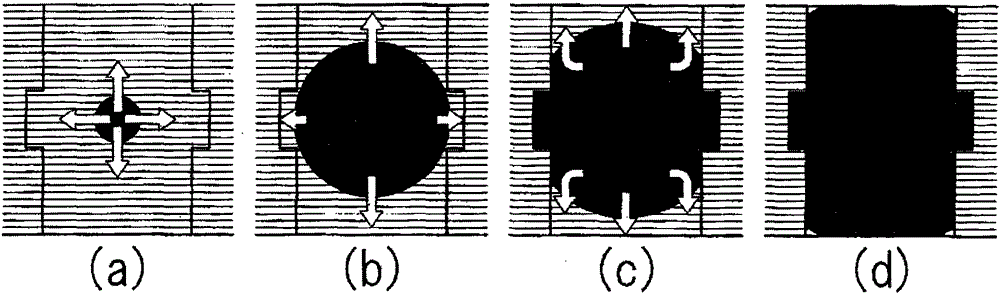

Automatic universal mold clamping mechanism for die casing machine or injection molding machine

The invention discloses an automatic universal mold clamping mechanism for a die casing machine or an injection molding machine and belongs to the field of die casting or injection molding equipment. The invention provides the automatic universal mold clamping mechanism in which an inconsistent gap is reserved between a moving mold plate and a fixed mold plate after a mold is clamped in the operation process of the mold plate, and the uniformity in stress is realized. The automatic universal mold clamping mechanism is characterized in that one end of a reamer composite connecting structure is connected with a tail board through a reamer, and the other end of the reamer composite connecting structure is hinged to the moving mold plate; the moving mold plate can reciprocate along the mold clamping direction relative to the fixed mold plate by matching the reamer composite connecting structure with the reamer; an automatic adjusting device for automatically adjusting the parallelism of the moving mold plate is arranged at one end, which is connected with the reamer, of the reamer composite connecting structure; the end, which is connected with the reamer, of the reamer composite connecting structure is movably connected with the reamer through the automatic adjusting device for automatically adjusting the parallelism of the moving mold plate; the parallelism of the moving mold plate in the operation process relative to the fixed mold plate is automatically adjusted and kept stable and consistent by the automatic adjusting device for automatically adjusting the parallelism of the moving mold plate in the working process.

Owner:张忠信

Air conditioner indoor unit, wind guide plate and method for reducing gaps between wind guide plate and panel body

ActiveCN104596072AMeet the requirements for cover installationConsistent clearanceLighting and heating apparatusAir conditioning systemsEngineering

Owner:GREE ELECTRIC APPLIANCES INC

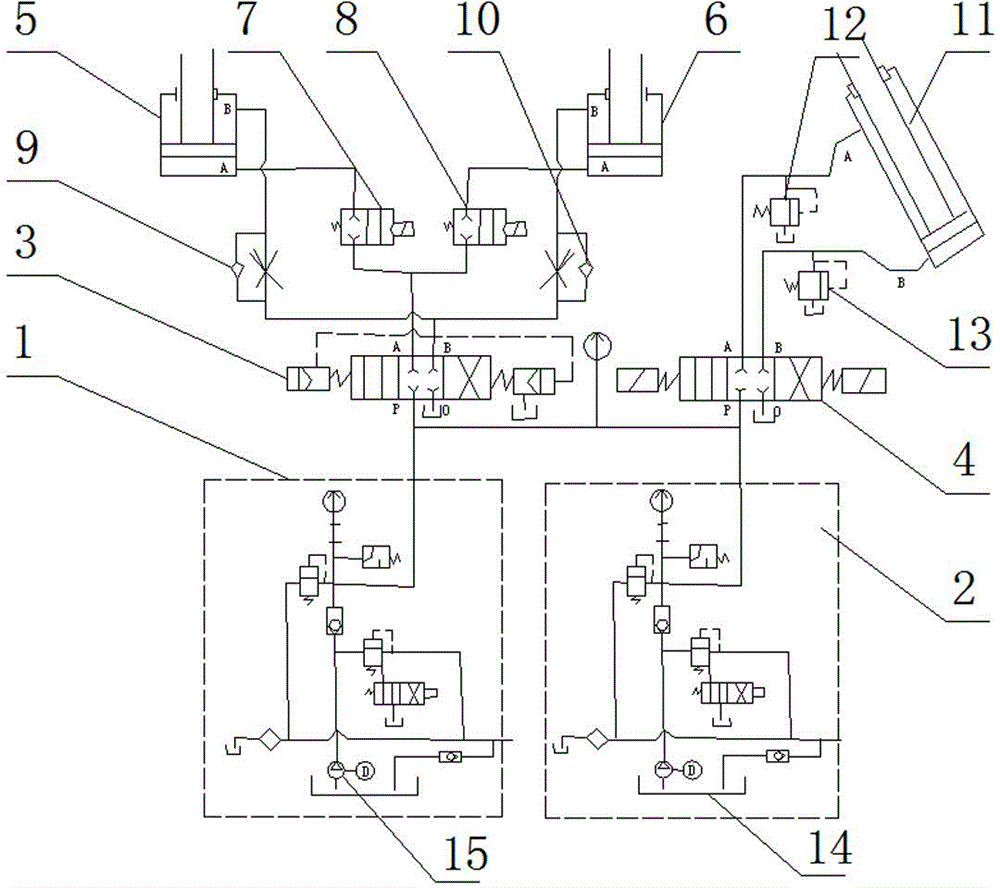

Hydraulic system for driving middle lower roller of four-roller plate bending machine

InactiveCN104832478AConsistent clearanceAvoid defective productsServomotor componentsServomotorsElectro hydraulicEngineering

The invention discloses a hydraulic system for driving middle lower roller of a four-roller plate bending machine. The hydraulic system comprises a first hydraulic station and a second hydraulic station, wherein an oil outlet pipe of the first hydraulic station is connected onto a port P of an electro-hydraulic reversing valve; a port A of the electro-hydraulic reversing valve is connected with two branches, one branch is connected with a reversing valve VII and a lower cavity of a first oil cylinder, and the other branch is connected with a reversing valve VIII and a lower cavity of a second oil cylinder; a port B of the electro-hydraulic reversing valve is connected with two branches, one branch is connected with a throttling valve I and an upper cavity opening of the first oil cylinder, and the other branch is connected with a throttling valve II and an upper cavity of the second oil cylinder; an oil outlet pipe of the second hydraulic station is connected onto a port P of a electromagnet reversing valve, and a port A of the electromagnet reversing valve is connected with an overflow valve I and an upper cavity of a third oil cylinder; the port B of the electromagnet reversing valve is connected with an overflow valve II and a lower cavity of the third oil cylinder. The hydraulic system has the advantages that the gap between the middle lower roller and an upper roller is uniform during processing, so the production of defective products is avoided, and the working efficiency is greatly improved; the functions of reversing and resetting a overturn device are realized, and the operation is automatic.

Owner:江苏亚星波纹管有限公司

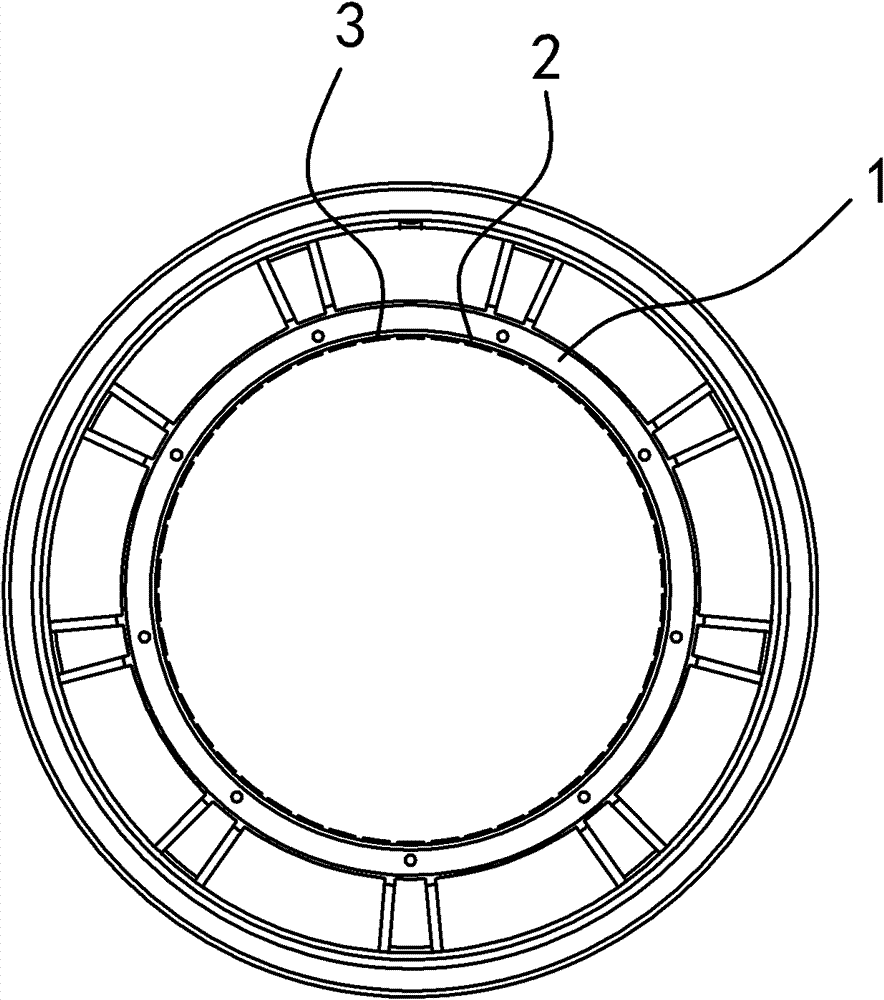

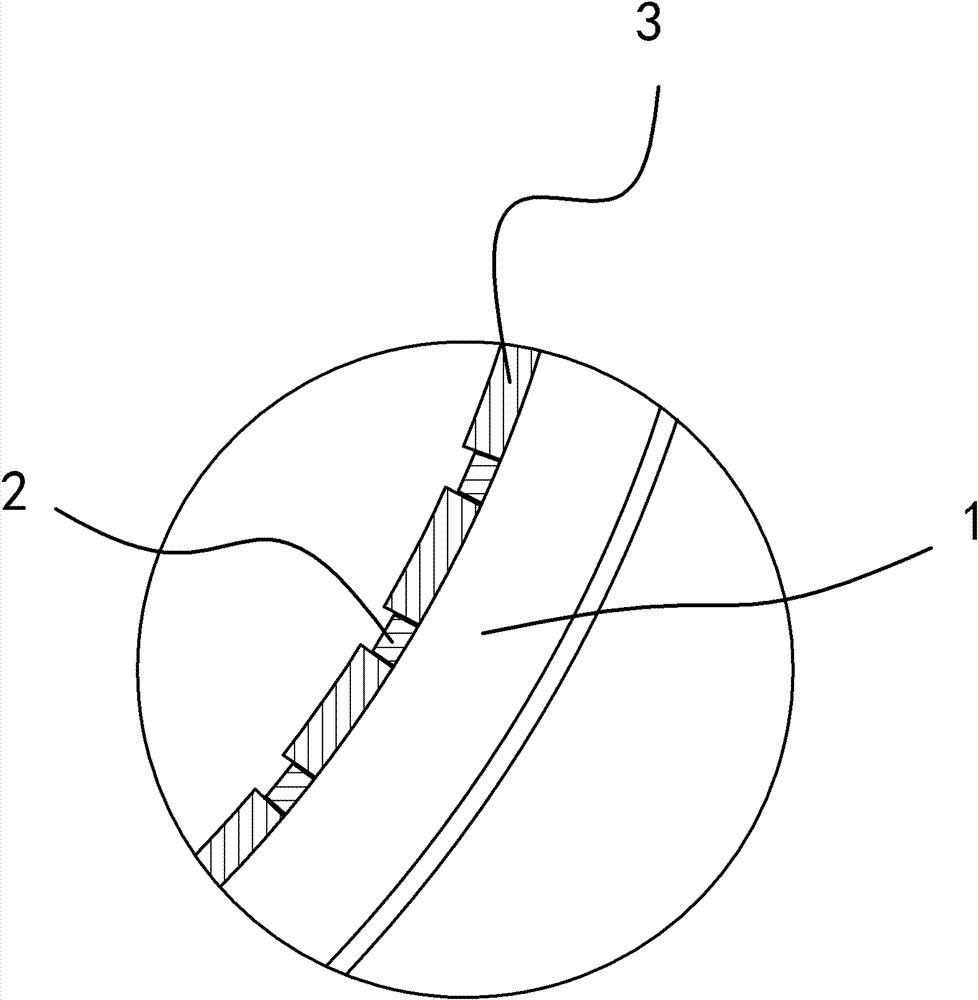

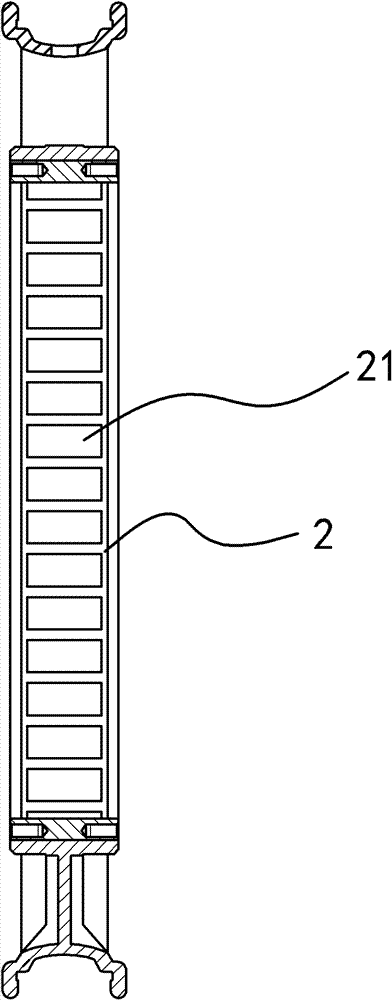

Plastic bearing with good anti-seismic property

ActiveCN107575470AIncrease the lengthImprove seismic performanceRoller bearingsNon-rotating vibration suppressionEngineeringFriction force

The invention belongs to the technical field of bearings, and particularly relates to a plastic bearing with a good anti-seismic property. Aiming at the shortcoming and problem that an existing plastic bearing is prone to being abraded and shaking during movement, the following scheme is provided. The plastic bearing comprises a bearing inner ring; the outer ring of the bearing inner ring is movably sleeved and connected with a bearing outer ring; the two ends of the bearing inner ring are movably sleeved and connected with inner ring damping mechanisms in sliding sleeving connection with thebearing inner ring; the two ends of the bearing outer ring are provided with first sliding grooves in sliding sleeving connection with the inner ring damping mechanisms; first containing grooves are formed in the outer ring of the bearing inner ring in the axis direction in an array mode; and second containing grooves corresponding to the first containing grooves are formed in the inner ring of the bearing outer ring in the axis direction in an array mode. The plastic bearing can effectively ensure the effect that intervals between parts of the bearing inner ring and the bearing outer ring areconsistent, reduces friction force between the bearing inner ring and the bearing outer ring during movement, effectively avoids the influence of bounce of a rotary shaft during rotation on the bearing inner ring, and improves the anti-seismic property of the bearing inner ring.

