Pull up and down push driven reverse push garbage incinerator

A waste incinerator, driven technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of large calorific value fluctuations, the thickness of the material layer is not easy to be uniform, and the waste incineration effect is not ideal, so as to achieve stable combustion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

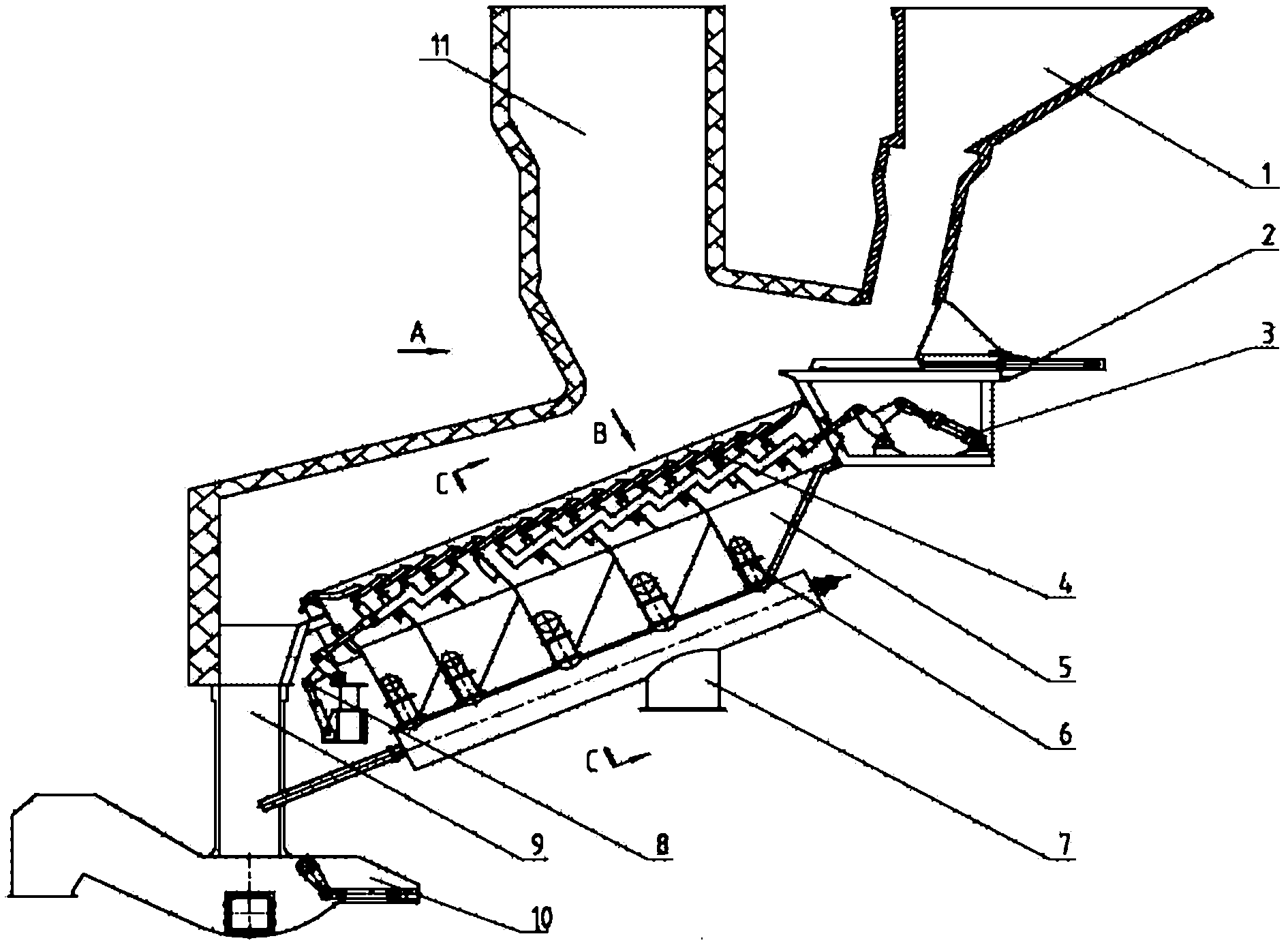

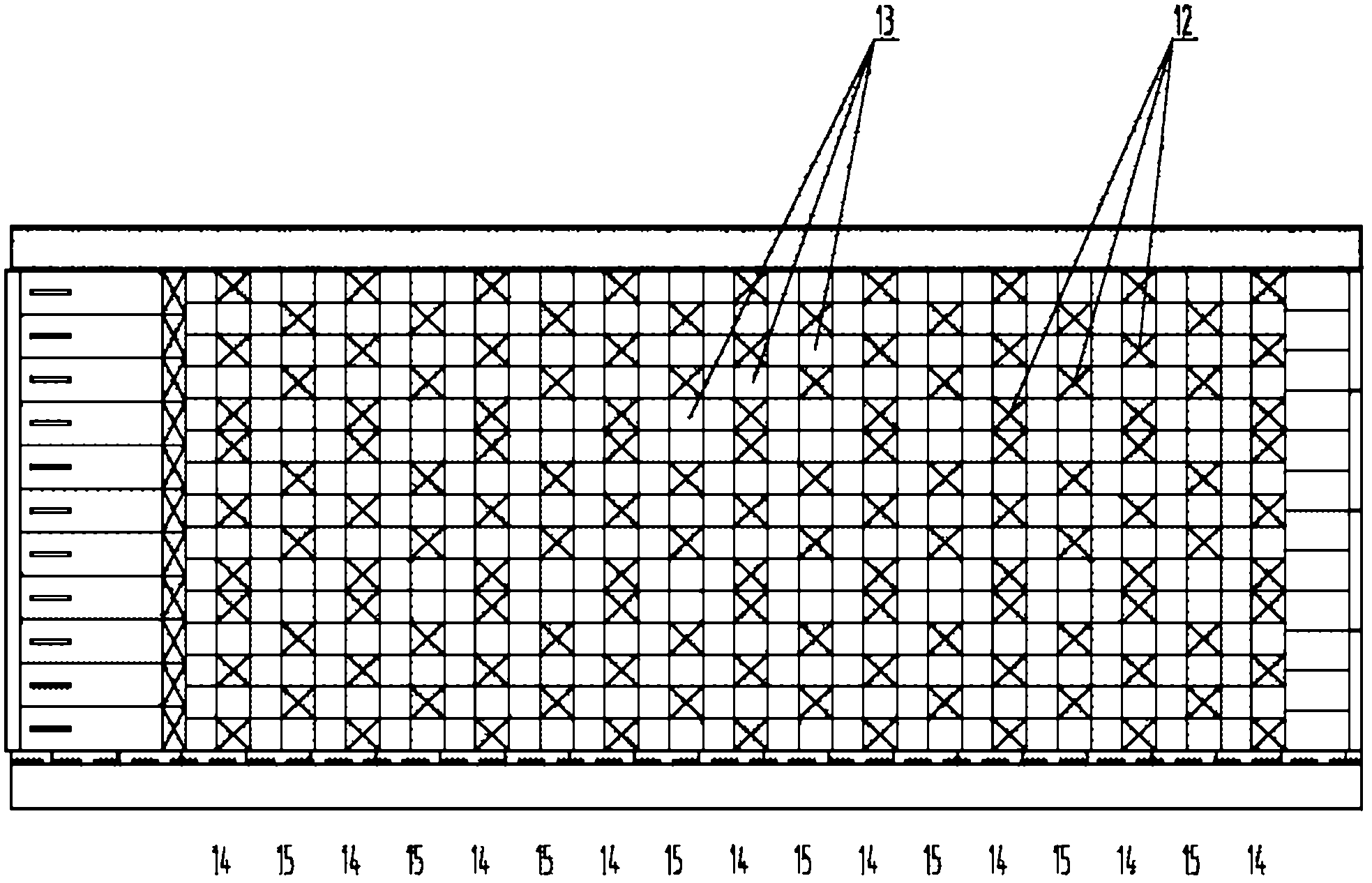