Owner:NINGBO CHUANGXIAN BEARINGS CO LTD

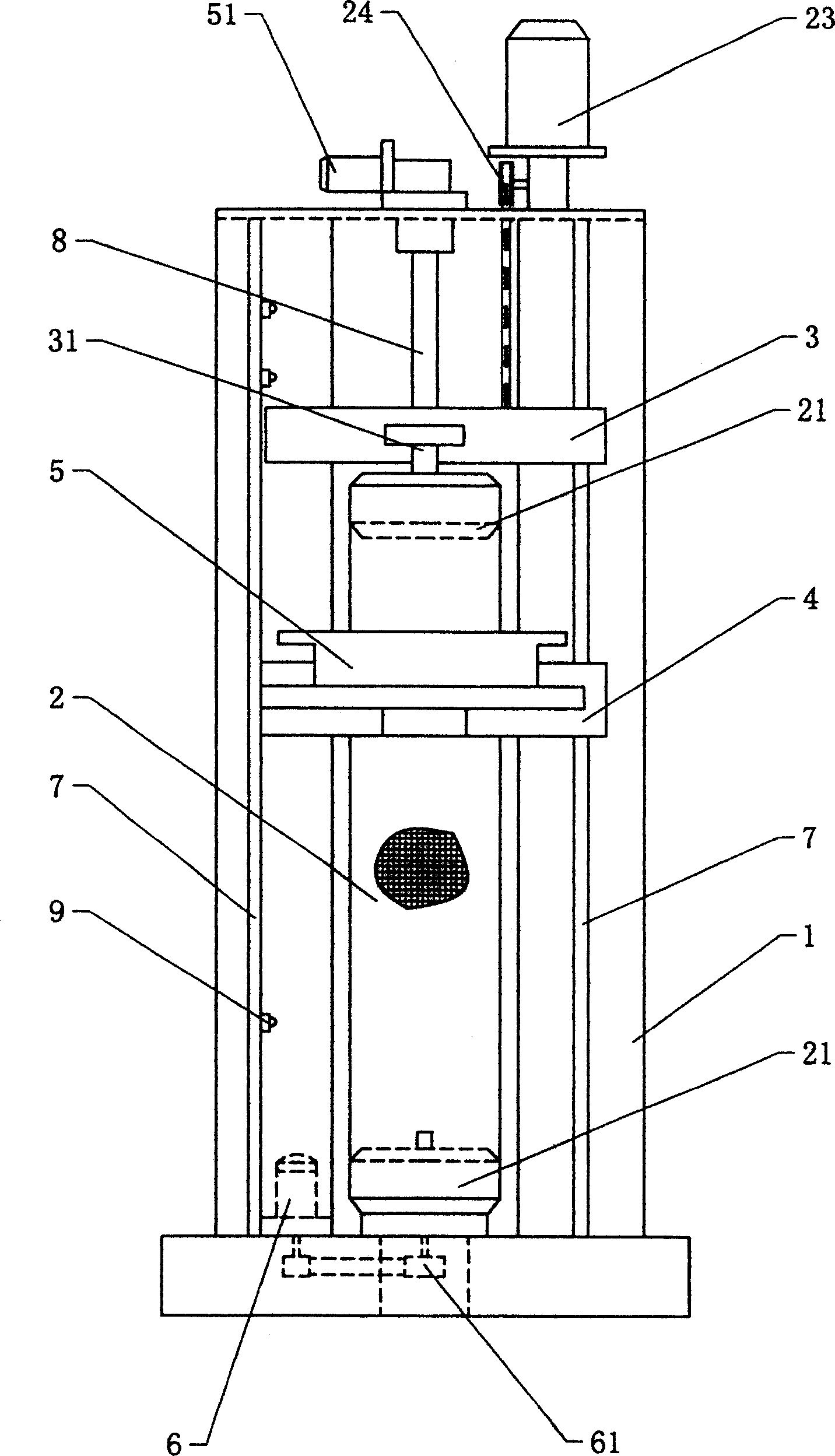

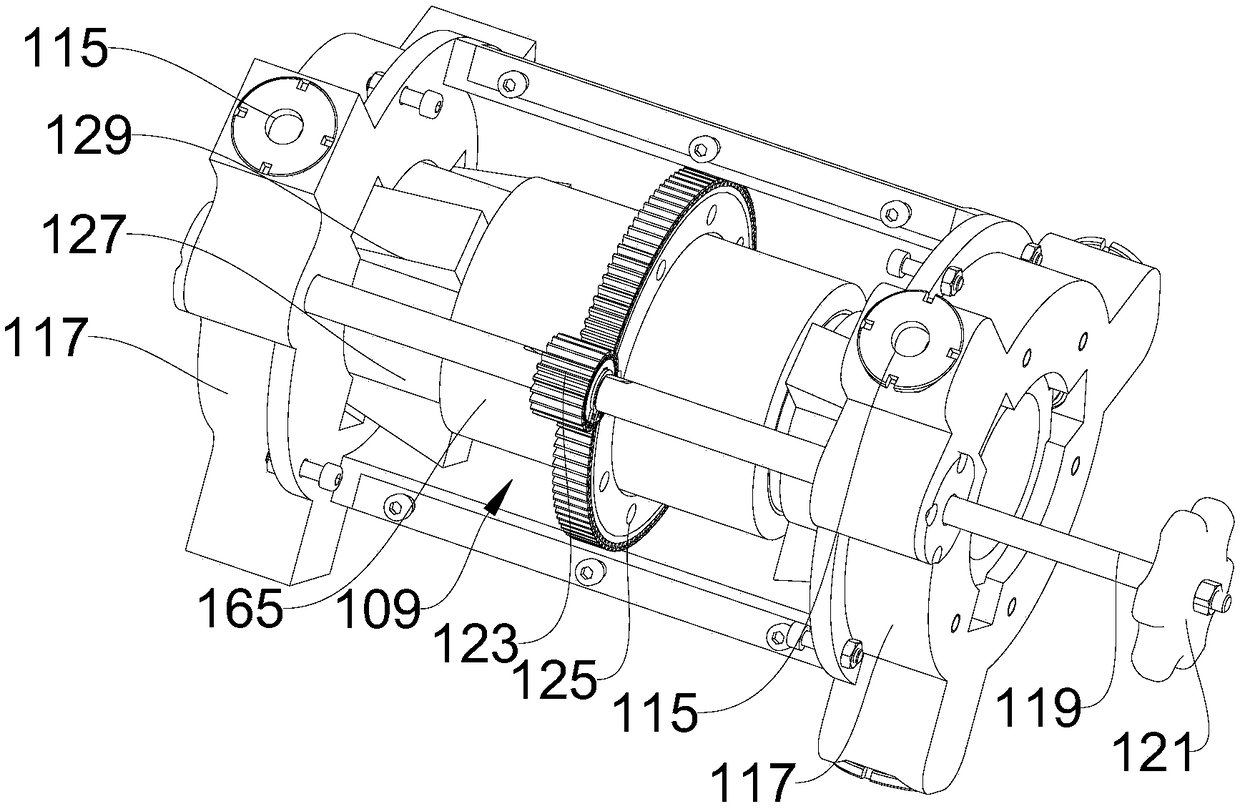

Automatic creel lifting device of rotor spinning machine

ActiveCN103422201AConsistent clearancePlay a regulatory roleContinuous wound-up machinesOpen-end spinning machinesYarnEngineering

The invention relates to an automatic creel lifting device of a rotor spinning machine. The automatic creel lifting device of the rotor spinning machine is characterized in that the device comprises an installation base, a yarn carrying rod piece, a first spring, a lifting arm, a first electromagnet, a lifting arm cam and a supporting arm, the yarn carrying rod piece is provided with a connecting arm, a yarn carrying rod part and a rotary shaft part, the rotary shaft part is installed on the installation base in a rotary mode, the first spring is connected between the installation base and the connecting arm, the lifting arm is fixed on the end portion of the rotary shaft part, the first electromagnet is fixed on the lower portion of the lifting arm, a first bearing is installed on the end portion of an iron core of the first electromagnet, the lifting arm cam is fixed on the rotary shaft, and the middle of the supporting arm is connected to the installation base in a rotary mode. According to the automatic creel lifting device of the rotor spinning machine, when a yarn breaking signal is transmitted to the first electromagnet, the first bearing is made in contact with the lifting arm cam rotating along with the rotary shaft, the movement of the lifting arm cam enables the lifting arm to deviate, then the whole yarn carrying rod piece is driven to deviate upwards to lift a creel, and then the automatic yarn lifting function of the creel is achieved.

Owner:太仓满金机械有限公司

Microwave device cavity, microwave device and antenna

PendingCN110994085AImprove stabilityLow costWaveguide type devicesAntennasMicrowaveMechanical engineering

The invention provides a microwave device cavity, a microwave device and an antenna. The microwave device cavity is suitable for installing a circuit board with a microwave circuit, and comprises an inner cavity, two opposite side walls of the inner cavity are provided with a first neck and a second neck, the first neck and the second neck face each other, the circuit board can be inserted into the first neck and the second neck, and the first neck is higher than the second neck, so that the lower plane of the first neck supports the back side of a pad. The first neck and a second neck are formed in the side wall of the inner cavity; a circuit board can be inserted into the inner cavity; for a thin circuit board, the heights of the first neck and the second neck are larger than the thickness of the circuit board, the first neck and the second neck are arranged in an up-down staggered mode, the lower plane of the first neck makes contact with the circuit board, the back side of the bonding pad of the circuit board is supported, and therefore the stability of the circuit board is improved when a cable is welded in a microwave device.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD

Wafer bearing mechanism convenient to replace

ActiveCN106298624ANot easy to replaceConsistent clearanceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

A wafer bearing mechanism convenient to replace is used for solving the problem that an existing wafer bearing mechanism is not liable to replace. The mechanism comprises a hot disc, a porcelain sleeve, a porcelain post and a special clamp, wherein a round counter bore is processed in the hot disc, the porcelain sleeve is placed in the counter bore, the porcelain post is placed in the porcelain sleeve, a bevel is fabricated at an edge of an inner hole of the porcelain sleeve, a spherical surface part of the porcelain post can be exposed, and a wedge-shaped groove is formed in the spherical surface part of the porcelain post; when the special clamp is loosened, an opening part of the clamp can pass through the spherical surface part of the porcelain post and sleeves the spherical surface part of the porcelain post, the porcelain post can be pulled out of the porcelain sleeve by upwards pulling the special clamp; and a spherical surface bulge is arranged at a top end of the porcelain post and is used for bearing a wafer, the height between the spherical surface bulge of the porcelain post and an upper surface of the hot disc is measured by a height gauge, the porcelain post is pulled out by the special clamp, a corresponding porcelain post is replaced to reach a required height, all bearing mechanisms on the hot disc are adjusted to the same height by using the same method, so that a gap between the wafer and the hot disc is maintained consistent. The wafer bearing mechanism can be widely applied to the technical field of semiconductor thin film deposition.

Owner:PIOTECH CO LTD

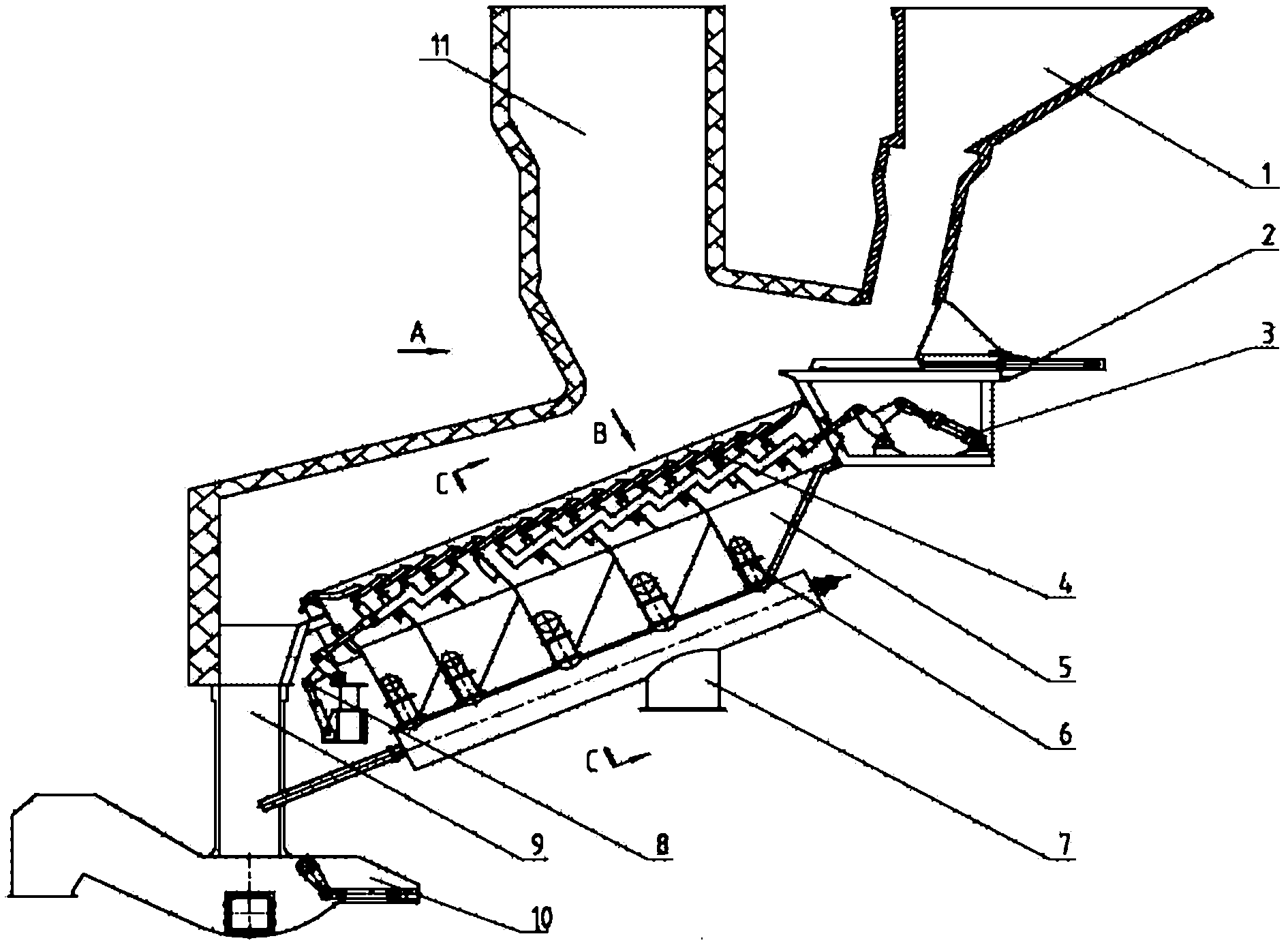

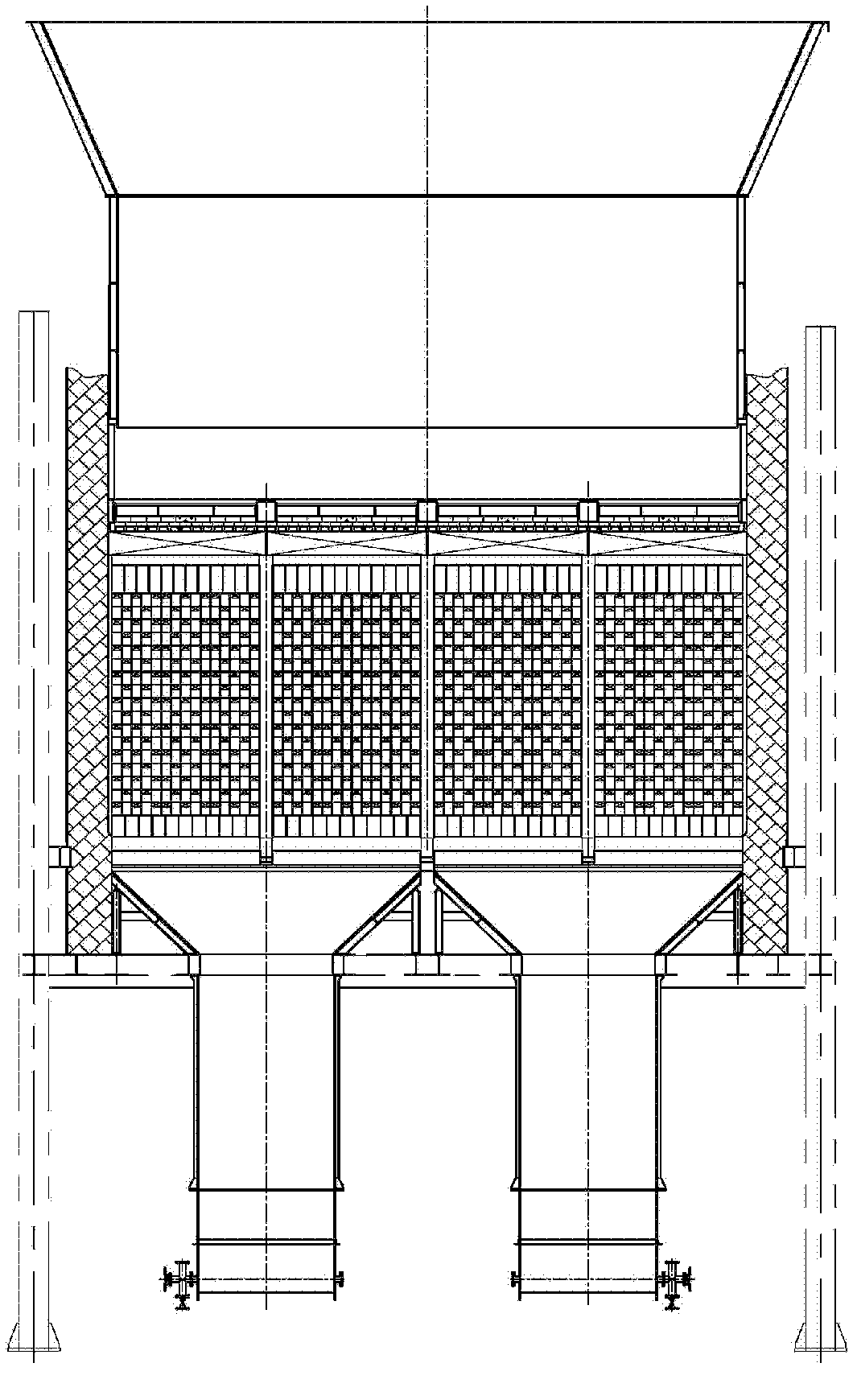

Pull up and down push driven reverse push garbage incinerator

ActiveCN102278763AAdjust the speed of movementExtension of timeIncinerator apparatusBurn treatmentSlag

The invention discloses a pull-up push-down driven reverse push garbage incinerator, which comprises a feed hopper, a feeding mechanism, grates, a heath, a grate lee chamber, a slag falling well and a slag discharger, wherein the grates are divided into static grates and dynamic grates, the static grates and the dynamic grates are arranged alternately up and down to form a column, a dynamic gratedrive consists of an upper section and a lower section, the driving mechanism of the upper section is arranged at the upper end of the grates, and the driving mechanism of the lower section is arranged at the lower end of the grates; and an air chamber is formed below the grates, and an electric air door is arranged on an air inlet pipeline of the air chamber. The garbage incinerator has the advantages that: the movement speed of the grates of each section is adjustable, and the grates can be properly lengthened, so that the burning treatment time is prolonged; the incinerator of different capacity can be combined; and the grates of each column are independently driven and do not interfere with one another, so the incinerator has simple structure and can be modularized. The intertwined garbage cluster is easily scattered, and the garbage is mixed uniformly and burnt stably; the incinerator is provided with a heat expansion absorption device, so that the grate sheets are not blocked due to expansion; and the air quantity of the air chamber can be adjusted, so that the garbage can be stably burnt.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

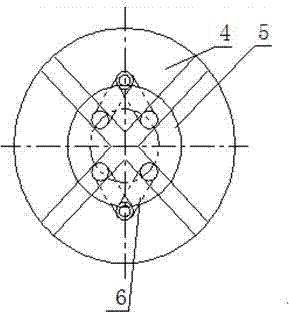

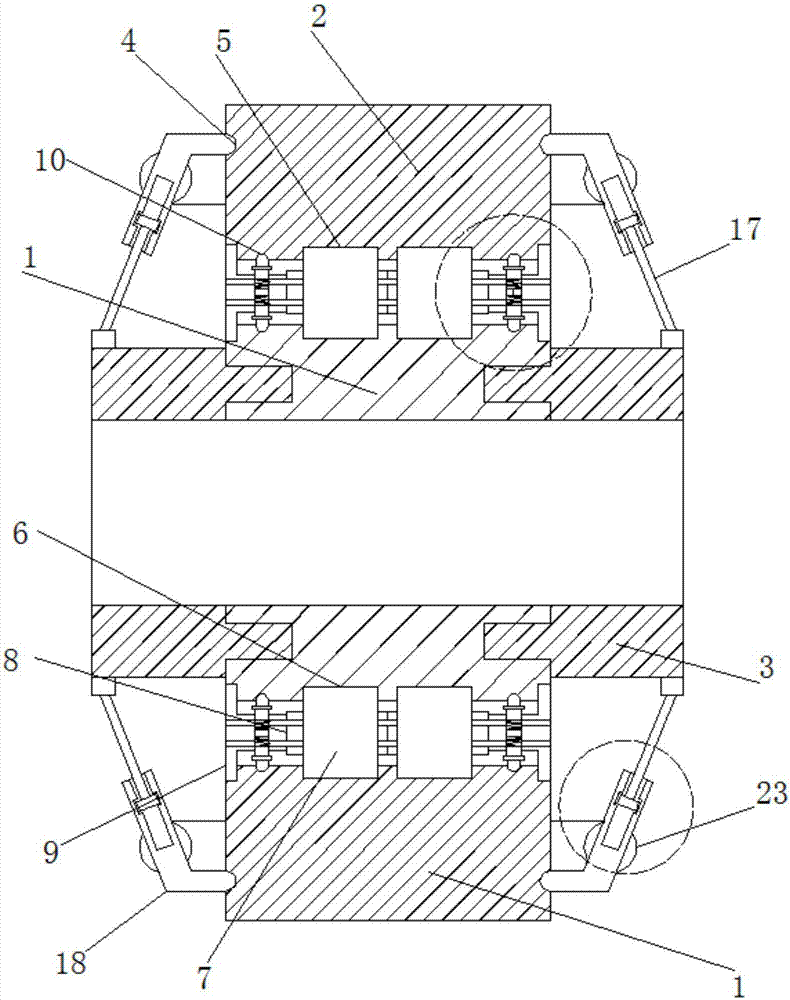

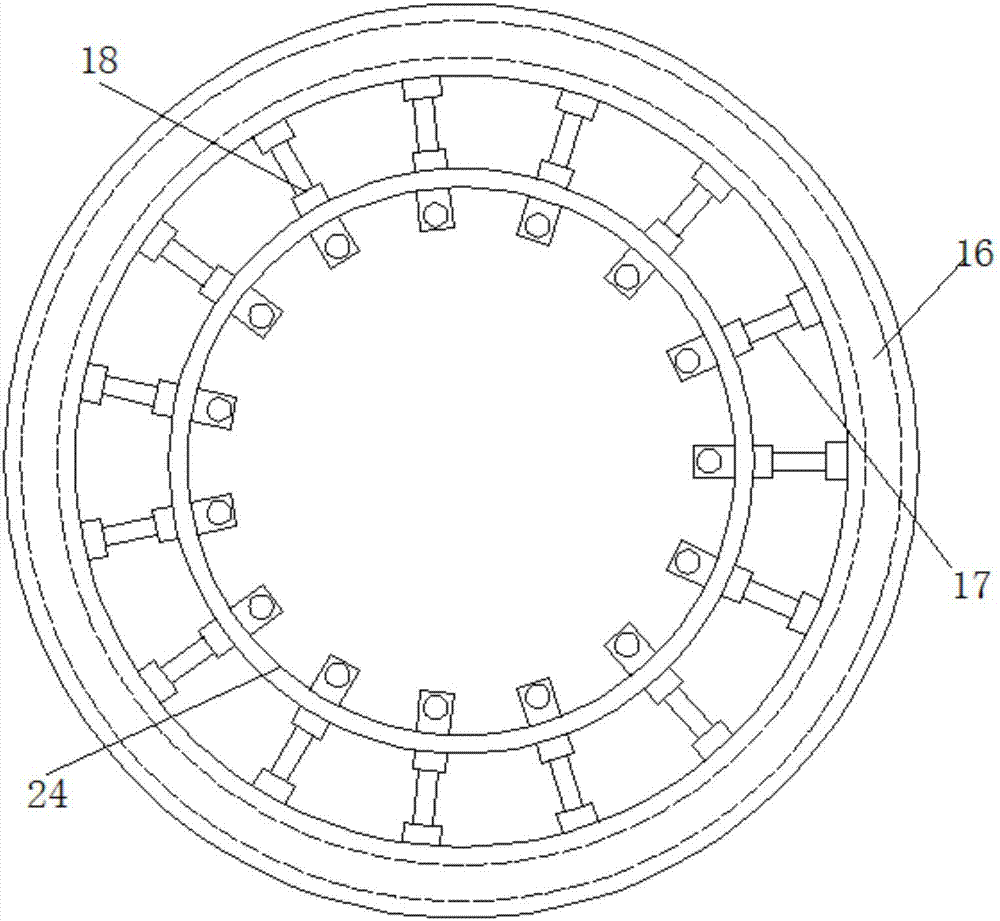

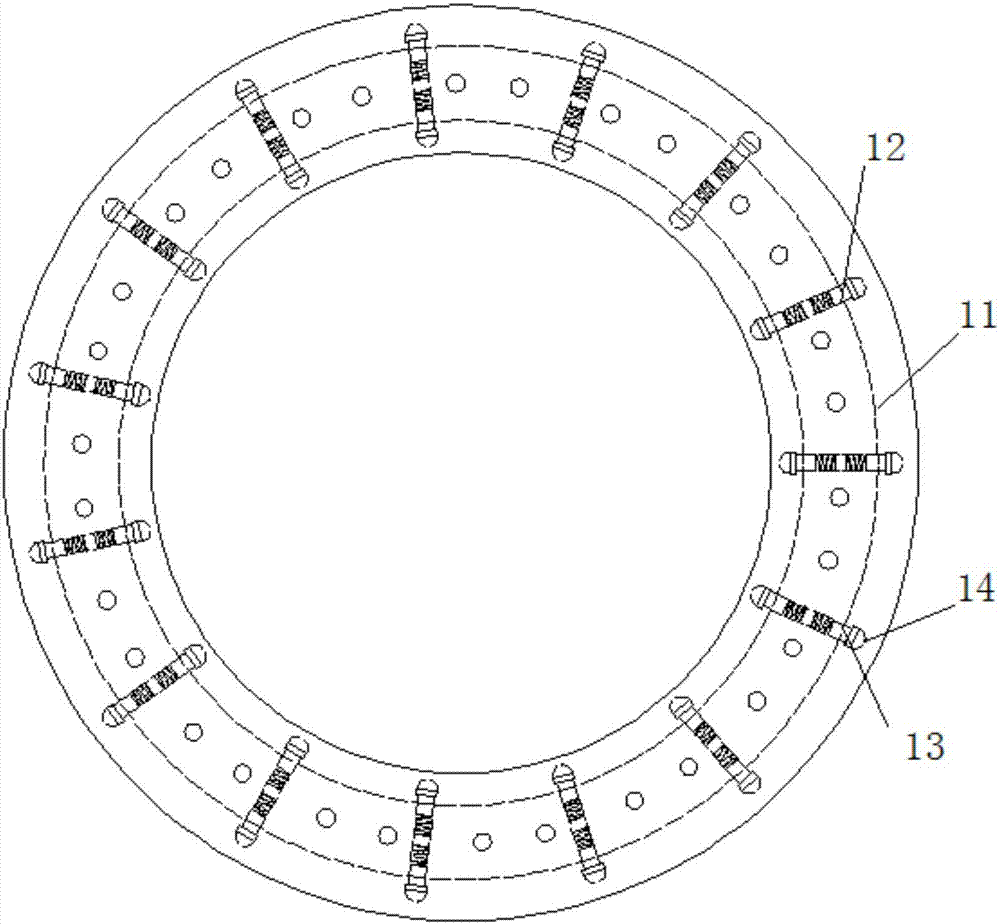

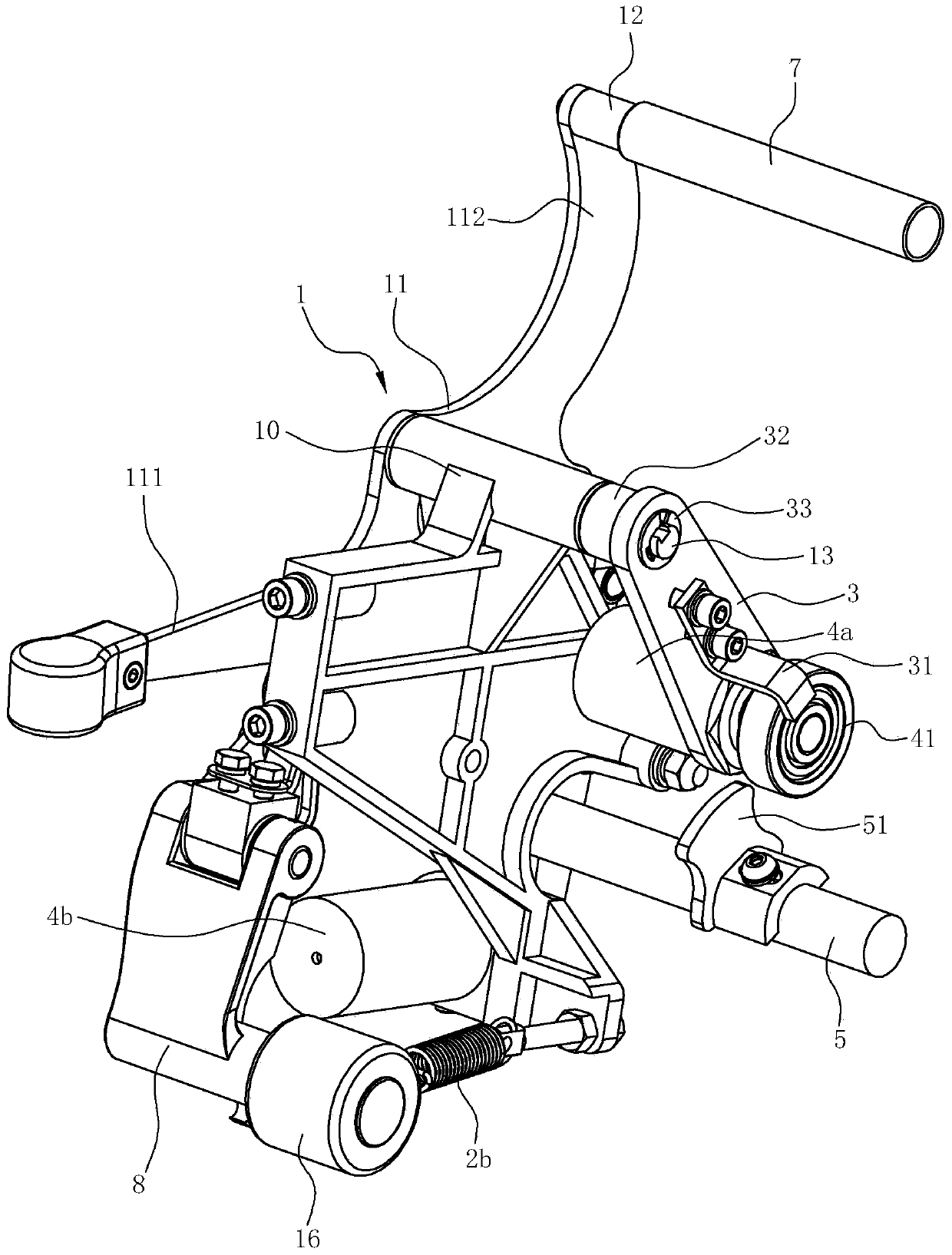

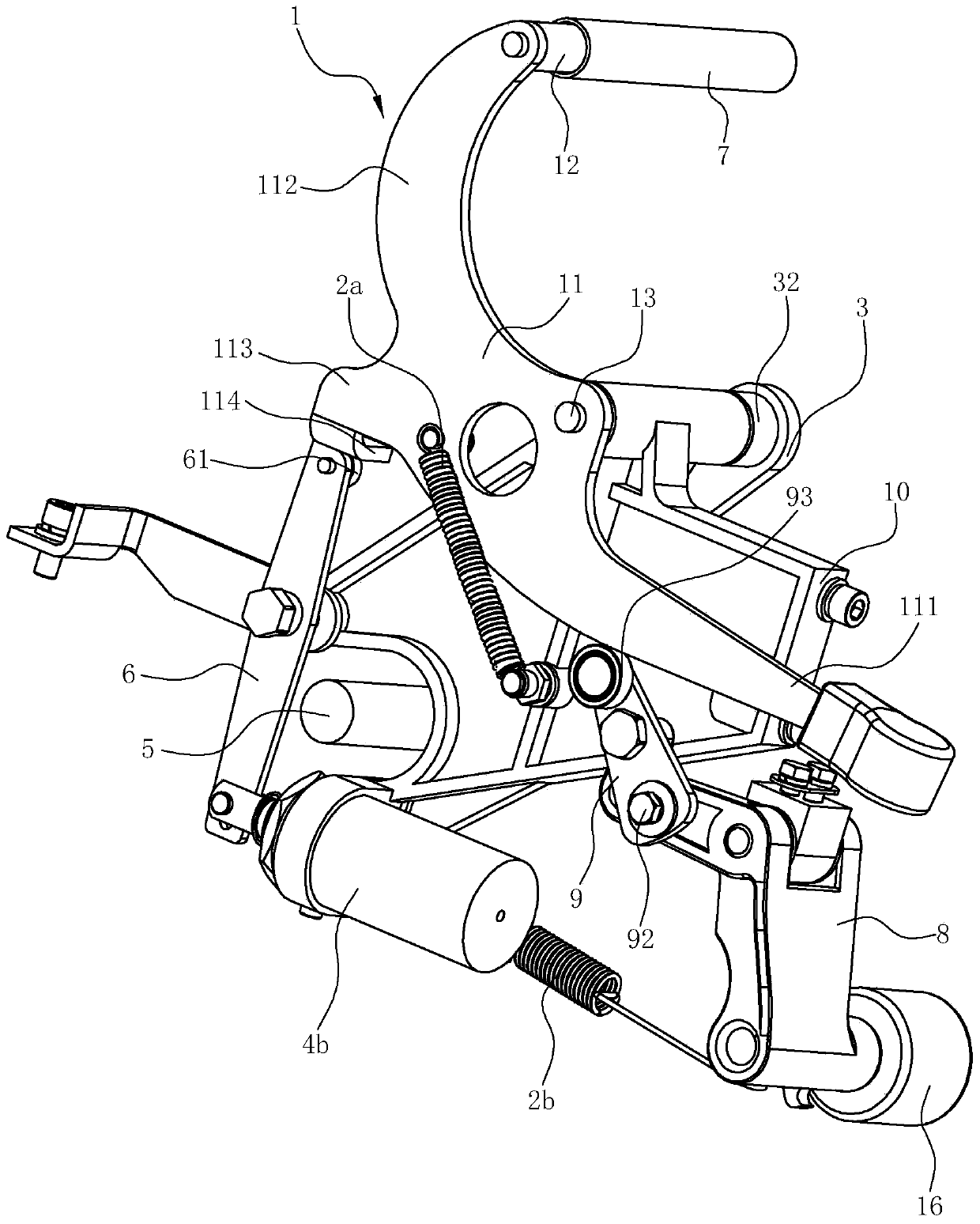