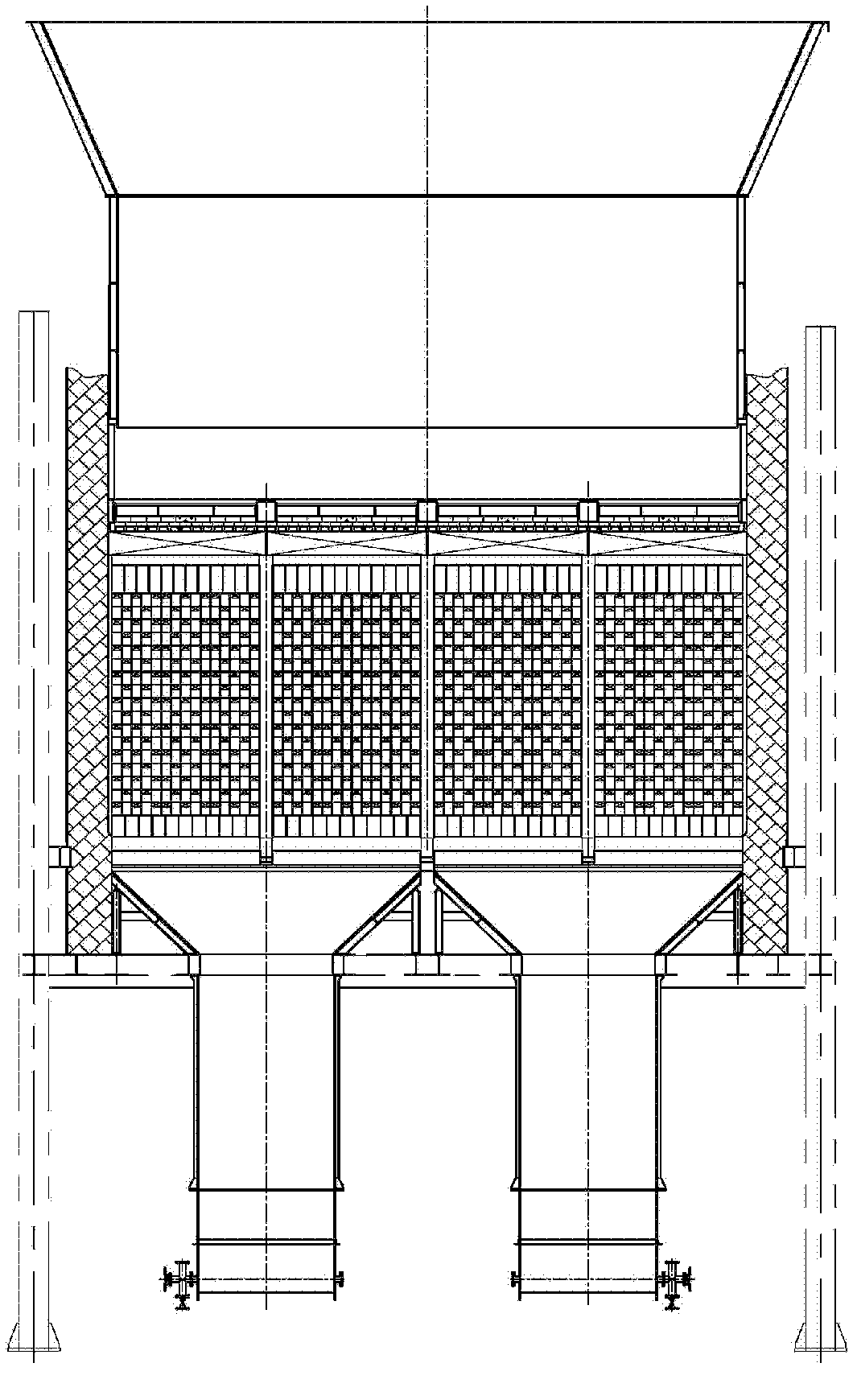

[0030]The garbage incinerator includes a feed hopper 1, a feeding mechanism 2, a fire grate 4, a furnace 11, an air chamber 5, a slag well 9 and a slag extractor 10. Row. There are two types of grate, convex grate 12 and flat grate 13. Convex grate 12 is a grate with a pyramid-shaped convex hull at the front end of flat grate 13. Convex grate 12 and flat grate 13 are staggered to form a static furnace. Row 15 and moving grate 14. The grate 4 is installed on the grate body inclined at 20-30°, and the static grate 14 and the movable grate 15 are alternately arranged up and down to form a row of grate, that is, the head of the movable grate is close to the tail of the previous static grate , the afterbody of moving fire grate is compressed by next static fire grate head again, alternately arranged successively, the incinerator of the present embodiment is four rows of fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com