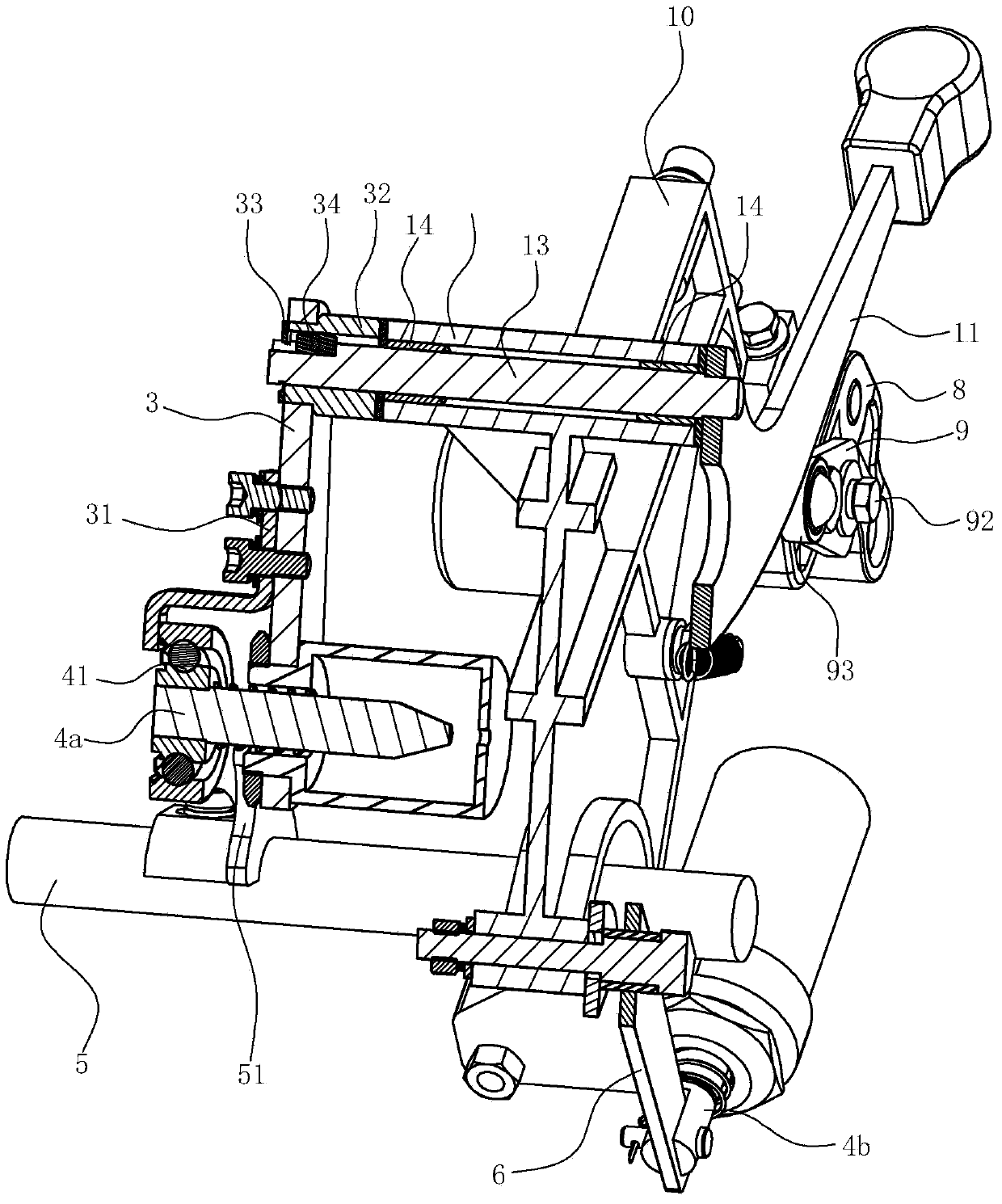

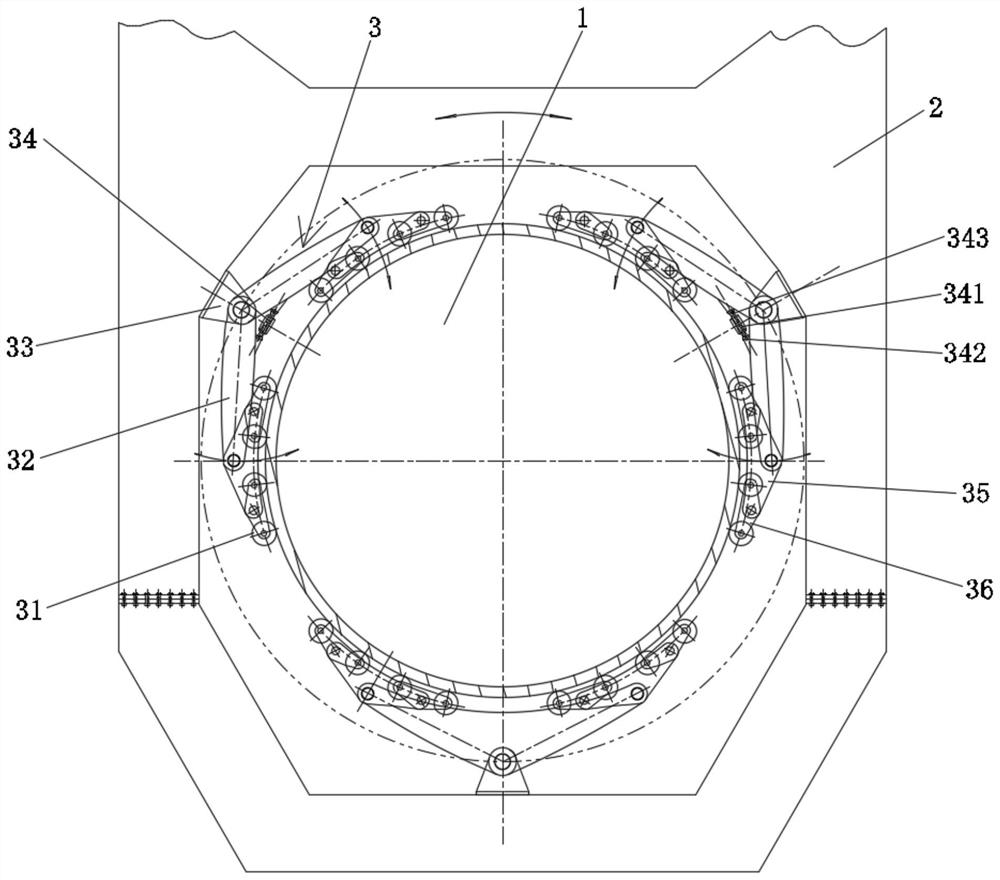

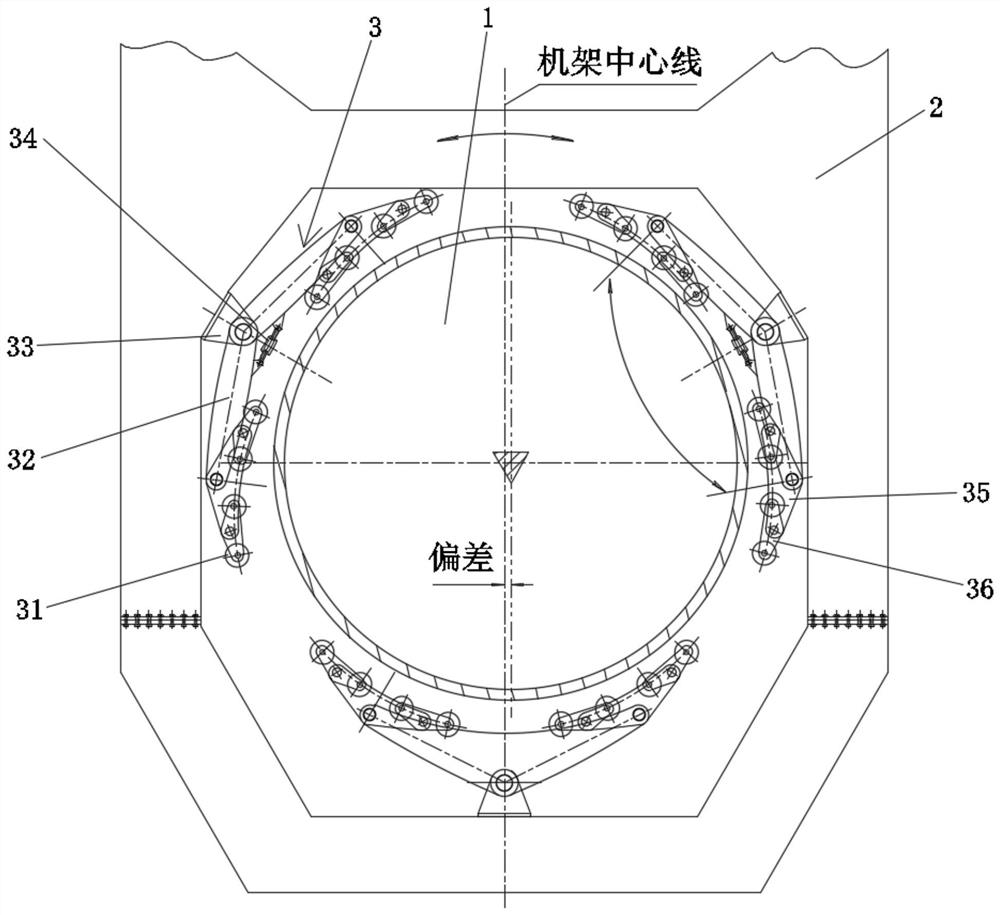

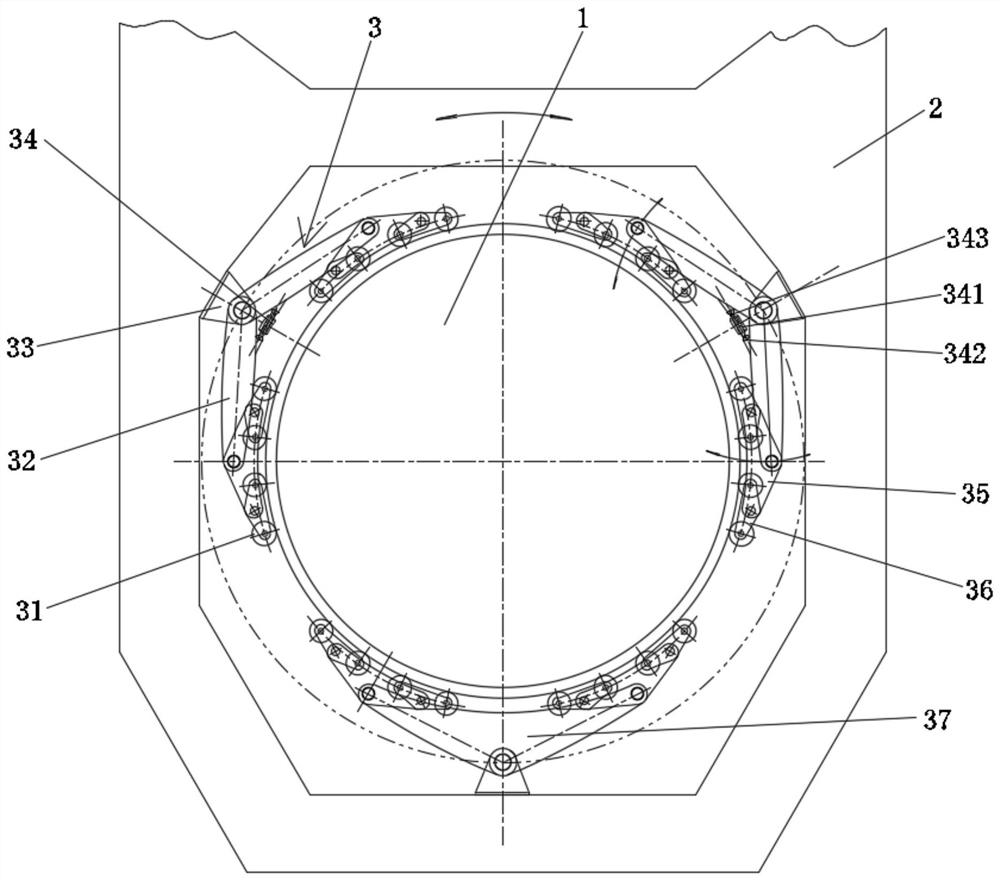

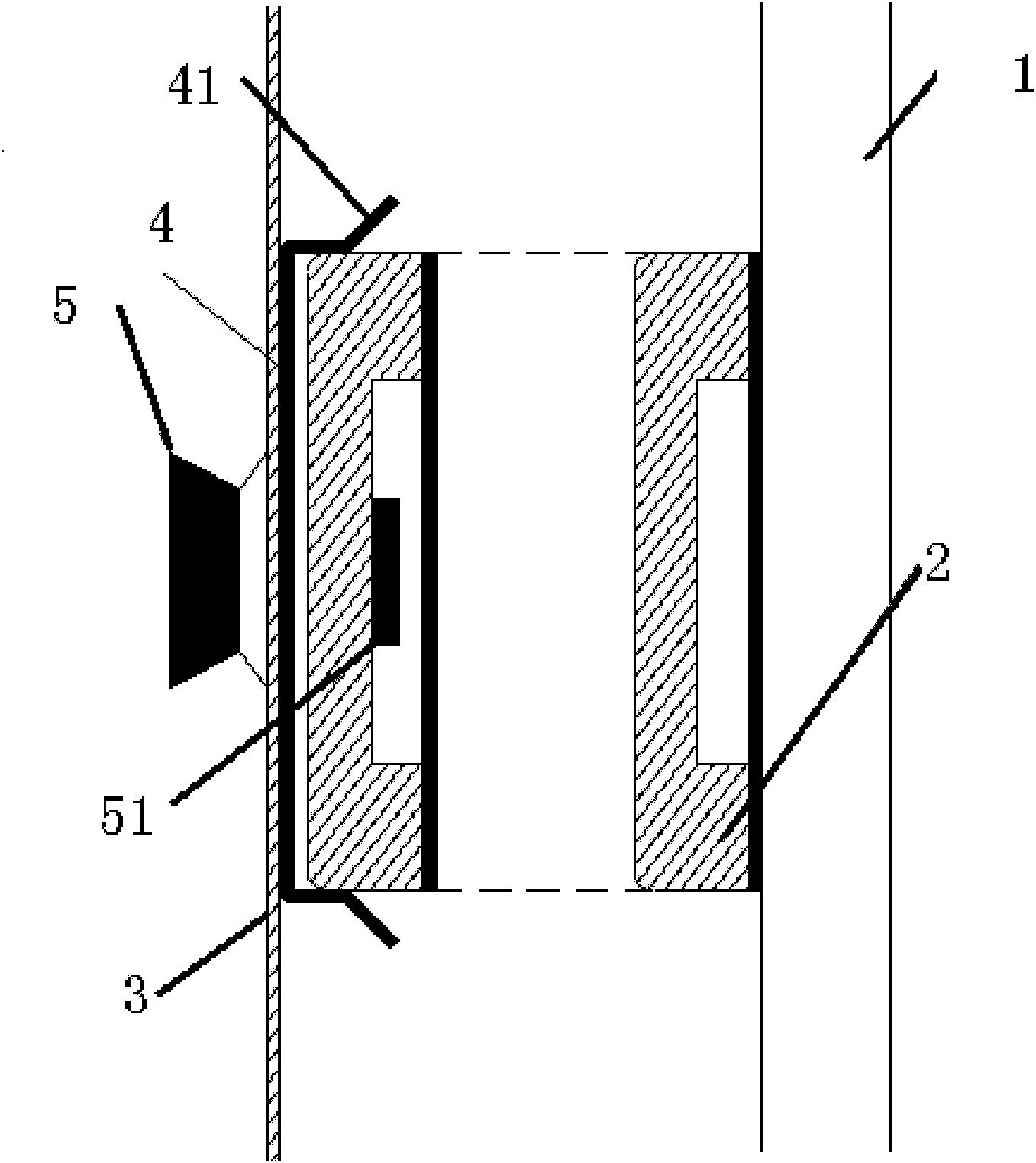

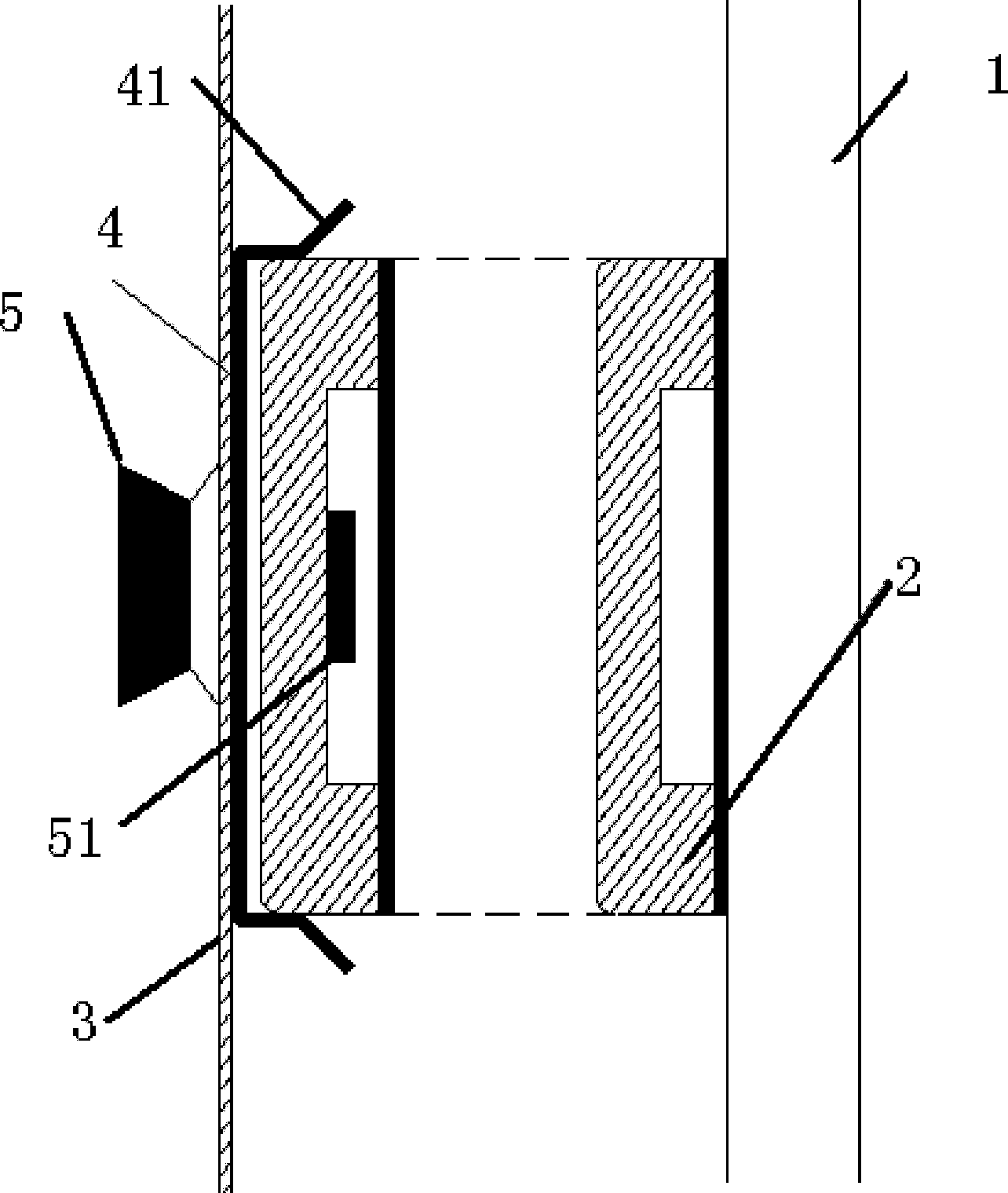

Self-centering mechanism for large-diameter centering rotary equipment

ActiveCN112664574AAchieve displacementPrecise positioningBearing unit rigid supportEngineeringStructural engineering

The invention discloses a self-centering mechanism for large-diameter centering rotary equipment. The rotary equipment comprises a fixed part and a rotating part, wherein the self-centering mechanism is arranged between the fixed part and the rotating part; one of the fixed part and the rotating part is cylindrical while the other one is provided with a corresponding inner cavity; the cylinder is located in the inner cavity; a roller path is arranged on the outer circumferential surface of the cylinder; the self-centering mechanism comprises at least two groups of rolling units, wherein at least one group of rolling units are adjusting units used for adjusting the position of the rotating part; at most one group of rolling units are positioning units, and the positioning units are arranged at the positioning reference of the fixed part; and the rotating part concentrically rotates relative to the fixed part through the adjusting units. According to the self-centering mechanism for the large-diameter centering rotary equipment, an aligning tool does not need to be additionally arranged, automatic centering is achieved, the assembly precision of a rolling pair is high, stress is balanced, and the self-centering mechanism is suitable for an inner centering outer rotation mechanism or an outer centering inner rotation mechanism.

Owner:TIDFORE HEAVY IND

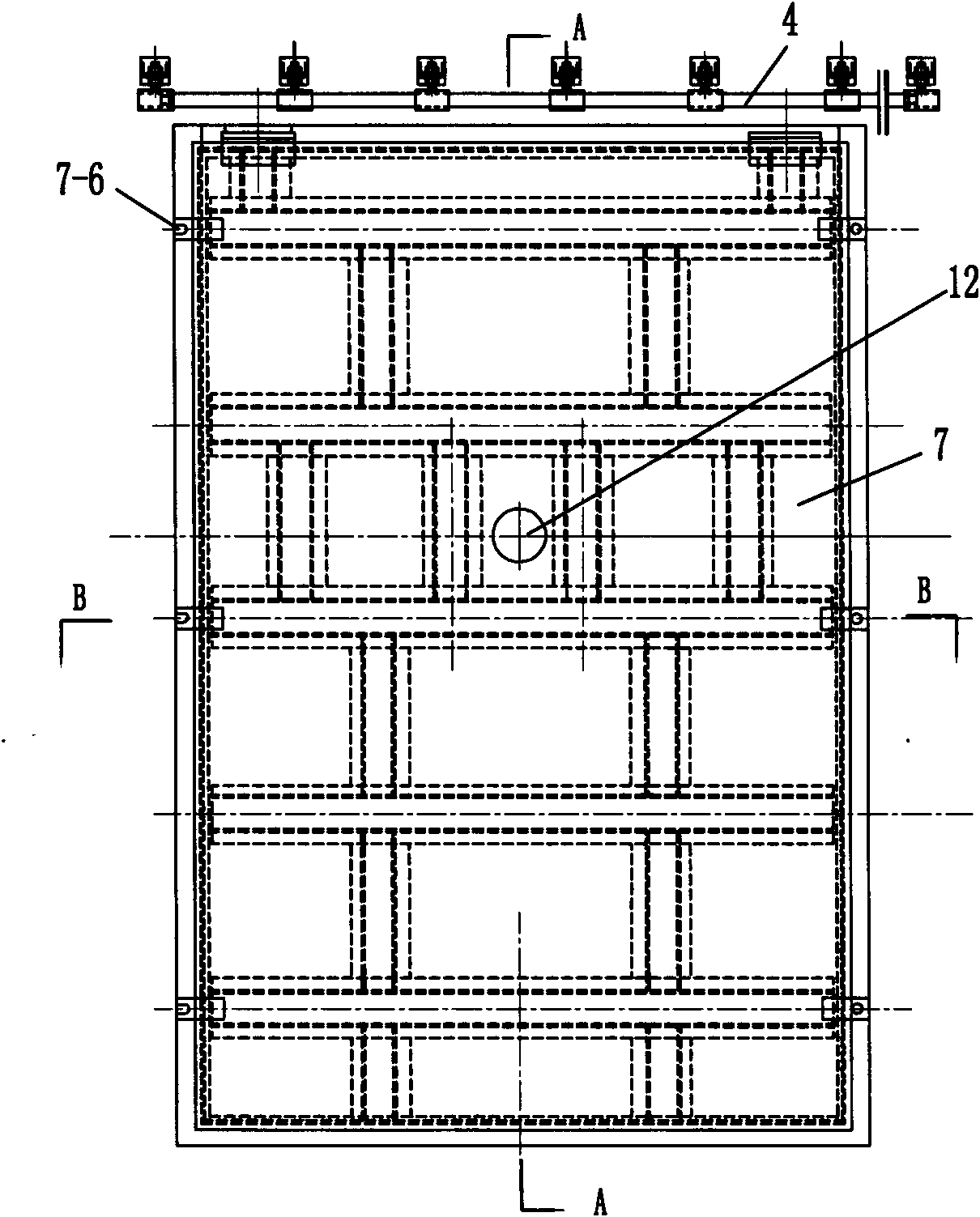

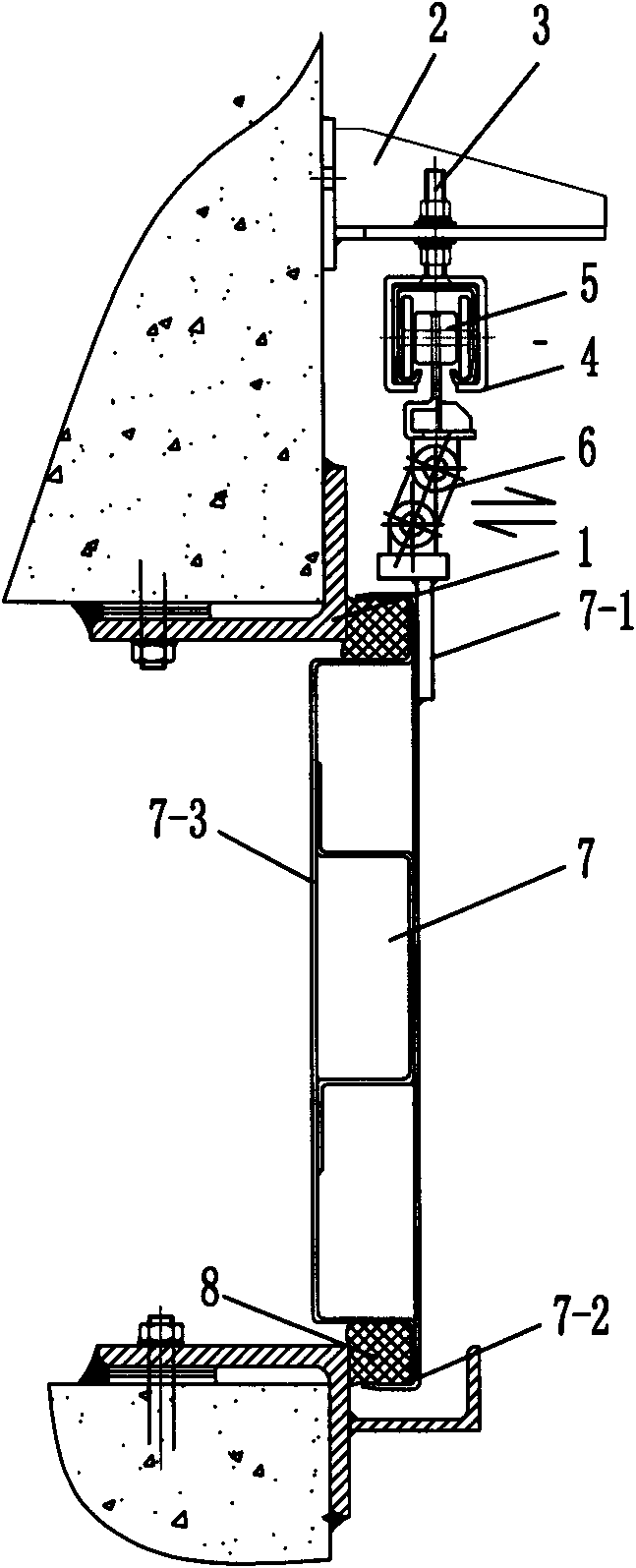

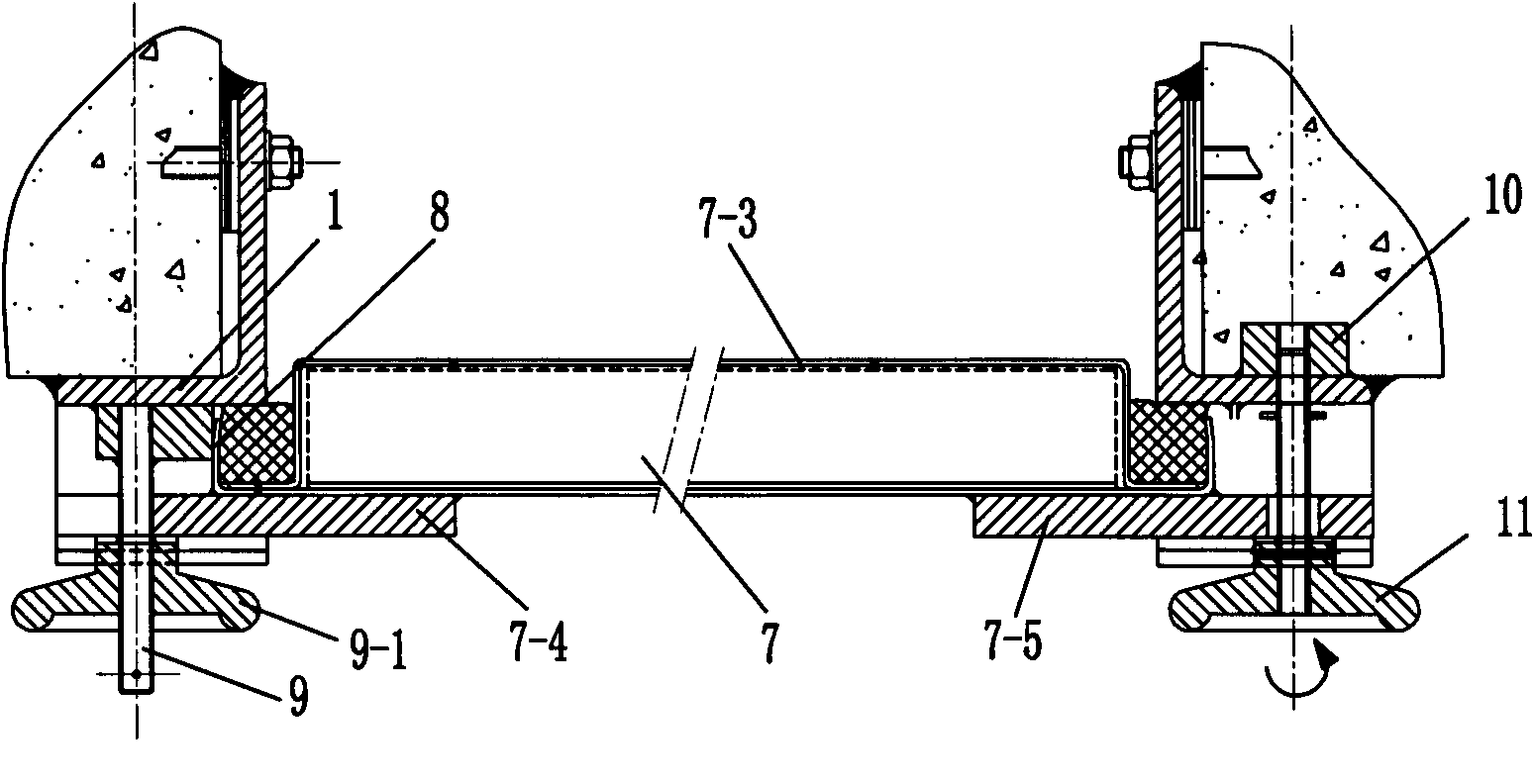

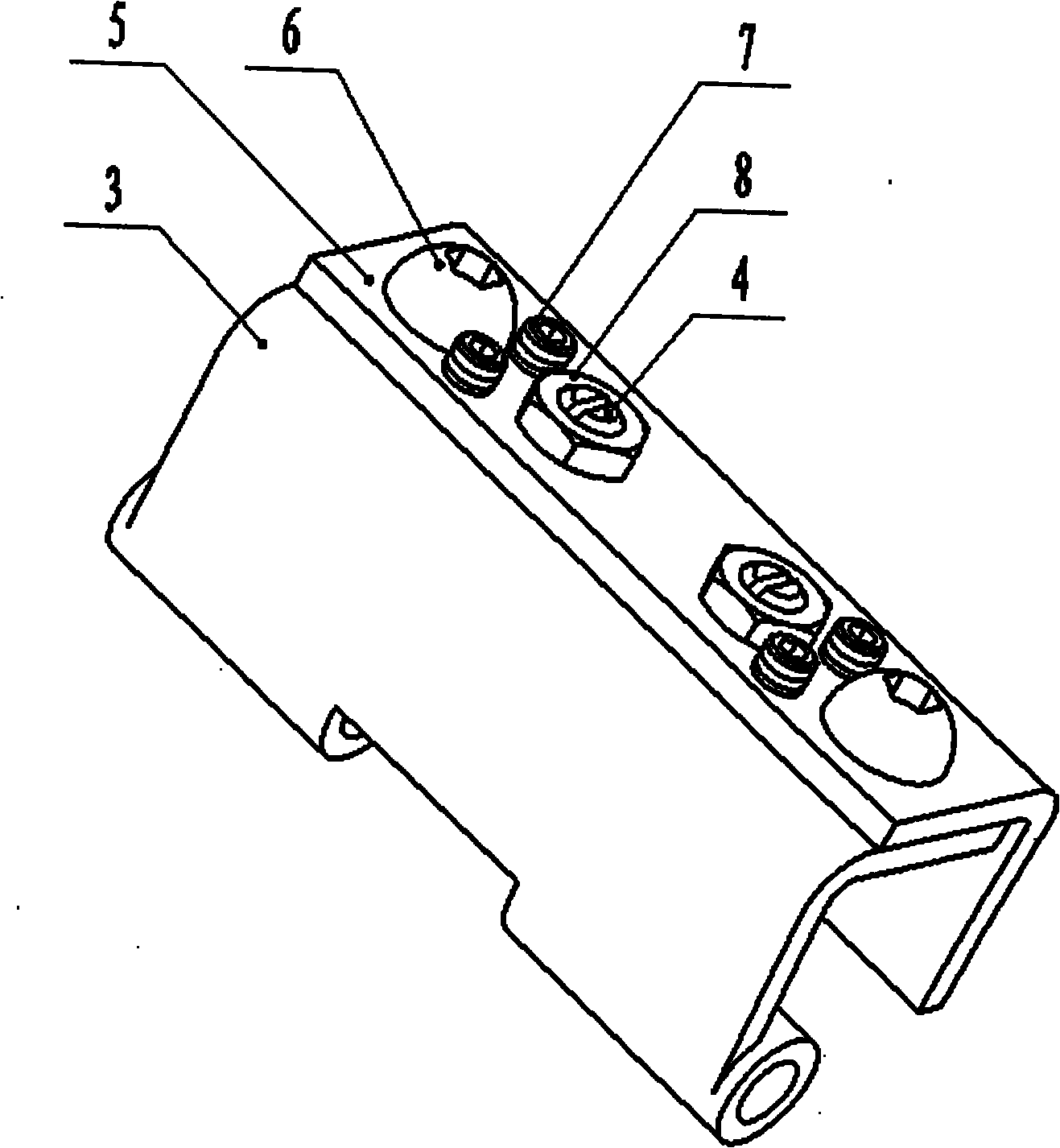

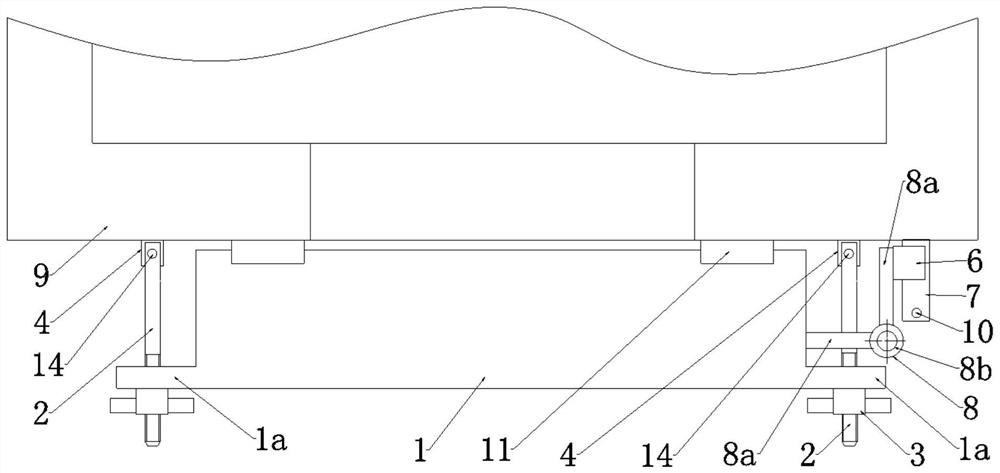

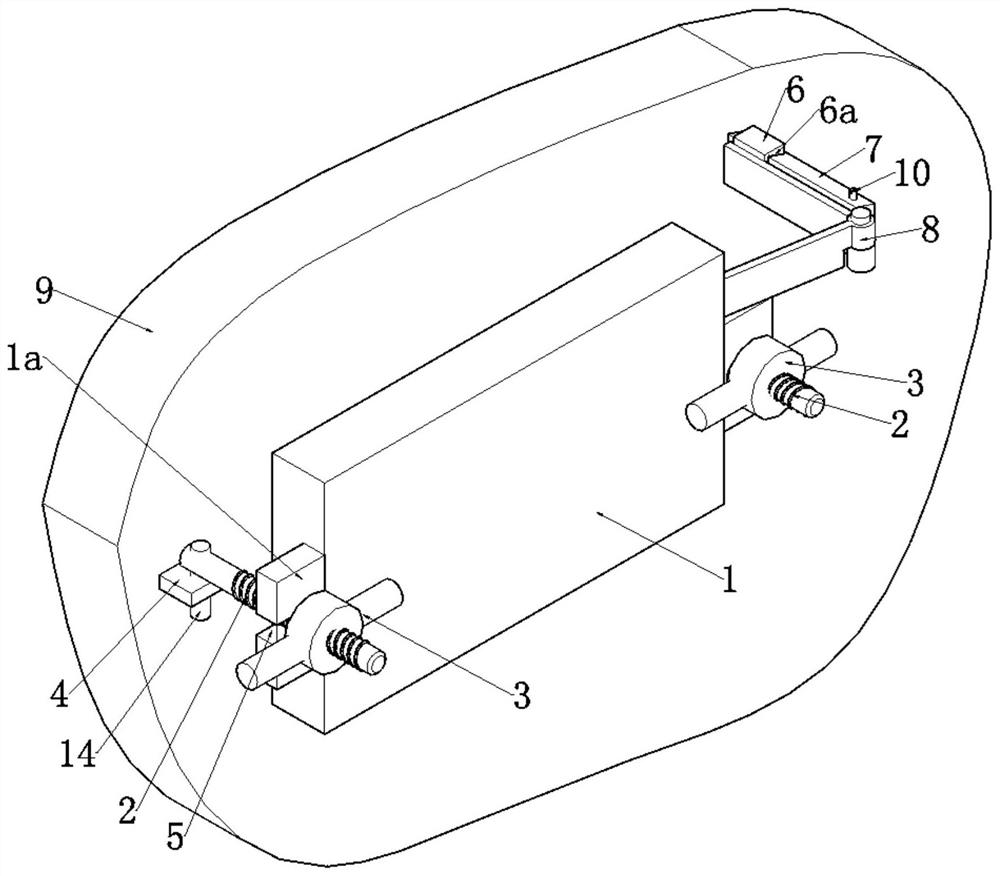

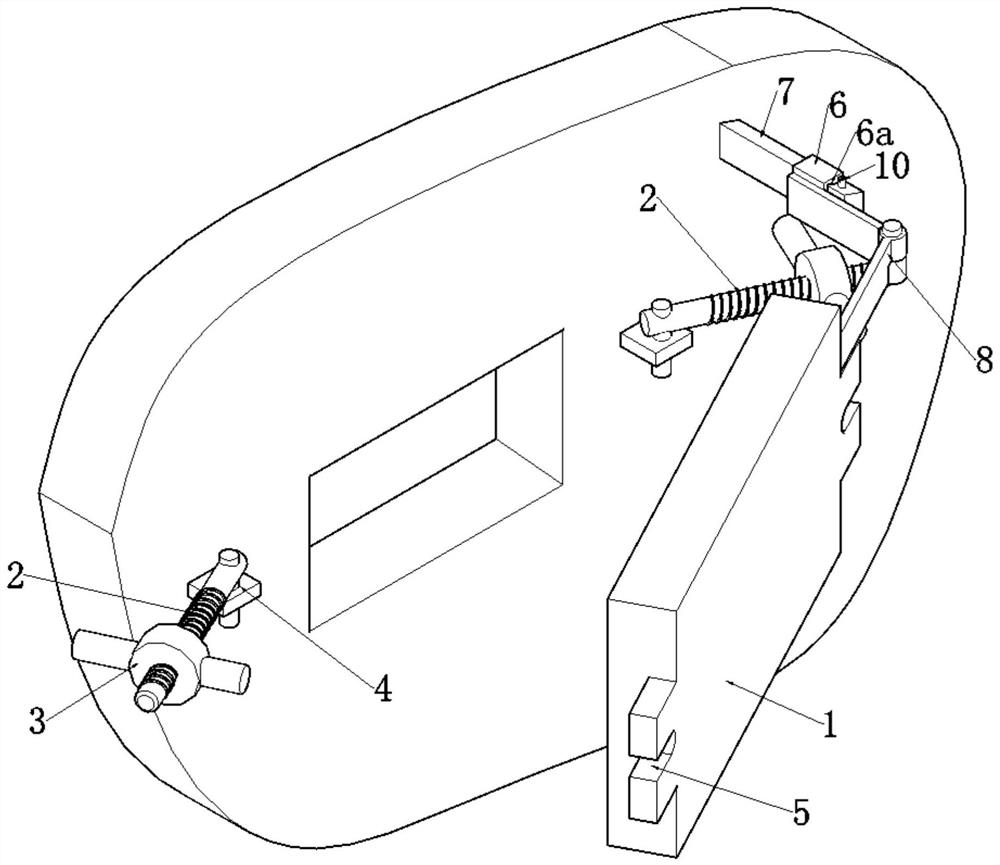

Switch cabinet door plank lifting mechanism

InactiveCN102611009AConsistent clearanceQuality assuranceSubstation/switching arrangement casingsEngineeringSwitchgear

The invention relates to a switch cabinet door plank lifting mechanism, comprising a cabinet body frame and a door plank. A first door lifting fixed part is fixed on one side of a cabinet body frame lock and is plate-shaped; a second door lifting fixed part is arranged on one side of a door plank lock; and the middle part of the second door lifting fixed part is linear, and each of two ends of the second door lifting fixed part has a buckle structure corresponding to the plate shape of the first door lifting fixed part. The switch cabinet door plank lifting mechanism has the beneficial effects that after the door plank is closed, the gap of the door plank is automatically adjusted to ensure that the gap of each door plank is the same, so that the door plank of a switch cabinet is not easy to droop, and the quality of the switch cabinet is ensured.

Owner:SHANGHAI PEOPLE ELECTRICAL APPLIANCE GROUP

Improved cylinder gluer

InactiveCN1746771AGuaranteed uptimeQuality improvementPhotomechanical coating apparatusScreening processesEngineeringLimit switch

A modified spreading machine of round screen consists of round screen seat on base plate of body frame, dop and its slide rest for round screen seat on body frame, spreading pot and its seat, guide screw, linear track, servo motor and feed in motor. It is featured as driving guide screw to make spreading pot seat move along linear track to let spreading pot slide along peripheral surface of round screen by servo motor for carrying out glue spreading, using limit switch to control servo motor for varying speed of spreading pot.

Owner:郝强

Butt welding assembly method for stainless steel tubes

InactiveCN112427826AImproved accuracy and stabilityClearance and Shrinkage ConsistentWelding/cutting auxillary devicesAuxillary welding devicesSteel tubeContact position

According to a butt welding assembly method for stainless steel tubes, multiple pieces of triangular embedded iron are placed in a butt welding seam between the circumferences of the stainless steel tubes, and by adjusting the depths by which the triangular embedded iron is inserted into the butt welding seam, the size of the welding seam gap between the stainless steel tubes is controlled and kept consistent in the circumferential direction, and spot welding positioning is conducted at the contact position. Argon filling protection is not needed, the operation efficiency is improved, the welding quality of the stainless steel tubes is improved, and the butt welding assembly method has the advantages of being simple in structure, convenient to use, low in process cost, high in precision and stability, wide in application range and the like.

Owner:CSSC MES DIESEL

Automatic keyboard keycap assembling equipment and process

The invention discloses automatic keyboard keycap assembling equipment and process, belongs to the technical field of keyboard assembling equipment, and particularly relates to the automatic keyboardkeycap assembling equipment and process. Keycaps are mounted in a mold, and a protective film material is injected into the mold through injection molding equipment, so that a formed protective film is more attached to the keycaps. Smaller garbage is prevented from entering a gap, the waterproof effect is improved, meanwhile, the smaller garbage on the protective film is convenient to clean, the protective film can be prevented from falling off due to friction between the keycaps in the future use process, the formed protective film has certain elasticity, the durability of the product is improved, convenience is brought to a user,in the aspect of the installation process, the keycaps are limited through suction holes matched with the keycaps in shape and position, then suction cups in thesuction holes are used for sucking and fixing the keycaps, finally, a keyboard and the keycaps are installed in a unified manner, and operation is easier and more convenient.

Owner:昆山雷钜创鑫达塑胶制品有限公司

Thermal start-up control method of steam turbine in trough solar thermal power station

ActiveCN112065513BControl clearancePressure balanceMachines/enginesSafety/regulatory devicesTemperature controlPressure rise

This application relates to the technical field of start-up control of steam turbines, in particular to a method for temperature-state start-up control of steam turbines in trough-type solar thermal power plants, which includes: when the shaft seal is put into operation, delay the start-up time of the shaft plus fan, and when the low-pressure cylinder When the pressure of the shaft seal rises to 5KPa, start the shaft adding fan; the temperature of the steam supplied to the shaft seal is controlled to be 20-25°C higher than the temperature of the high-pressure cylinder to ensure the superheat of the steam supplied to the shaft seal; The compressed air source of the oil gear is withdrawn, and it is re-introduced after the steam turbine is connected to the grid; when the warm state is started, the temperature of the shaft seal behind the high-pressure cylinder is controlled at 160-175°C; When controlled below ‑0.2mm. This application has the effect of being able to solve the temperature start-up stability of the new unit of the domestic trough-type photothermal power station, ensure the smooth start-up of the new-type steam turbine, and meet the use requirements of the new-type steam turbine of the trough-type photothermal power station.

Owner:中广核太阳能德令哈有限公司 +1

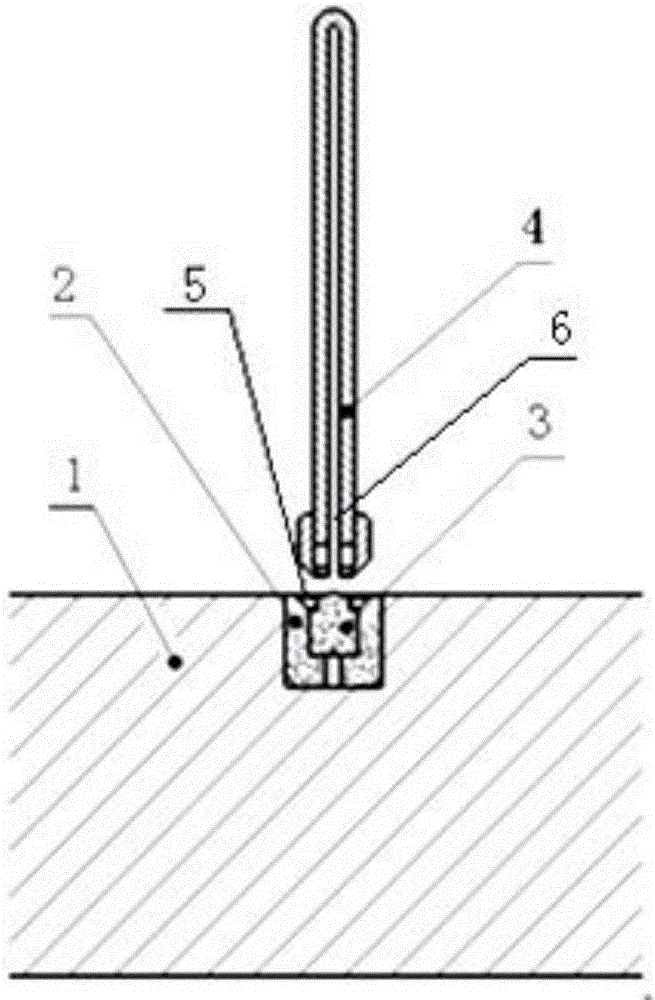

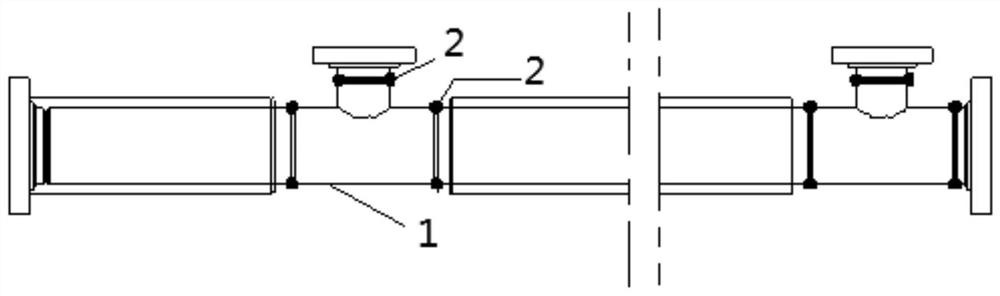

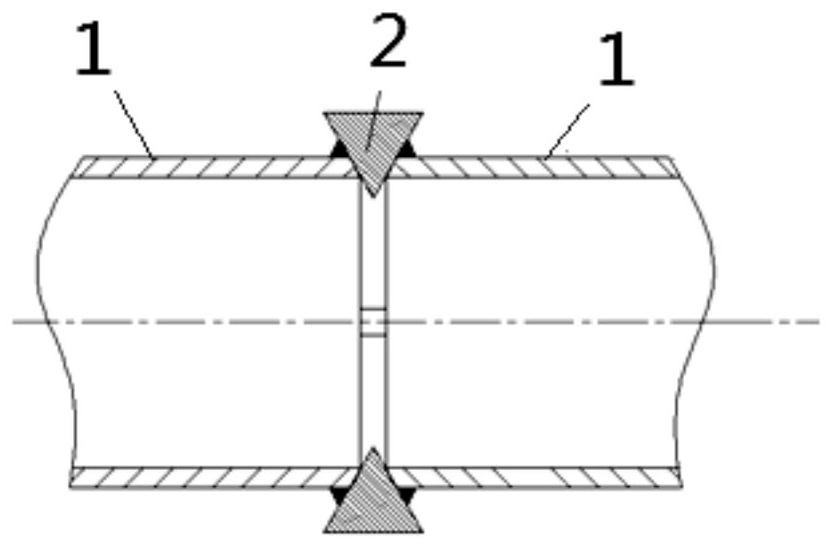

Weld joint back face gas protection system

PendingCN109014509AConsistent clearanceGood gas protection effectShielding gas supply/evacuation devicesShielding gasEngineering

The invention discloses a weld joint back face gas protection system and relates to the technical field of welding. The system includes a gas protection device, a positioning mechanism and a drive mechanism. The gas protection device comprises a back protection gas cover, a water cooling component and a gas protection component, and the gas protection component is used for providing protection gasfor the back protection gas cover; and the water cooling component is used for providing cooling water for the back protection gas cover to simultaneously cool the back protection gas cover and the protection gas. The positioning mechanism is used for achieving automatically centering to the axis of a pipe with the inner wall of the pipe as a positioning reference, and is used for ensuring that gaps between the back protection gas cover and the inner wall of the pipe to be consistent in the circumferential direction. The drive mechanism is used for driving the back protection gas cover to rotate. Meanwhile, the driving device drives the back protection gas cover to rotate, meanwhile, the gas protection device is used for cooling the back protection gas cover, the protection gas cooling and weld joint gas protection, and the good gas protection effect is achieved.

Owner:CHINA-UKRAINE INST OF WELDING GUANGDONG ACAD OF SCI

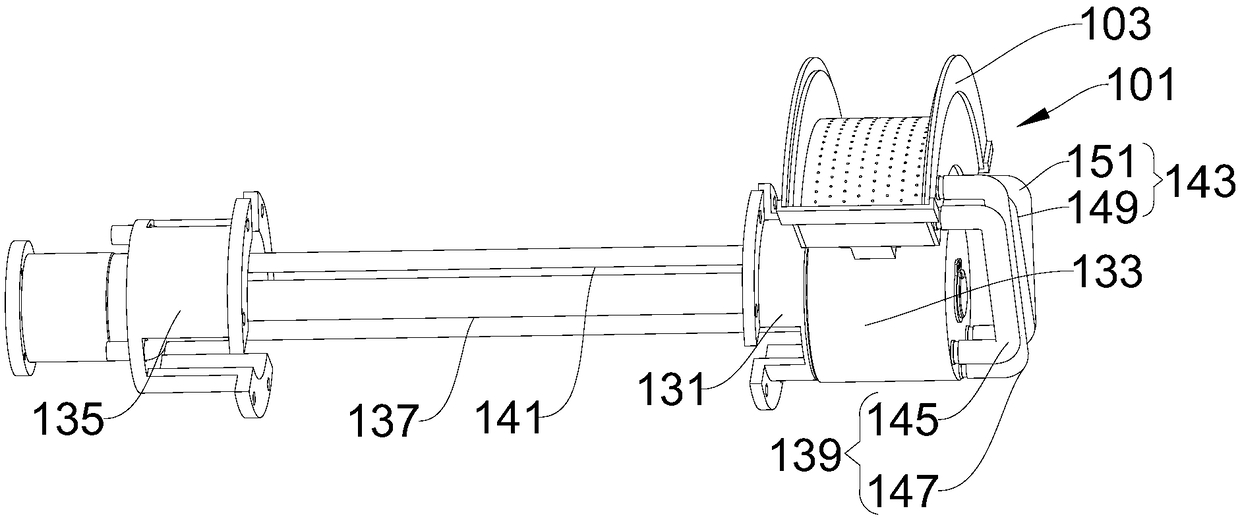

Permanent magnet motor and manufacturing method thereof

ActiveCN102545427BReduce workloadRaise the gradeMagnetic circuit rotating partsManufacturing stator/rotor bodiesSteel platesMagnet

PROBLEM TO BE SOLVED: To provide a function for confirming that an adhesive agent is filled uniformly between a permanent magnet and a rotor core over the whole area with ease and with certainty when adhering the permanent magnet to the rotor core in a permanent magnet motor. SOLUTION: In a permanent magnet motor, a groove matched to a shape of a permanent magnet is formed to an electromagnetic steel plate constituting a rotor core. An adhesive agent reservoir recessed part to which an adhesive agent flowing out from between bottom surfaces of both parties via a gap between a side wall of the groove and a side wall of the permanent magnet is introduced when the permanent magnet is pushed in the groove to be adhered by the adhesive agent applied between the bottom surfaces of both parties, is formed at an upper end of the side wall of the groove. The quantity of the adhesive agent stored in the recessed part can be visibly recognized to confirm an application state of the adhesive agent. COPYRIGHT: (C)2012,JPO&INPIT

Owner:HITACHI IND EQUIP SYST CO LTD

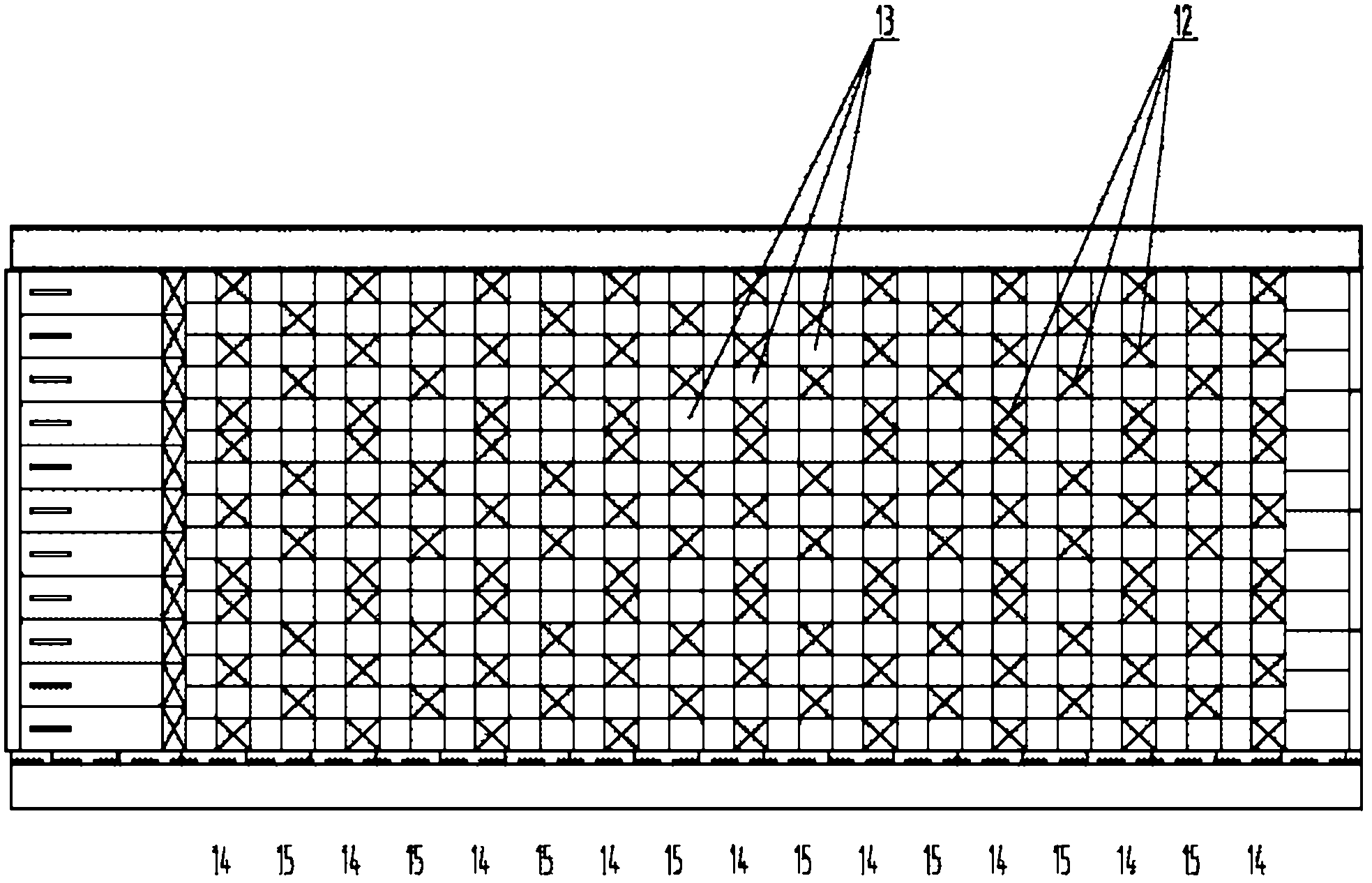

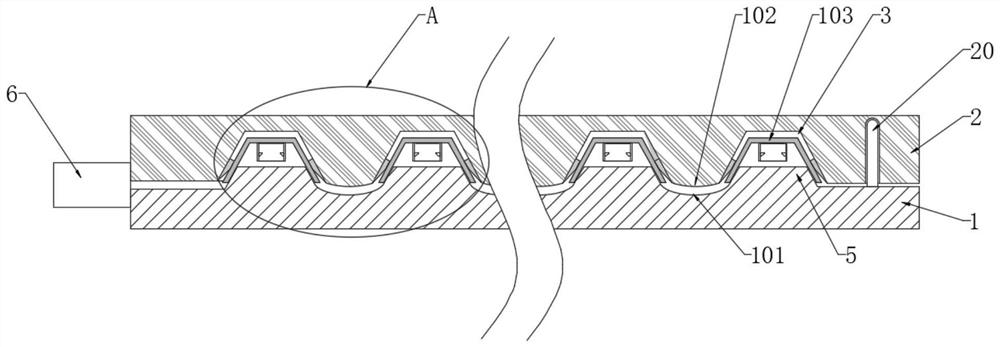

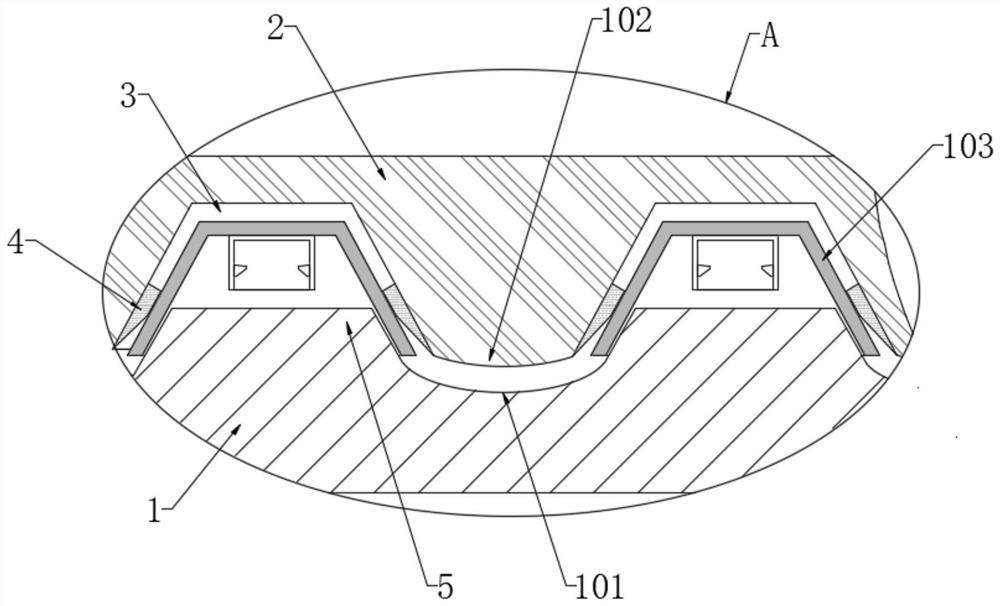

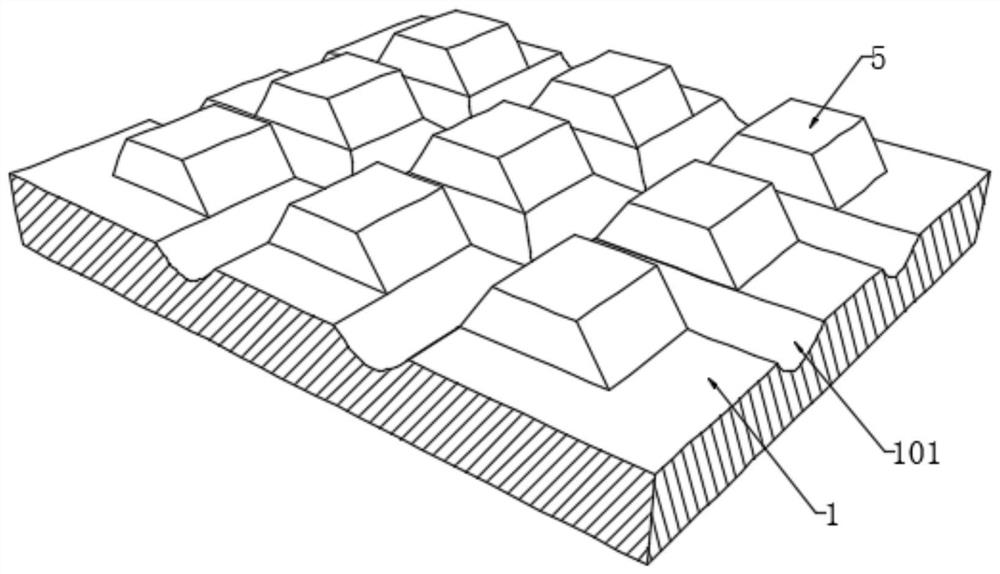

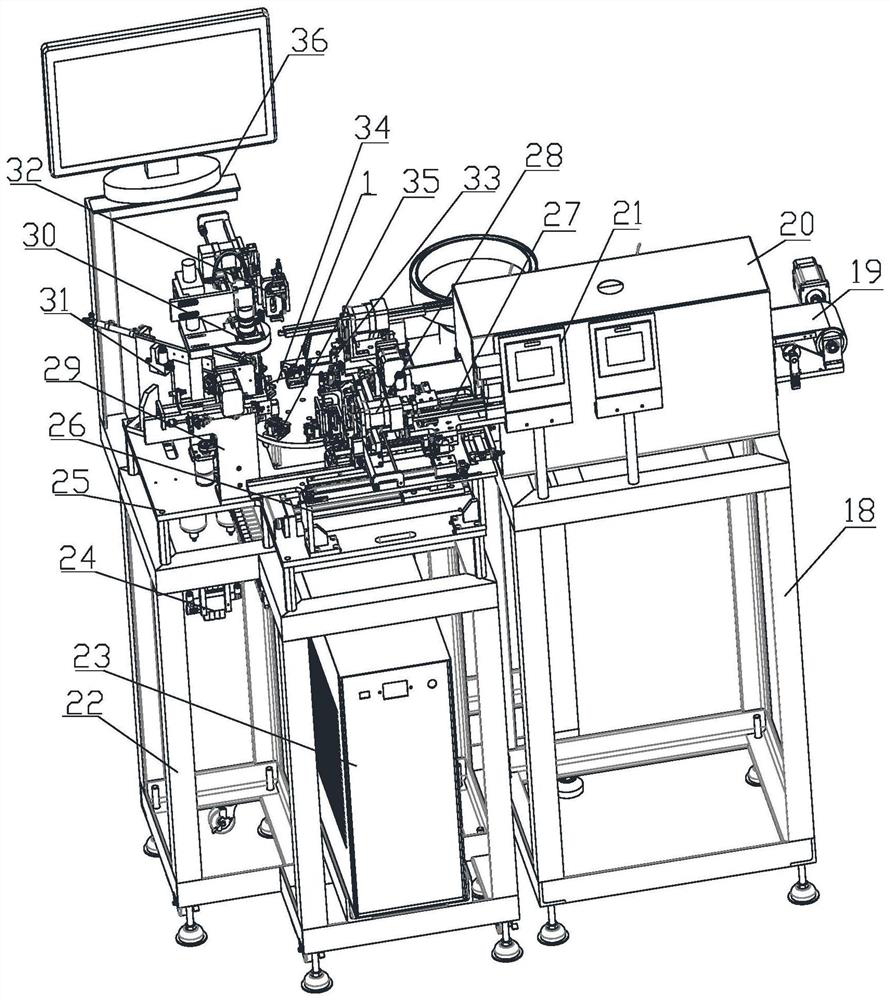

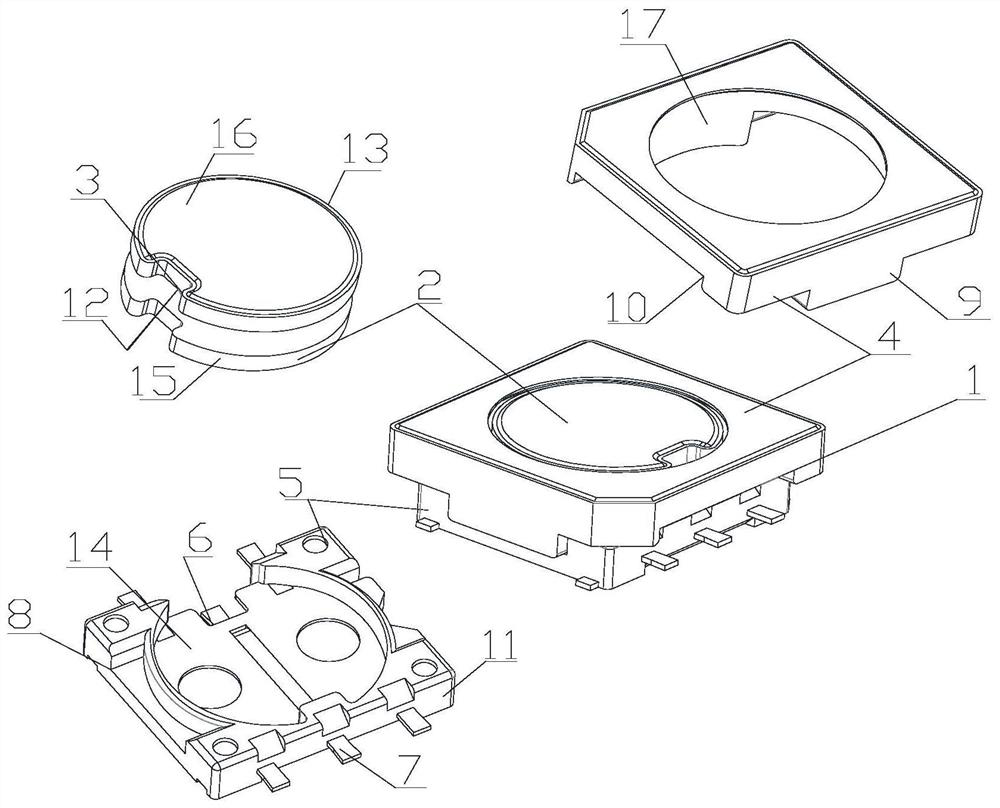

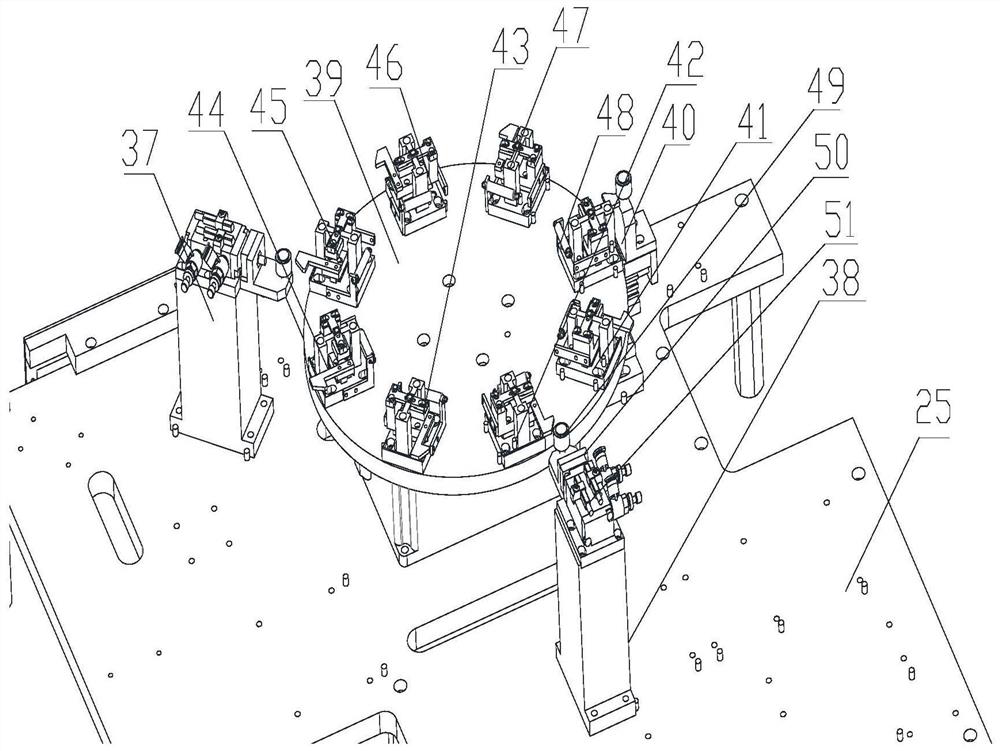

Production line for automatic assembly and bonding of surface inductor cores

ActiveCN111354565BConsistent clearanceAssembly gap constantMagnetic core manufactureProduction lineElectrical control

The invention discloses a production line for automatic assembly and bonding of surface inductance cores. The turntable in the turntable assembly on the main support adopts eight-station indexing drive, each station is provided with a jig; the main support is also provided with Display and operation panel and electrical control unit; the turntable is indexed and transposed clockwise. Station 1 is equipped with opening component 2, base pick-up assembly, assembly sending mechanism, finished product pick-up assembly, and station 2 is equipped with tin-adhesive glue unit , station three is equipped with ccd detection unit, station four is equipped with bad sorting unit and opening assembly one, station five is equipped with ring magnetic core picking assembly, station six is equipped with height inspection assembly, station seven Equipped with mesh belt conveying, soldering mesh belt furnace and opening component 3, there is a finished product picking assembly between station 7 and station 8; the point-stick tin glue used is composed of tin powder, silver powder, resin, acetone , acetate, rosin and water are mixed. The invention has novel structure and reliable product quality.

Owner:YUEQING YEDAO ELECTROMECHANICAL CO LTD

Rear wheel of direct-current brushless permanent-magnet motor

ActiveCN102170214BEasy to fixEasy to installMagnetic circuit rotating partsPermanent magnet motorEngineering

The invention provides a rear wheel of a direct-current brushless permanent-magnet motor, belonging to the field of mechanical technology. The invention solves the problems that the current rear wheel of the direct-current brushless permanent-magnet motor is inconvenient to install, and the cost is high. The rear wheel of the direct-current brushless permanent-magnet motor comprises a wheel hub. A ring-shaped fixed strip is fixedly connected to the wheel hub, a plurality of mounting holes are evenly distributed on the fixed strip, each mounting hole is internally provided with a magnetic steel, and between two adjacent magnetic steels is a gap. The rear wheel of the direct-current brushless permanent-magnet motor has the advantages of being convenient in installation and low in productioncost.

Owner:WENLING JIUZHOU ELECTROMECHANICAL

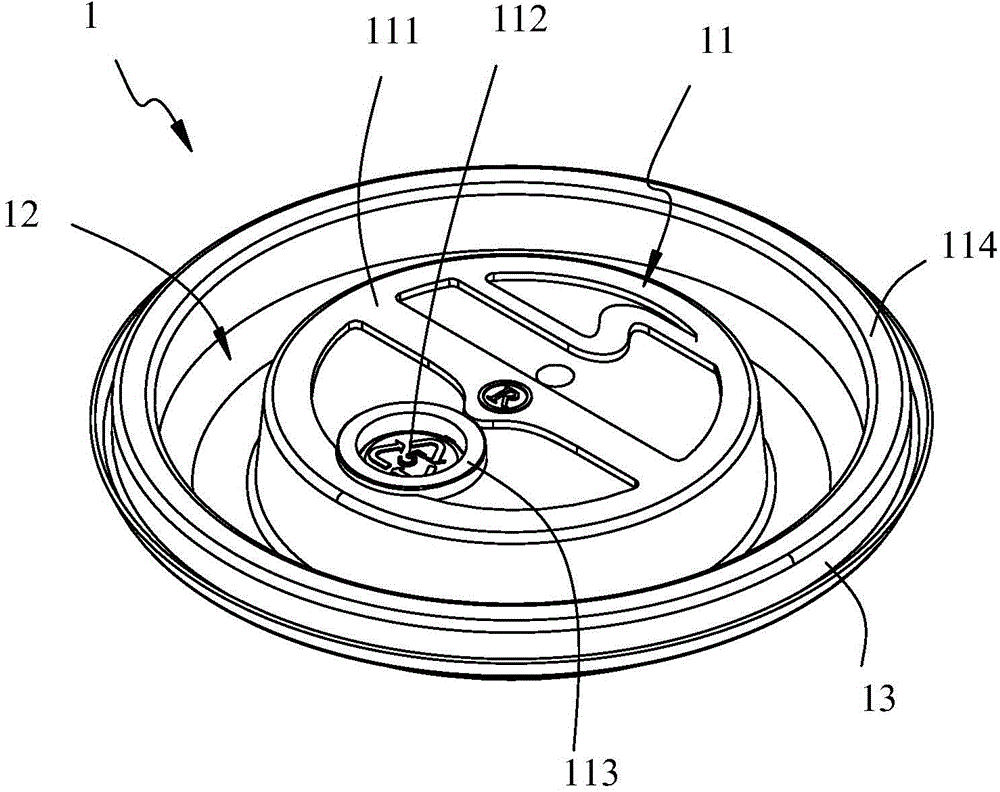

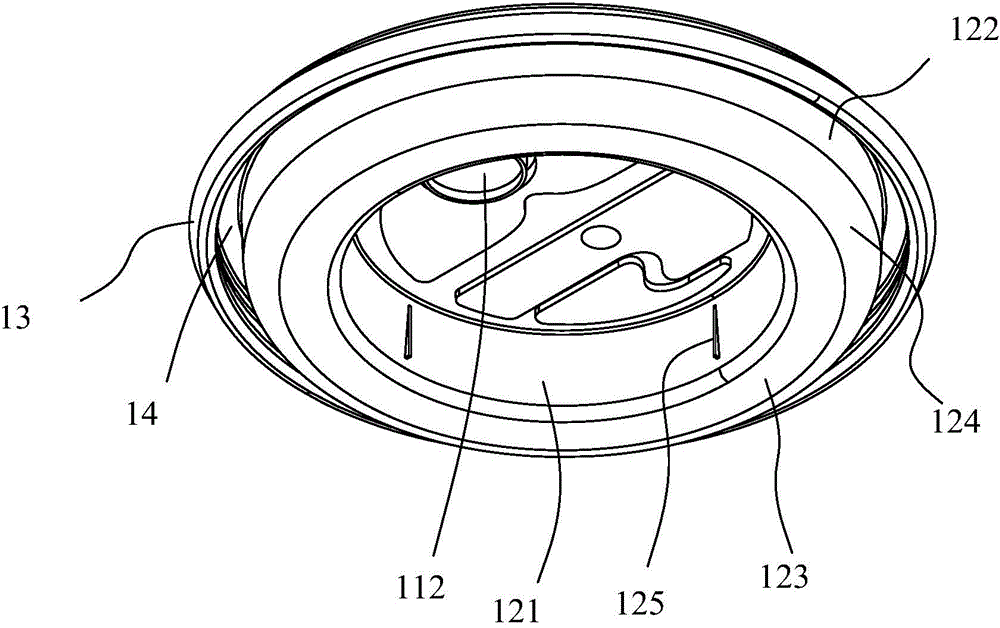

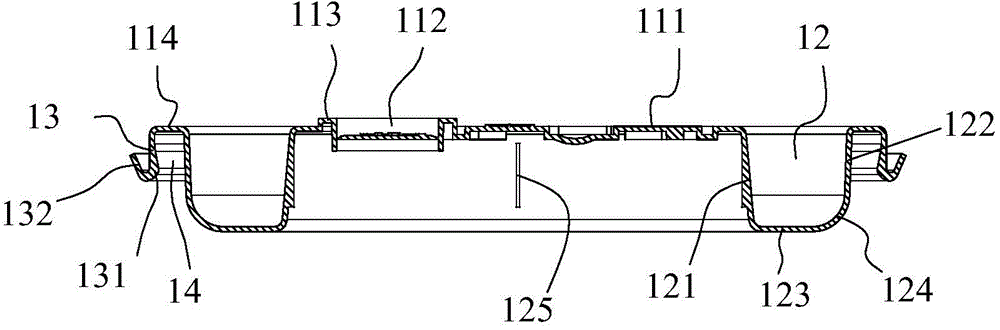

Cup cover

The invention relates to a cup cover, which covers a cup body, wherein the cup body comprises a cup body, a cup bottom and a fastening lip which is arranged around an opening in the upper side of the cup body; the cup cover comprises a cup cover main body; an annular concave part is formed along the periphery of the cup cover main body, so that the cup cover main body is fastened in the opening of the cup body; at the radial inner side of the concave part, a cup cover opening is formed in the cup cover main body; the cup cover main body extends horizontally at the radial outer side of the concave part so as to form a lap edge, and a fastening cover extends downwards along the periphery of the lap edge; and an accommodating groove for accommodating the fastening lip is defined by the fastening wall, the lap edge and the concave part. The cup cover disclosed by the invention is simple in structure and convenient for mass production; moreover, the cup cover is high in reliability, easy to stack, easy to separate and easy for covering; and the cup cover is especially suitable for automatically covering various automatic drink equipment.

Owner:SHENZHEN PRAFLY TECH

Assembly positioning tool and assembly method for four-bar linkage hood hinge

ActiveCN104985559BSolve the problem that the gap is difficult to keep in the proper rangeSolve the unstable positioningMetal-working hand toolsFour-bar linkageEngineering

The invention relates to the field of automobile part assembly tools, in particular to an assembly positioning tool and an assembly method for a four-bar linkage hood hinge. The assembly positioning tool comprises a first sample frame and a second sample frame. The first sample frame is used for positioning and installing a fixed leaf on the hinge. The second sample frame is used for positioning and installing a movable leaf on the hinge. The two sample frames are matched to assemble the four-bar linkage hinge. The first sample frame is used for positioning and installing the fixed leaf, and the distance between the fixed leaf and an automobile body column A is accurately positioned; the second sample frame is used for installing a hood, the distance between the movable leaf and the hood is accurately positioned, and the problem that assembly accuracy between the hood and the column A is not certain when the hood is opened and closed due to clearances between screw bolts and bolts is solved. In addition, the assembly efficiency is improved, the hinge installing difficulty is lowered, the structure is simple, use is convenient, and great promotional value is achieved.

Owner:DONGFENG PEUGEOT CITROEN AUTOMOBILE

A connection flange assembly device

ActiveCN103921043BGuaranteed verticality requirementsGuaranteed parallelismWelding/cutting auxillary devicesAuxillary welding devicesBall bearingButt joint

The invention discloses a connecting pipe and flange assembling device, belongs to the technical field of oil and gas field connecting pipe assembling, and aims to solve the problems that manual connecting pipe flange assembling efficiency is low through a skid mounted unit and assembling quality is difficult to guarantee. The assembling device comprises an L-shaped operating platform, a fixing support member, a rail, a flange fixing member, a flange, a rotary shaft, a locking nut, a planar pushing ball bearing, a deep groove ball bearing and the like. According to the device, by controlling the coaxiality during connecting pipe and flange assembling, high accuracy of connecting pipe and flange assembling is guaranteed, and consistence requirements of assembling gaps and unfitness of butt joint in the same batch can be improved; in addition, by adjusting the device once, rapid assembly of connecting pipes and flanges in batches can be implemented, labor force is saved, and assembling efficiency is improved.

Owner:XIAN CHANGQING TECH ENG

Furnace door device with long service life and durable sealing

InactiveCN112595124AWith balanceImproved and improved closure sealing performance effectFurnace componentsProcess engineeringSelf adaptive

Owner:景德镇市英才科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com